Used CHARLES ROSS LDM-2 #9037460 for sale

URL successfully copied!

Tap to zoom

ID: 9037460

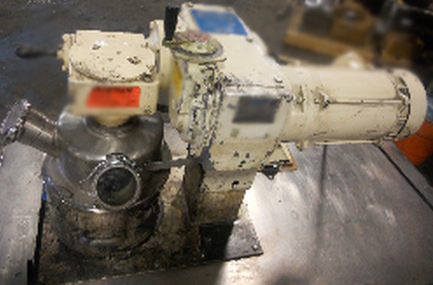

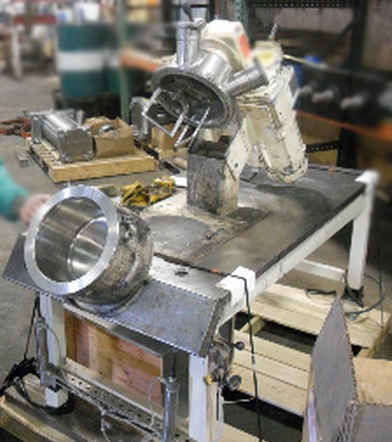

Double planetary mixer

Vacuum, jacketed

(2) 3-in sight glasses

(2) Air cylinders

2-Gallon capacity

With jacketed mix can approx: 9 5/8 in. ID x 6 1/2 in. deep.

Sterling variable speed

Stainless steel contact parts

Tilt back mix head

Vacuum top cover

1 HP/XP, 115-208/230 V motor

Mounted on stainless steel covered table

CHARLES ROSS LDM-2 is an industrial, multi-functional machinery designed to provide a safe and accurate form of mechanical production. It is utilized in the production of items such as machine-part components, rubber seals, and other specialized items among others. This machine is based on the Venturi Model and provides a highly automated and efficient operation. LDM-2 features a number of components, including a large vertical tank with dimensions of 1000 mm (L) X 700 mm (W) X 1350 mm (H). This tank is filled with a mixture of rubber seals, drilling jigs, and other items necessary for the production process. The items are moved along the tank by an automated pulley equipment. CHARLES ROSS LDM-2 also features a manual hopper that allows the operator to easily feed items into the tank. Additionally, the machine features a robust shaking head system that is designed to ensure equal movement and application of each item throughout the process. This movement is driven by a pneumatic cylinder with an adjustable speed range. The machine is also equipped with a high-pressure gripper unit composed of two adjustable arms which are designed to move, secure, and cut items as needed. For processing the items, LDM-2 is equipped with a hammerhead cutting tool. This tool is adjustable to provide a range of cutting parameters for both soft and hard materials. It is driven by a 30 KW motor with a spectrum range of 0-3000rpm and an accuracy to 0.1mm. Additionally, a worktable with a size of 500 mm (L) X 400 mm (W) is built-in to the equipment. This table is designed with a micro adjustable stage and a friction-adjustable platform. CHARLES ROSS LDM-2 also features several other components to ensure a safe and efficient production process. This includes a safety switch, an adjustment tool, an adjustable speed regulating machine, and a voltage regulator. Additionally, the machine is equipped with a Programmable Logic Controller (PLC) with a digital adjustable timer for controlling the production process. This PLC is equipped with sensors which are designed to detect errors and alert the operator of stopping the tool. Finally, LDM-2 comes equipped with a number of fixturing and assembly tools to ensure the secure and flexible production of items. This includes drill holders, clamping tools, and a heavy-duty clamping arm for safer and accurate assembly. These tools are designed to ensure secure and accurate assembly and machining of items.

There are no reviews yet