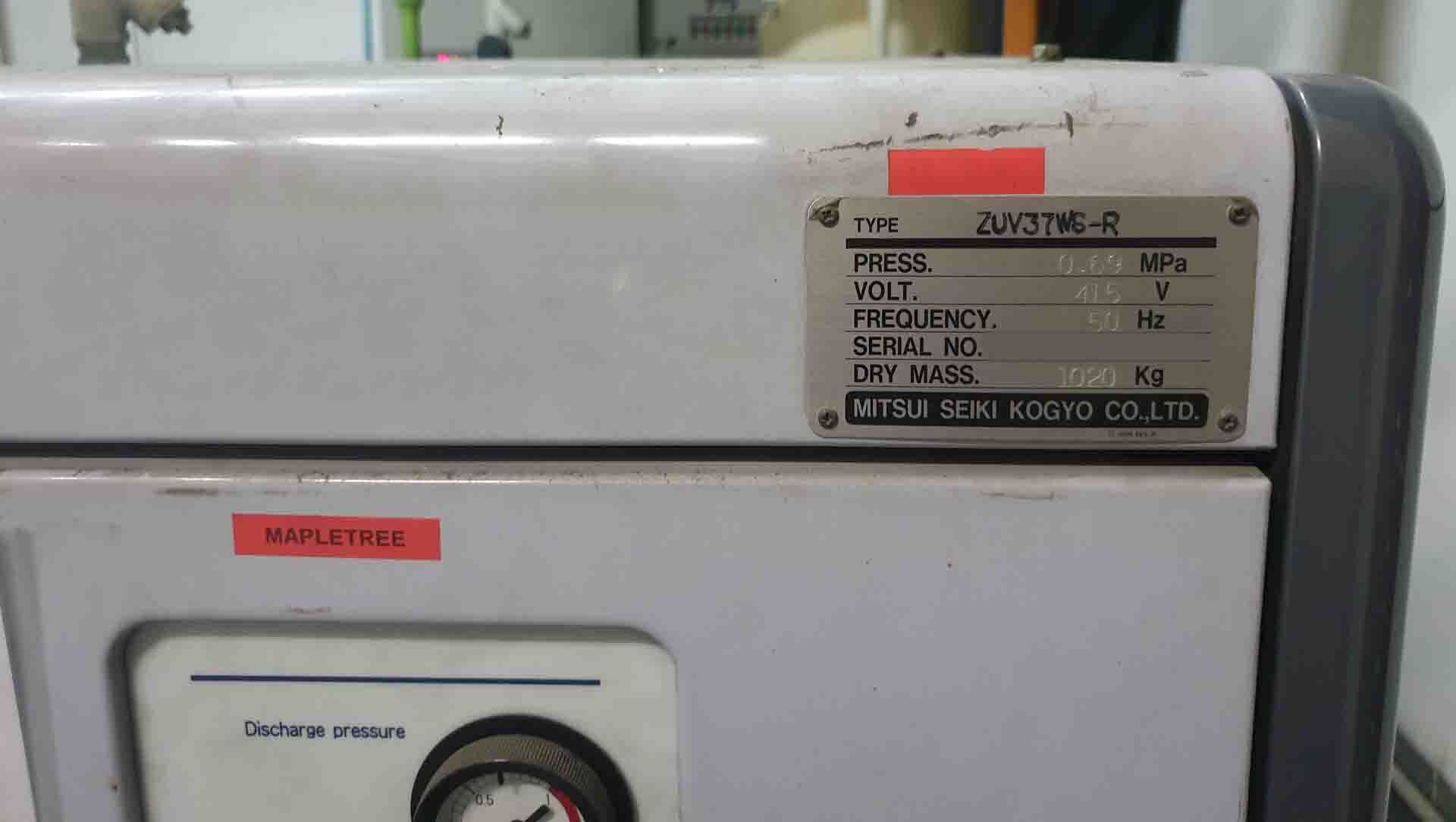

Used MITSUI SEIKI ZUV37WS-R #293587374 for sale

URL successfully copied!

Tap to zoom

MITSUI SEIKI ZUV37WS-R is a five-axis, high-speed, universal machining center ideal for applications that require simultaneous five-axis machining. This highly precise and powerful machine tool, built for demanding machining needs, is an excellent choice for optimizing the production process. Its spindle output and cutting feedrates, combined with the integrated control equipment, enable improved chip removal efficiency and precise machining, leading to shortened machining times and higher tool traversing speeds. This CNC machine features a 3700 rpm high-speed spindle, double tool changer, and a constantly running B-axis. The machine operates on a TOYODA automatic conversational control system and has a 200-block storage capacity. Relative features include multiple axes, a full C-axis with indexing base, and a built-in rotary table for enhanced cutting productivity. ZUV37WS-R, with its 10-station drum type automatic tool changer, can store up to 20 tools at a time, with each station offering a maximum tool-holding capacity of 10 kilograms. This machine is able to achieve maximum spindle speeds of 30,000 rpm and maximum cutting feedrates of up to 1,000 mm/min. These features combine to make this machine highly productive and efficient when compared to others in its class. The machine is also equipped with a 5 MPA fast connection air tap with a turnover rate of 0.2 seconds, allowing for almost instant pressure change. 400 Nm of torque at 0-200 rpm is available and a high-stiffness 2800 rpm spindle ensures excellent results. This machine also has a full fanuc control unit with a 12.1" LCD display and an ergonomic touch-screen interface. This allows for intuitive operation of the machine, making programming and operation fast and error-free. The machine also has network compatibility for data management. MITSUI SEIKI ZUV37WS-R is a reliable and powerful machining center that will ensure rapid, high-precision machining. Its integrated control machine and cutting feedrates allow for improved chip removal efficiency and precise machining, resulting in shortened machining times and higher tool traversing speeds. Its spindle output in combination with its 10-station drum type tool changer with a maximum tool holding capacity of 10kg and its C-axis with indexing base and built-in rotary table, guarantee high productivity and efficiency. Its full fanuc control tool with a 12.1" LCD display and intuitive touch-screen interface give the user full control over the machine's operation. The machine's network compatibility enables easy data management. ZUV37WS-R is the perfect tool for optimizing production processes.

There are no reviews yet