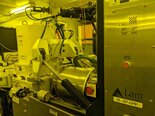

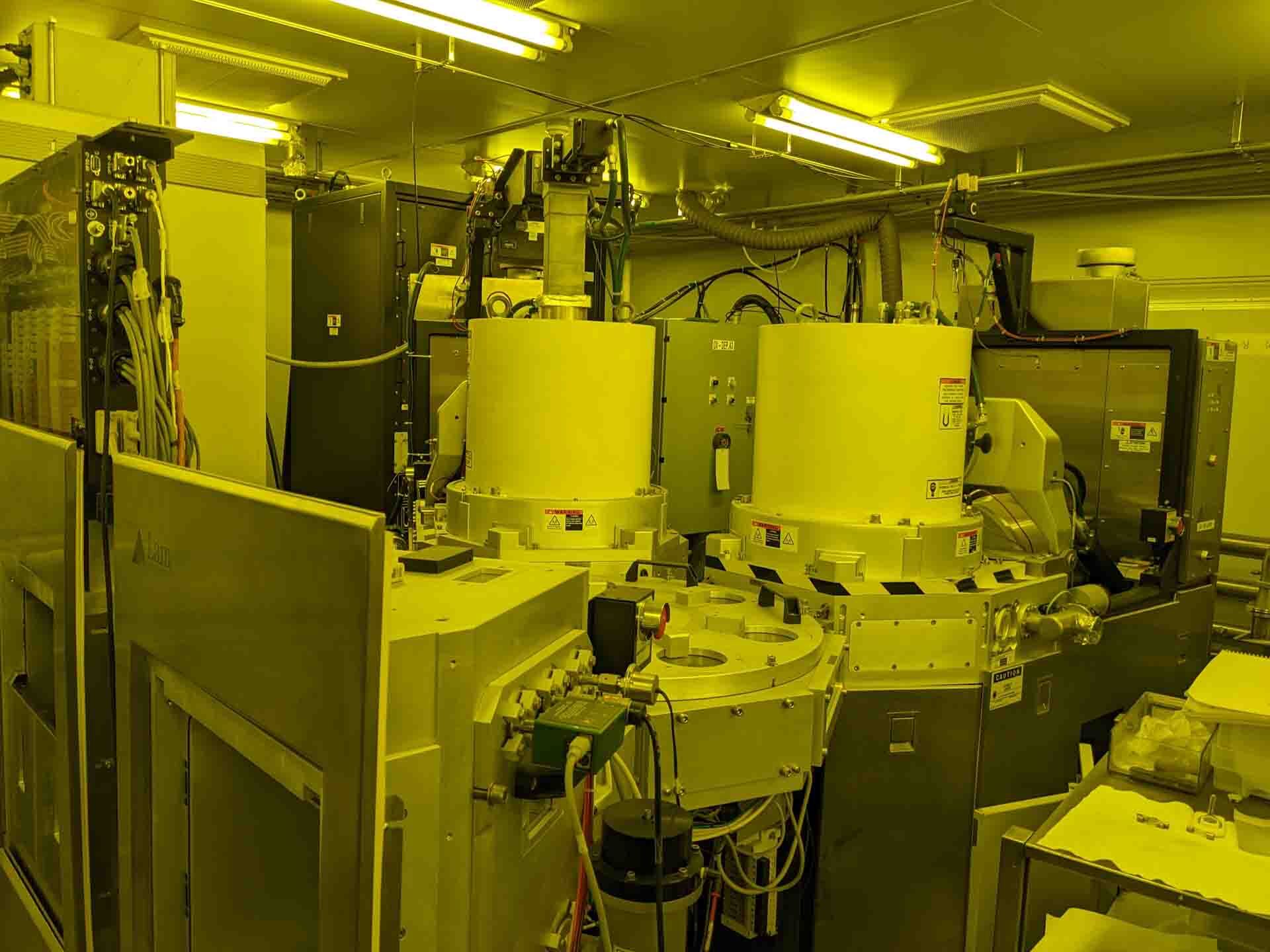

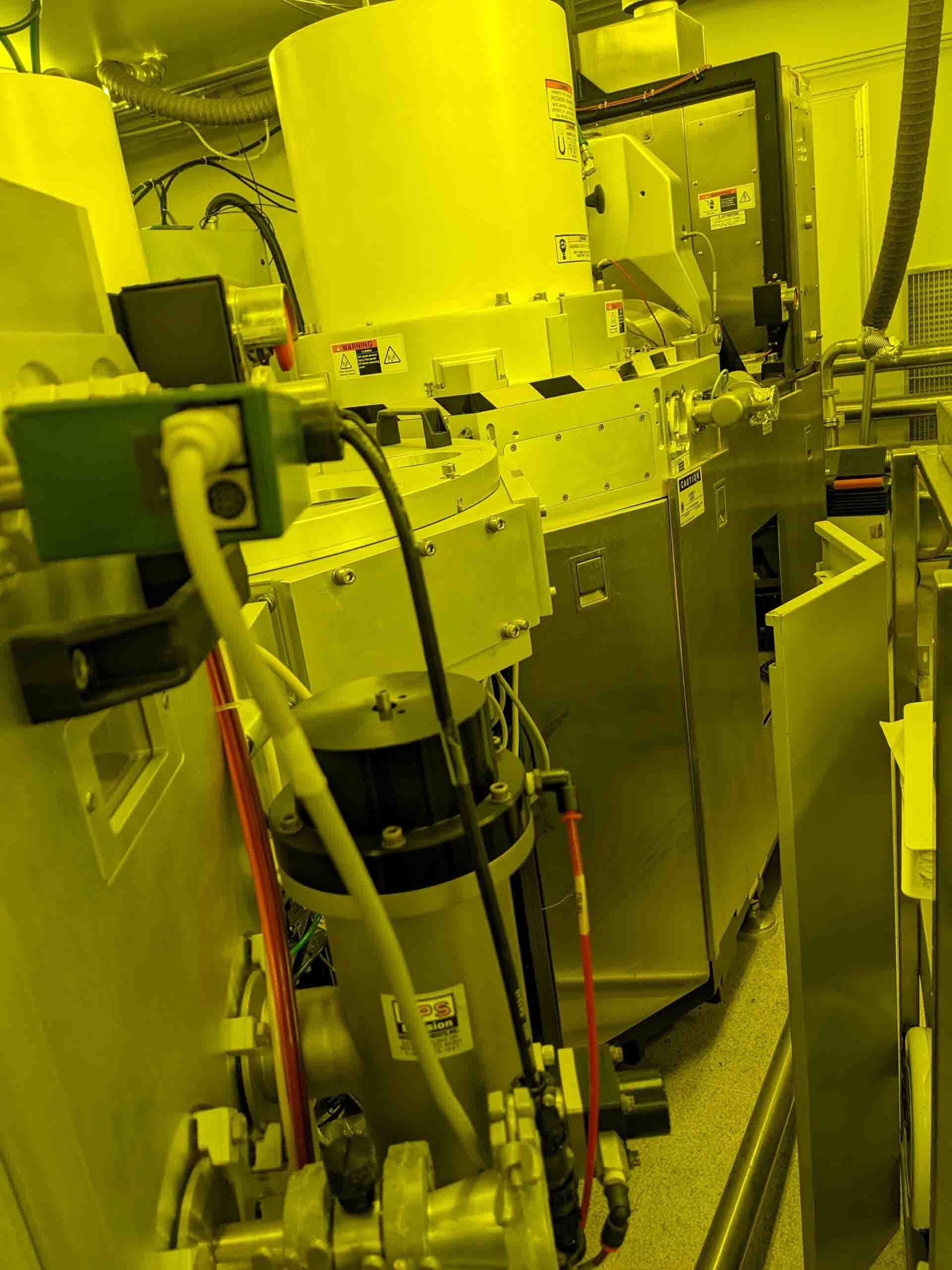

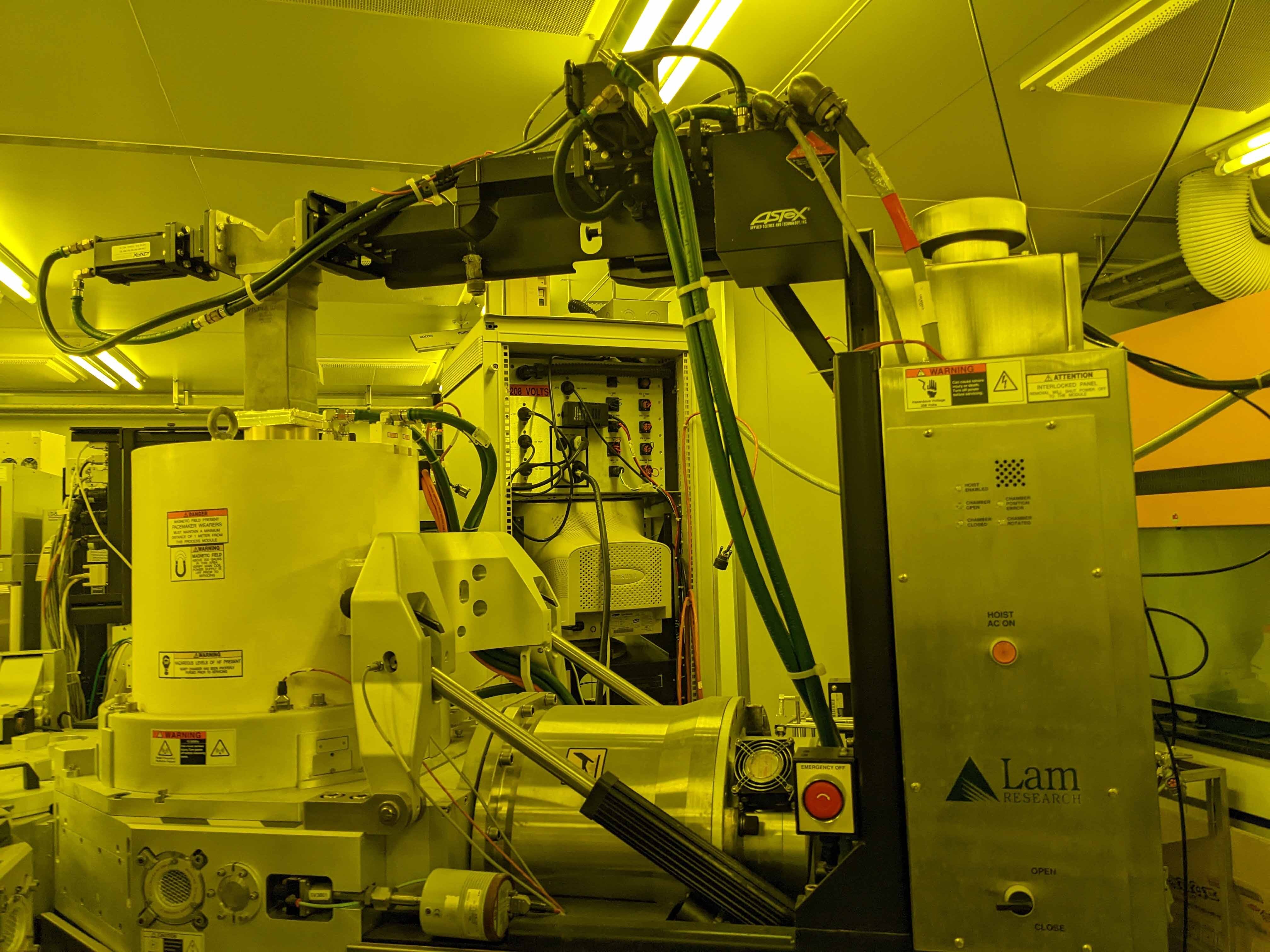

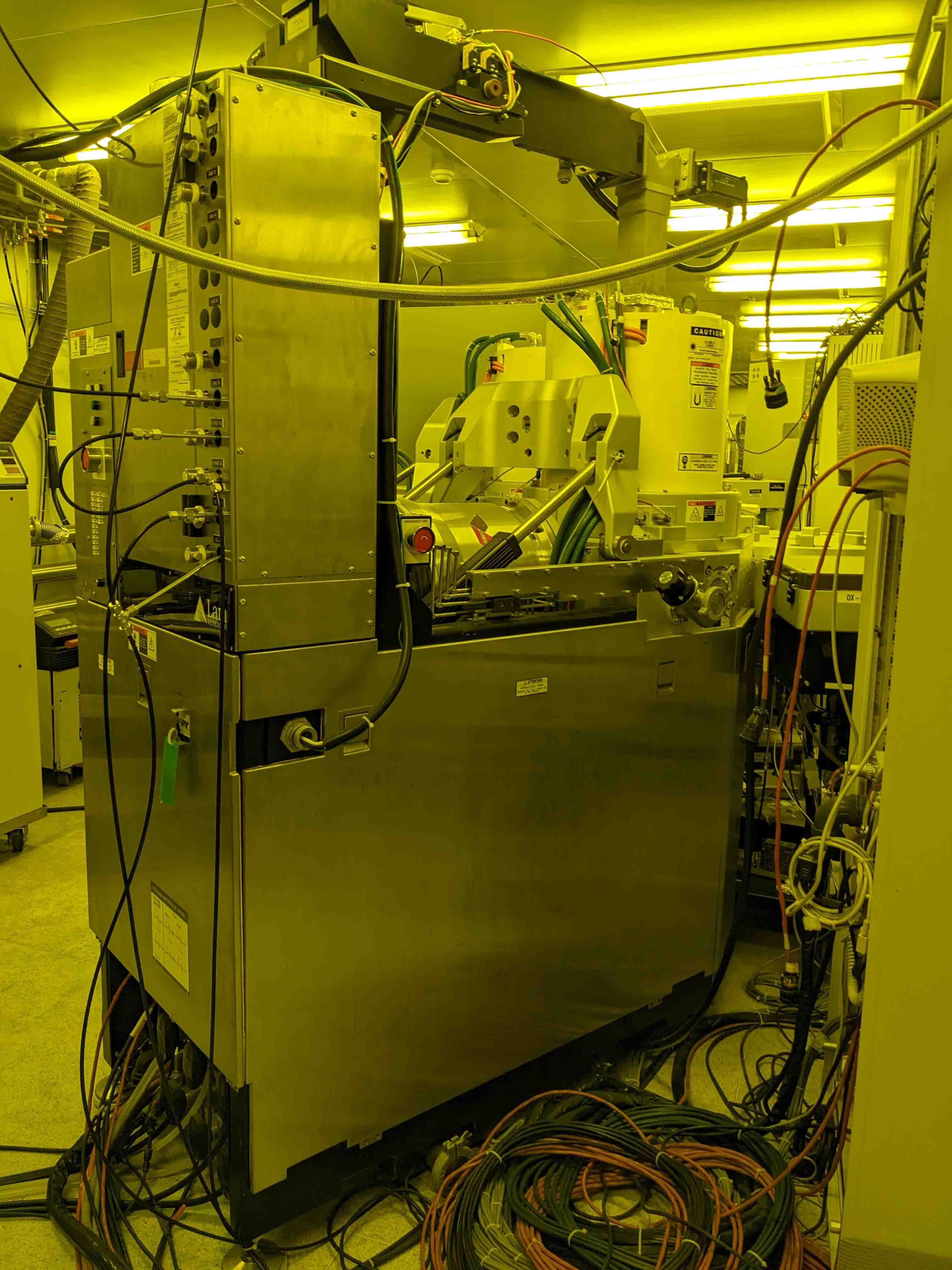

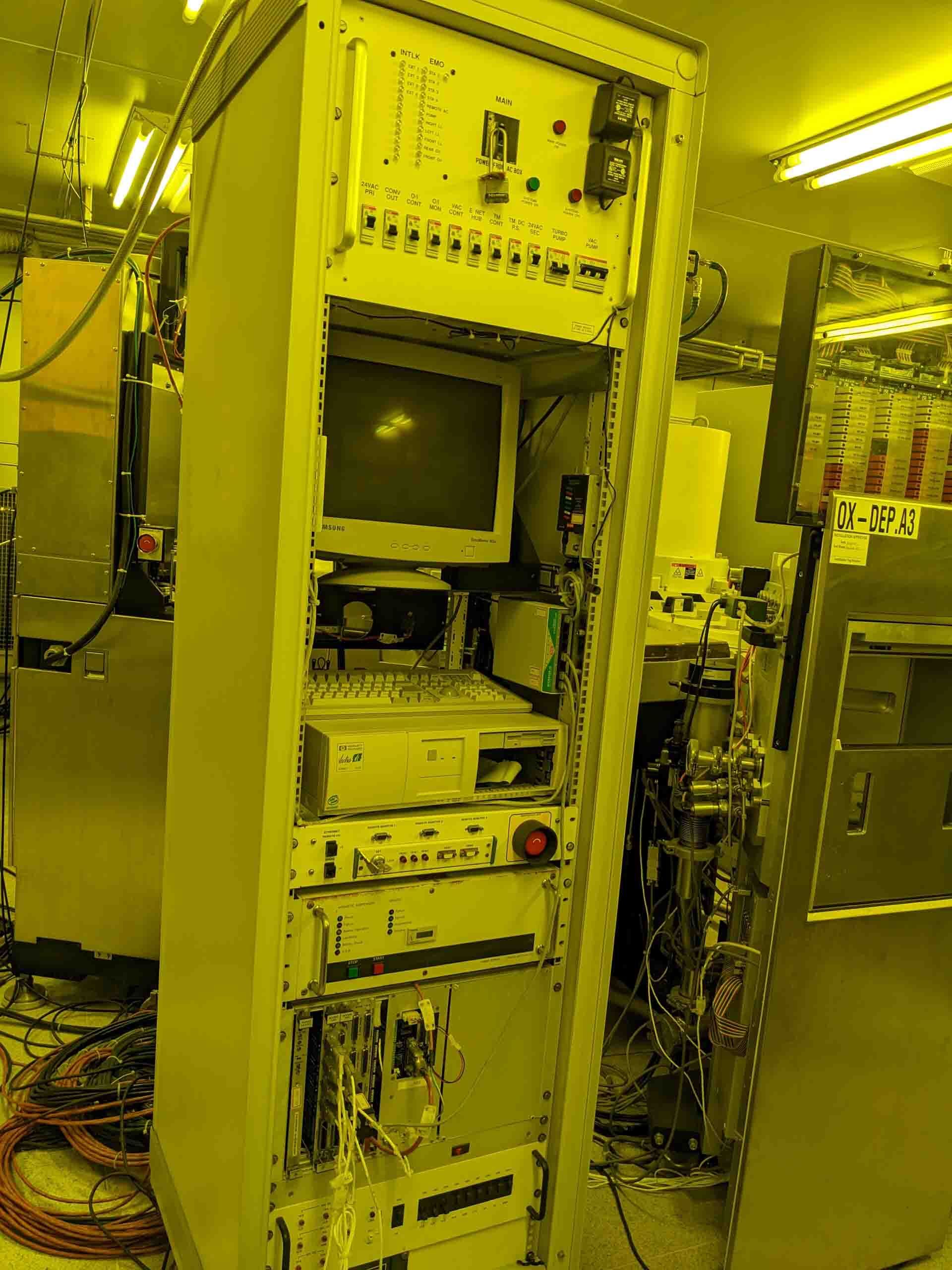

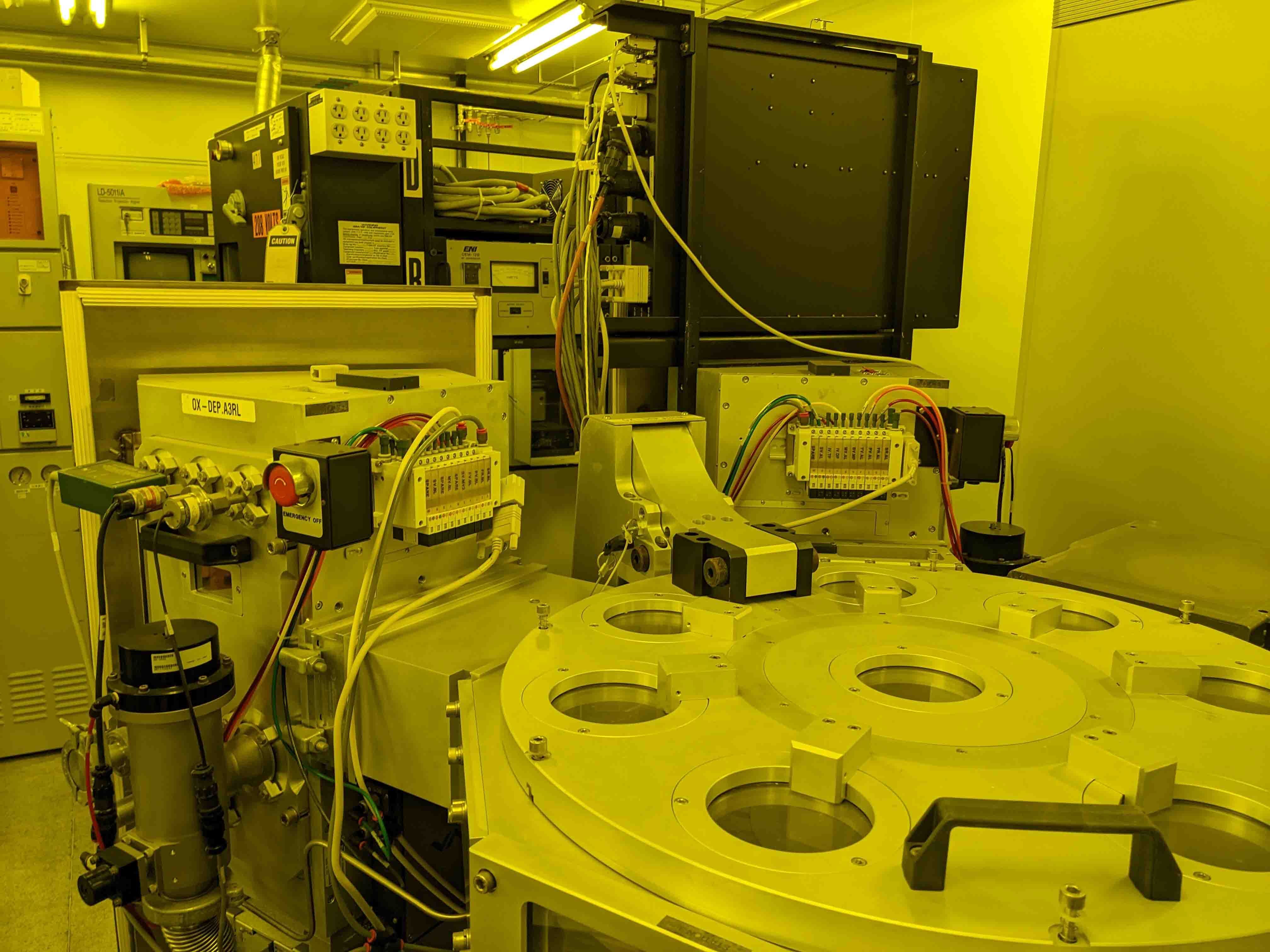

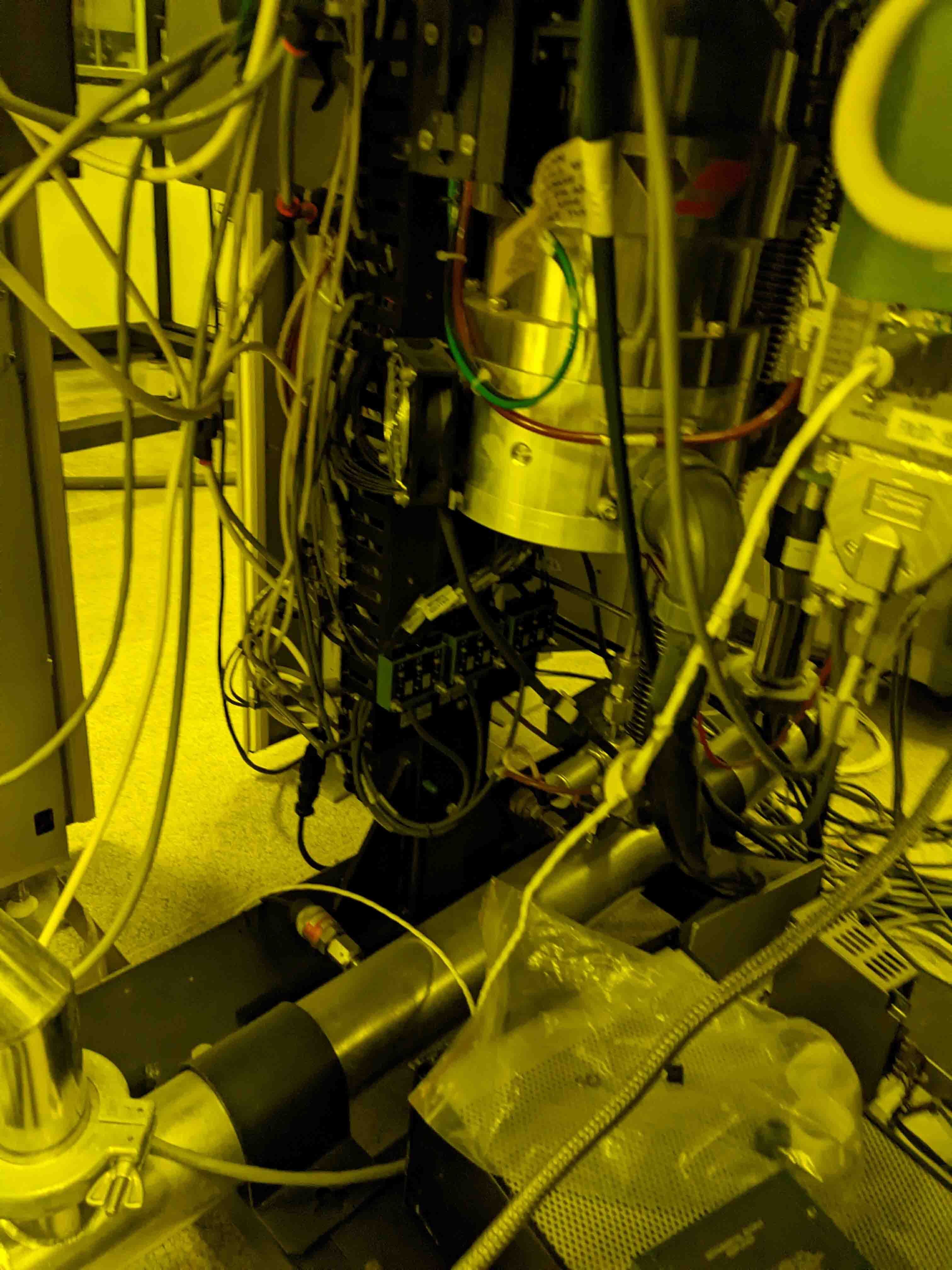

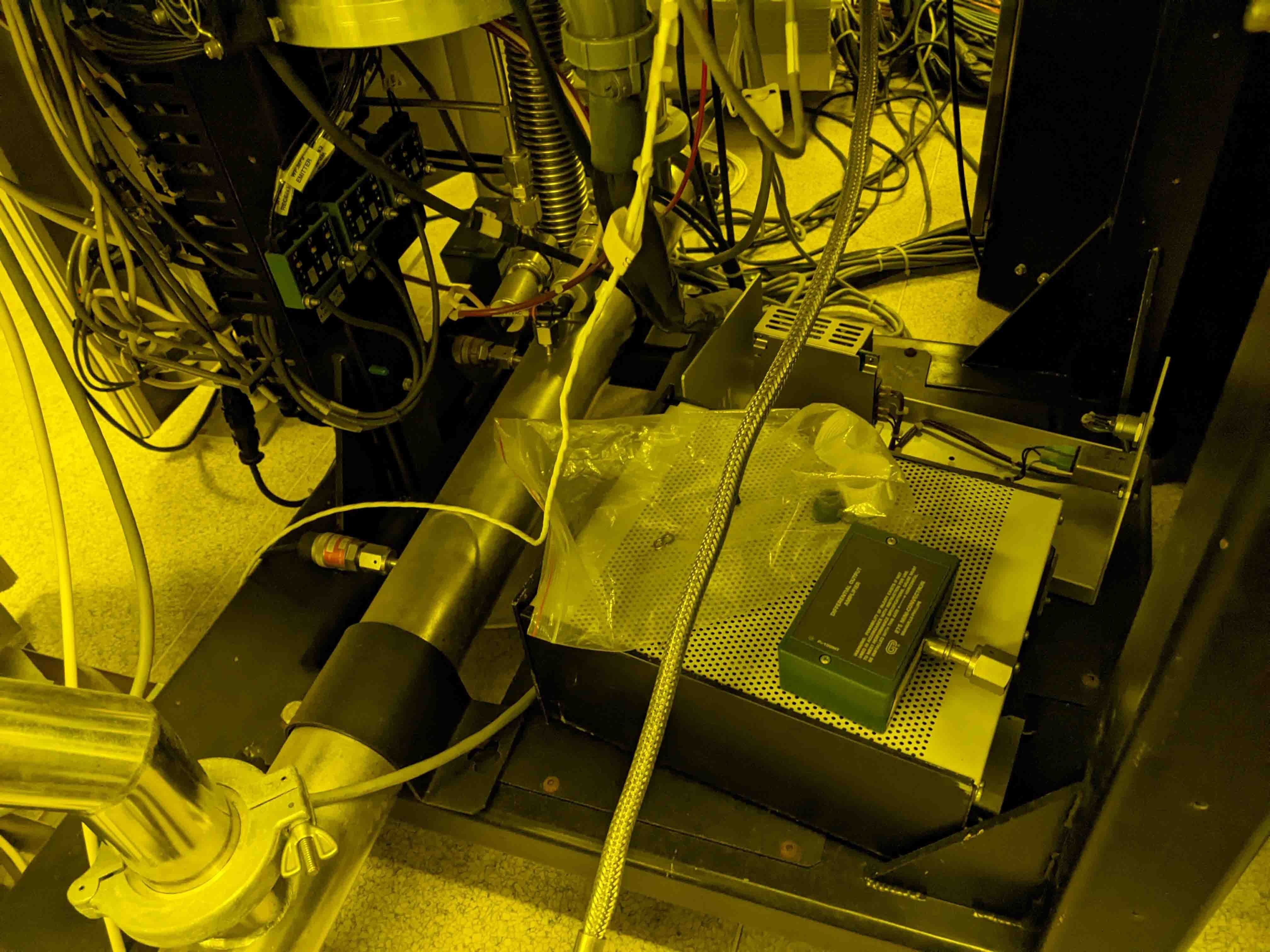

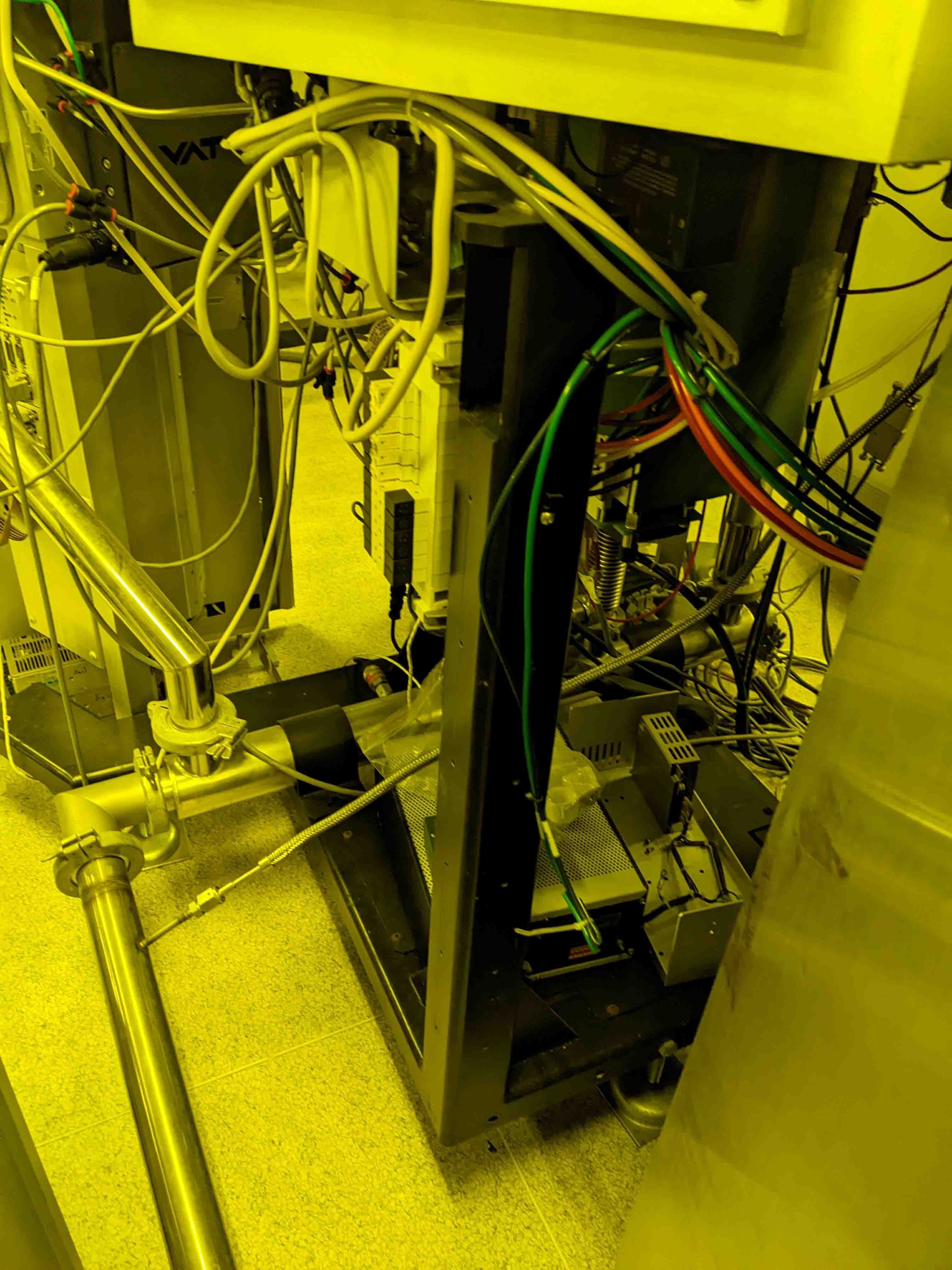

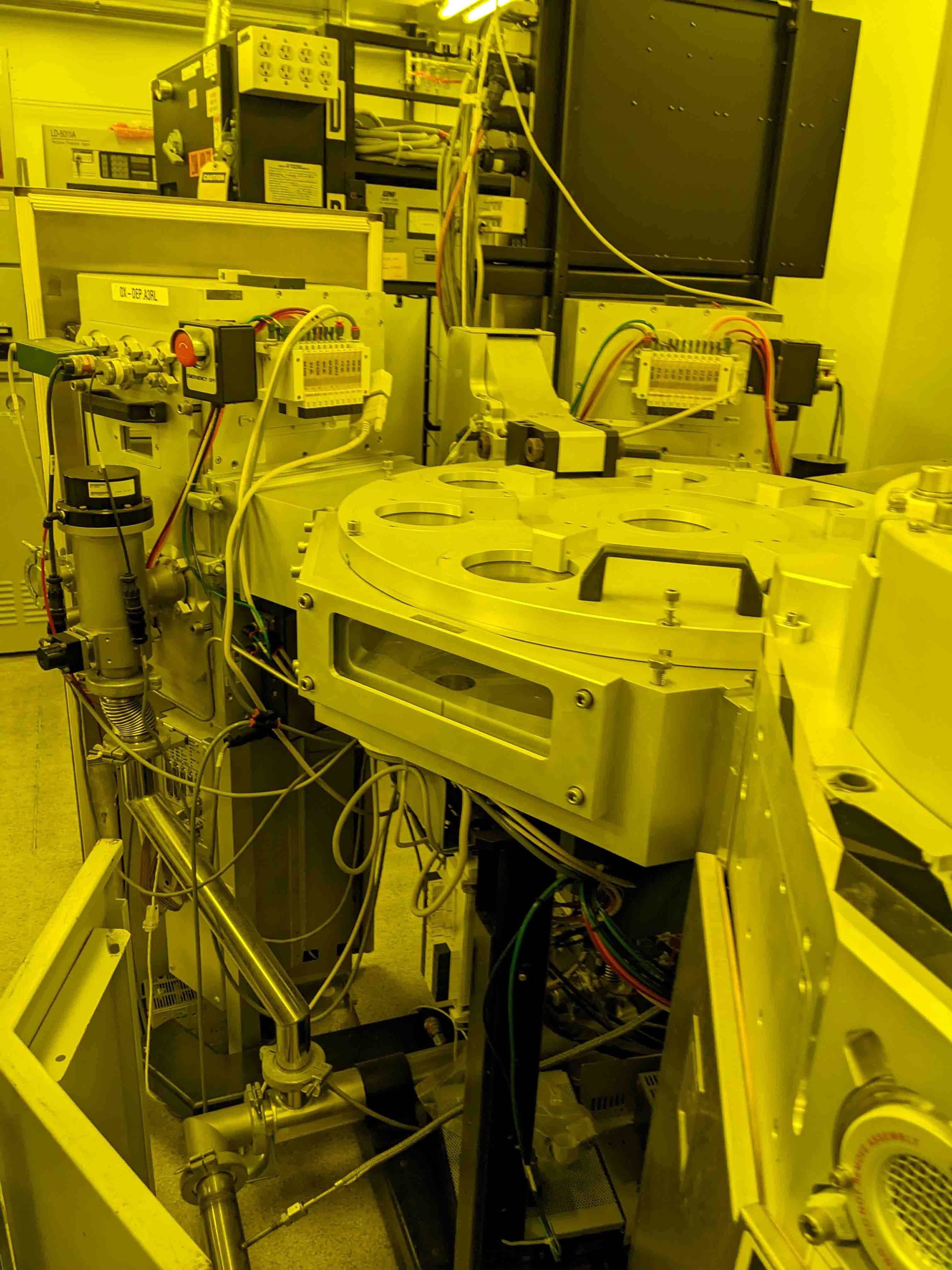

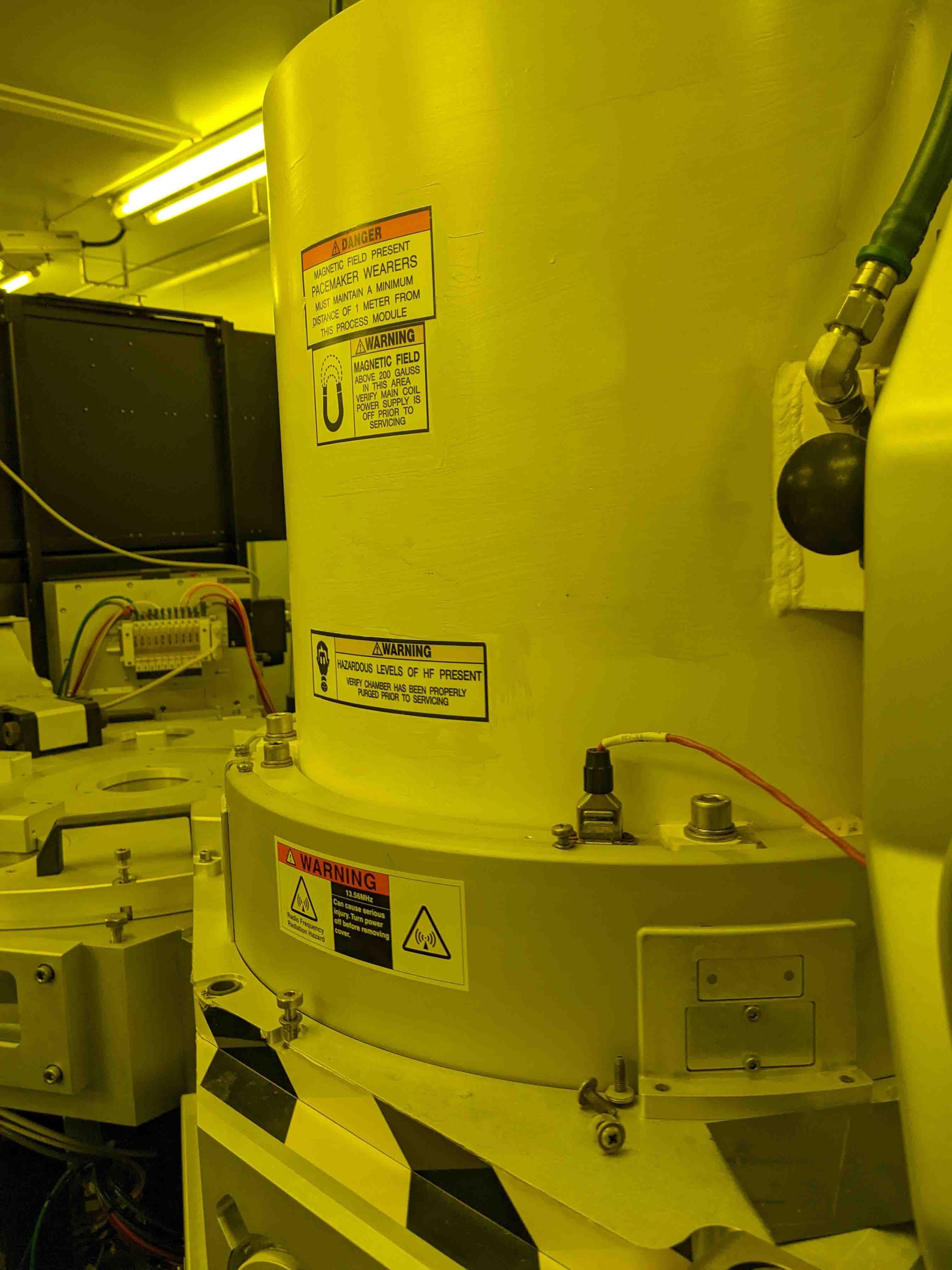

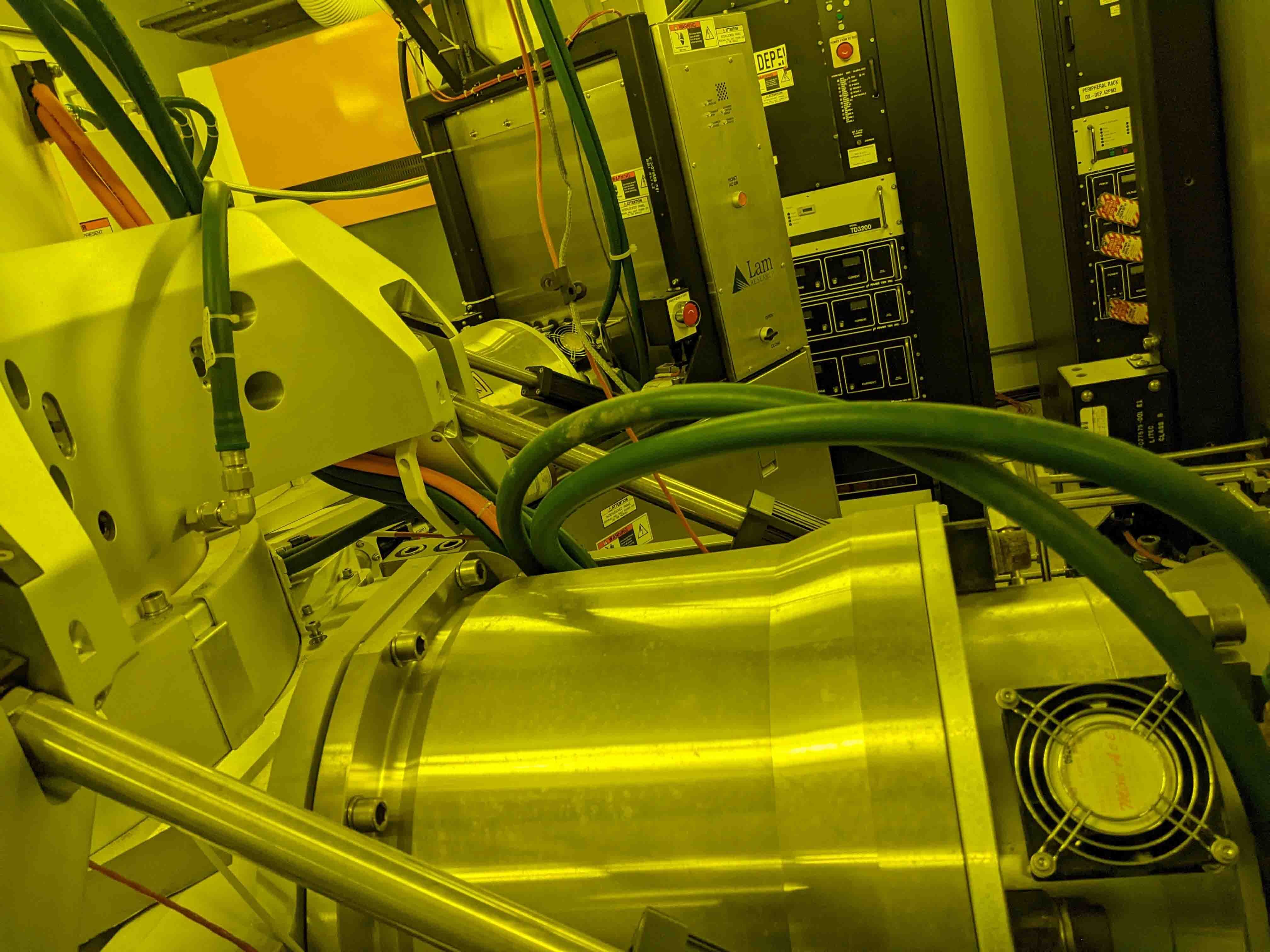

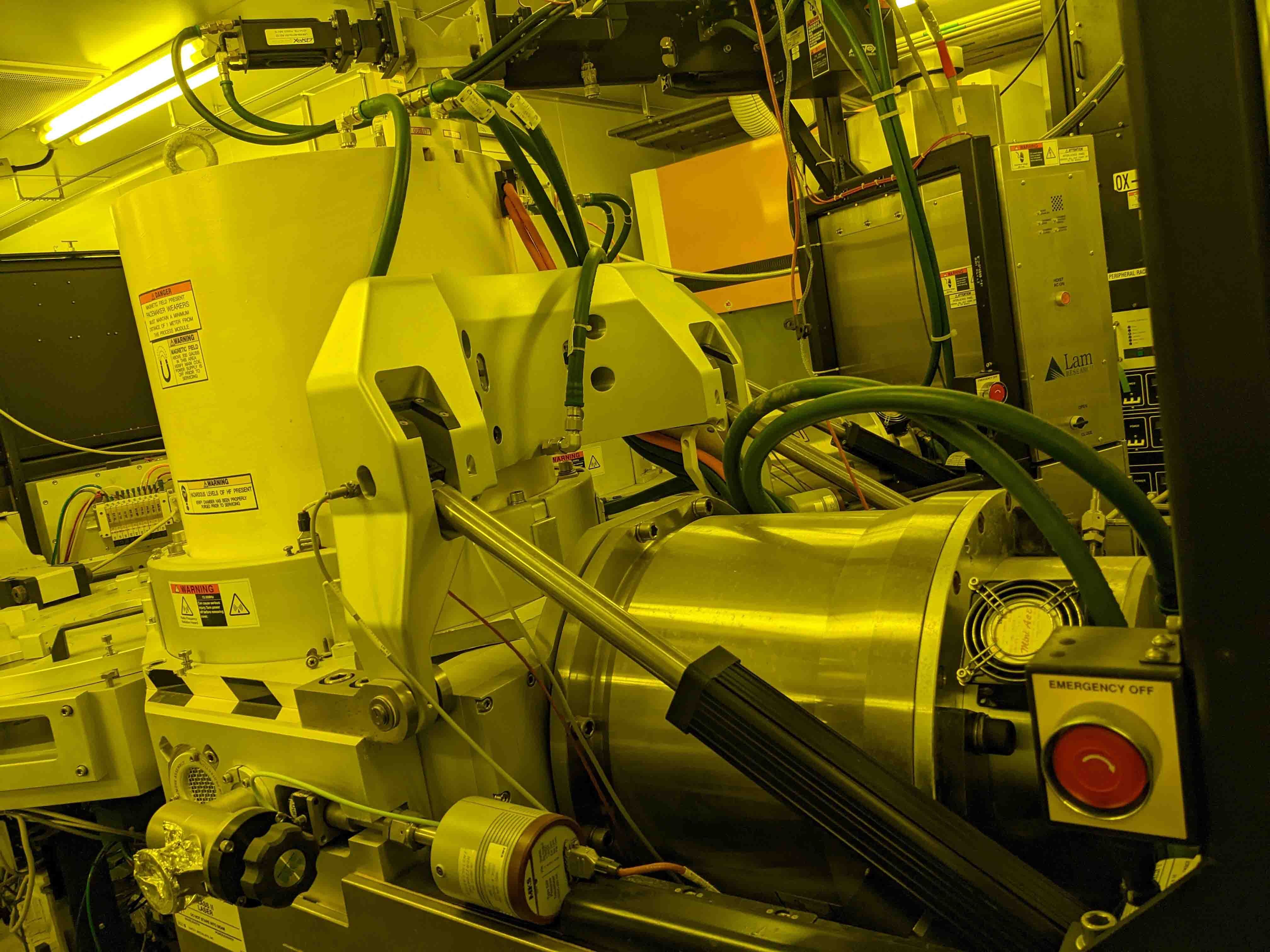

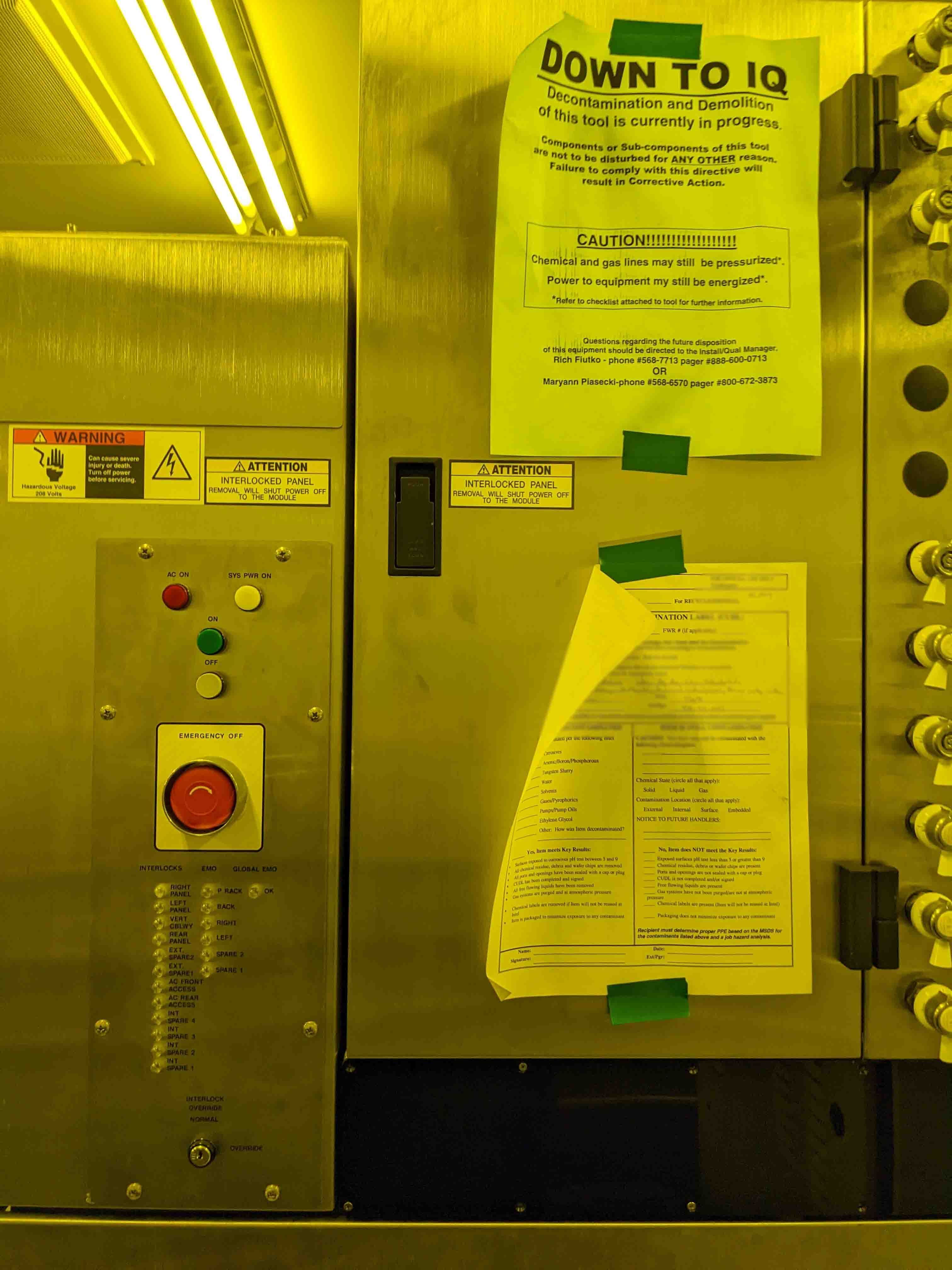

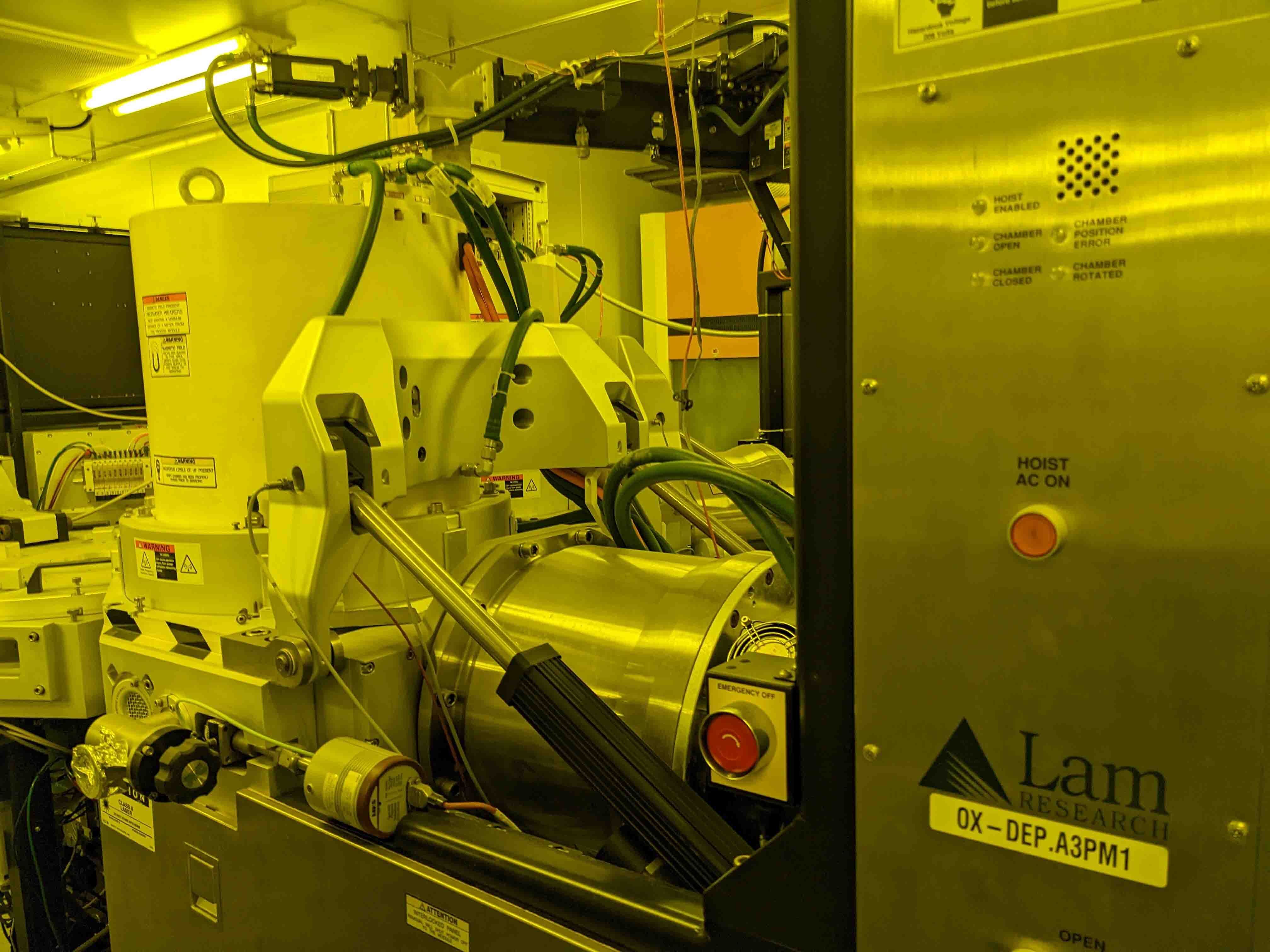

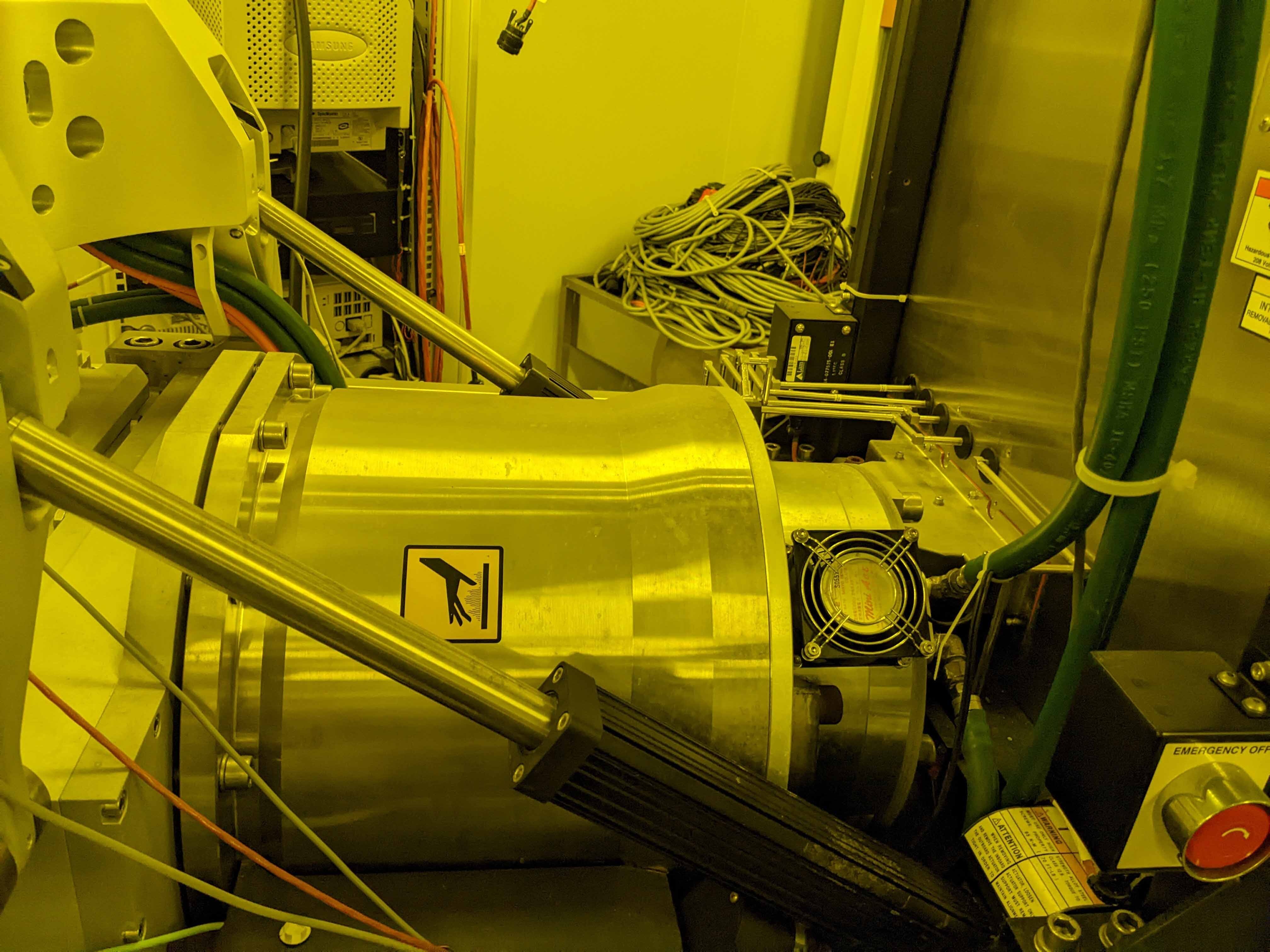

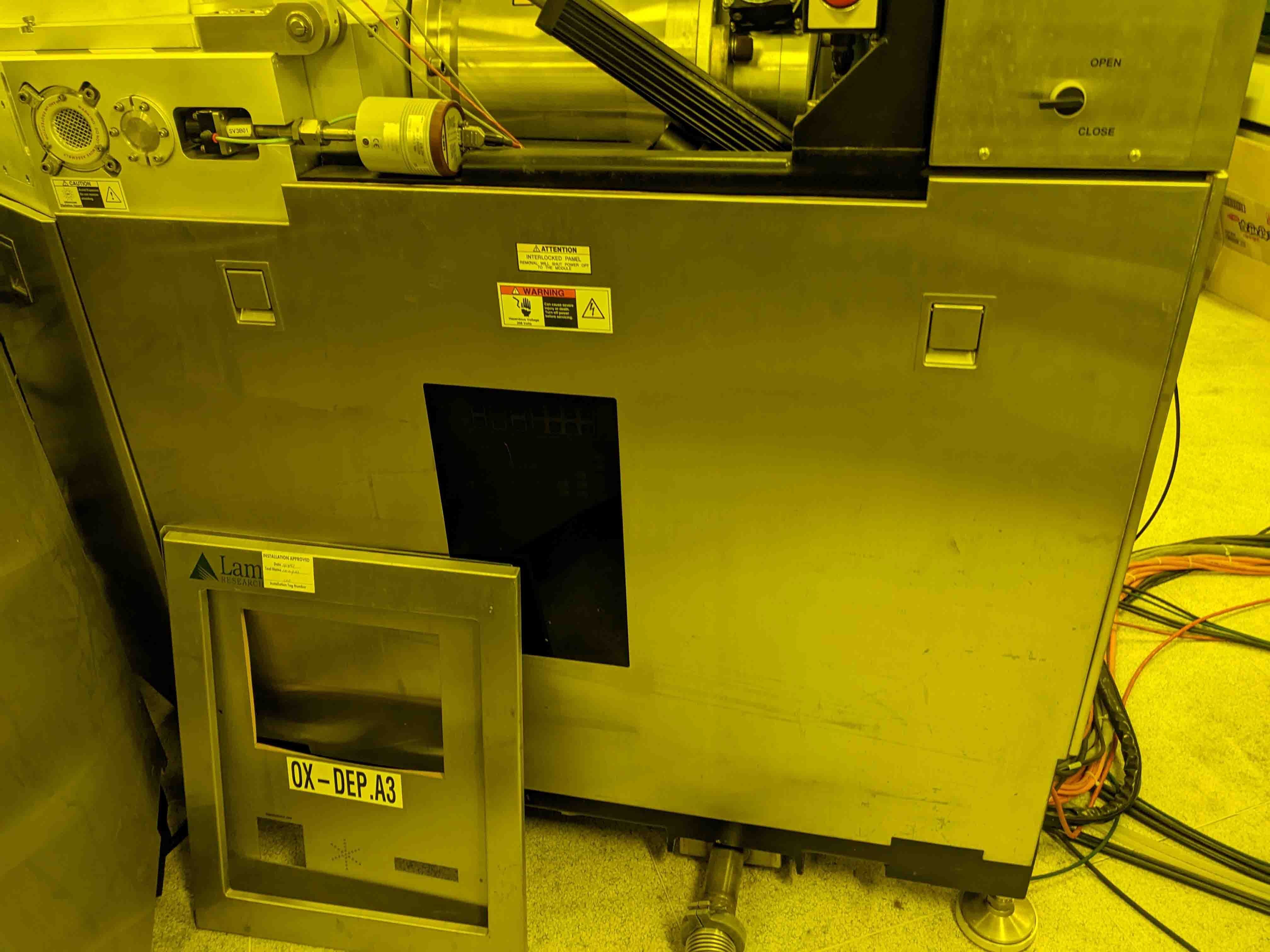

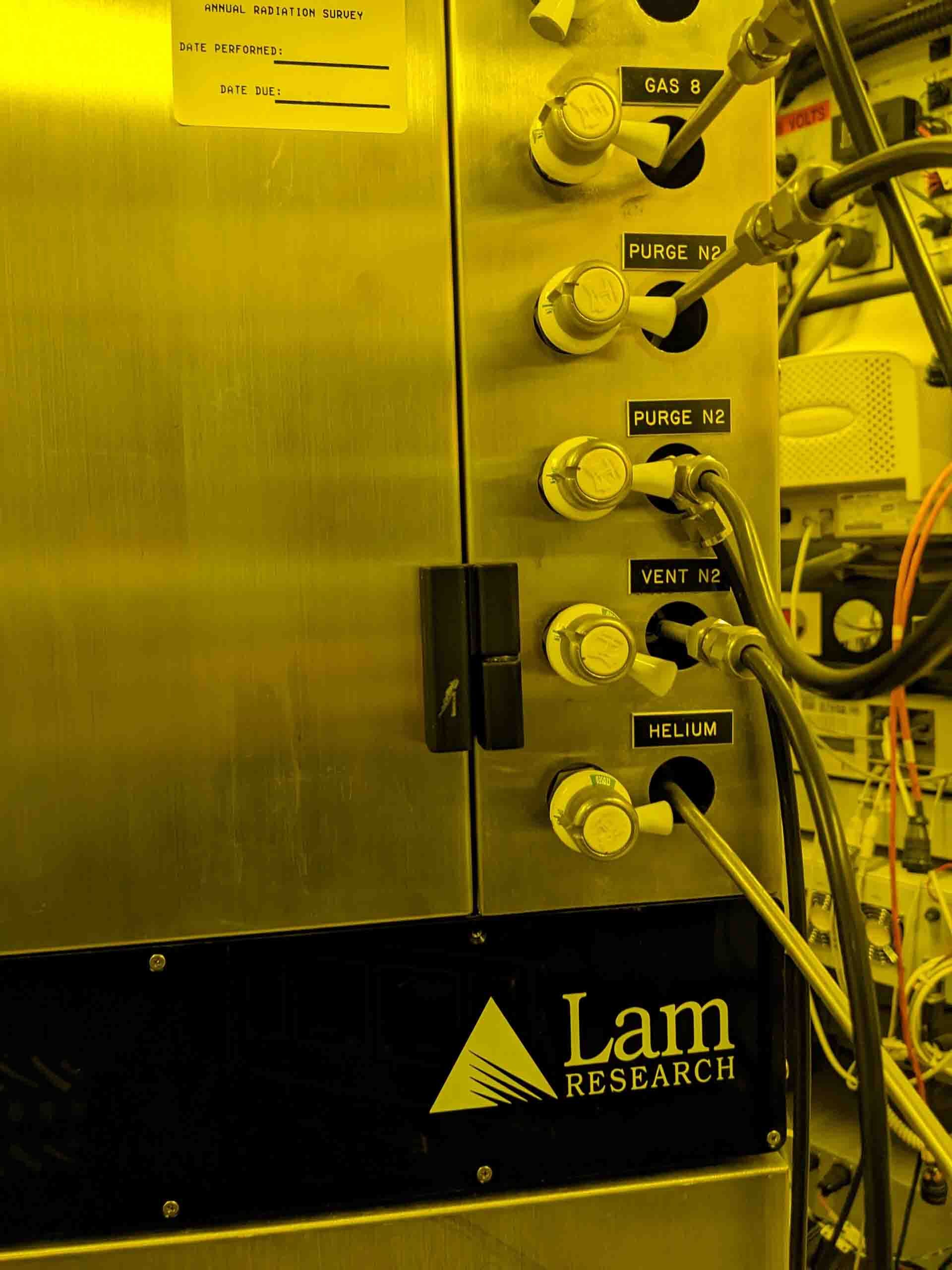

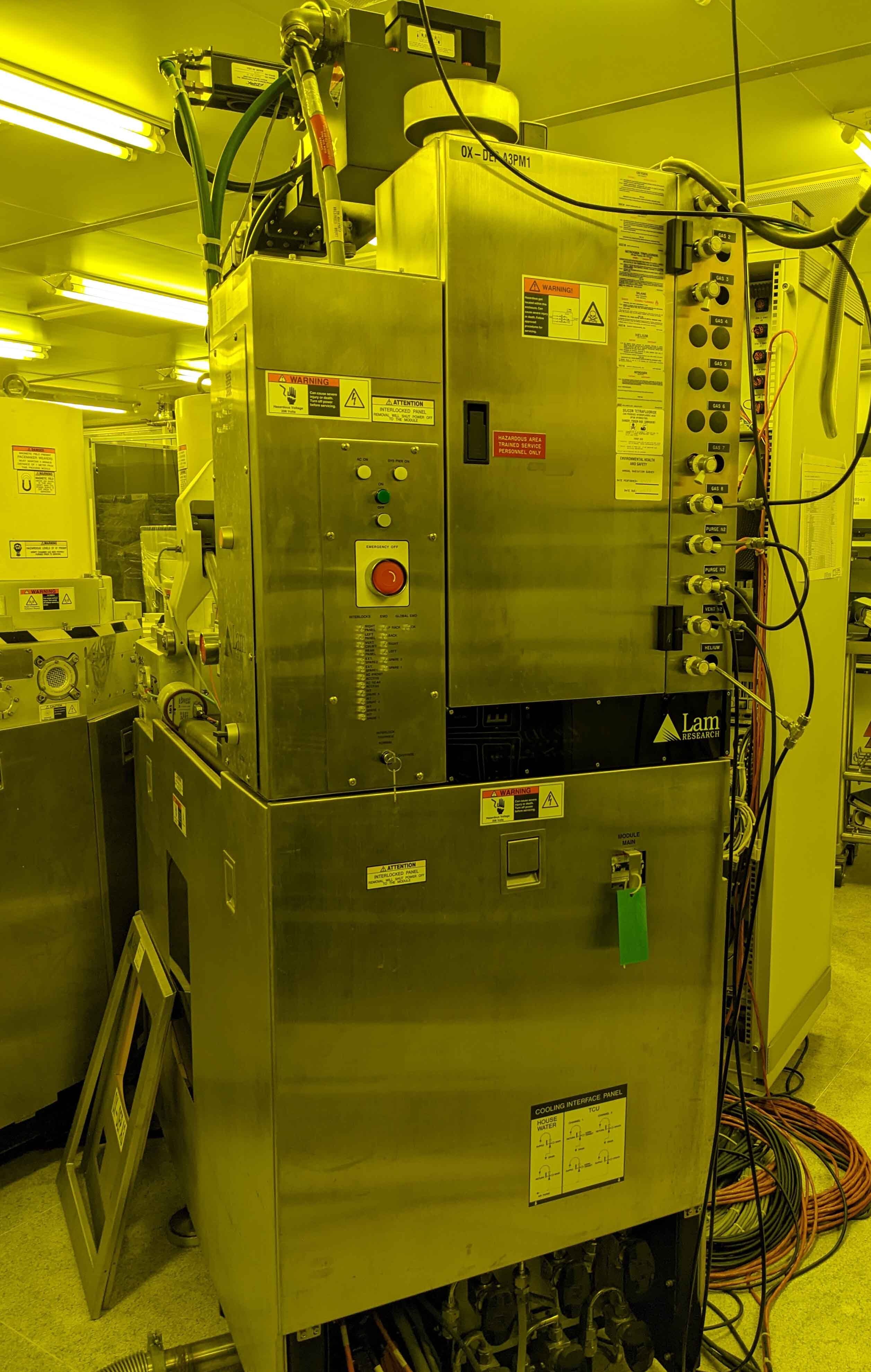

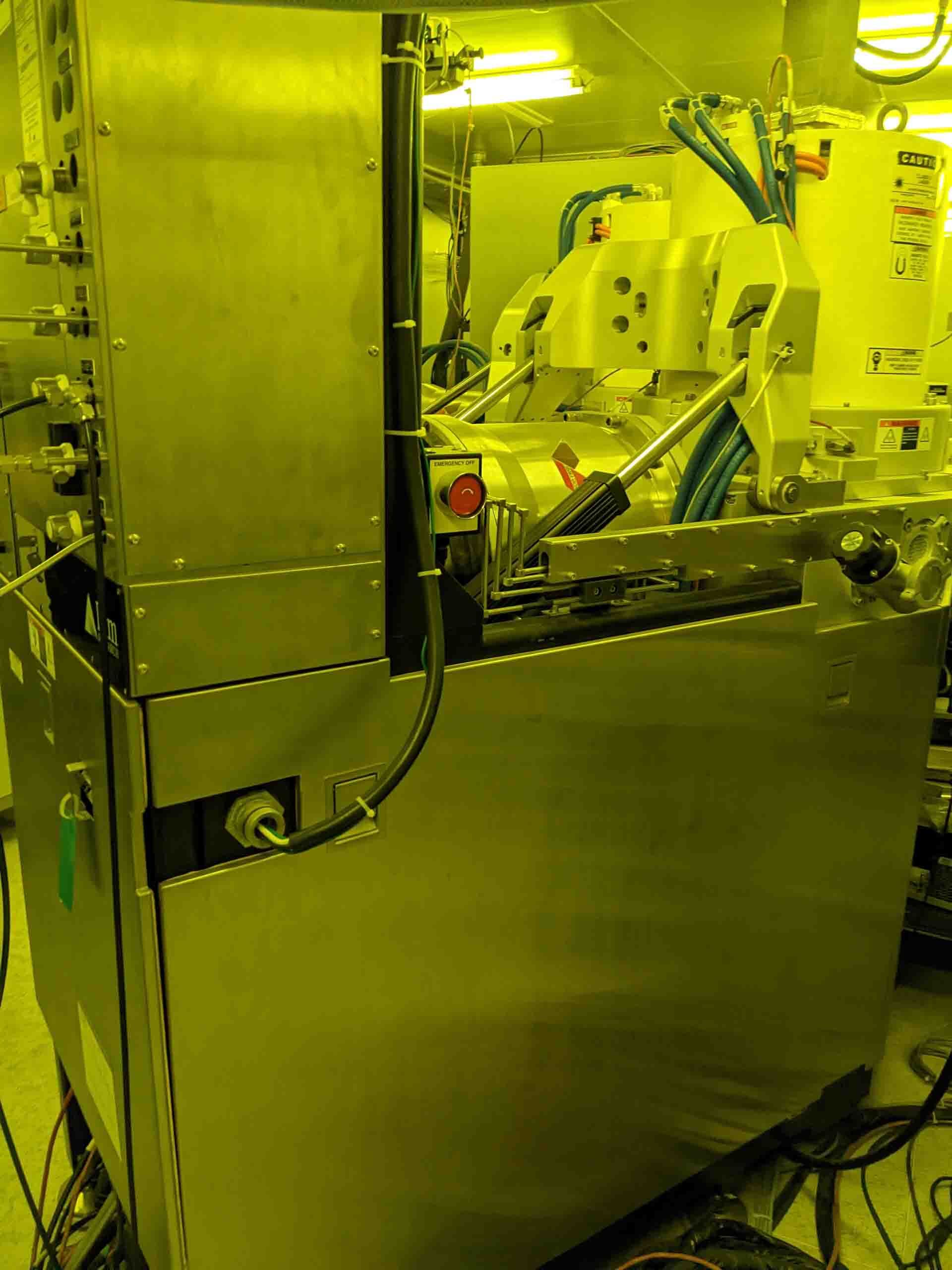

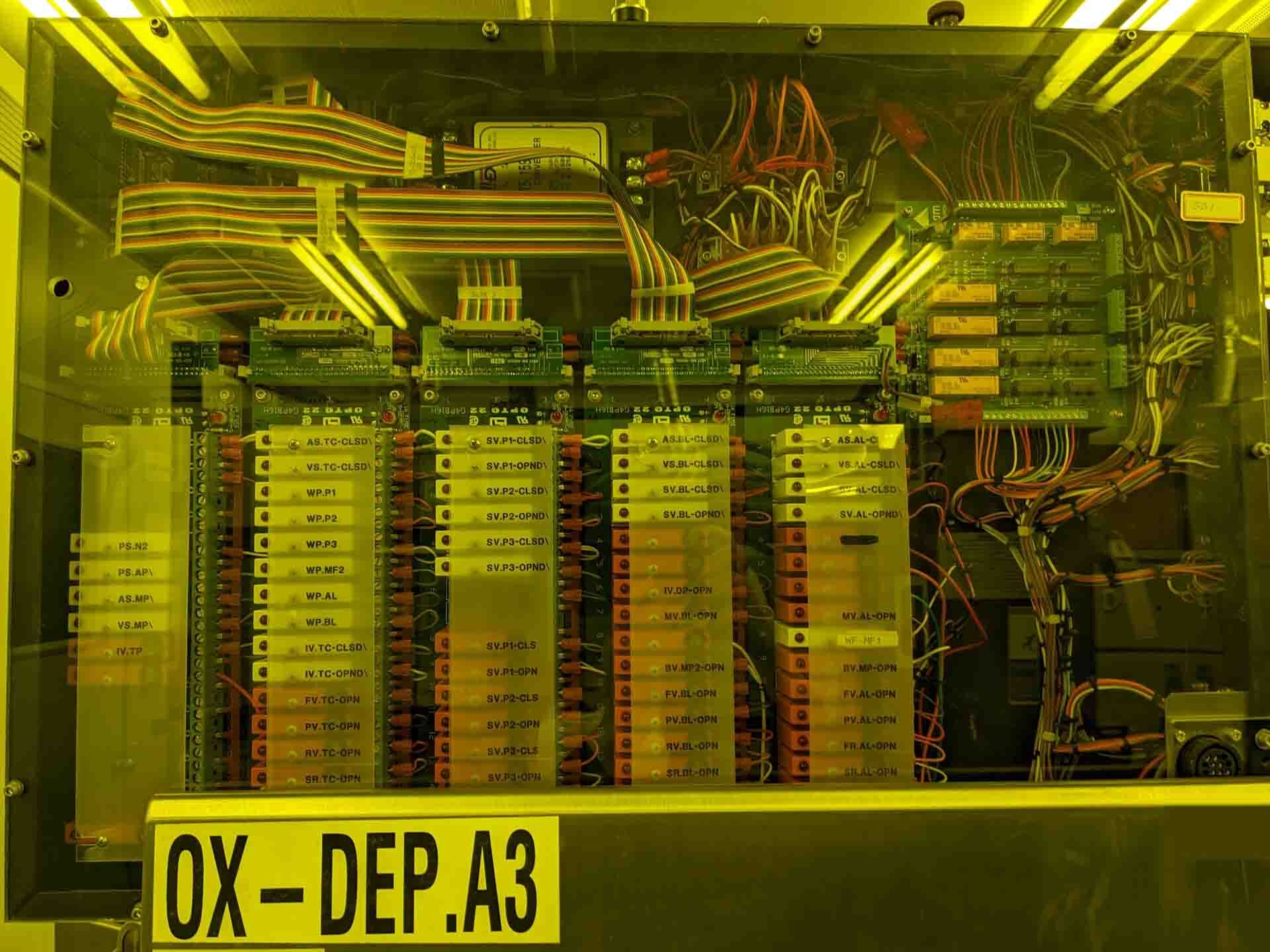

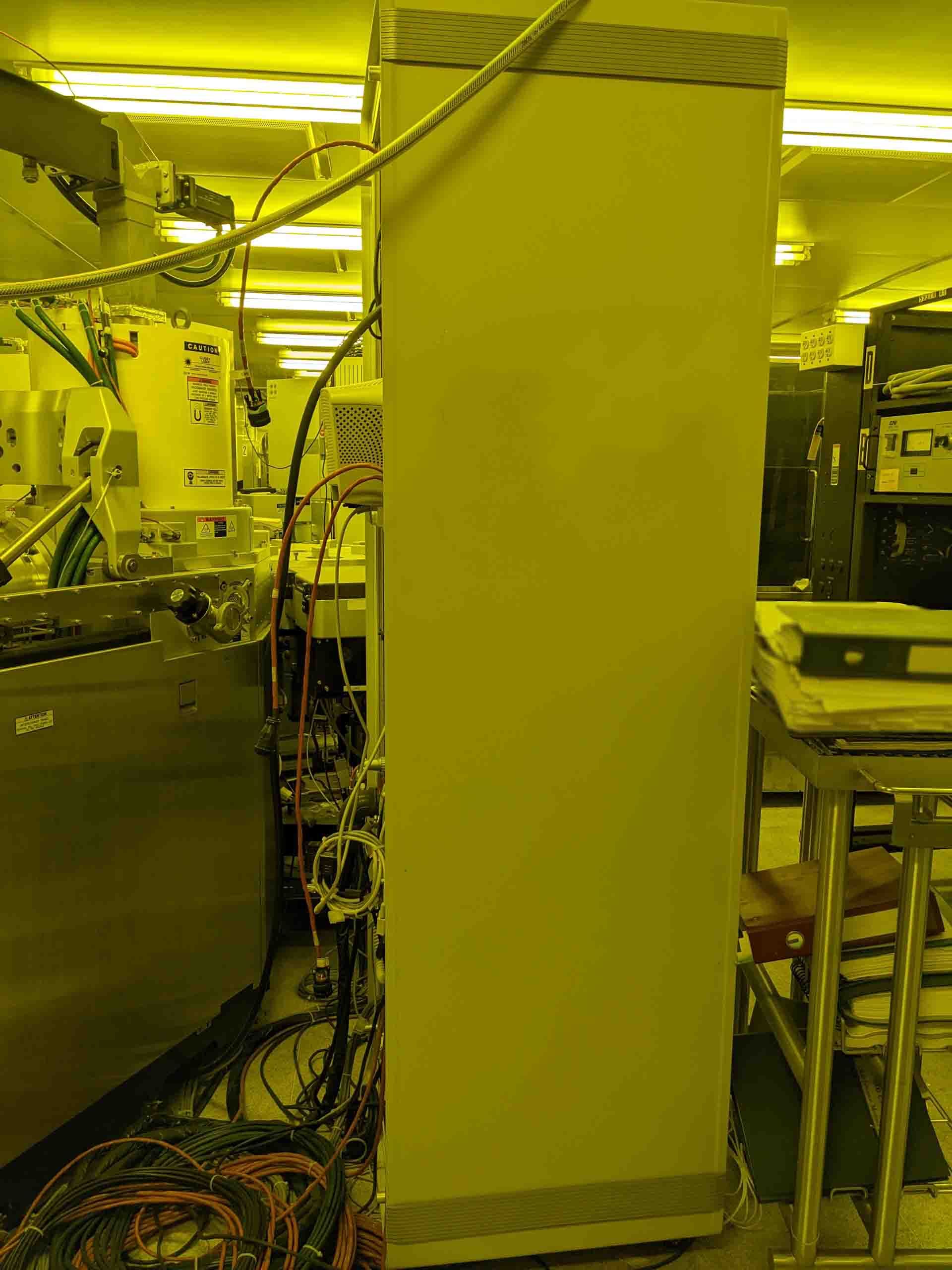

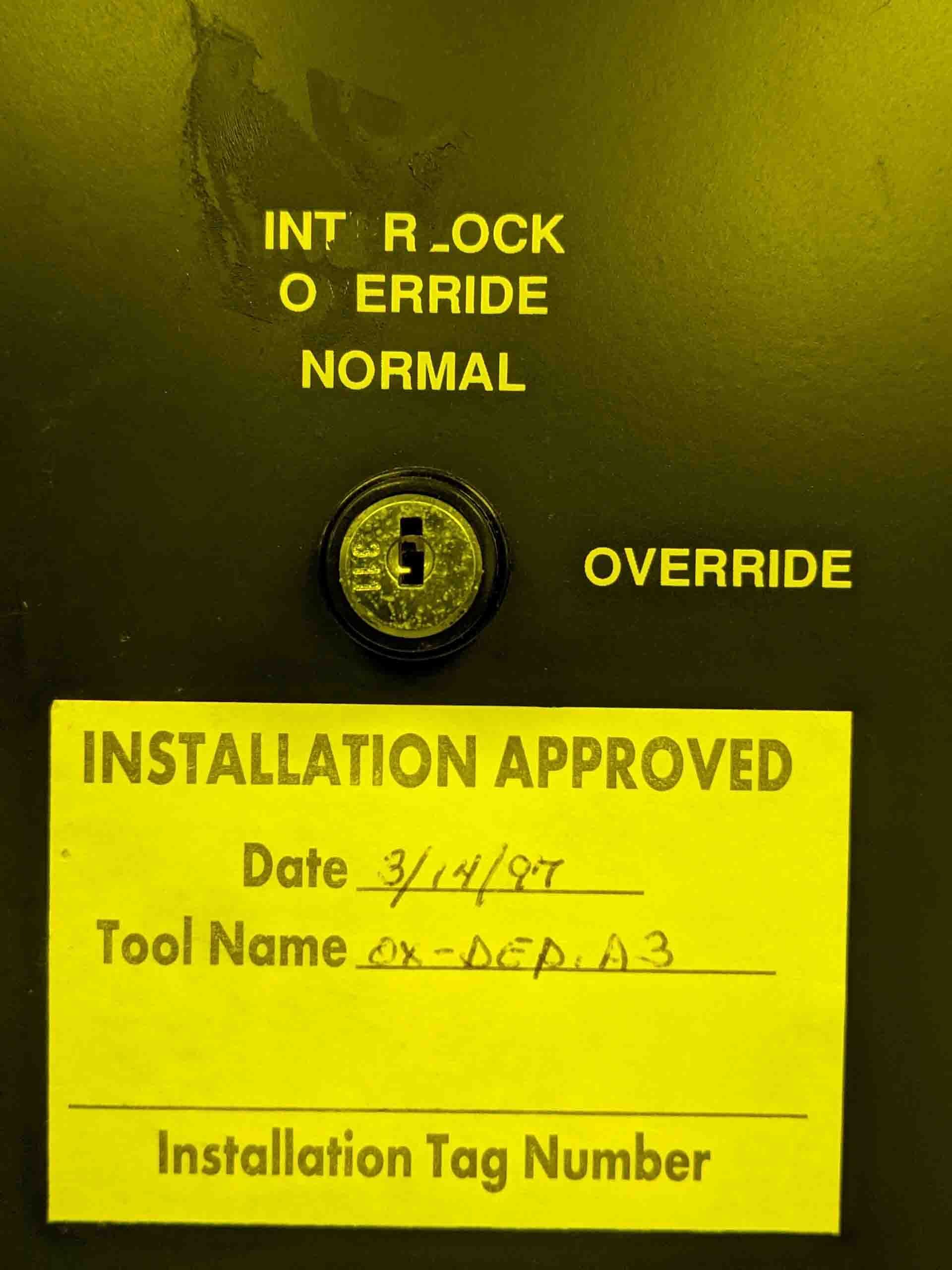

Used LAM RESEARCH OX-DEP.A3 #293628077 for sale

URL successfully copied!

Tap to zoom

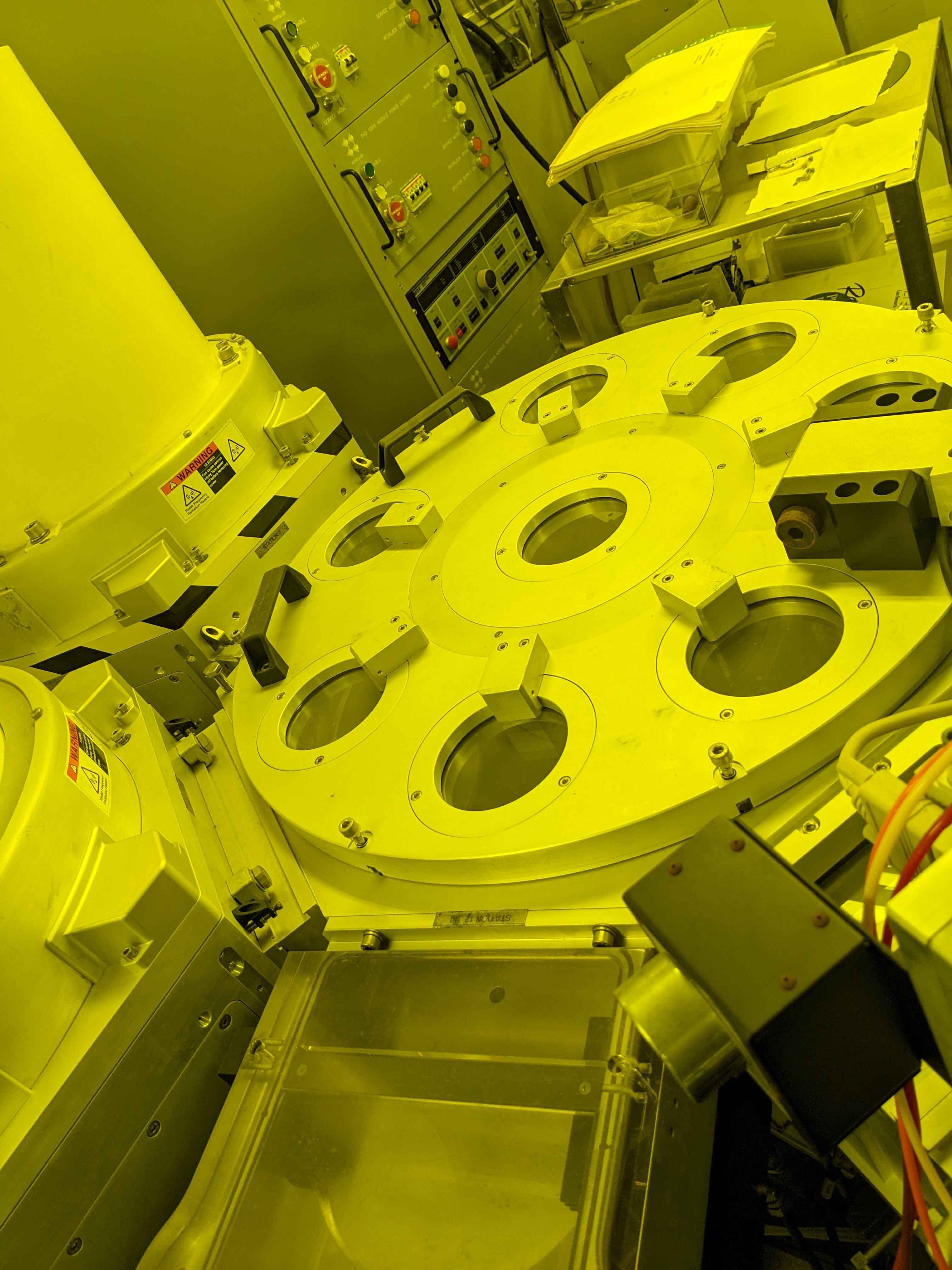

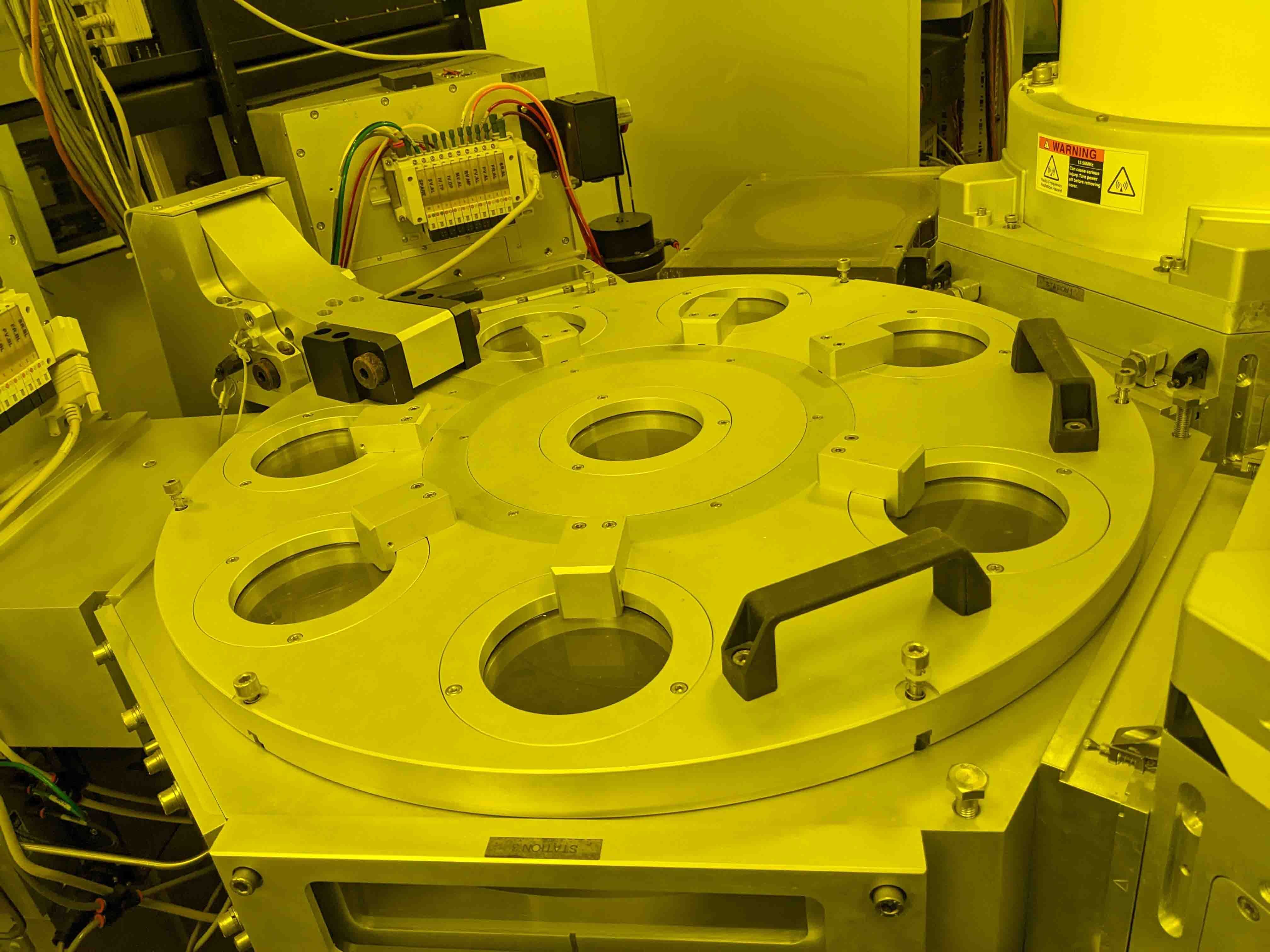

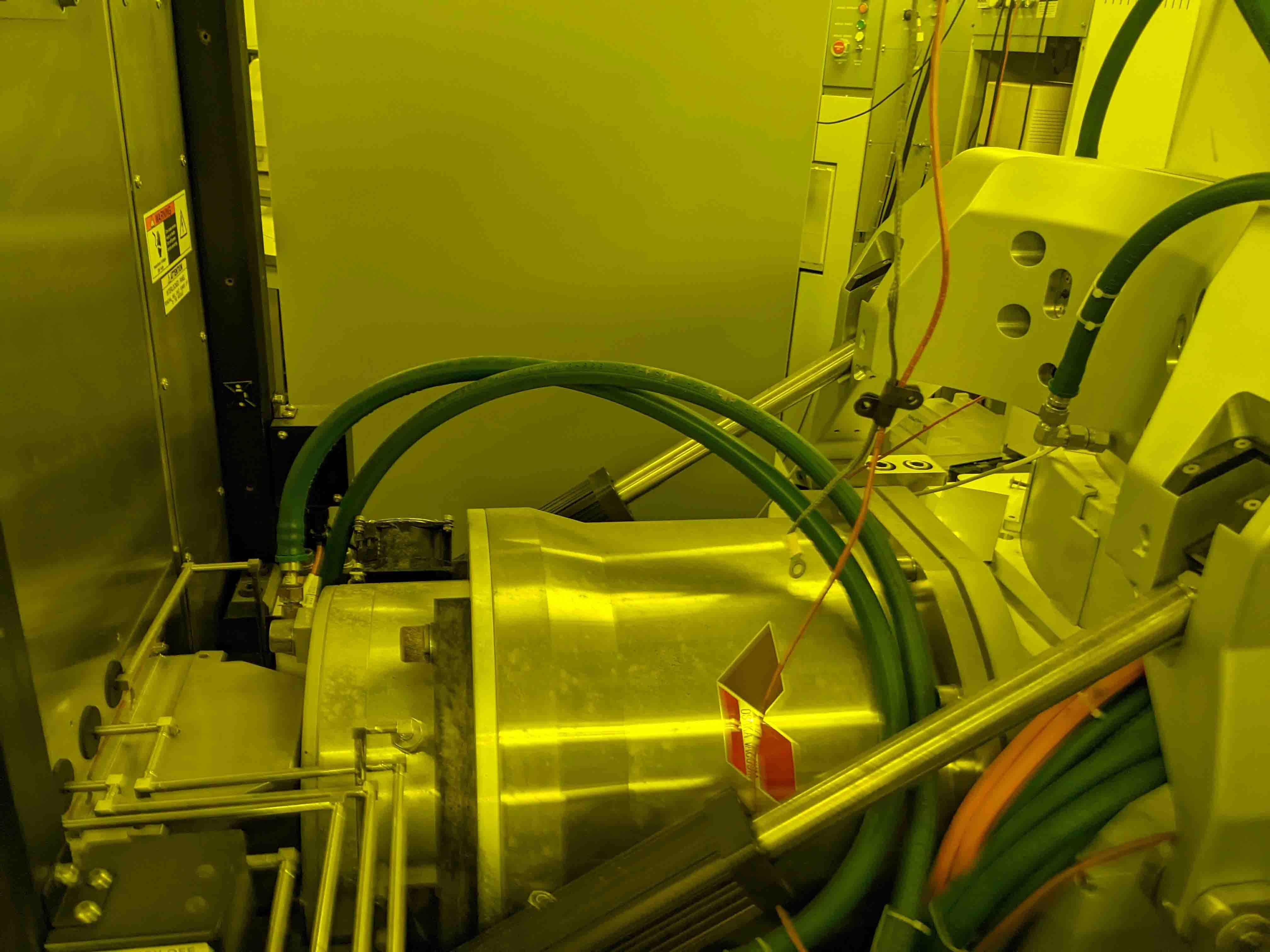

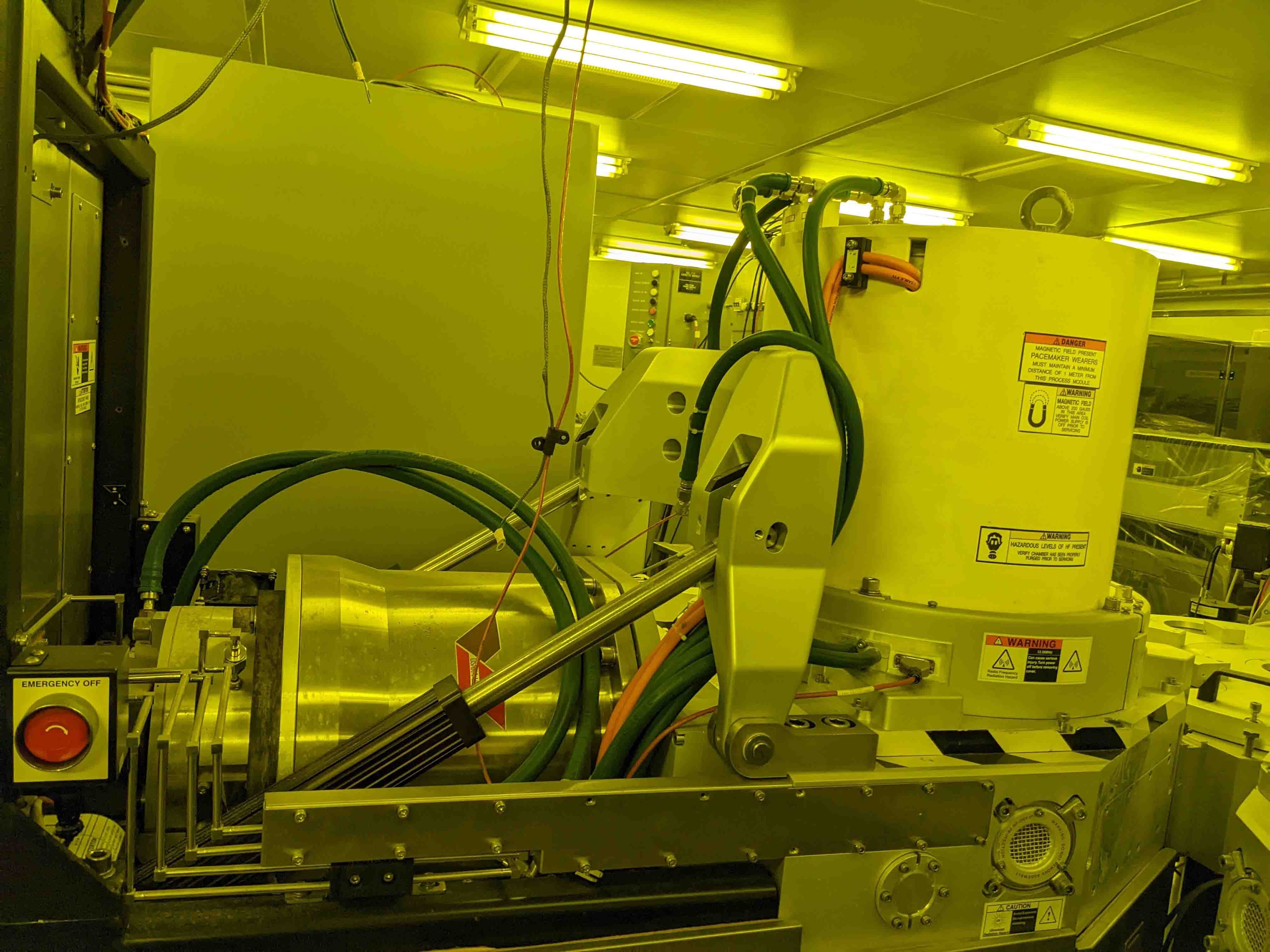

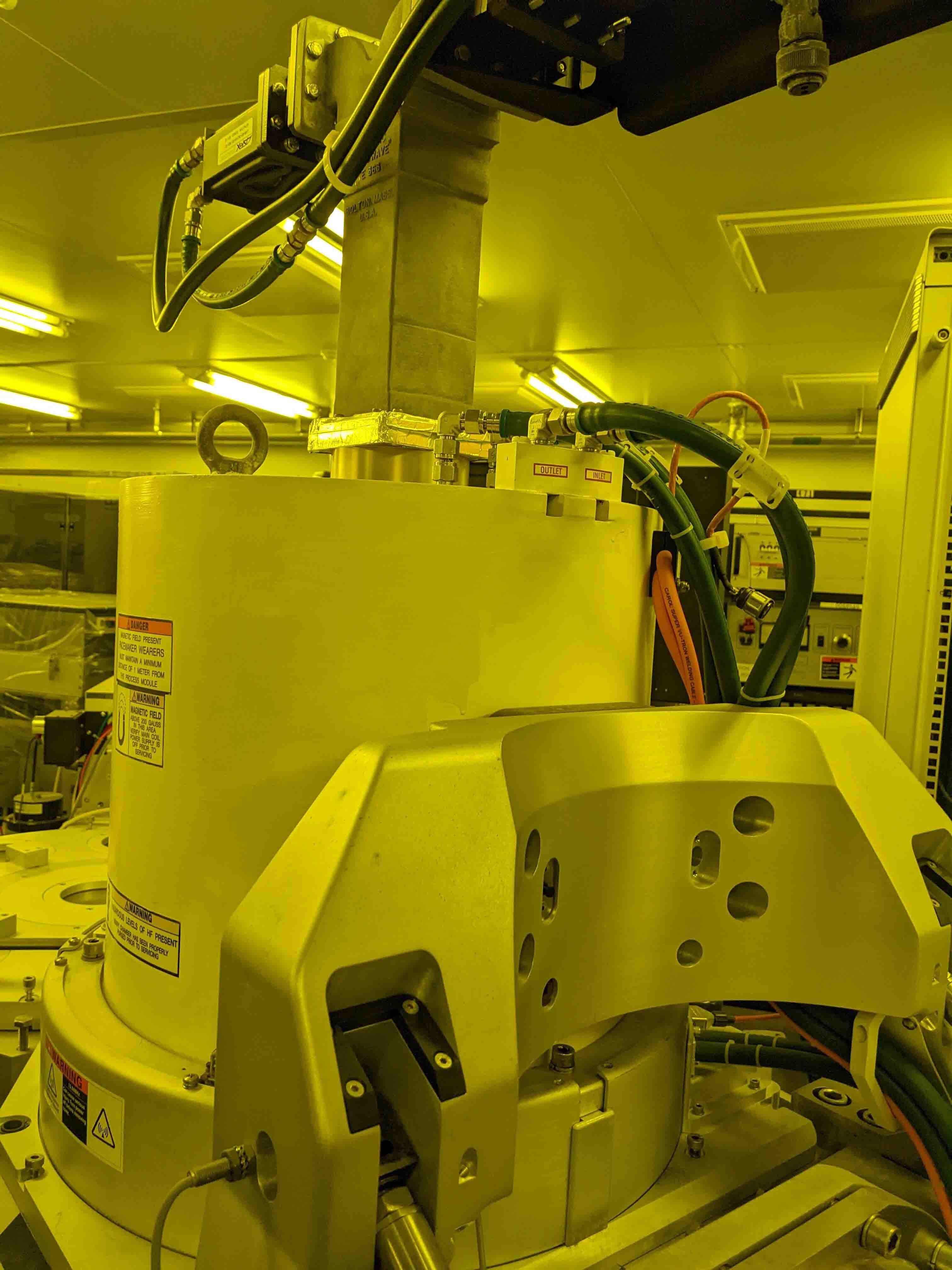

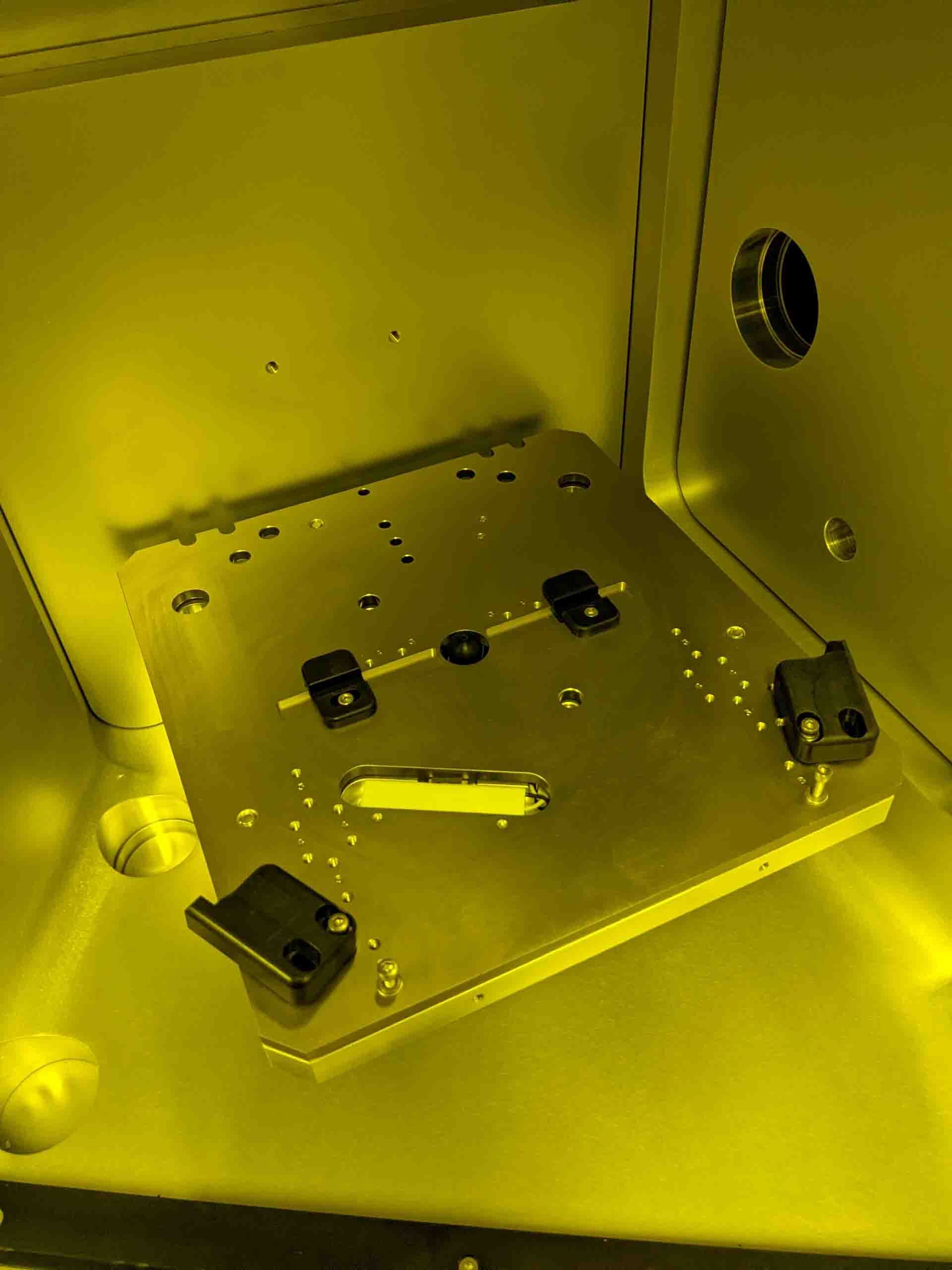

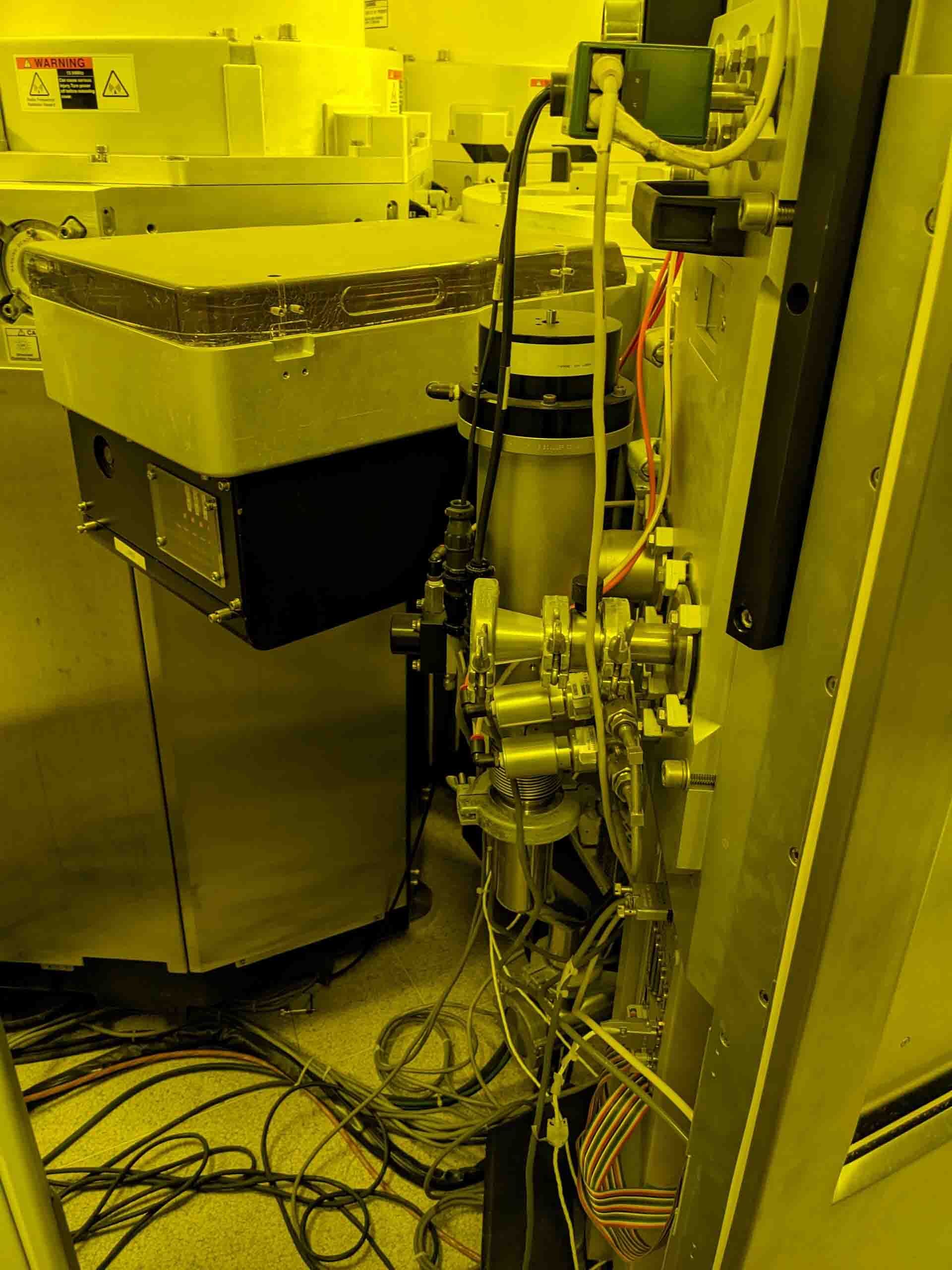

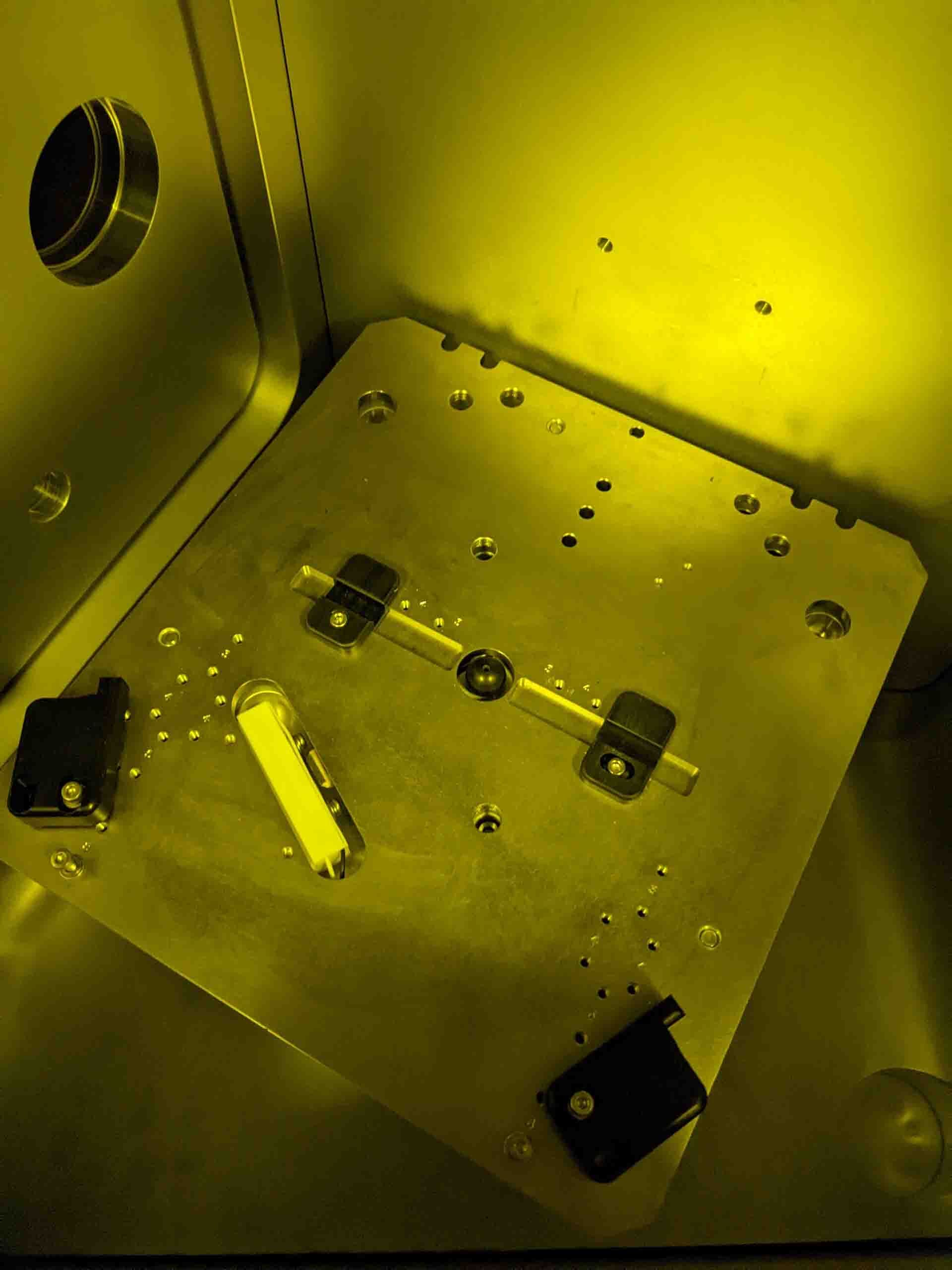

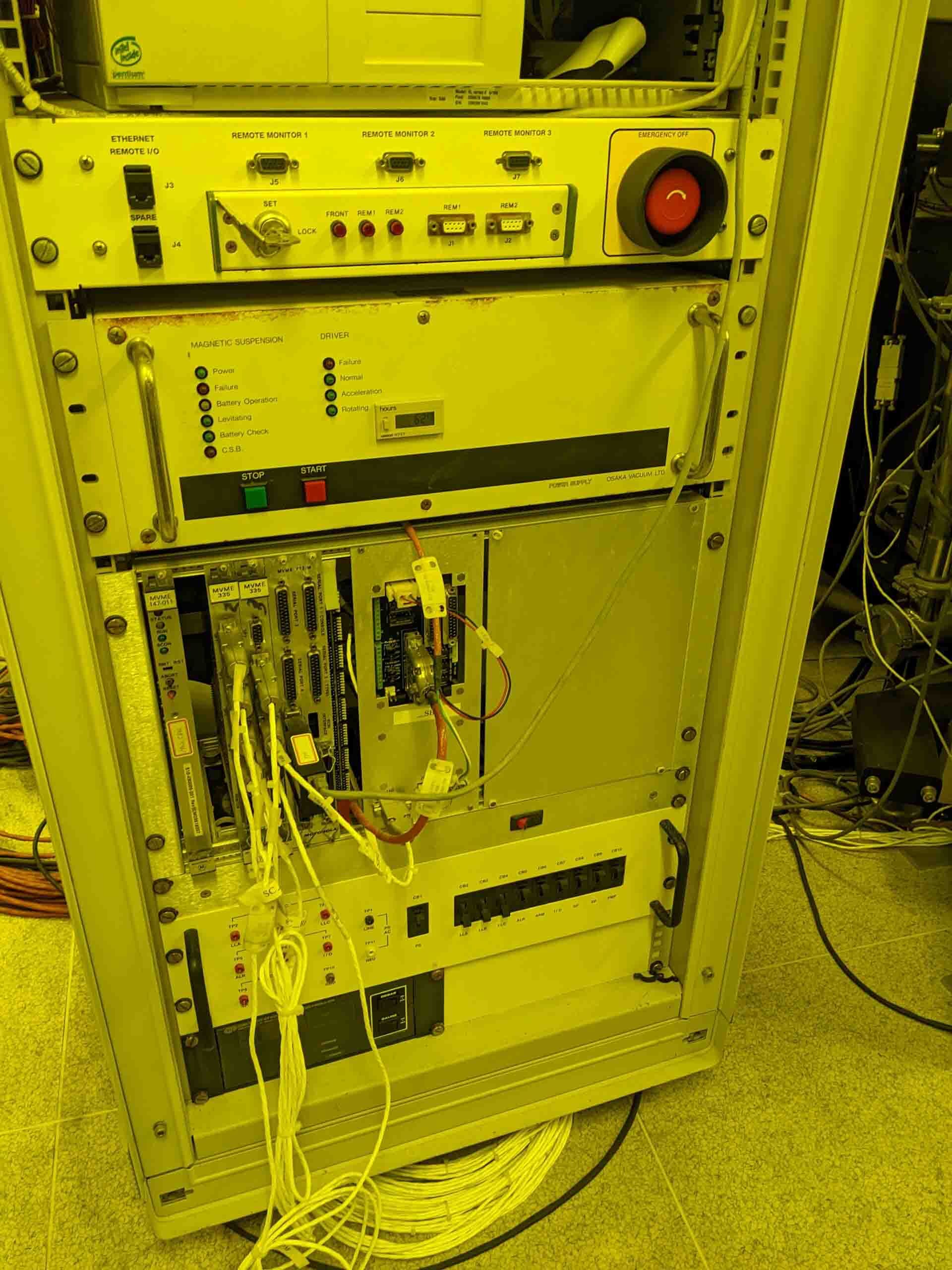

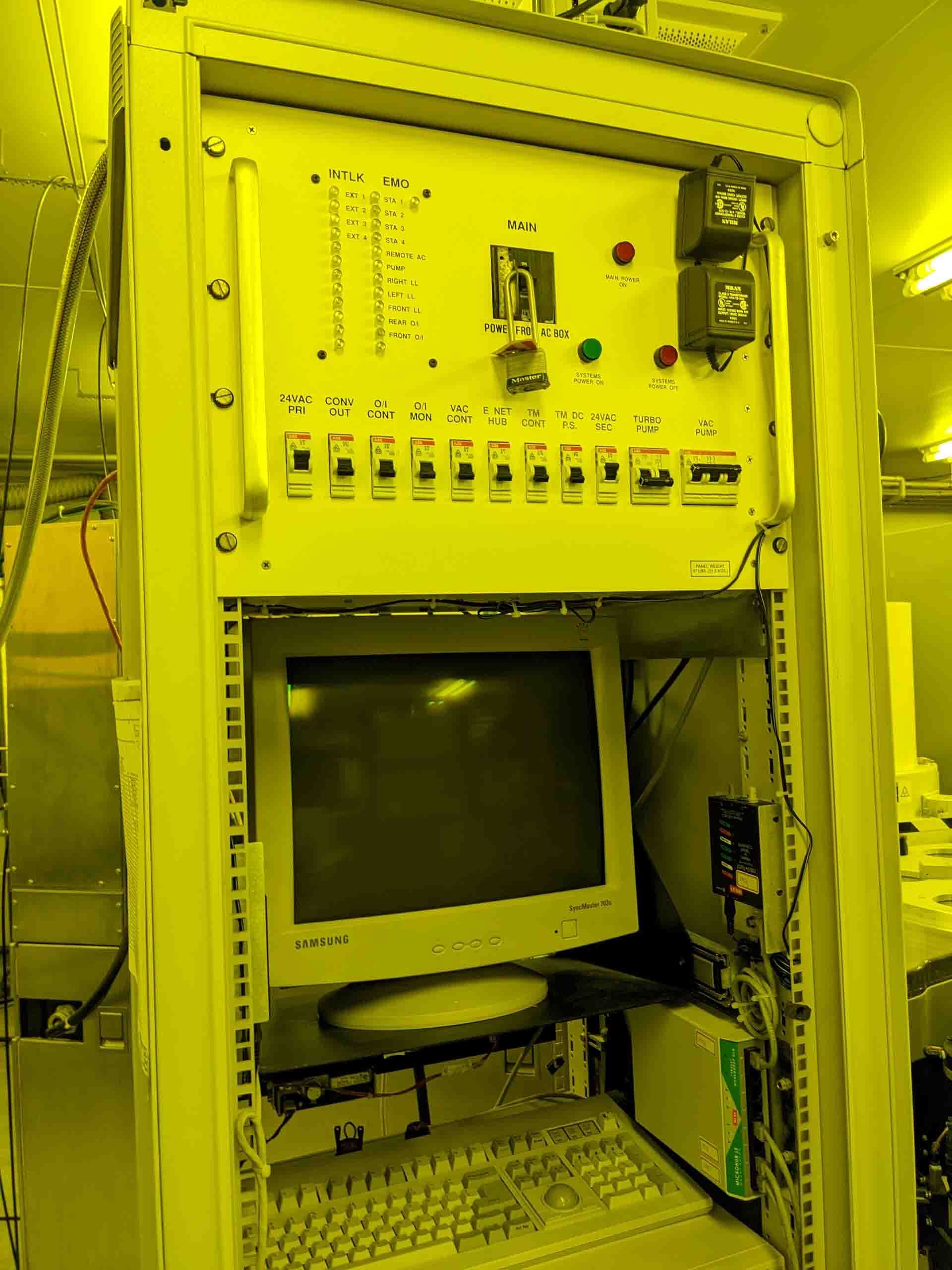

LAM RESEARCH OX-DEP.A3 is a high performance facility equipment that is used in the semiconductor industry to etch and deposit thin films of oxygen onto silicon wafer surfaces. This process is referred to as ox-deposition and is used to create ultra-thin layers with high electrical conductivity, for example for transistor elements or other electronic components. The equipment has been designed to operate with maximum efficiency and provide a stable process platform for a wide range of oxide etch and deposition applications, from low-cost shallow oxide deposition to high-temperature, high-mask oxide etches. The OX-DEP.A3 features an efficient gas delivery system to ensure precision gas control and provide accurate uniform etch and deposition rates across the entire wafer surface. This capacity is enabled by the use of multiple high throughput aluminum oxide (Al2O3) chuck assemblies and quartz piezo injectors. The equipment provides a high degree of control at all stages of the etching/deposition cycle - including wafer loading and handling, uniform etching and deposition rates, uniformity of material thickness, and minimal contamination. The ox-deposition process on the OX-DEP.A3 is fully automated and monitored, allowing it to consistently deliver quality results at high speeds. The advanced digital control systems enable technicians to quickly adjust the programmed process parameters and enable real-time feedback and monitoring. To ensure optimal performance, advanced in-situ monitoring techniques such as Ultra High Vacuum (UHV) are used to detect contaminants and ensure that the deposition rate, flow rate, and ion bombardment are within acceptable limits. The OX-DEP.A3 is designed with a large stainless steel chamber measuring 3800mm x 2700mm x 800mm (W x D x H), a high pressure operation of up to 600mtorr, and a 10,000-watt resistance heating capability. This high-performance facility equipment is designed to be both robust and reliable, with an ability to provide the accuracy, high throughput, and low maintenance required for effective oxide etch and deposition processes. Its combination of advanced features, advanced monitoring technology, and reliable performance make it the ideal choice for both research and production applications.

There are no reviews yet