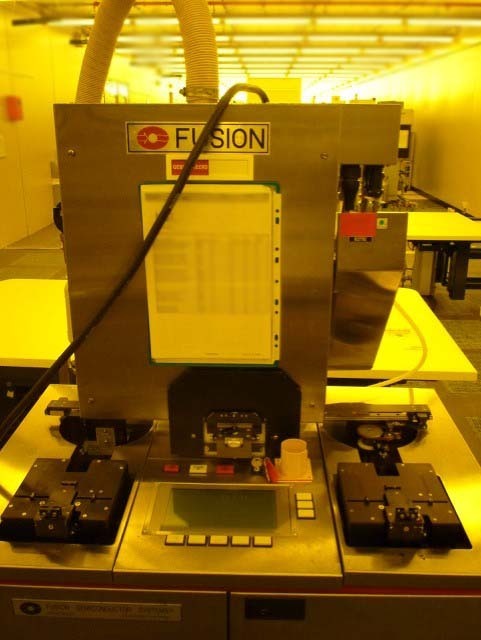

Used AXCELIS / FUSION M 150PCU #9355454 for sale

URL successfully copied!

Tap to zoom

ID: 9355454

Wafer Size: 6"

Lithography system, 6"

Process chamber / Bath

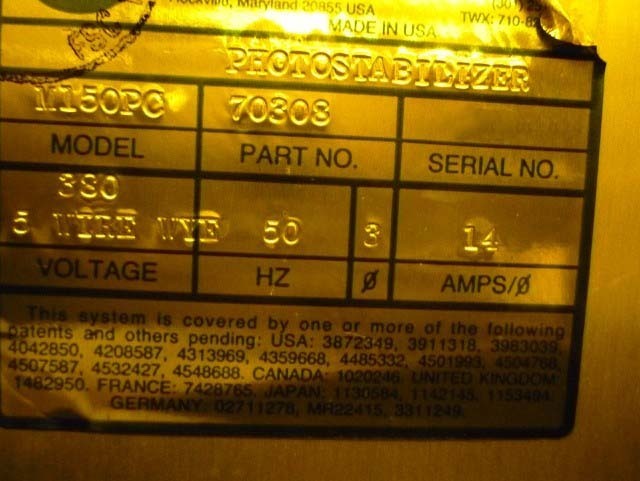

Process type: Photo stabilizer

Cassette

Mechanical chuck

Alarm box

Manuals

Power supply: 400 V, 6 kW, 14 Amps, 3-Phase.

AXCELIS / FUSION M 150PCU is an exposure equipment designed for the production of advanced semiconductor device layers. It utilizes a single-piece, double-beam, in-line machine system contoured to a single unified platform to enable precision processing and placement. The unit offers superior imaging quality at ultra-high wafer throughput for a variety of wafer sizes and layers. The machine's state-of-the-art optics, laser-cut wafer holder and loading tool provide precise alignment, reducing die placement nonuniformity. FUSION M 150PCU comes equipped with advanced designs for automatic exposure, pattern alignment, die-to-die casting, and alignment along with optimal target-level alignment. Its software features are designed to maximize throughput, control mats, speed, enable continuous alignment and high throughput imaging. The asset allows for precision control of exposure parameters such as illumination power, numerical aperture, sensor location, dose, and focal spot size. AXCELIS M 150 PCU comes with six different imaging systems including a high-resolution standard lens, high-resolution ion-sensing, ring-scanning, auto-focusing, and ring-scanning plus laser alignment. This ensures flexible and high-quality imaging at various wavelengths and numerical apertures. For efficient operation, the model comes designed with inliers, outliners, placement patches, and applied undockable bumpers. This eliminates micrometer vibration and eases exposure times. Additionally, the equipment features automatic die-to-die registration for mask to excimer (MTE) alignments and improved edge-to-edge registration accuracy. The system is also designed with multiple-target wafer-handling capabilities. Its auto-aligner is capable of handling up to four wafer stacks and is designed to compress the wafer group through automated sensing, pushing, and clamping, to enable exposure of the entire wafer. In summary, M 150PCU is a single-piece, double-beam, in-line machine unit designed to enable precision processing and placement of advanced semiconductor layers. The machine offers superior imaging quality at ultra-high wafer throughput for a variety of wafer sizes and layers, and features high-resolution optics, an automatic die-to-die registration tool, multiple imaging systems, and automated inlier/outliner capabilities to reduce nonuniformity and enhance edge-to-edge accuracy. Additionally, the asset comes with multiple-target wafer-handling capabilities and an auto-aligner that can handle up to four wafer stacks.

There are no reviews yet