Used PFEIFFER Classic 590 #9179746 for sale

URL successfully copied!

Tap to zoom

ID: 9179746

PVD Sputtering systems

Evaporator

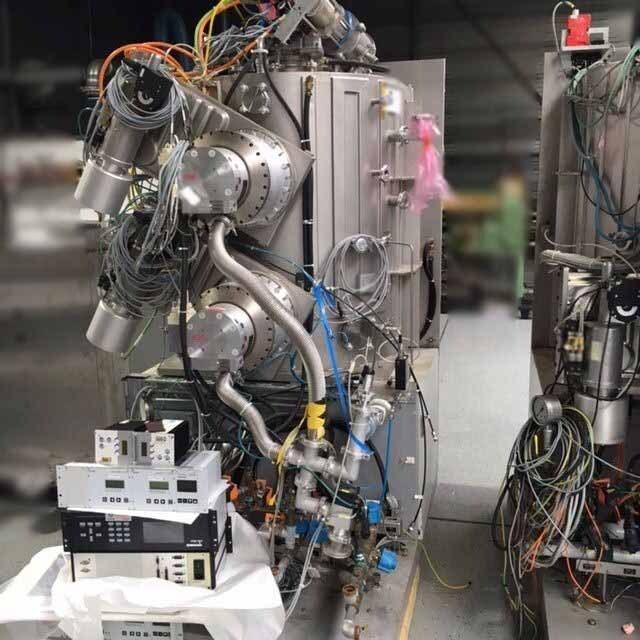

Configuration coater 1:

(2) PFEIFFER TPH 2301 (2300ls)

PFEIFFER DCU 600

(2) VAT Throttle valves 64048-pe48-ads2 / 0001

(1) PFEIFFER PKR251 Full range sensor

PFEIFFER TPR280 Prevacuum

PFEIFFER DUO 120 Prepump (120m3/h)

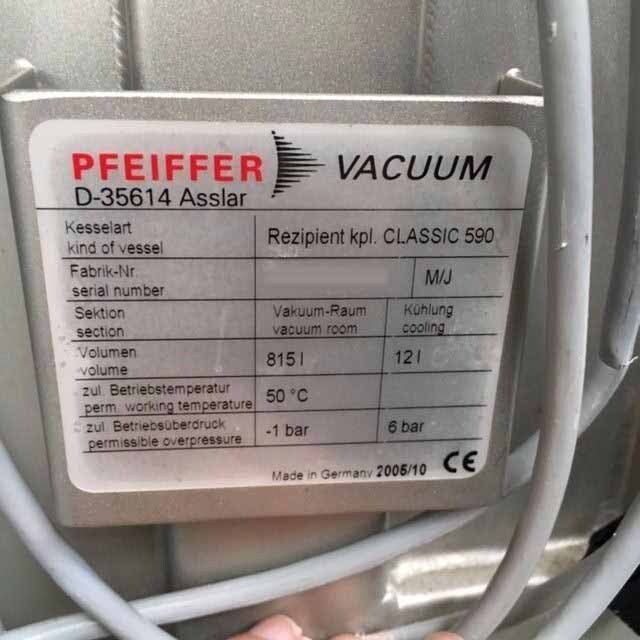

Vacuum chamber:

Substrate size round: 840 mm

(2) Viewports

Several feedthroughs

Rotating feedthrough included thermocouple

Infrared heater

Water manifold plus valves

Vacuum valves venting-pump down

Includes:

Shielding

Spare shielding set

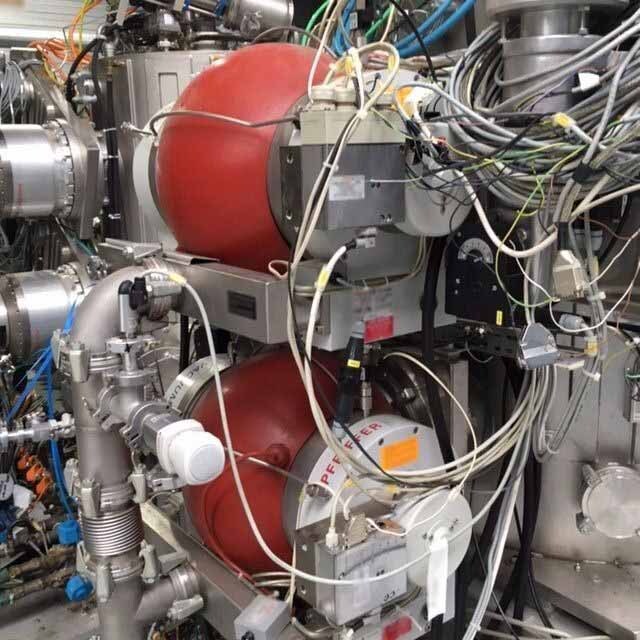

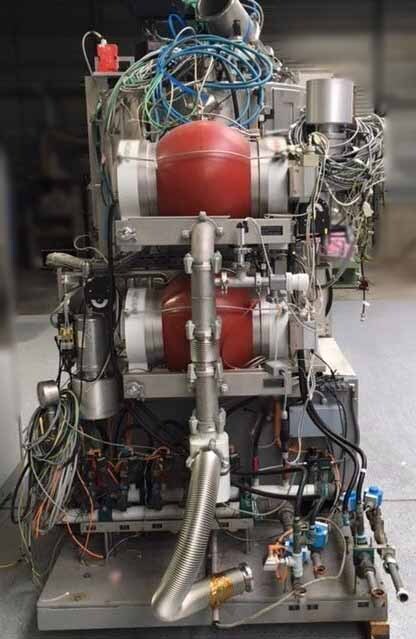

Configuration coater 2:

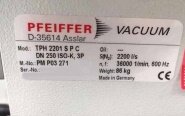

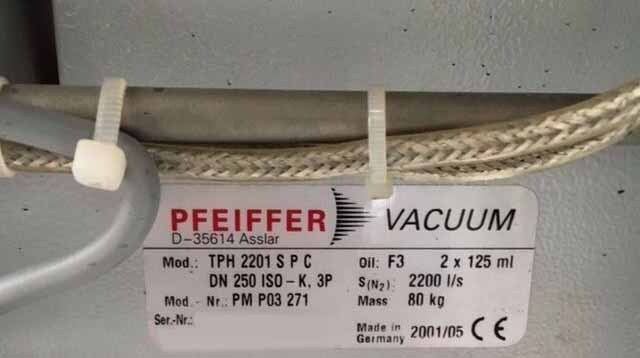

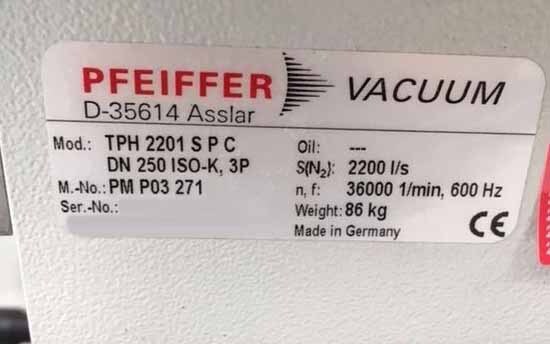

(2) PFEIFFER TPH 2201 s p c (horizontal turbo 2200ls)

PFEIFFER DCU 600

(2) VAT Throttle valve 64048-pe48-ads2 / 0001

(1) PFEIFFER PKR251 Full range sensor

PFEIFFER TPR280 Prevacuum

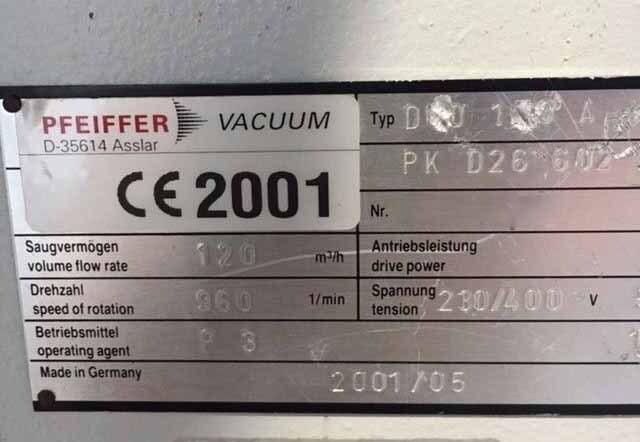

PFEIFFER DUO 120 Prepump (120m3 / h)

Vacuum chamber:

Substrate size round: 840 mm

(2) Viewports

Several feedthroughs

Rotating feedthrough included thermocouple

Infrared heater

Water manifold plus valves

Vacuum valves venting-pump down

Includes:

Shielding

Spare shielding set

2001-2005 vintage.

PFEIFFER Classic 590 evaporator is a versatile and efficient unit designed for use in a variety of industrial applications. The chassis of the evaporator is constructed of 304 stainless steel for a robust and sanitary design that ensures reliable operation over long periods of time. The high performance evaporator utilizes a conductive heating system to safely and effectively vaporize low boiling point liquids in a closed system. The interior of Classic 590 is lined with stainless steel while the exterior of the machine is outfitted with thermally insulated walls. This ensures a safe and reliable operation that does not transfer heat outside of the evaporator. The interior chamber also features a scraping system which evenly distributes processed material and helps to keep the unit clean. The evaporator is driven by an electric motor that utilizes powerful fans to evenly circulate air within the chamber. This ensures optimal performance as materials are sealed from the rest of the environment. The fan is set to optimize the temperature of the machine, while the fan speed can be adjusted to vary the rate of evaporation. The evaporator has a variable rate valve designed to control the flow of processed material out of the chamber. This valve can be adjusted to match the evaporation rate and provides precise control of material throughput. A digital display also allows users to monitor material processing, temperature, and output. The evaporator is designed with safety features to minimize the chance of harm to personnel and equipment. PFEIFFER Classic 590 evaporator is designed to be user friendly and easy to maintain. The evaporator routinely requires minimal maintenance, and can be serviced and inspected without requiring the removal of components. The evaporator provides reliable operation with minimal downtime and is the perfect choice for applications that require quick turnarounds.

There are no reviews yet