Used ADVANCED ENGINEERING 951 #9101227 for sale

URL successfully copied!

Tap to zoom

ID: 9101227

Wafer Size: 8"

Vintage: 2003

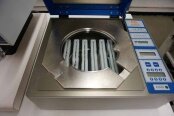

UV Dicing tape curing system, 8"

Wavelength: 365 nm

Ozone free UV irradiation source

Timer

UV Intensity meter

Lamp hour and status indicator

Voltage: 110 V

2003 vintage.

ADVANCED ENGINEERING 951 is a state-of-the-art exposure equipment that allows for complete control and analysis of the production and fabrication environment. It can be used for a wide variety of applications and can be customized to meet the needs of any specific process. The system features a high-resolution control unit, field-programmable gate array (FPGA) integration, software-defined control of multiple processes, and advanced automation components. The central component of 951 machine is its high-resolution control tool. This asset utilizes state-of-the-art FPGA technology to provide precise control of the entire model. The FPGA can be programmed to control the speed, temperature, and other critical process parameters. This allows for great versatility and accuracy for the user as they work to fine-tune the equipment for their specific tasks. ADVANCED ENGINEERING 951 system also features advanced software-defined control of multiple processes. This software-defined control allows for automation of complex tasks, with the user setting from simple instructions and complex algorithms, whatever may be needed to perform the task. The software-defined control of the unit can be programmed and stored in the FPGA, so that once programmed, it can easily be reused without the need to reprogram the model each time. 951 machine also features additional automation components, allowing for complete control and analysis of the production and fabrication process. With these components, users can track, control, and analyze the entire production process. This provides unparalleled accuracy and efficiency in the production process. ADVANCED ENGINEERING 951 is a powerful and versatile exposure tool. With high-resolution control, FPGA integration, software-defined control of multiple processes, and advanced automation components, it is the perfect tool for production and fabrication applications. Its features allow for the highest accuracy and level of control, making it an excellent choice for any production or fabrication process.

There are no reviews yet