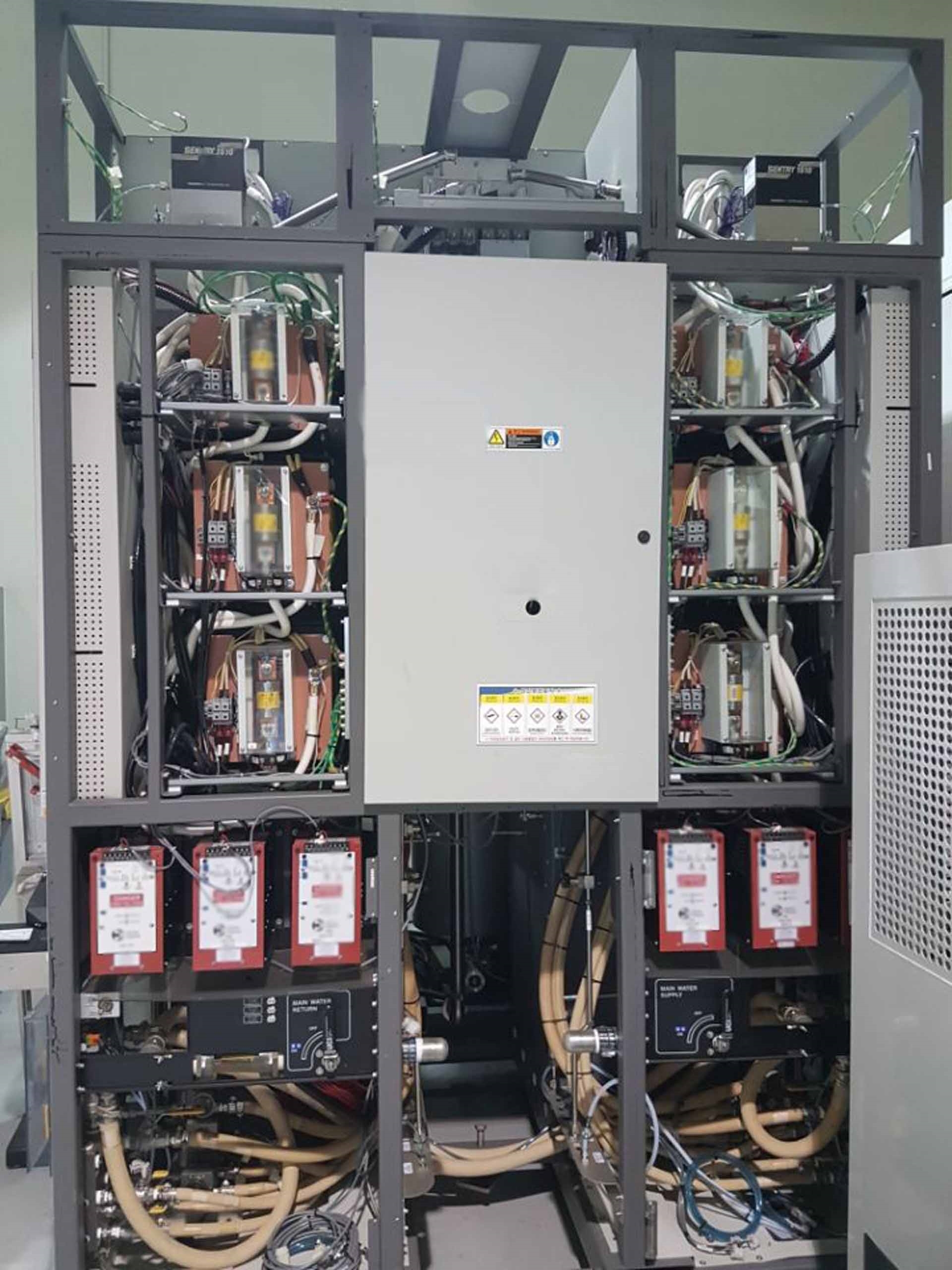

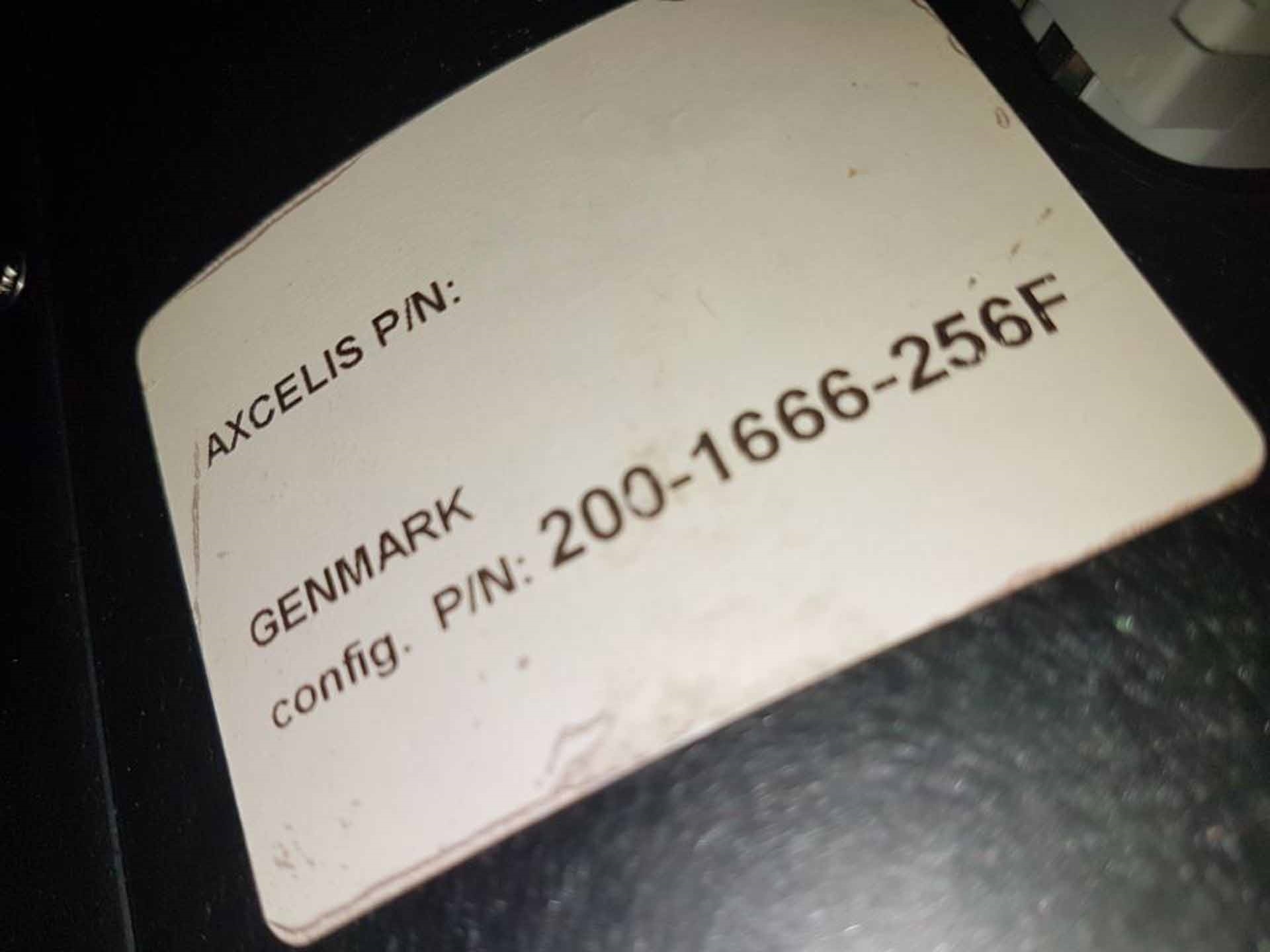

Used AXCELIS / FUSION Summit XT #9107033 for sale

URL successfully copied!

Tap to zoom

ID: 9107033

Wafer Size: 12"

Vintage: 2005

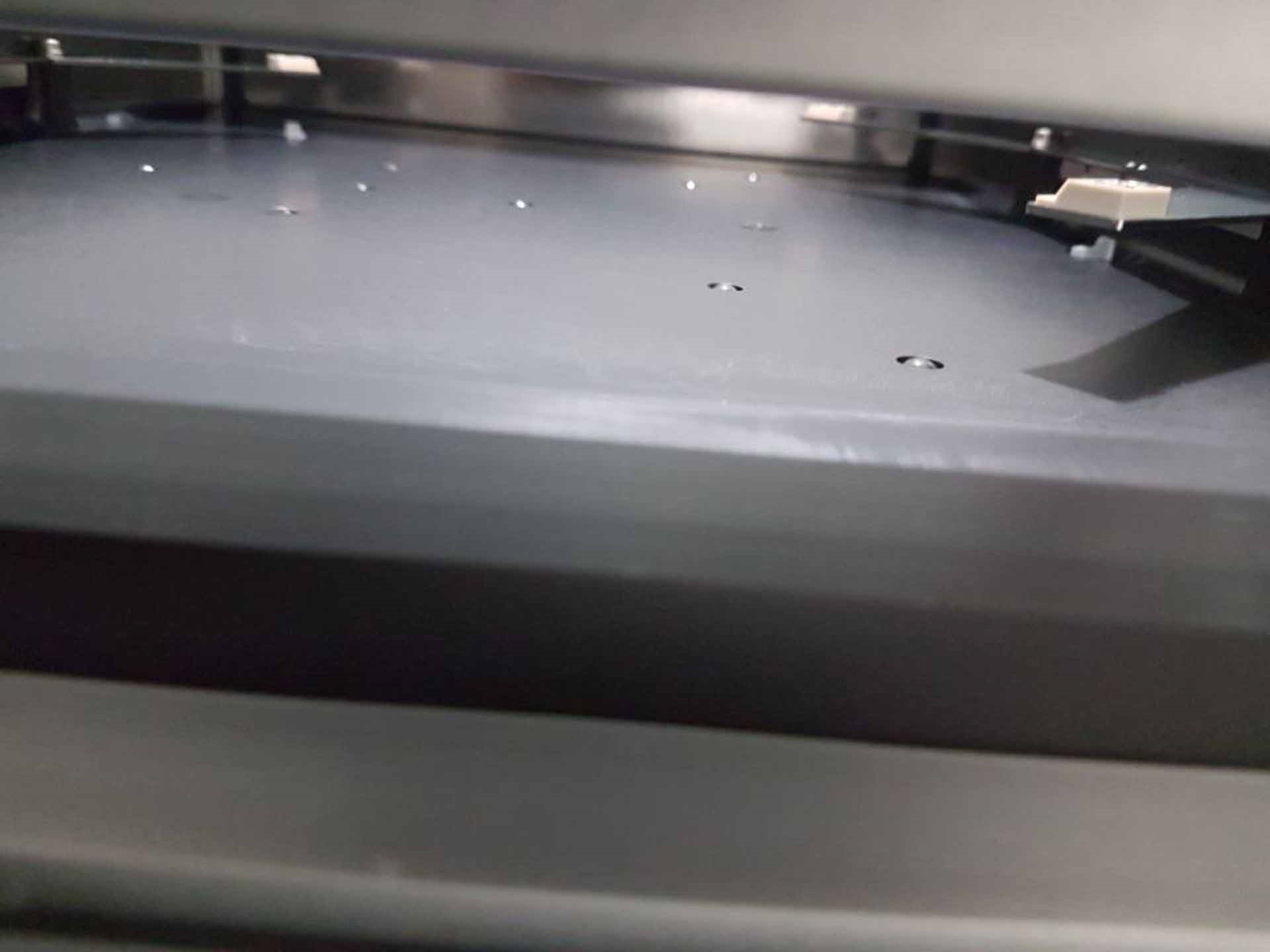

Rapid Thermal Processor (RTP) system, 12"

2005 vintage.

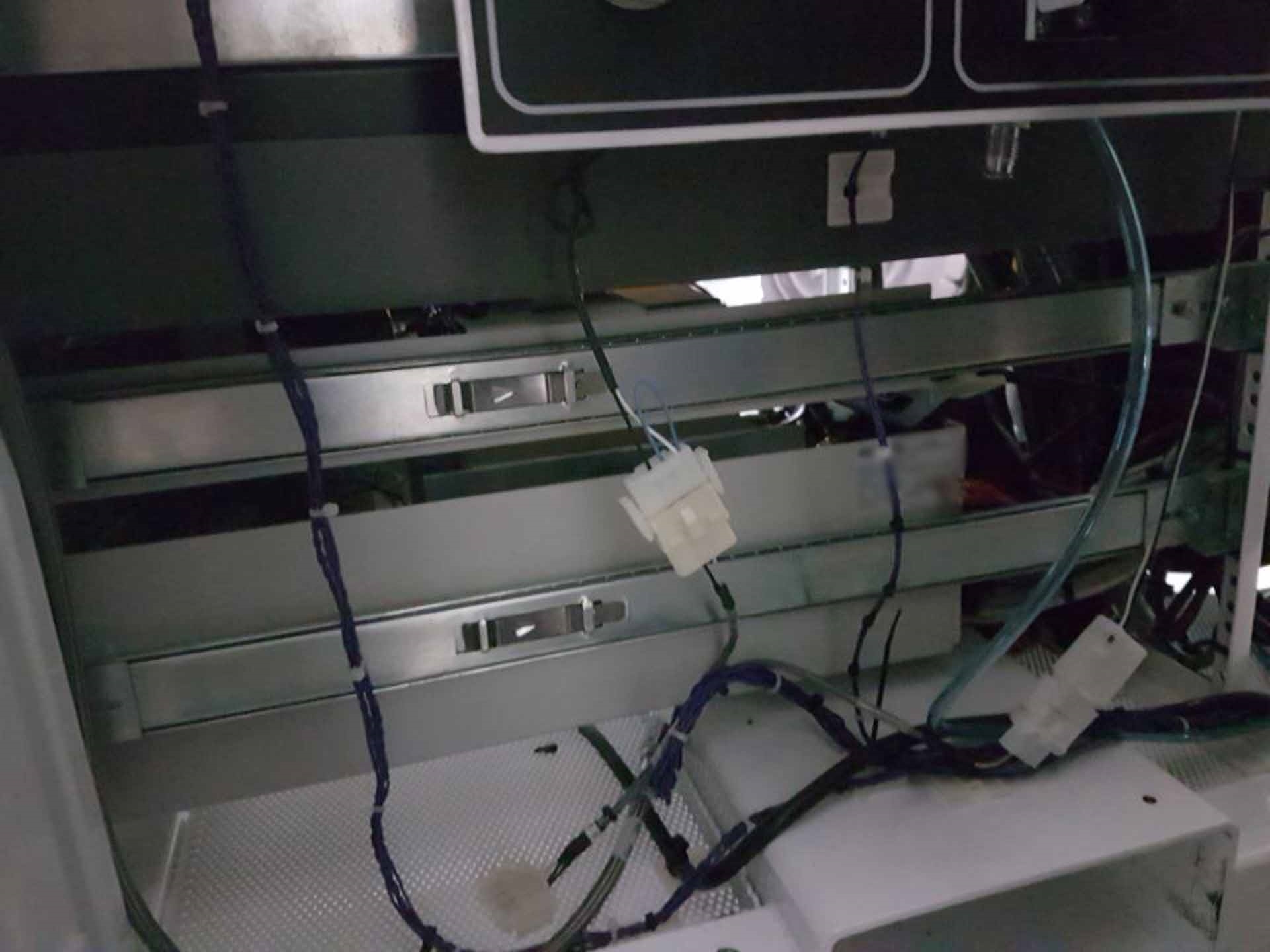

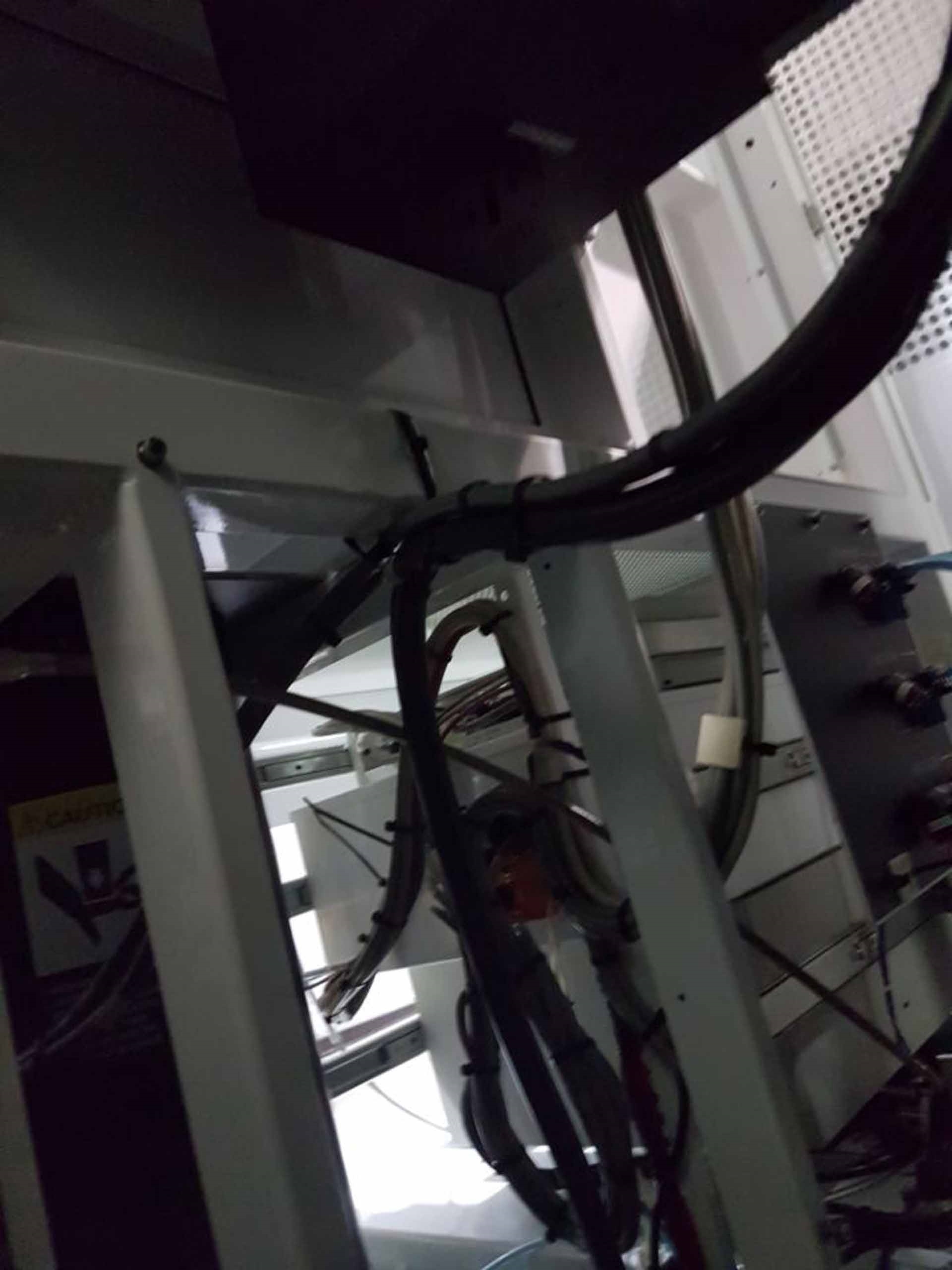

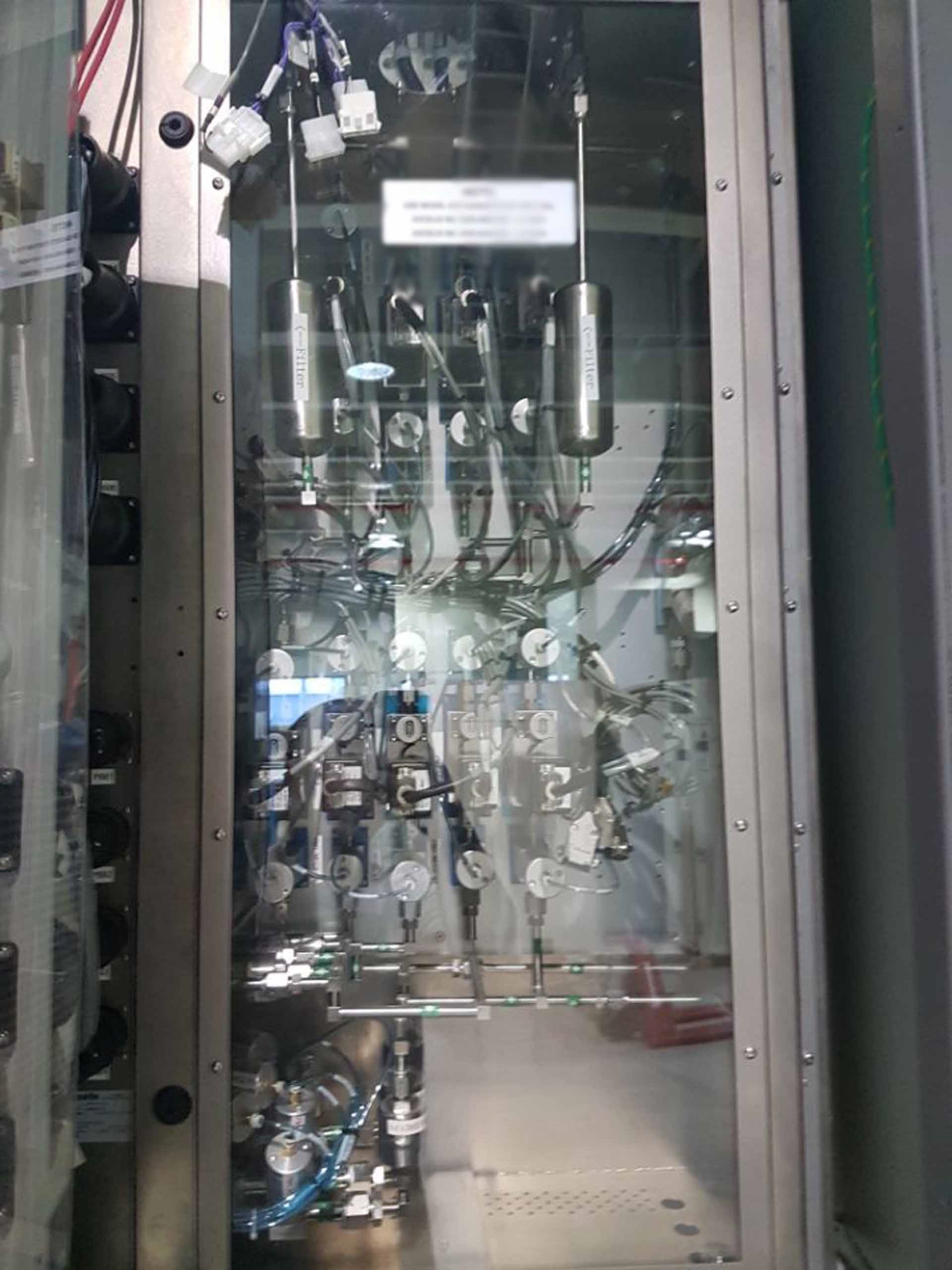

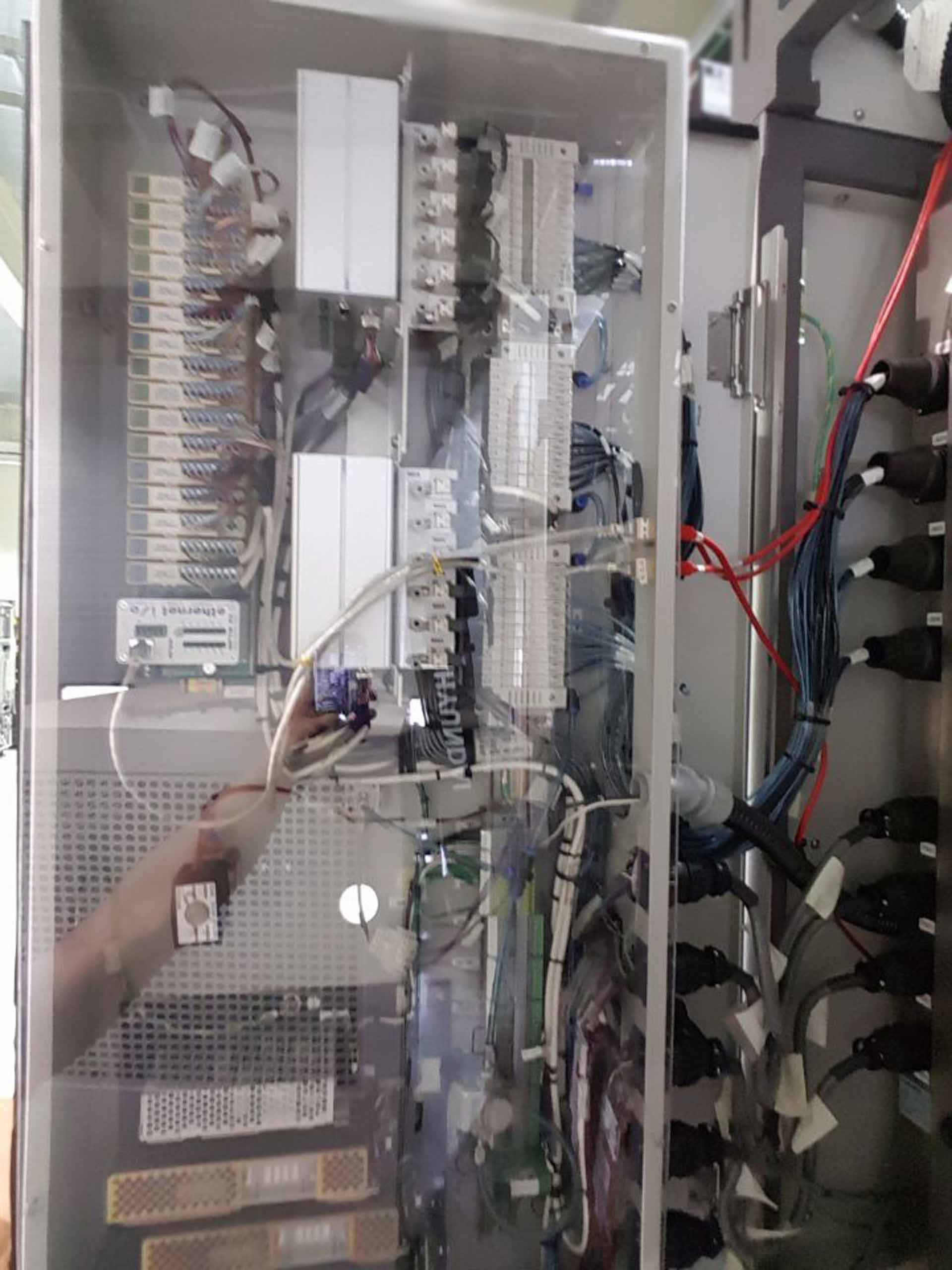

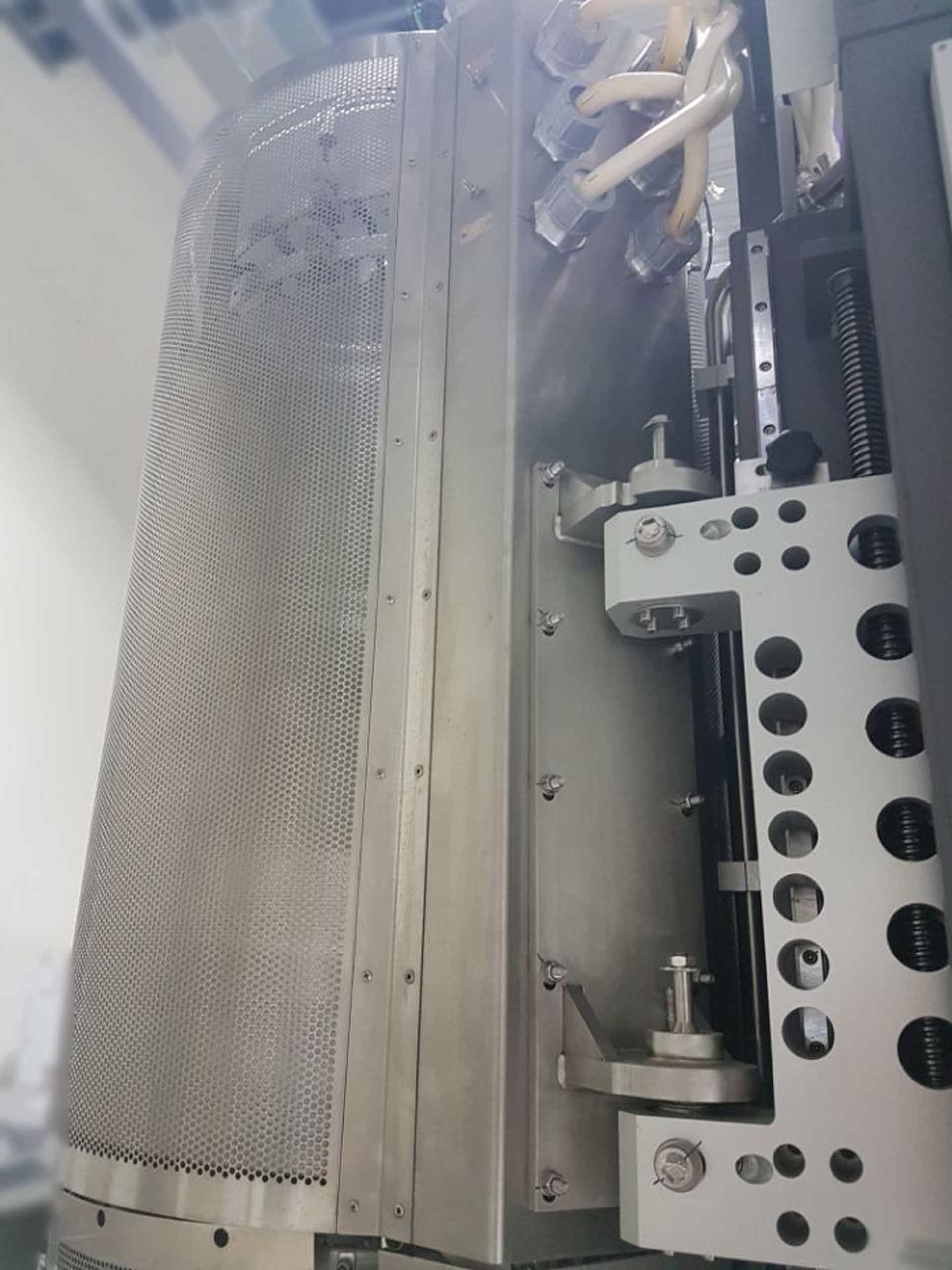

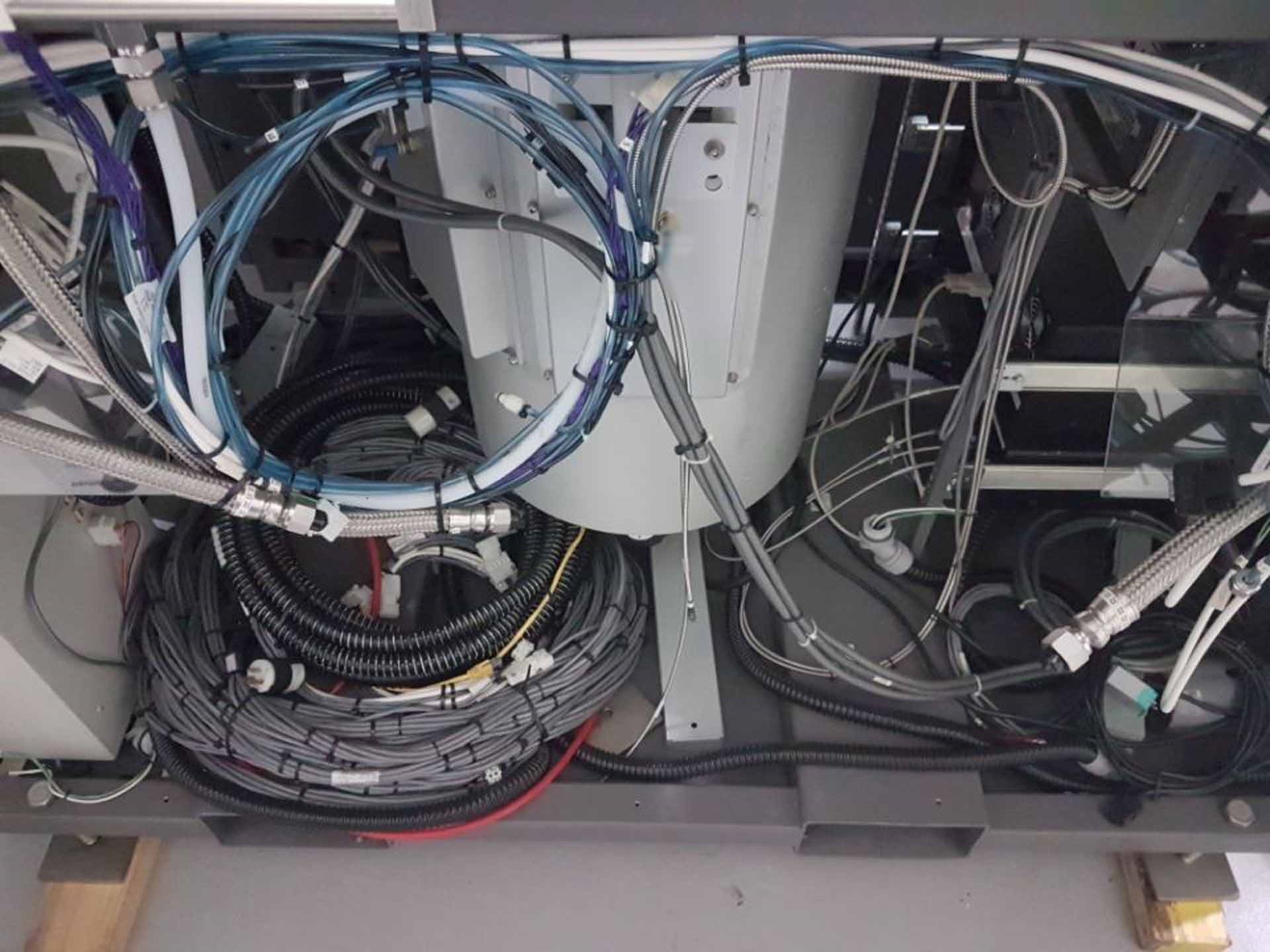

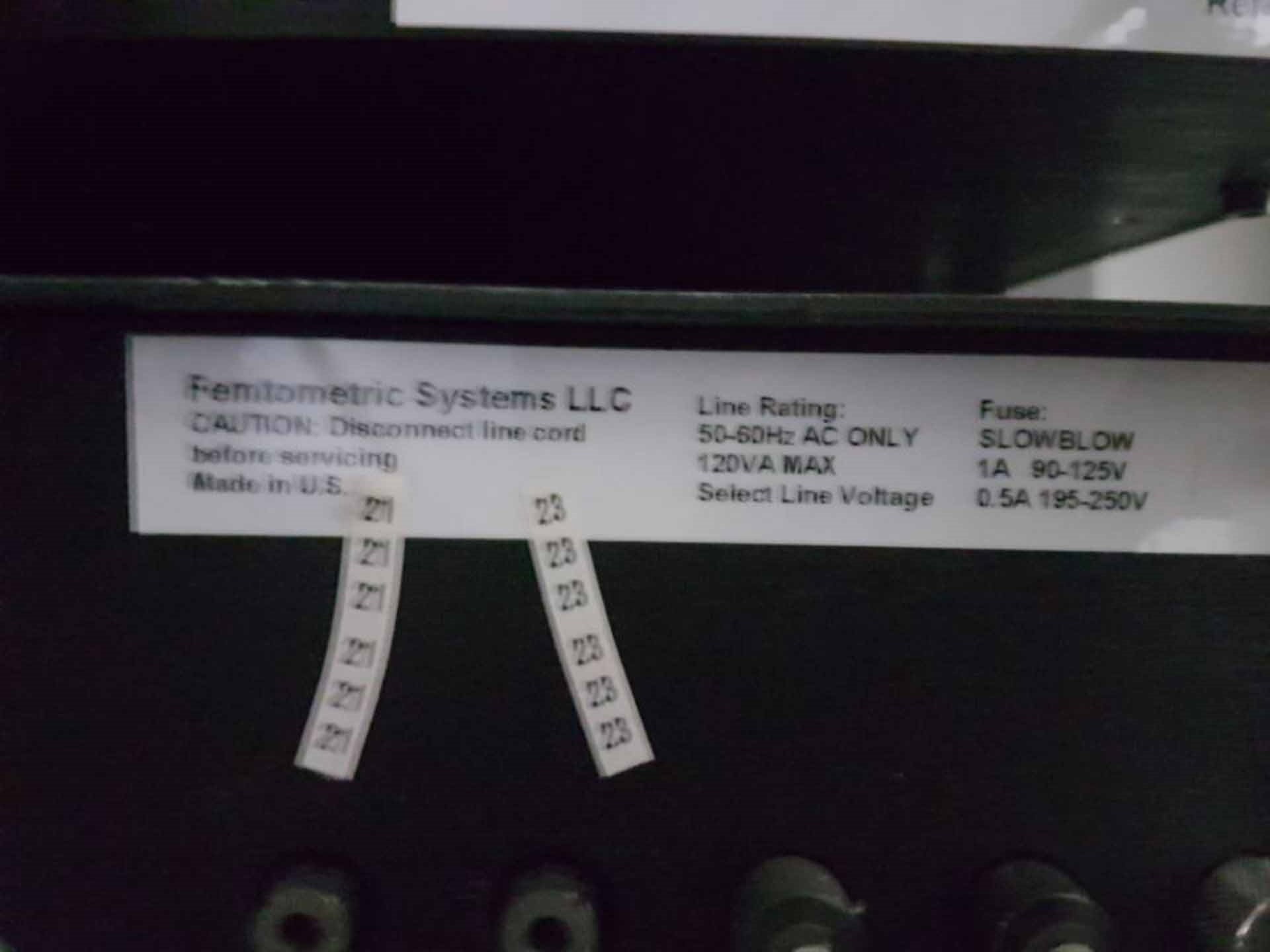

AXCELIS / FUSION Summit XT is an integrated equipment designed for precision wafer exposure in the semiconductor device fabrication process. It is composed of a number of different components, including an ultra-high resolution stepper motor, a vacuum chamber, a focus and alignment assembly, a photomask, and a robust robotic control system. The systems are capable of achieving sub-micron design rule compliance to produce superior resolution devices. The stepper motor is an important component of the unit, and allows for precision movement of the exposure field to ensure consistent alignment and accurate exposure. The motor's high resolution supports the production of extremely small structures, such as circuit paths, contact fingers, and even the tiniest of trenches. The vacuum chamber prevents unwanted air and environmental contaminants from entering the machine. It acts as a pressure barrier between the exposure assembly and the outside environment, ensuring that the tool remains clean. The clean environment is a key factor in achieving consistent image quality as well as repeatable results across multiple chips. The focus and alignment assembly is used to align the photomask and the wafer before the exposure process. This ensures that the exposed patterns are accurate and precise. The assembly also helps to ensure that the photomask is properly aligned with respect to the wafer, minimizing the possibility for misalignment leading to errors or fluctuations in the device characteristics. The photomask contains the patterns that are transferred onto the wafer during the exposure process. The accuracy and resolution of the mask design has a direct impact on the quality of the patterning and subsequently the characteristics of the device. Lastly, the robotic control asset is responsible for controlling the movements of the stepper motor and the focus and alignment assembly to ensure that the model is operated in a predictable and consistent manner. The equipment incorporates various feedback mechanisms which can detect any errors or anomalies in the system and respond automatically to correct any deviations from the normal operation. In summary, FUSION Summit XT is a comprehensive unit designed for precise wafer exposure in semiconductor device fabrication. Its advanced components are optimized for accuracy and reliability in order to produce high-resolution devices of consistent quality.

There are no reviews yet