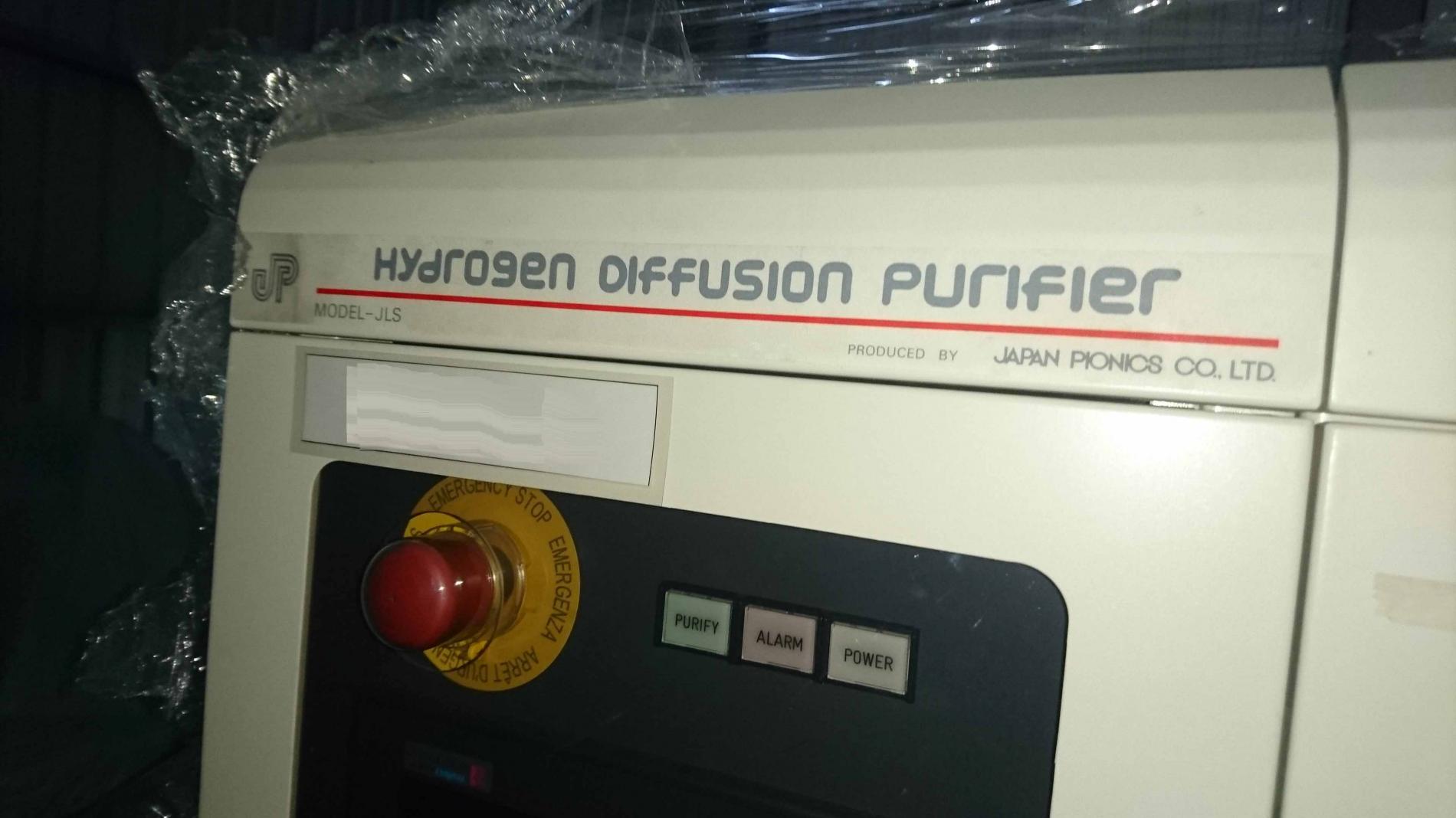

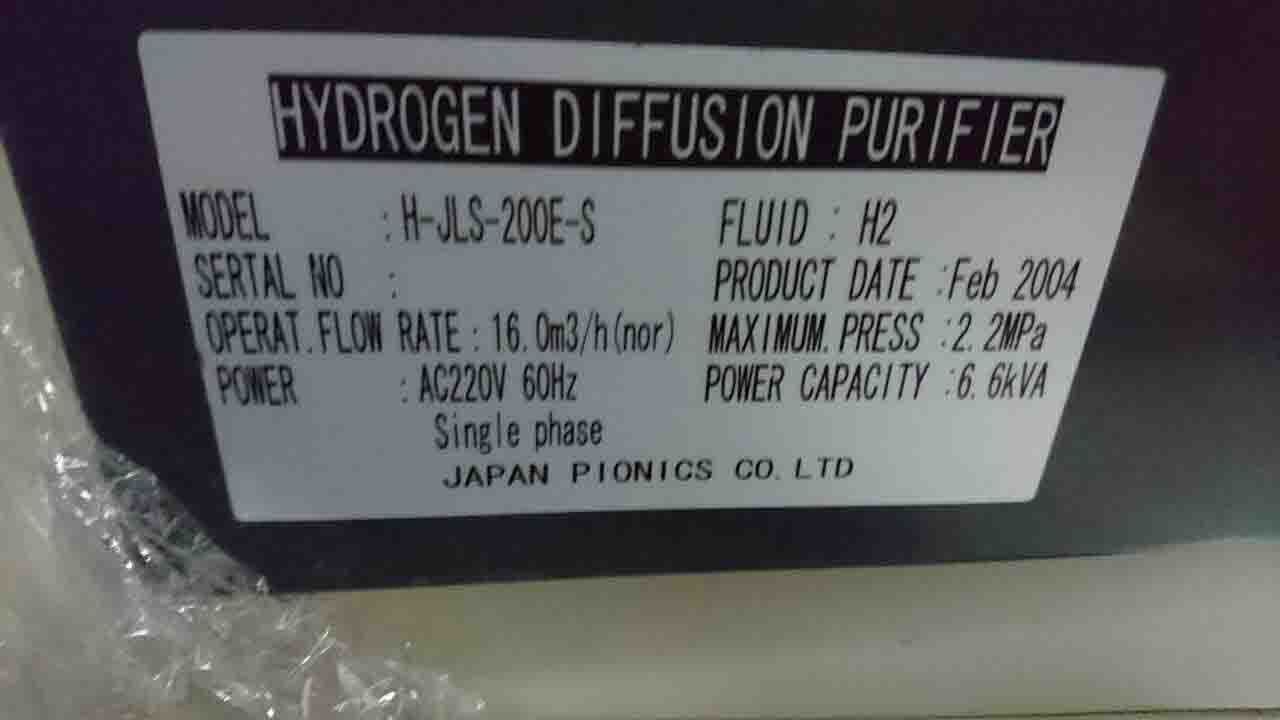

Used PIONICS H-JLS-200E-S #9163506 for sale

URL successfully copied!

Tap to zoom

PIONICS H-JLS-200E-S is a facility equipment designed for multiple applications ranging from automotive manufacturing to electronics assembly. It is a high-precision device that accurately and quickly assembles printed circuit boards, threaded rods, and other parts with a wide range of materials. H-JLS-200E-S is an accurate, fast, and easy-to-use automated workstation that is optimized for high-volume production. The device is equipped with an adjustable four-jaw chuck, which can be adjusted to the component size and shape with the press of a single button. It is also equipped with a five-axis servo motor that can be independently adjusted to compensate for different angles and heights. This ensures precise alignment of the drilled holes and components as necessary. In addition, PIONICS H-JLS-200E-S offers a range of features that allow users to customize the tool for specific needs. These features include a choice of drive systems, variable speed control, and programmable settings that allow users to set the optimal parameters for a specific application. H-JLS-200E-S also has a number of safety features. It is equipped with a protective guard that helps to prevent accidents from occurring, as well as a safety key that prevents unauthorized operation. As an additional safety measure, the device is designed with an emergency stop button that immediately deactivates the servo motor in case of an emergency situation. PIONICS H-JLS-200E-S is a reliable and versatile facility equipment, with an intuitive user interface and a wide variety of settings and features. It is suitable for use in a number of applications, from automotive assembly to electronics assembly. The device is capable of producing components with accuracy and speed, and its many safety features make it a safe and reliable tool for any production environment.

There are no reviews yet