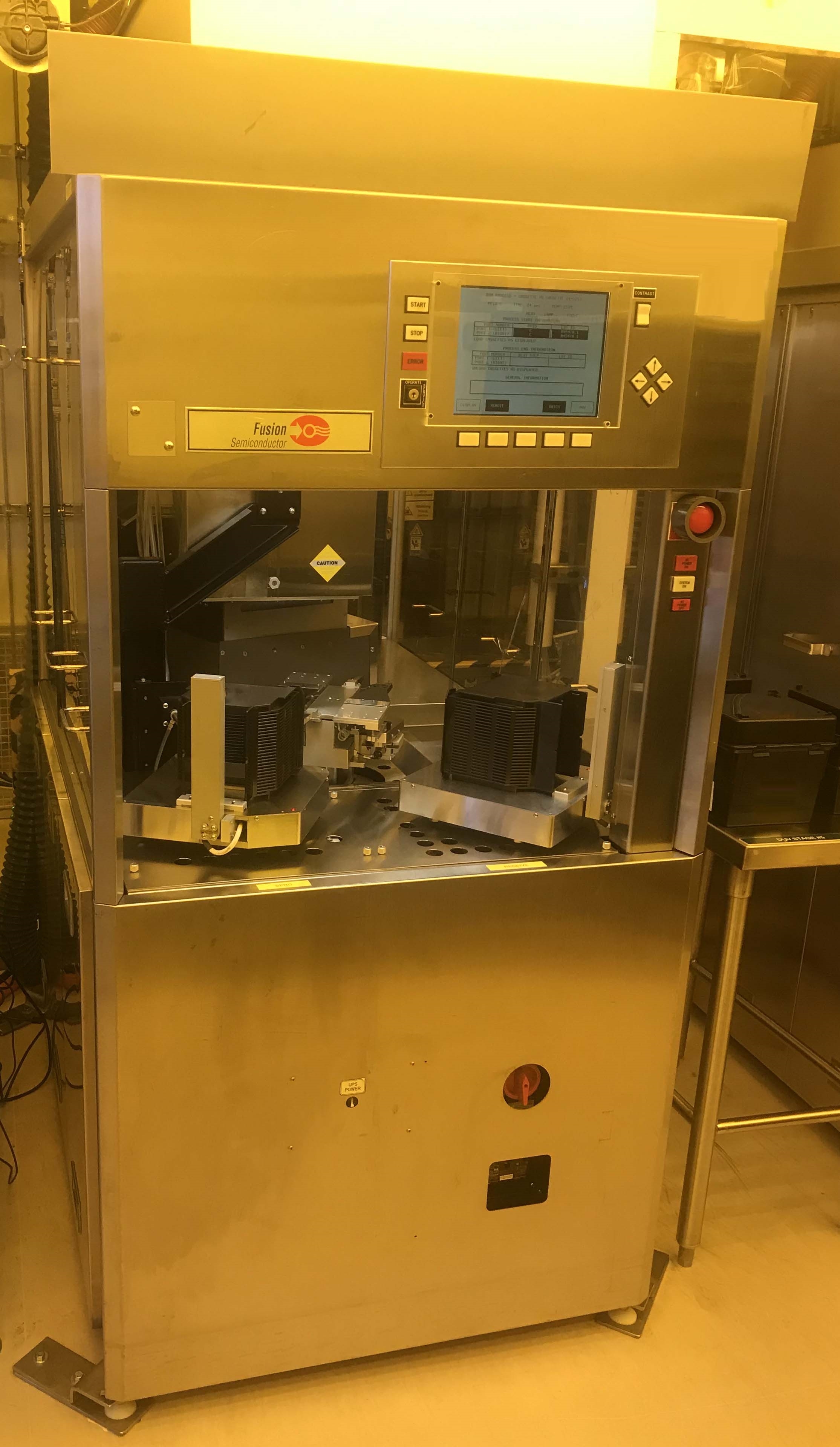

Used AXCELIS / FUSION 200 PCU #9258173 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

AXCELIS / FUSION 200 PCU (Photomask Creation Unit) is an advanced high-precision lithography equipment designed for the semiconductor industry. It is used to expose semiconductor wafers to ultraviolet (UV) light with extreme accuracy and repeatability, thus satisfying the requirements for high-quality, high-yield, and high-volume device fabrication. FUSION 200 PCU is equipped with a high-precision Direct-Drive Stepper with Sub-Micron Accuracy (DDSSA) that enables extremely precise processing of the exposed semiconductor wafers. The stepper includes a highly accurate, high-resolution optical alignment subsystem to ensure accurate placement of exposure masks onto the wafer. The system also includes an attenuated optical path length (AOPL) function that allows independent exposure of different regions of the wafer. AXCELIS 200PCU also includes an advanced registration unit that ensures that each exposed chip is in the right position relative to other chips, as well as a double-edge exposure perforation and peg machine that further enhances the accuracy of the exposures. This ensures that the exposure intensity is uniform across the entire image, as required for high-precision lithography. To ensure compatiability with various types of exposure masks, the tool is equipped with an array of filters to support exposure of various photosensitive and doped layers of semiconductor wafers. For lithography of very small features, the asset also includes an alternative exposure technique, the scanning tunneling lithography (STL) model, where the exposure is performed with a local scanning probe tipped with an array of emitters. 200 PCU employs several safety features to minimize accidental exposure to radiation. These include optical safety curtains, a closely monitored interlock equipment, and an automatically set analog exposure timer. The system also includes an auto-reflection compensation unit that adjusts the intensity of the exposure accordingly. Finally, to meet the challenging requirements of high-volume device fabrication, AXCELIS 200 PCU includes a high-speed data interface that allows programming of the machine remotely. This allows complex imaging sequences to be executed in a completely automated fashion. In summary, AXCELIS / FUSION 200PCU is an advanced lithography tool designed to meet the demanding requirements of high-precision and high-volume semiconductor device fabrication. This asset is equipped with a high-precision DDSSA and a close monitoring model, as well as an array of filters, an STL equipment, and a high-speed data interface for programming the system remotely. The various features ensure accuracy and uniformity of exposure as well as a high level of operational safety.

There are no reviews yet