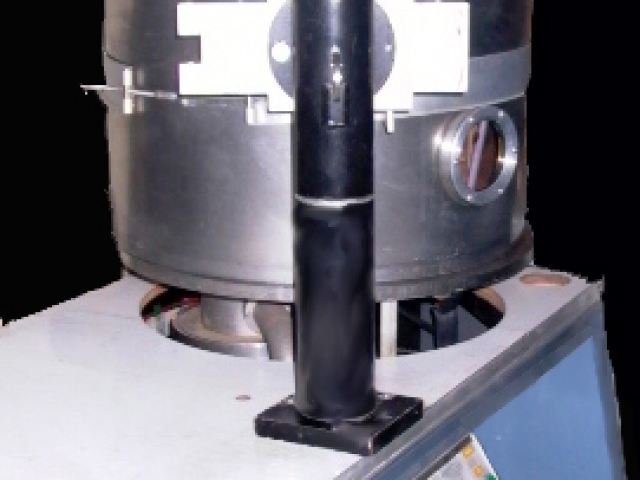

Used VEECO 775 #165752 for sale

URL successfully copied!

Tap to zoom

ID: 165752

Filament evaporator

24" x 30" High S/S Chamber

Automatic / manual valving

Digital ion / dual TC gauge

Diffusion pump

2 Stage direct drive roughing pump.

VEECO 775 is an evaporator used primarily in a Vacuum Thick Film Processing machine. The system is designed to promote efficient evaporation of deposits and removal of unwanted contaminants from various substrates during the growth process. This high-performance evaporator allows for precise temperature control, improved process control and flexibility, and more reliable source material deposition. 775 is constructed from stainless steel for durability and corrosion resistance, and is vacuum tight with a maximum operating pressure of 800 Torr. It includes two quartz double temperature zones, two resistant heaters for each zone, and a primary cold fingerprint to provide temperature uniformity across the substrate surface. The evaporator features a dual depth chamber with separate source loading and power control to ensure homogeneity of source material deposition. The multi-level source lock allows for source loading without mechanical disturbances, while a replaceable bottom plate ensures thermal uniformity of the evaporation chamber. VEECO 775 utilizes a dynamic microbalance feedback control system to monitor the weight deposited on the substrate and maintain a precise deposition rate. Additional evaporation adjustments can be made to increase or reduce ceramic deposition rate in the affected area. It also has an advanced filtration system, which maintains crystal clean deposition environment, eliminating residues or contaminants and ensuring product quality. This evaporator offers a number of benefits, including faster deposition rates, improved process control and flexibility and superior source material accuracy. Its robust design ensures reliable operation in any process conditions and makes it easy to maintain for longer equipment life and maximum uptime. 775 is an ideal solution for substrates and materials requiring high deposition rates and precise control of the deposition process. It is also a great choice for highly corrosive environments where reliability and performance are key.

There are no reviews yet