Used CHA SE 600 RAP #9133348 for sale

URL successfully copied!

Tap to zoom

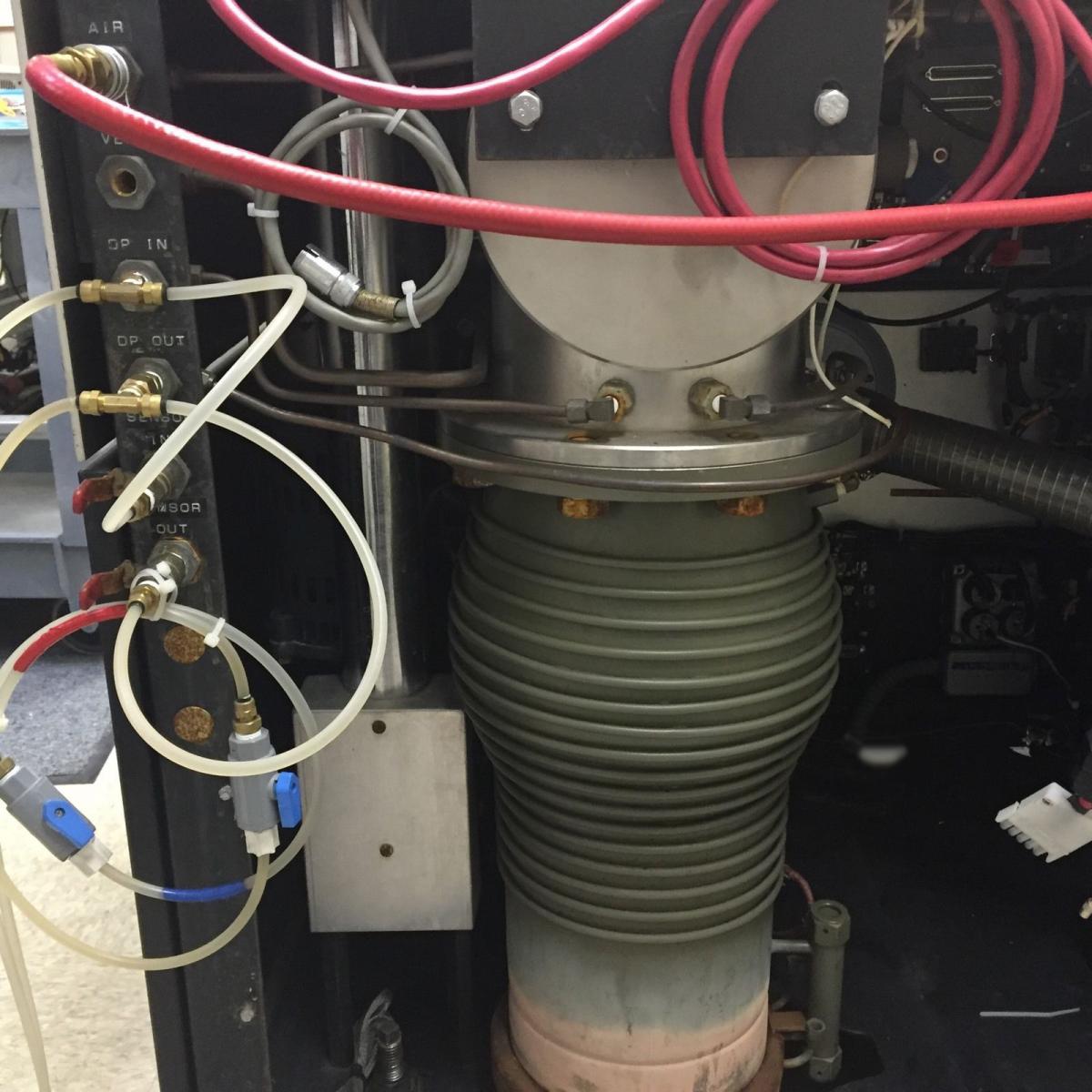

CHA SE 600 RAP (Regenerative Adsorption Process) is an evaporator utilized in industrial processes to reduce water content in a solution. The evaporator works by using a heat exchanger to heat a water-based solution within an evaporator body. The heated solution is then vaporized, reducing the moisture content in the solution. Heat is simultaneously recovered from the evaporator body and then passed as steam to heat the liquid solution for a subsequent cycle or other purposes. The heat exchanger in the evaporator is composed of interlocking slotted disks, referred to as "cells." The cells are radially arranged within an outer spiral shell which houses the solution in the evaporator body. The slots create a very fine gap that contributes to a superior heat transfer. The design of the evaporator's heat exchanger shell also provides for improved efficiency by allowing the cells to withstand higher temperatures and pressures than conventional heat exchangers. During operation of the evaporator, the solution is pumped into the evaporator body at a controlled rate and heated by the heat exchanger, which is then passed as steam to the outside environment. The vaporized solution is collected on the inner wall of the evaporator body, allowing for the condensation of water droplets which are then discharged to drain. The remaining solution is then passed on for further processing. CHA SE-600 RAP evaporator is known for its reliablity, efficiency and high output as a result of the efficient heat exchanger construction and superior heat transfer ability. The evaporator is capable of evaporation rates up to 6000 kg/hour of liquid water and can be used in a wide variety of industrial applications such as cooling towers, power stations, chemical process plants, and other cooling and refrigeration systems. The evaporator is also commonly used for food and beverage processes and for dewatering of sludges and concentrates. It is a reliable and cost-effective way of reducing moisture contents in industrial processes.

There are no reviews yet