Used YES / GLEN R3 #9251749 for sale

URL successfully copied!

Tap to zoom

ID: 9251749

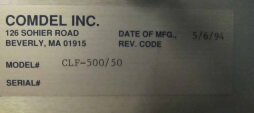

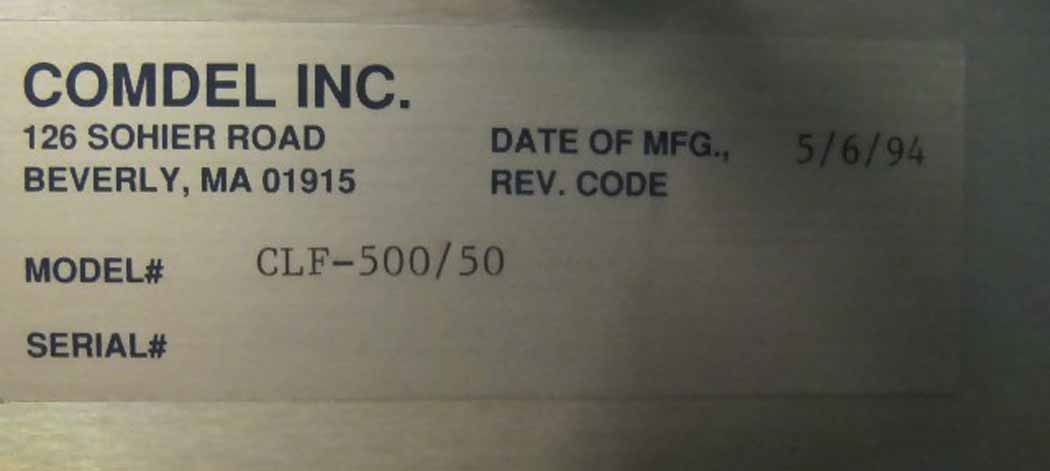

Vintage: 1994

Plasma cleaner

Low frequency

Mass Flow Controller (MFC)

N2 Flow rate: 1.7 SCFM

Process gas flow rate: 20-50 SCCM

Chamber material: 6061-T6 Aluminum

RF Plasma power: 0 - 500 W at 550 VAC

Nitrogen consumption: 0 SCFM idle, 1.7 SCF

Reactant gas consumption: 0 SCFM Idle, 150 SCC

KF 40 Vacuum plumbing

Clean room capability: Class 10

Compliance: SEMI S2

Touch screen interface

Analog MFC control and monitoring

Thermocouple monitoring for etch uniformity

Safety factors: Integral RF and pressure interlocks

TCP/IP Port

Self-diagnostic program

Constant real-time display

Audible and visual cycle complete indicators

Audible and visual indication of incorrect process with diagnostics display

Vacuum sensor: 0-1000 Torr

With (2) trip points

Load capacity:

Up to 4 active plasma areas: 15.13" x 15.39"

Operational modes:

RIE

Downstream electron-free

Active ion trap

Grounded ion trap

Measurements:

Interior chamber dimensions: 450 x 450 x 300 mm

Chamber process area: 931 in² or 233 in²

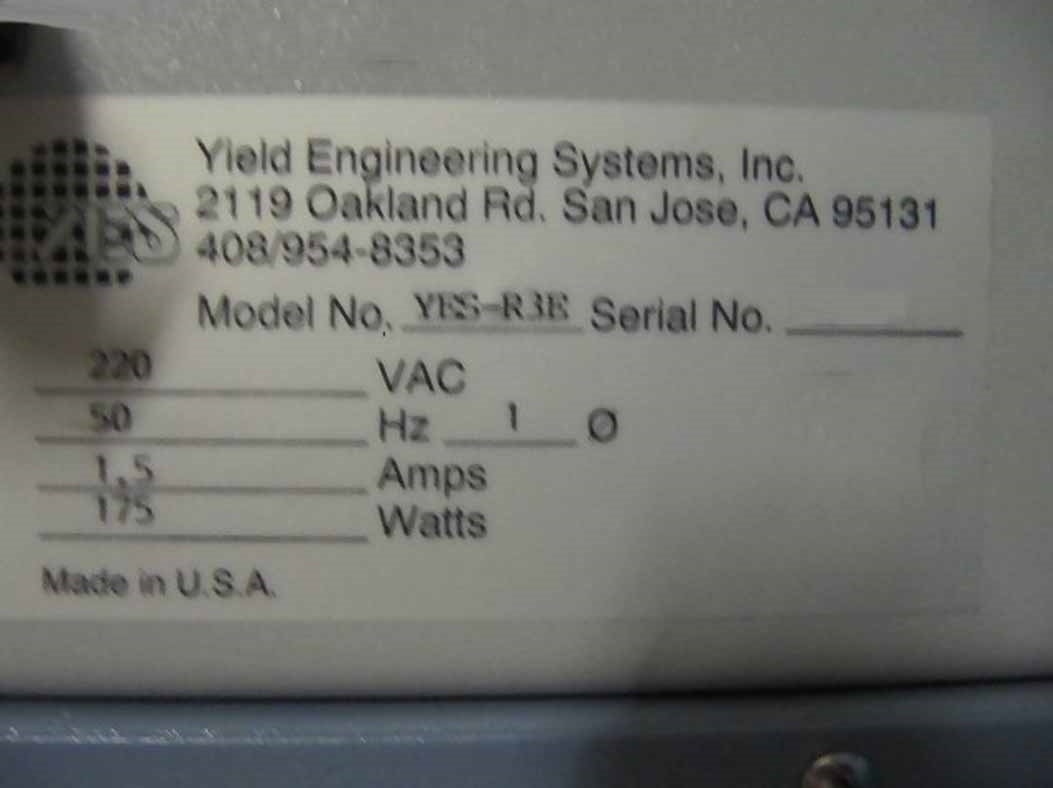

Power supply: 230 V, 20 Amps, 50/60 Hz, Single phase

1994 vintage.

YES / GLEN R3 is an etcher/asher created to improve the efficiency of the silicon via etch and aspect ratio measurement. It is designed with the capacity to process 15mm x 15mm, and up to 8-inch wafers. The equipment features a Precision Spinning Tab Die (PSTD) and an automated precision ejection system. This dual source process helps achieve increased process capability and variability. The enclosed 4" vacuum enclosure maintains process repeatability and is coupled with the traditional Multi-Boron Implant Plus (MBI+) unit to provide sample delivery and perform the etching. The PDT provides both single-sided flat-field and multi-point measurement capabilities through its automated scanhead. It employs a unique stainless-steel knife-edge access port and customized chuck jaws to provide very low distortion and accuracy. The PSTD is also optimized for isolation etching and aspect ratio measurements. It features a combined dual wafer temperature control machine, gas distribution, and a gas lift control. This is complemented with advanced process control and software for monitoring and manipulating the etch parameters, resulting in high process reproducibility, repeatable residues, and aspect ratio measurements. YES R 3 also features a combination of non-destructive and destructive arrayed etch measurement techniques. Dual-sided Flat-field Profiling (DSFP) and Multi-Point Profiling (MPP) capabilities are provided, complemented with a wide-range of variable etch rates and minimal wash times. DSFP and MPP measurements are extremely repeatable, providing fast and reliable process information to assist optimization and troubleshooting efforts. This etcher/asher is a robust and reliable tool, designed with improved process parameters for high process throughput and improved flux stability for increased productivity.

There are no reviews yet