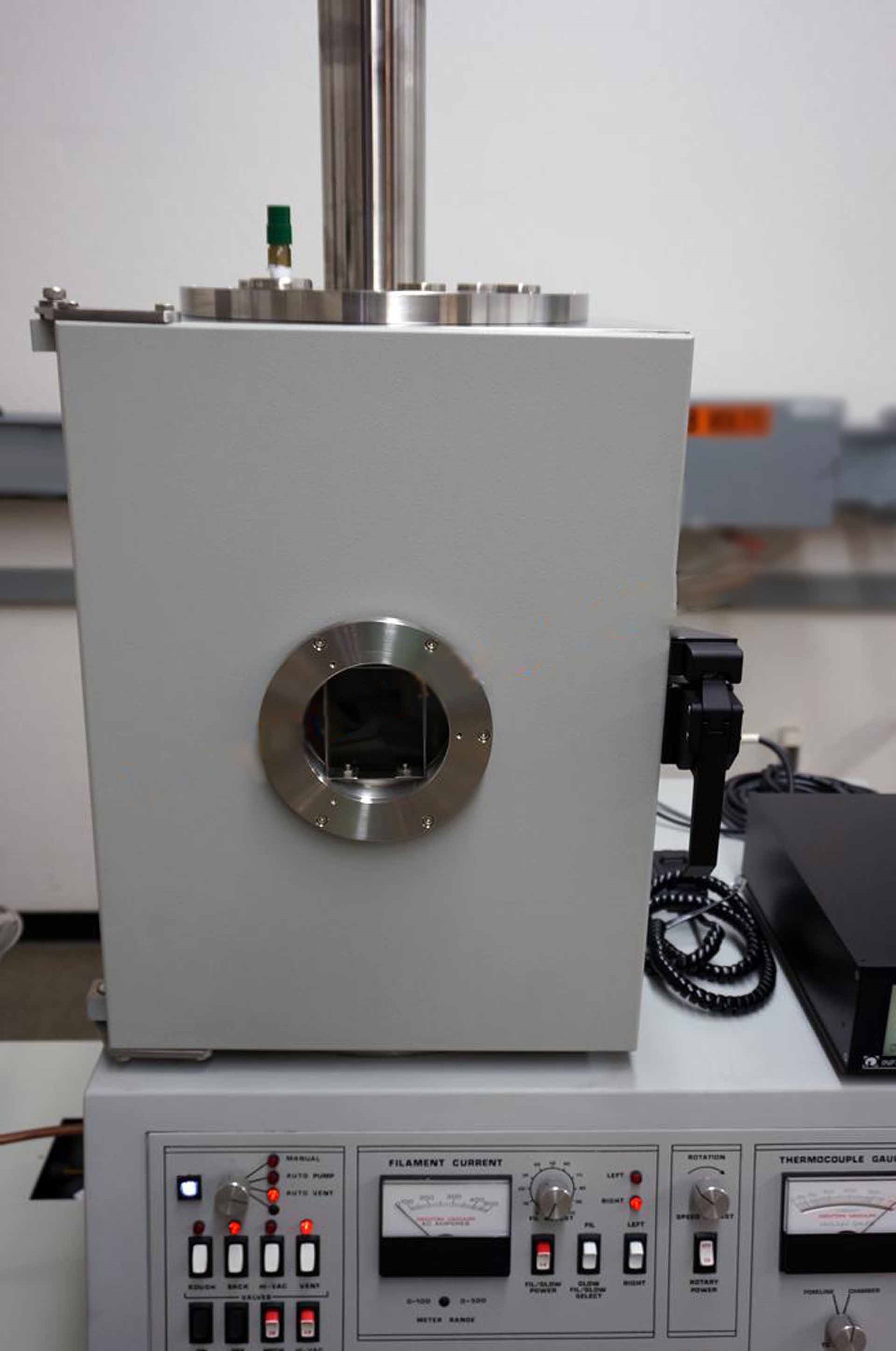

Used DENTON VACUUM DV 502A #9215858 for sale

URL successfully copied!

Tap to zoom

ID: 9215858

Filament evaporator

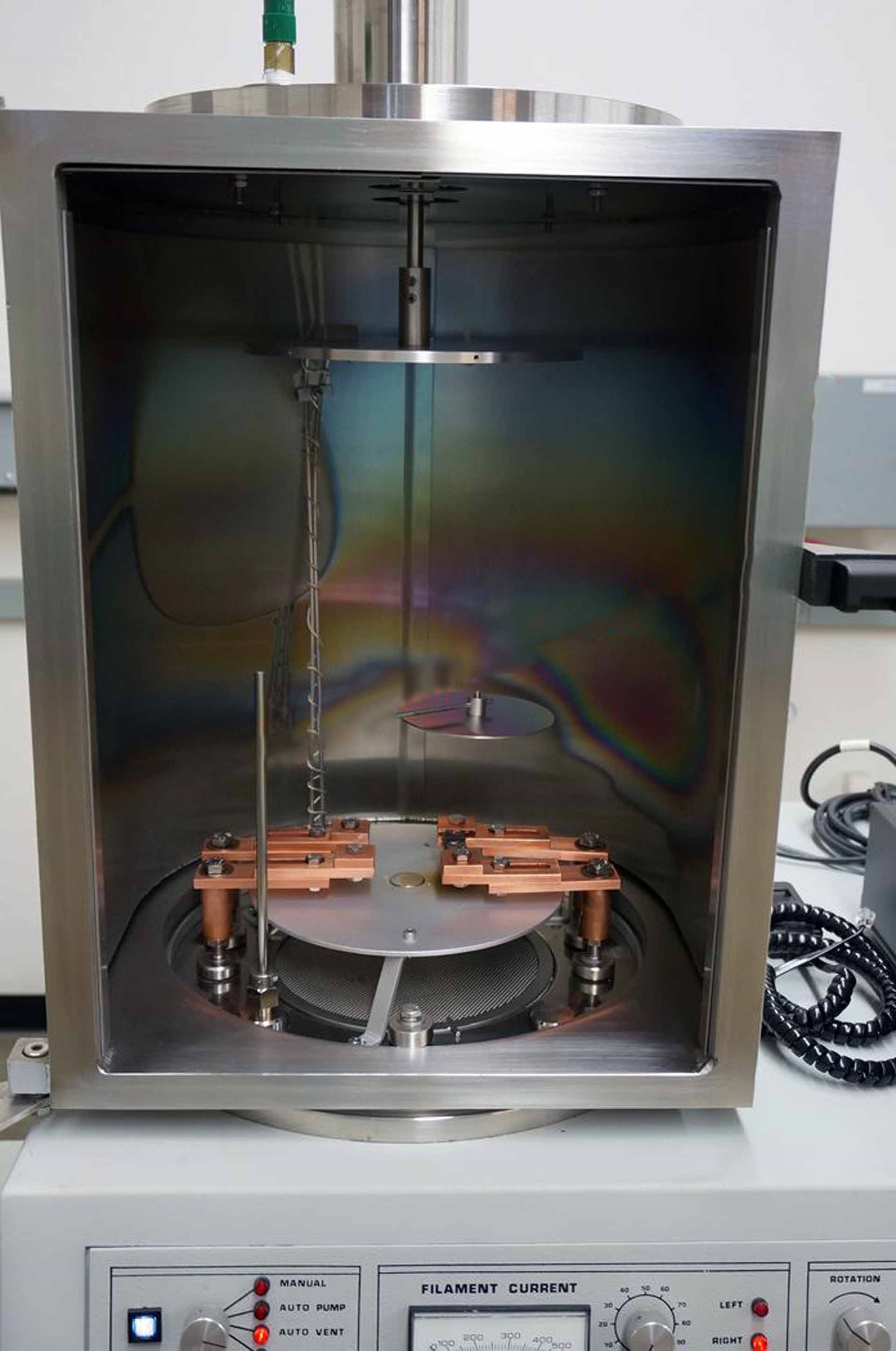

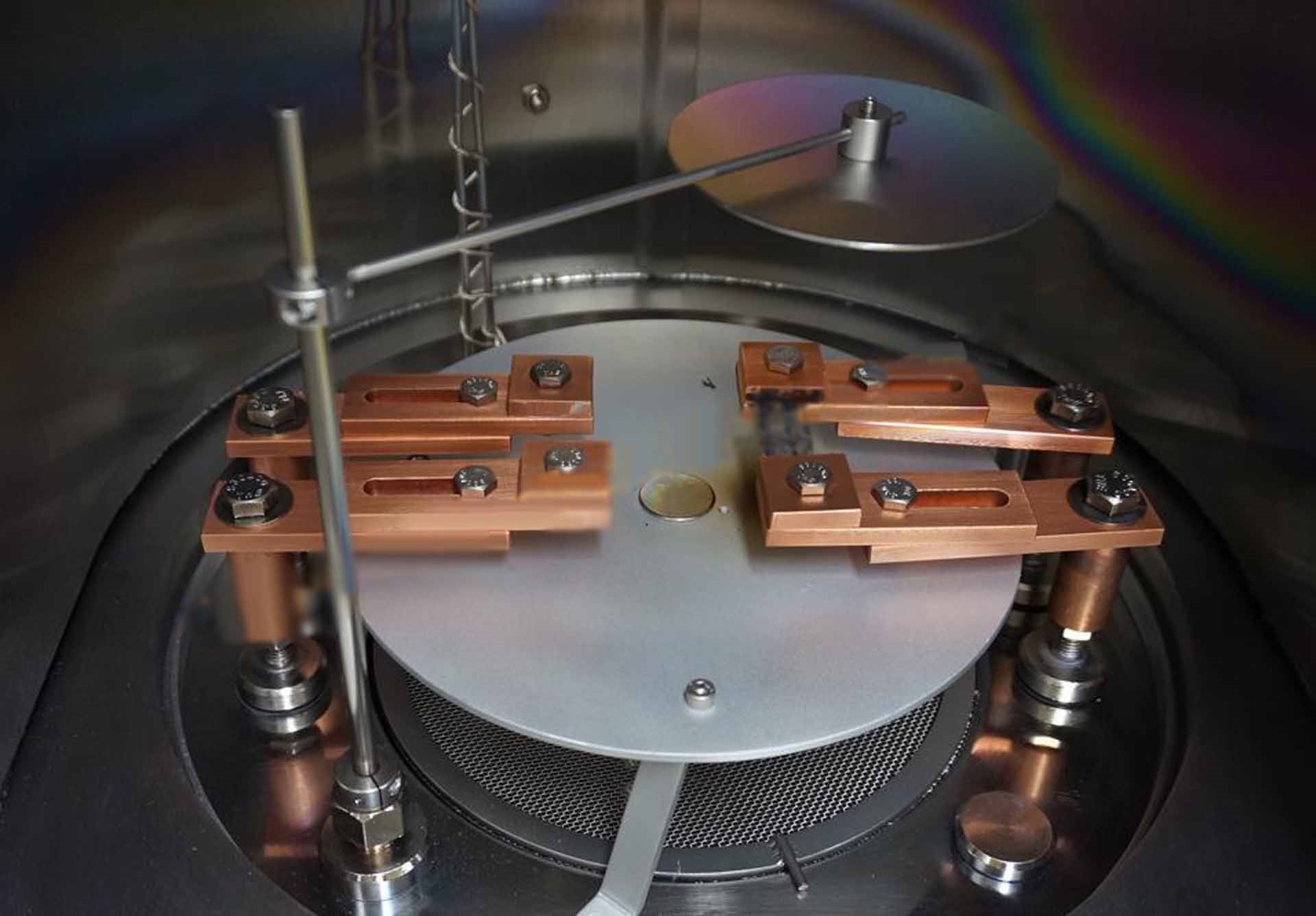

Dual filament holders

With (2) 2KVA transformers for coating up to 8" diameter

RF-3240

Front opening stainless chamber with 12" x 16" opening

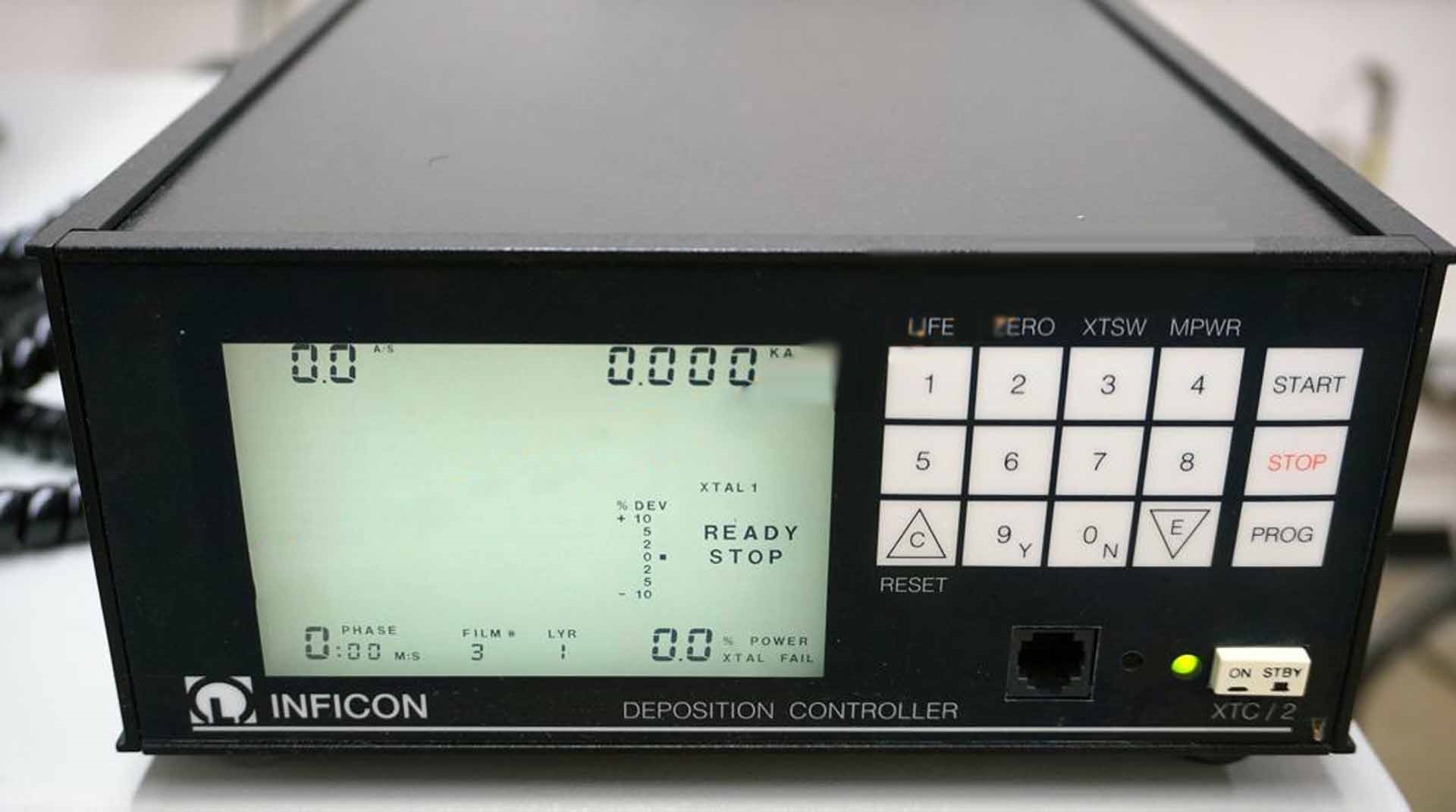

INFICON XTC/2 Deposition controller with quartz crystal holder

8" Rotating substrate holder with shutter

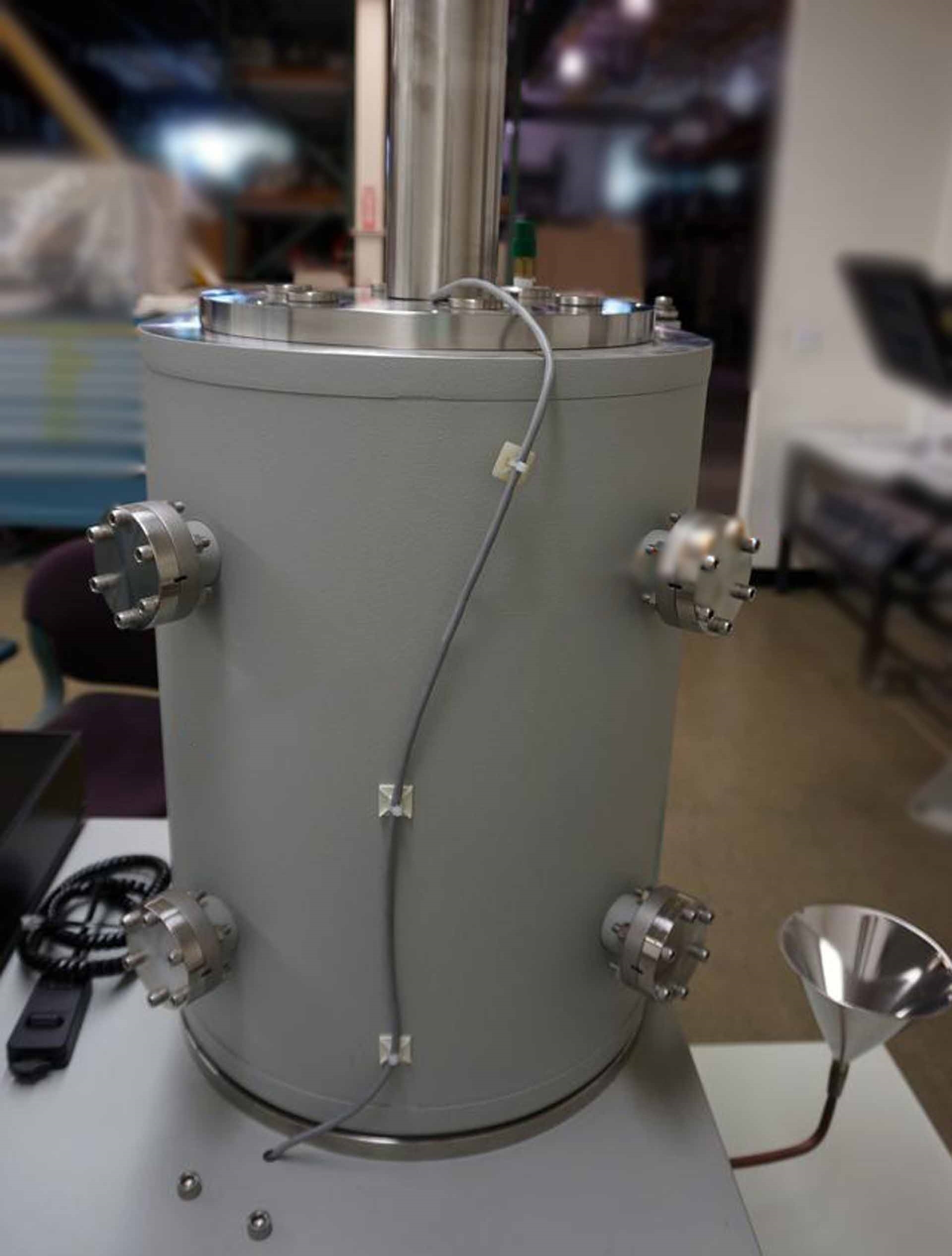

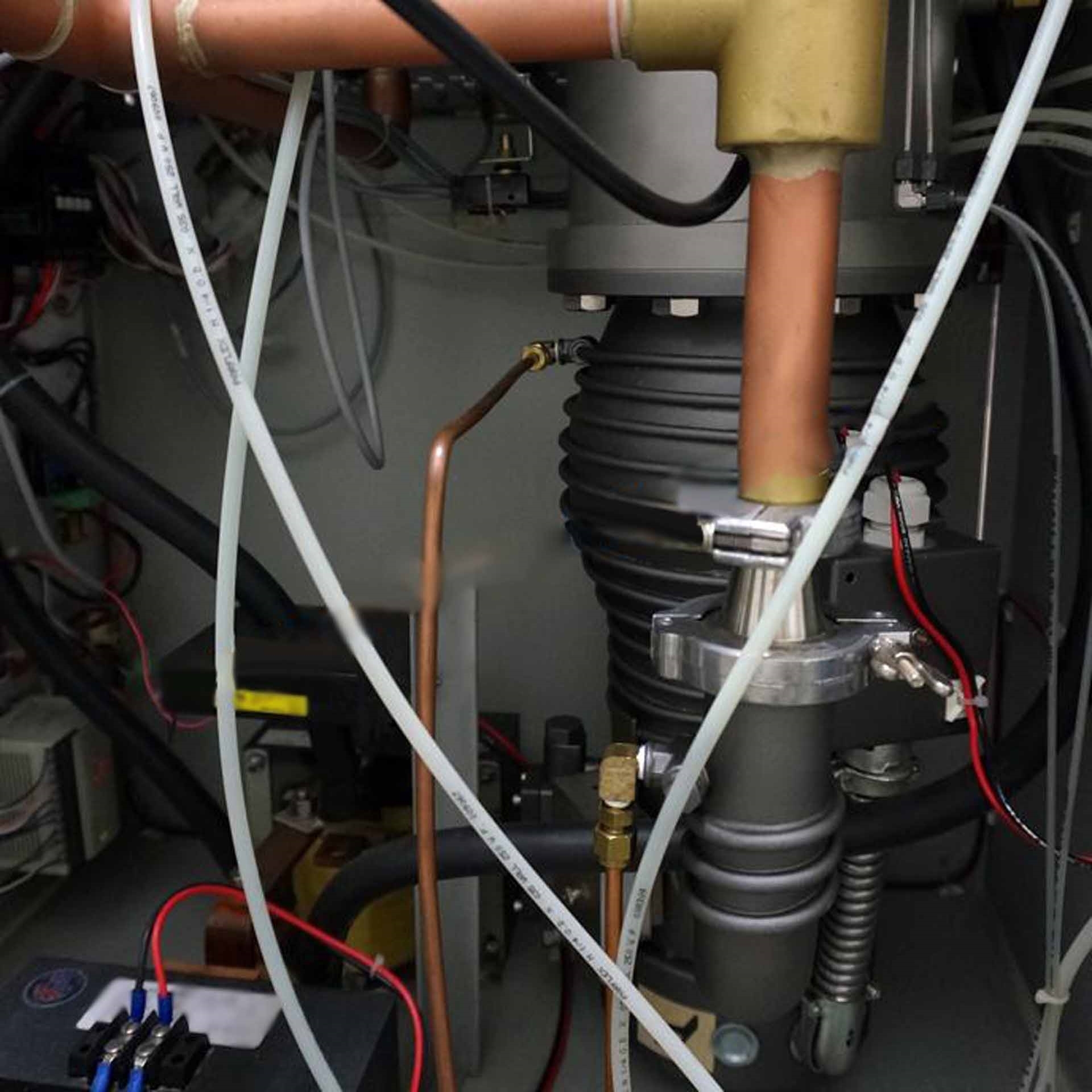

ALCATEL 2 Stage roughing pump

High vaccum diffusion pump

AC Glow discharge

LN2 trap with funnel

Removable shield inside vacuum chamber

NESLAB CFT-75 Chiller, 208-240 vac

Base pressure: 1x10-6 With no LN2

Power controller: XTC/2 or manual

(2) Legs: 115V, 1N, 1G

Power: 230/115V, 4 wire, 30A.

DENTON VACUUM DV 502A is a high-quality evaporator specifically designed for vacuum distilling and solvent evaporation applications. The evaporator has a simple, yet robust design that ensures quick and easy set-up and clean-down. It features a stainless-steel construction and is equipped with an integrated purge valve for convenient solvent recovery and a vacuum reservoir to provide a constant level of vacuum during the process. The Evaporator features a dual-position design; a vertical position, creating an upflow of solvent, and a horizontal position, creating a counterflow of solvent. This dual-position design improves solvent evaporation and contributes to an even concentration gradient. As well, the combination of the dual-position design and the integrated purge valve, results in reduced pressure fluctuations, ensuring a higher degree of process control and accuracy. The Evaporator also features a tank level monitor for better control of the process. This feature displays the current level of the solvent within the tank, allowing producers to adjust the evaporator's temperature, angle and rate of evaporation for optimal product uniformity. At the heart of the Evaporator lies its highly efficient heating of the solvent, ensuring minimal energy consumption. The evaporator is equipped with an adjustable heating element, specifically designed for solvent distillation and evaporation applications, and capable of attaining temperatures of up to 400°C. In addition, the evaporator features a cooling coil which reduces the chance of corrosive vapors from forming during the process. Finally, the evaporator comes with a touch-screen interface, allowing producers to easily configure it. The interface displays a variety of useful information such as process time, heating temperature and cooling temperature. With this ability, the evaporator can be programmed to meet the specific requirements of each process. Overall, DENTON VACUUM DV-502A is an advanced evaporator specifically designed to provide precise and consistent conceptual results. It features a dual-position design for improved immobilization uniformity, an accurate tank monitoring system, a robust and reliable heating system, and a convenient touch-screen interface for easy parameter programming. With its advanced design and reliable performance, DV 502 A is the best choice for a hassle-free and efficient vacuum distillation and evaporation process.

There are no reviews yet