Used DENTON VACUUM DV 502A #9180256 for sale

URL successfully copied!

Tap to zoom

ID: 9180256

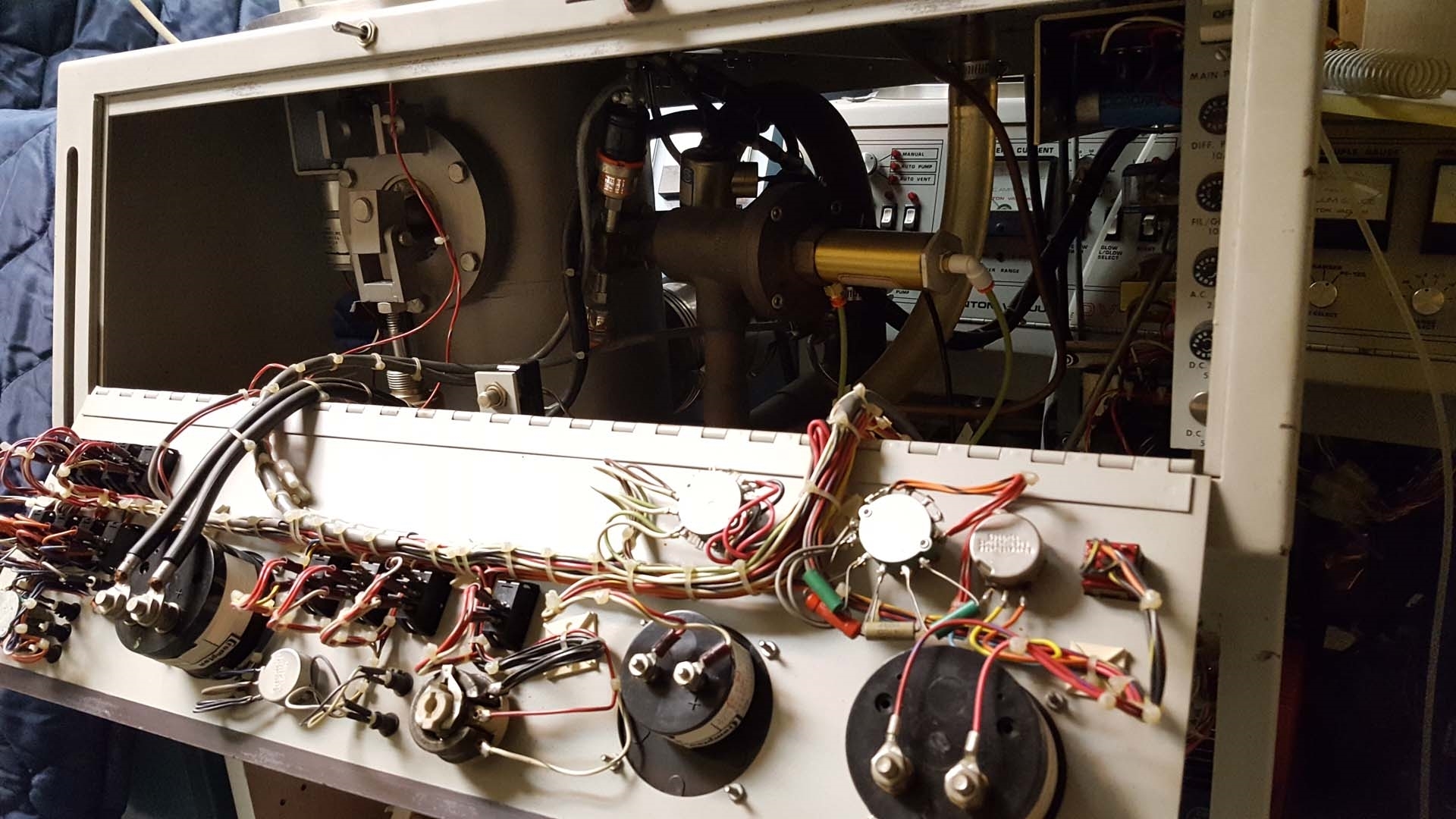

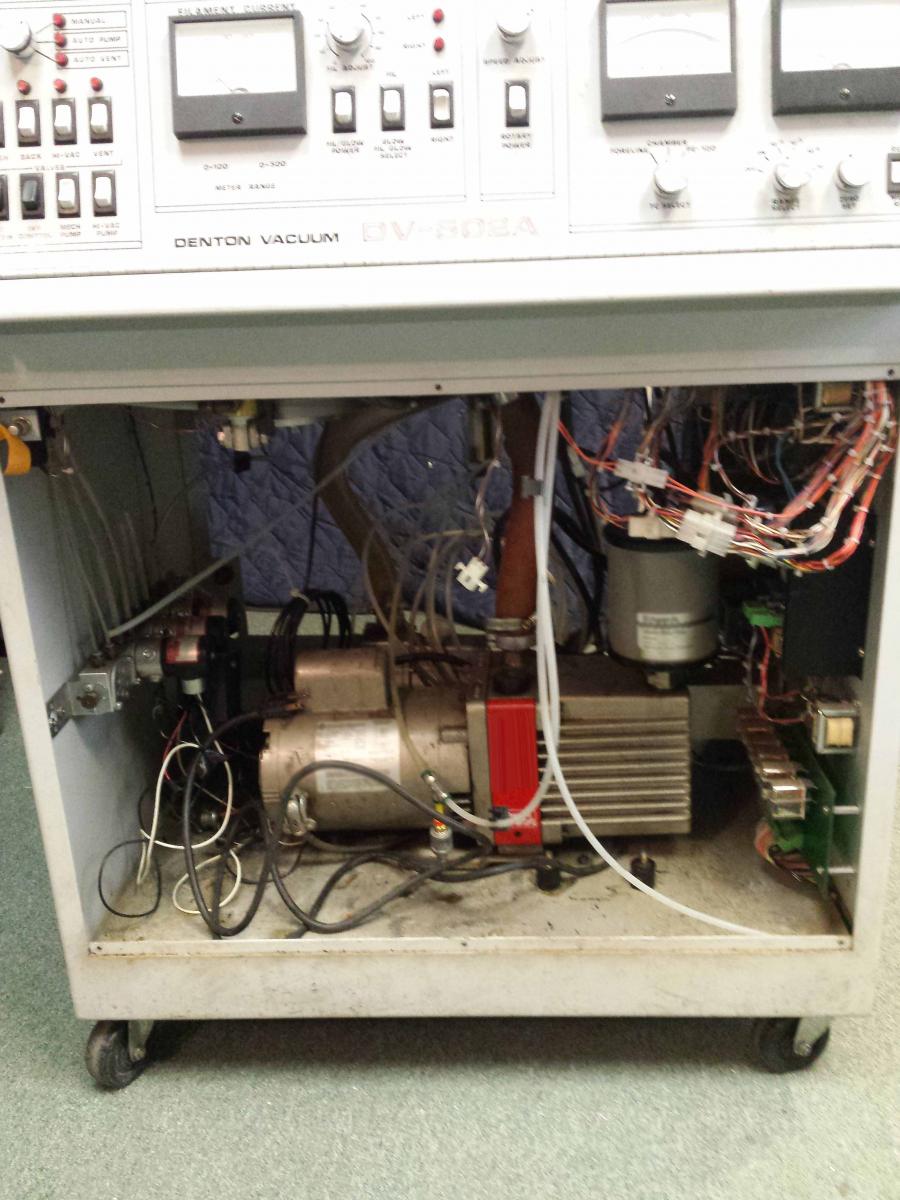

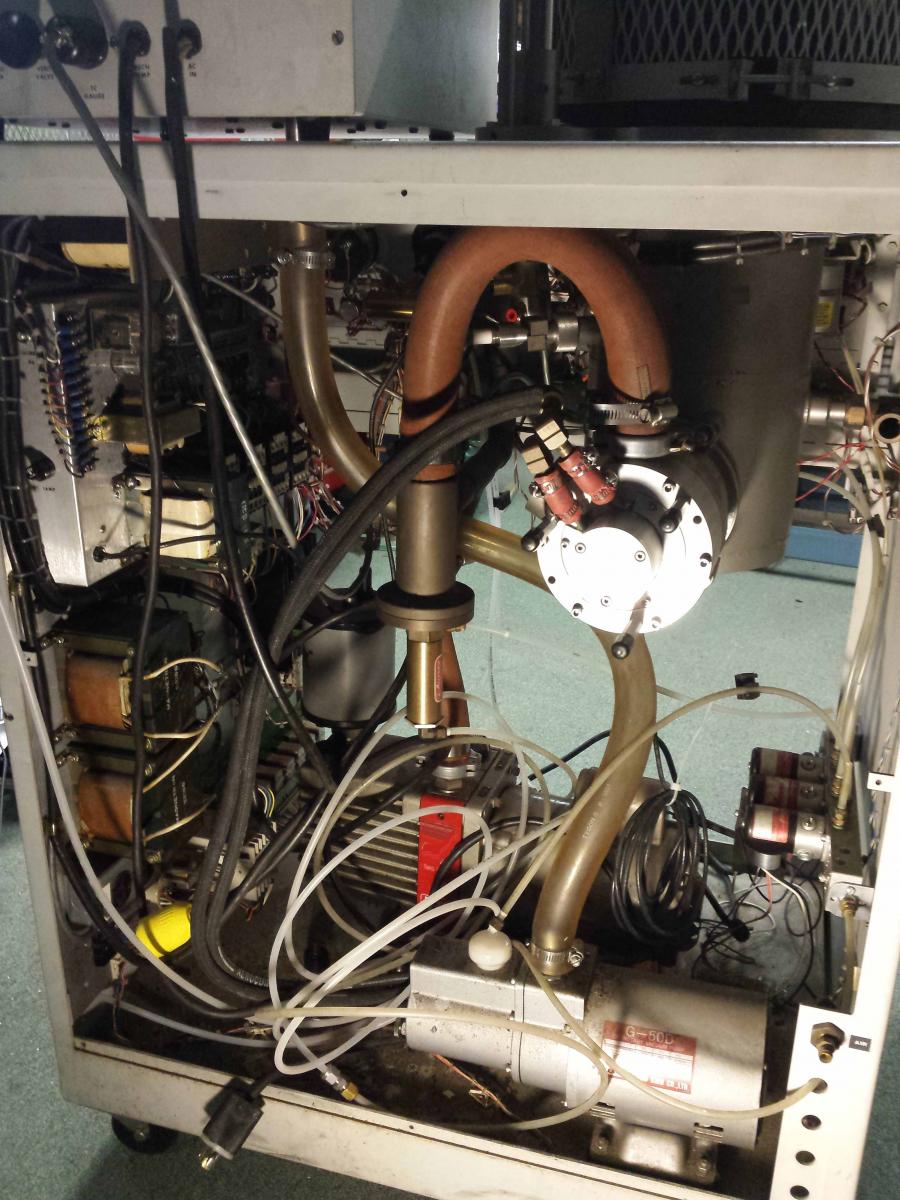

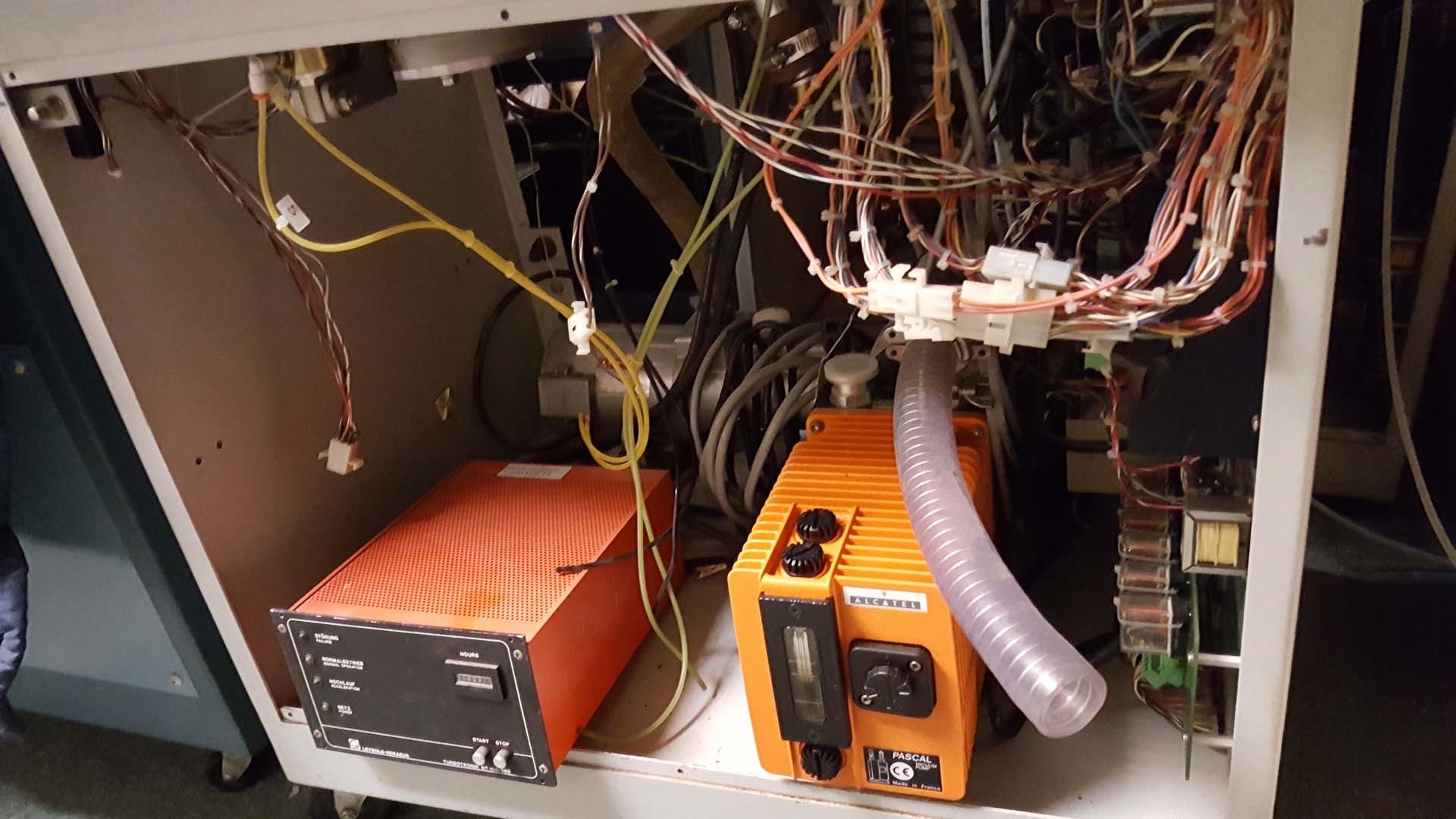

Thermal evaporator

PE-120 Plasma etch with mechanical pump

Turbo pump

Carbon fixture and rotation

Spare parts missing.

DENTON VACUUM DV 502A is an evaporator which utilizes advanced evaporation and sublimation technologies to create high levels of vacuumed vacuum levels to evaporate substances quickly and efficiently. The evaporator features a stainless steel chamber, which provides an environment that is resistant to corrosion and oxidation. The chamber also has a collectacle Ring that lines the inner wall, providing added insulation and protection from the elements. Additionally, the evaporator is equipped with a vacuum pump, which is capable of creating a vacuum level of over 4,000 mbar to facilitate rapid evaporation and sublimation processes. DENTON VACUUM DV-502A is designed with a dual element heating design, which allows the evaporator to melt or evaporate materials quickly while controlling temperatures accurately. Furthermore, the heating elements are mounted in a thermally insulated shell that prevents heat loss while providing stability during the evaporation process. The heat of up to 500C is transferred through the heat exchanger plate, without the need for additional mechanisms. Additionally, the evaporator is designed with a high-performance flow sensor, to enhance the performance of the heat exchanger plate by controlling the flow of materials through the evaporator. The evaporator also comes with an upper and lower chamber to ensure optimal evaporation rate. The upper chamber is designed with a stainless steel internal chamber, which houses the process chamber plate. The plate contains several smaller holes that facilitate the efficient vaporization of the materials, while allowing them to gradually reach the lower chamber. The lower chamber also features an integral vacuum source which provides additional support during the process. The evaporator also includes a number of safety features, which help to minimize potential hazards. It has been designed with a built-in explosive test to ensure that the evaporator is free from explosive materials. Additionally, the evaporator is fitted with a series of panes which can be used to control the intensity of the heat, minimizing the chances of thermal shock. In conclusion, DV 502 A is an advanced evaporation and sublimation unit, which provides a quick and efficient method for evaporating materials quickly and reliably. The evaporator is designed with a dual element heating design, a thermally protected shell, and a flow sensor, to provide accuracy and precision during the evaporation and sublimation processes. Furthermore, the evaporator is designed with a series of safety features, including an explosive test and adjustable heat plates, to reduce the risk of thermal shock.

There are no reviews yet