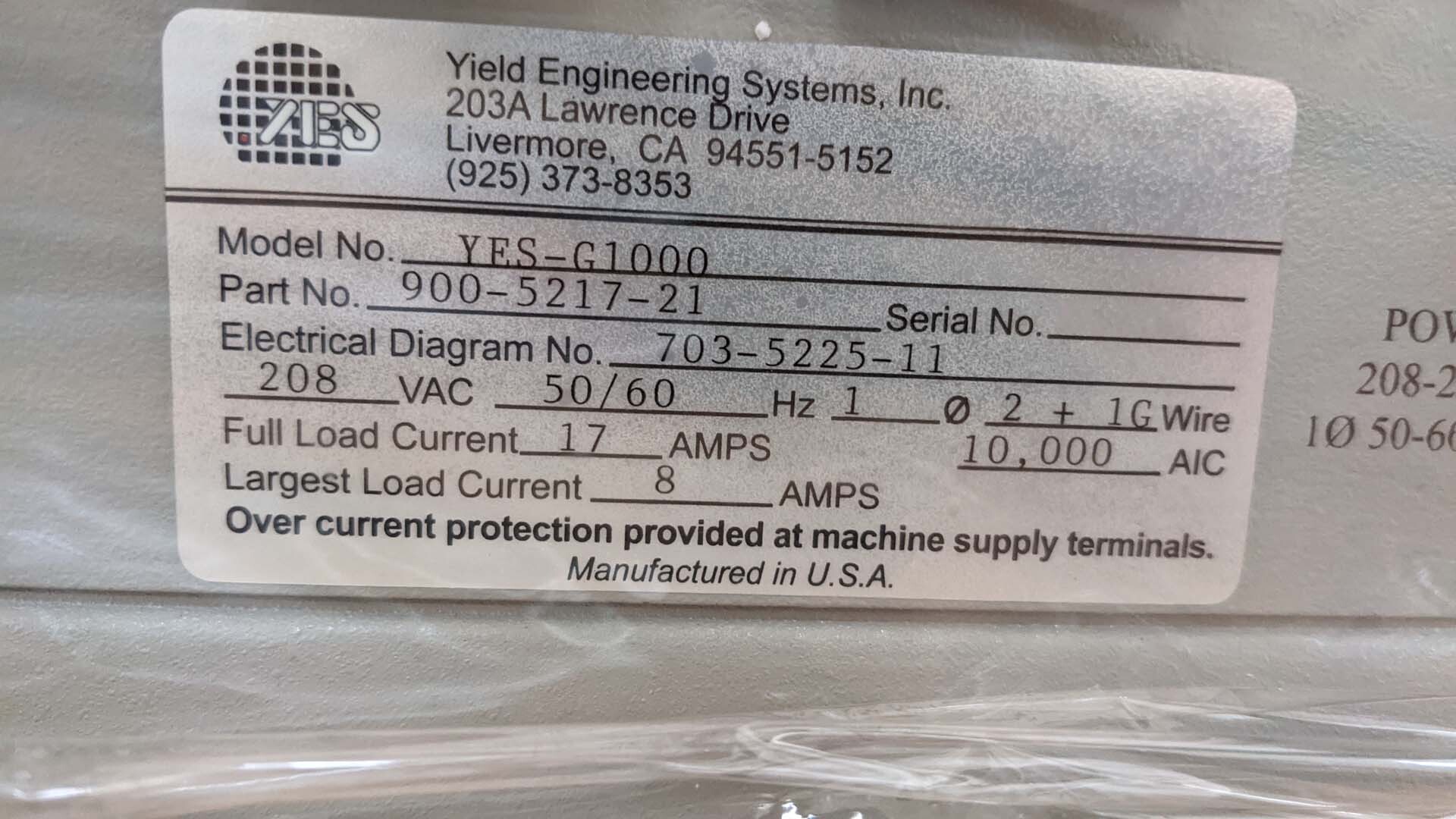

Used YIELD ENGINEERING SERVICES / YES G1000 #293652437 for sale

URL successfully copied!

Tap to zoom

YIELD ENGINEERING SERVICES / YES G1000 is a high-performance semi-automatic asher used in the front-end wafer production process of microelectronics manufacture. This equipment is designed to quickly plasma-etch circuit boards with high accuracy, allowing for improved yields in the production process. YES G1000 incorporates a nano-tunable high-powered radio-frequency generator to provide precision etching with quick acceleration and deceleration. It also utilizes a highly sophisticated gas delivery system to evenly disperse etchant gas throughout the enclosure, which ensures uniform etching processes. YIELD ENGINEERING SERVICES G1000 has a 25 inch by 25 inch (6370 cm2) plasma etching space with a 75 µm repeatability precision. It operates on a wide range of etchant materials, such as halides, fluorinated hydrocarbons, and nitrogen-phosphorus compounds. Its easy-to-use front-end controls allow users to adjust process parameters such as gas flow rate, gas mixture, and etch time, as well as track the process in real time. G1000 is specifically designed to process thin and delicate materials, such as nanomaterials and semiconductors. It has an ultra-low power and temperature range, which protects the integrity of temperature-sensitive devices. The unit is built with cleanliness in mind, and it features a closed-loop housekeeping machine for collecting spent etchant gases and particulates, as well as an integrated particle elimination tool to trap and remove contaminants. The optimized safety design of YIELD ENGINEERING SERVICES / YES G1000 makes it an ideal choice for wafer production applications. It contains a comprehensive safety package that includes several layers of process protection, remote control, and overpressure release. Additionally, the asset has built-in diagnostic routines to pinpoint potential problems, allowing users to run the model in the safest way possible. All in all, YES G1000 is a reliable and cost-effective asher ideal for high-precision and low-cost wafer production. It offers excellent process yields, increased throughput, and maximum safety. As such, it is an ideal equipment for any facility in the microelectronics manufacturing industry.

There are no reviews yet