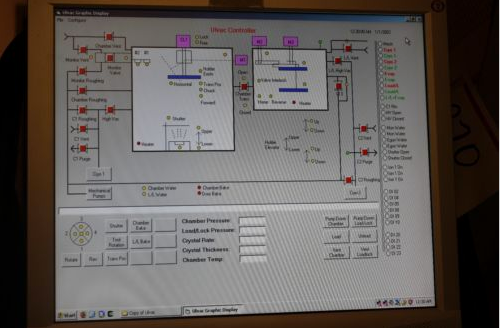

Used ULVAC Custom #9076778 for sale

URL successfully copied!

Tap to zoom

ID: 9076778

Wafer Size: 28

Vintage: 1996

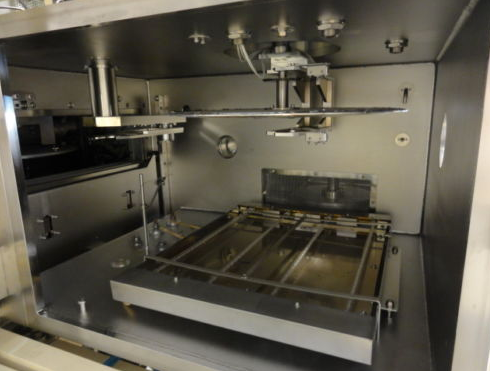

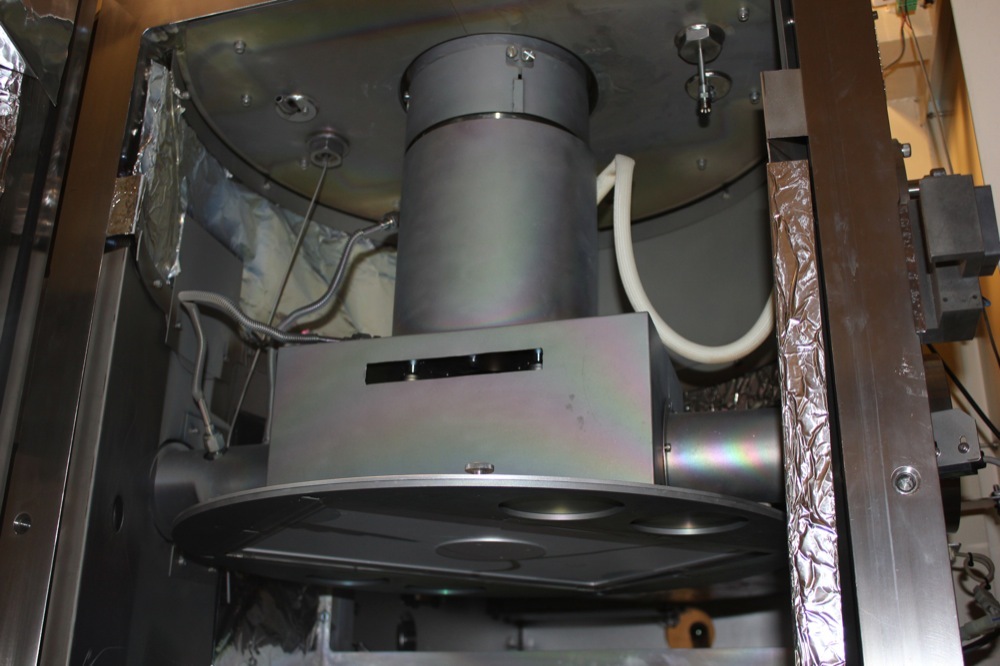

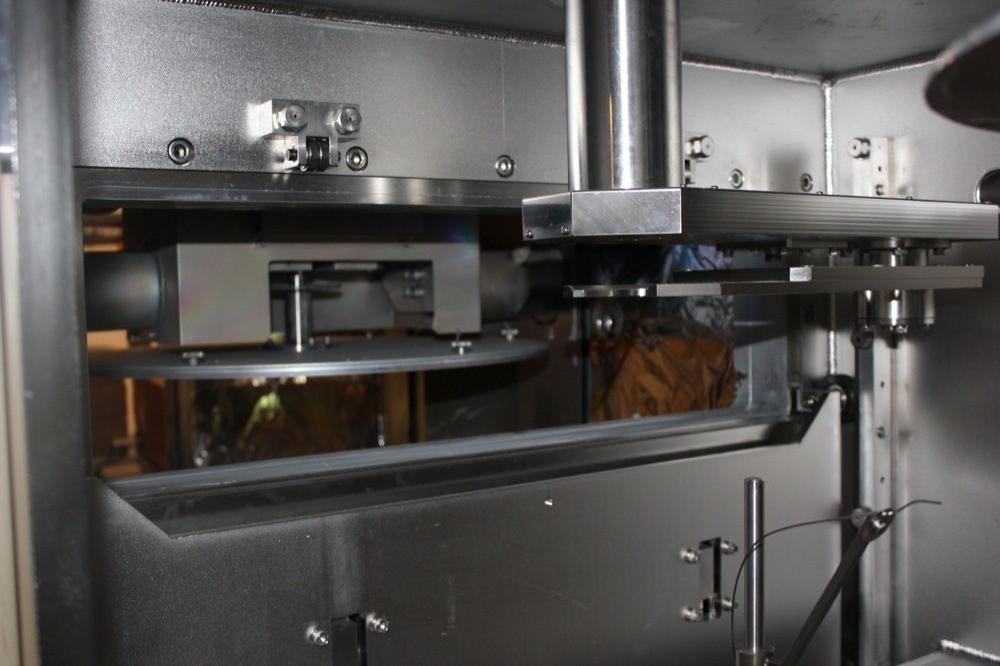

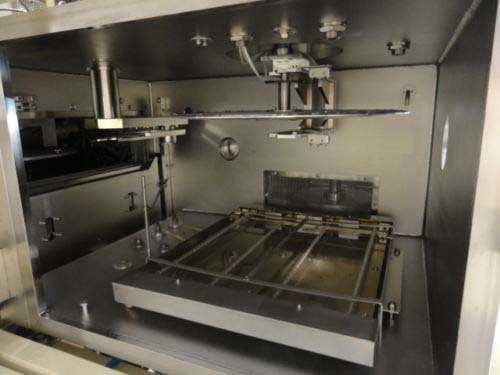

Vacuum coating chamber

High vacuum chamber, 96"

28" diameter

Long throw height

Load Locks for Parts and Crystals

EGL-80M 4-Pocket (110cc EA) E-Beam Gun

Process chamber: CTI-400 Cryo pump

Loadlock chamber: CTI Cryotorr 8F Cryo pump

Camera adaptable view: Robotic hand-offs

Pallet is the substrate stage: Rotatable

Glancing angle deposition (GLAD): 0 to 89 degrees

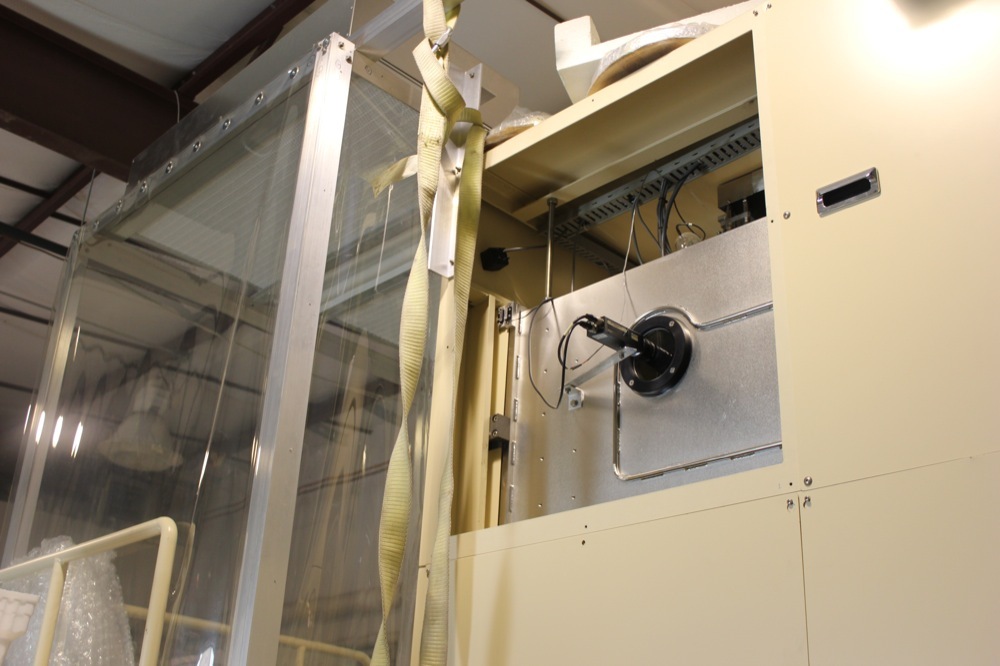

Main frame: 67" to 72" depth.

ULVAC Custom evaporators are widely used in a variety of industrial and research applications, ranging from medical production to thin-film deposition production. It is one of the most accurate, efficient, and versatile evaporators on the market. Custom evaporators use electron beam and thermal evaporation technologies to deposit thin films and coatings on substrates. The evaporators provide high-level performance and stability for a wide range of applications. This is achieved by careful design and engineering with superior materials, including corrosion-resistant stainless steel as the main body, force ventilation for evaporator cooling, and a fully-integrated touch panel for easy operation and control. The evaporator has the ability to provide precise vapor deposition and uniform coating thickness over a wide range of application areas. This is accomplished with a highly accurate mass flow controller and the option to have a dedicated SEC processing chamber. The easy-to-use automated control features allow users to set the desired deposition rate and temperature, as well as monitor and control the deposition process in real time. The high temperature capability of the evaporator allows for the precise deposition of metals, oxides, organic materials, and other film materials. The evaporator's temperature control is excellent due to its fast-response mass flow controller and precisely adjustable heating resistors. This temperature control allows for a wide range of process parameters to be set for high-end deposition materials, such as SiC or diamond-like carbon. The evaporator also includes a highly efficient convection chamber with a fan, a coarse and fine exhaust filter system, and a six-crystal quartz showerhead. Additionally, the evaporator's design incorporates advanced ventilation technology and an expansive viewing window to ensure that the entire process is under control at all times. Overall, ULVAC Custom evaporator is an advanced and precise evaporator system ideal for a variety of scientific and industrial applications. It provides unparalleled performance and stability with its sophisticated design, superior materials, and comprehensive touch panel control. Its high-level precision and easy-to-use features make Custom evaporator an ideal choice for thin film deposition and coating applications.

There are no reviews yet