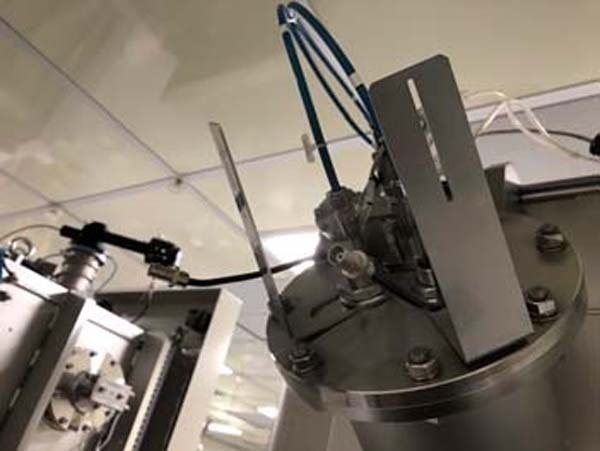

Used ULVAC ei-OPT085 #9376087 for sale

URL successfully copied!

Tap to zoom

ID: 9376087

Wafer Size: 4"

Vintage: 2010

Optical evaporation system, 4"

Wafer size: φ50mm±1.0mm

Thickness: 280±15μm

Dome size: 790φmm (4" Wafer x 110Pcs)

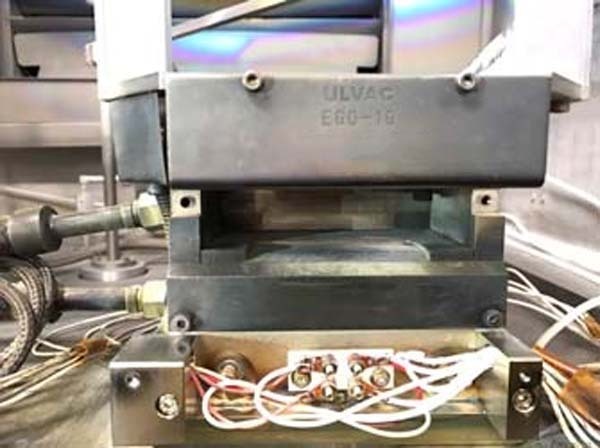

EB-Gun: EG0-1G

HPS-1000G-100 EB Power supply, 10kW

LR90 Dry pump

CP11 U-16P Cryo pump

DRP11 Dry pump with LR-90 Silencer

MFC: O2 Gas, 50 SCCM

Lamp heater: Maximum 350°C

PLC CPU

C-30VR Cryo compressor

TOKYO INSTRUMENTATION FS12-13-21-22 FA Series flow switch

VEECO Ion gun controller screen

CRTM-9000G Film thickness monitor

ET1515LJ Touch panel system

BENQ Monitor, 15"

Main source shutter

(4) Heating lamp units

Main breaker

IG Filament gauge

Ion gun

Pig gauge

MAINTE Button cover

Holder

Lid plate

(4) Spare parts for protective board

No quartz oscillator

No EBGU

No dome

2010 vintage.

ULVAC ei-OPT085 evaporator is a high performance equipment designed for the vacuum deposition process. It is a type of physical vapor deposition (PVD) evaporator that has been constructed for the deposition of metallic or ceramic films onto the substrate surfaces. The system is mainly used for industrial applications and as such its primary function is to provide thin film deposition on different surfaces with utmost precision. Ei-OPT085 is a single-substrate evaporator with symmetric design and high-vacuum chambers. Its cylindrical walls are made from highly durable stainless steel with dimensions of 200 mm (diameter) and 600 mm (height). The evaporator has a thermal resistance of 0.2 (C/s). Additionally, it provides excellent thermal conductivity, helping the substrate surface to reach the desired temperature quickly. The deposition chamber has a vacuum level of 330μM/sec, with an outlet pressure gauge. The evaporator uses ULVAC patented A-Mode Flow Booster (AFB) technology to precisely control the vapor flow. This ensures that the deposition process is consistent and reliable. ULVAC ei-OPT085 is powered by a variable frequency drive unit that reduces the need for mechanical components. Ei-OPT085 has several production process control functions, including a precise temperature control machine, computer-aided analysis tool, temperature feedback control asset, and data logger. Additionally, the evaporator has intelligent deposition control abilities, auto-monitoring of various critical parameters, and rapid process adjustment capabilities. An advanced cooling model provides the evaporator with superior temperature control, making it capable of high-quality film deposition with minimal impurities. Overall, ULVAC ei-OPT085 evaporator is an advanced equipment for physical vapor deposition, and provides users with reliable performance and highly accurate results. With its unique features and efficient design, the system is ideal for use in industries such as semiconductor, electronic and medical device manufacturing.

There are no reviews yet