Used TEL / TOKYO ELECTRON 849 CHP #9195625 for sale

URL successfully copied!

Tap to zoom

ID: 9195625

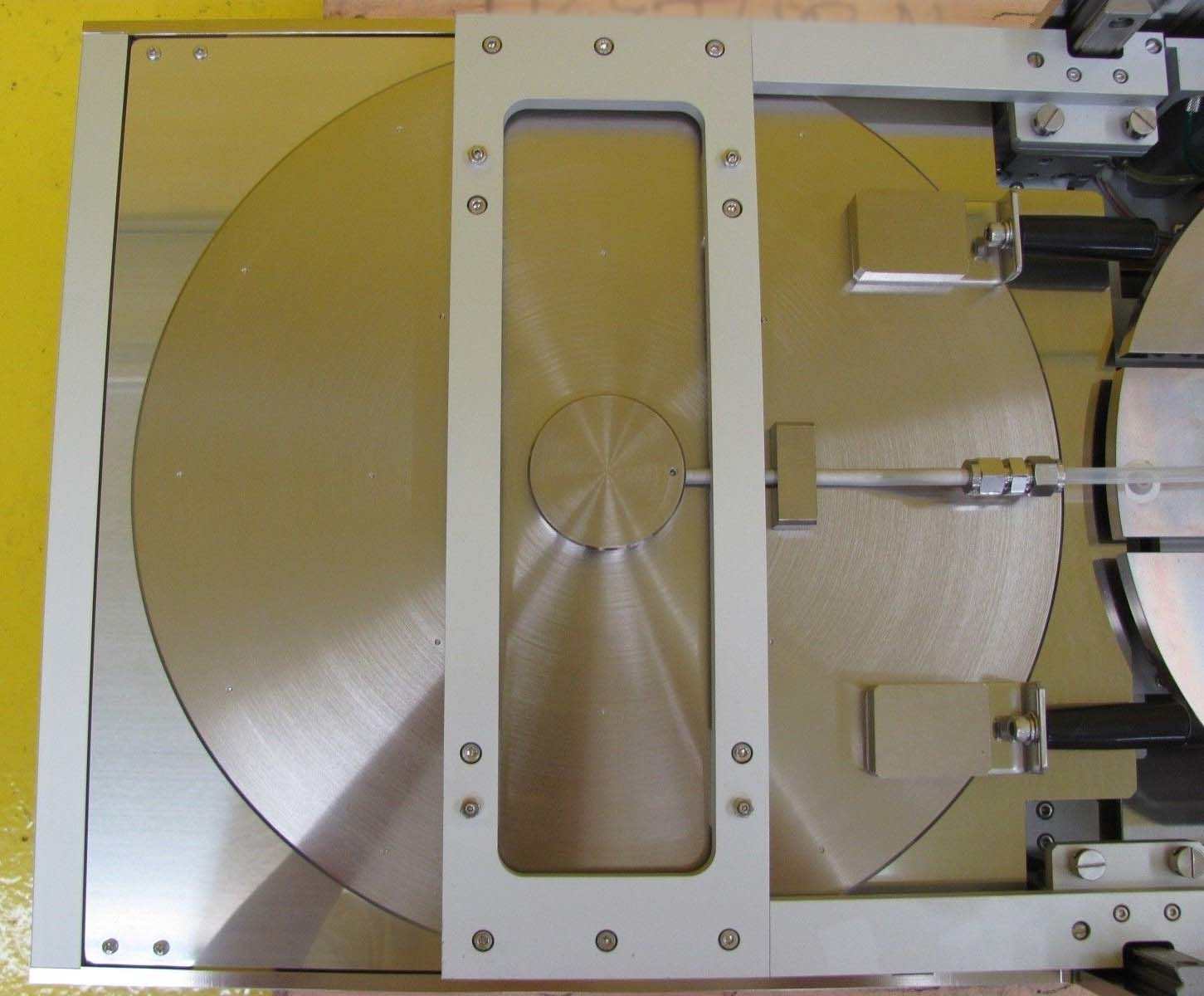

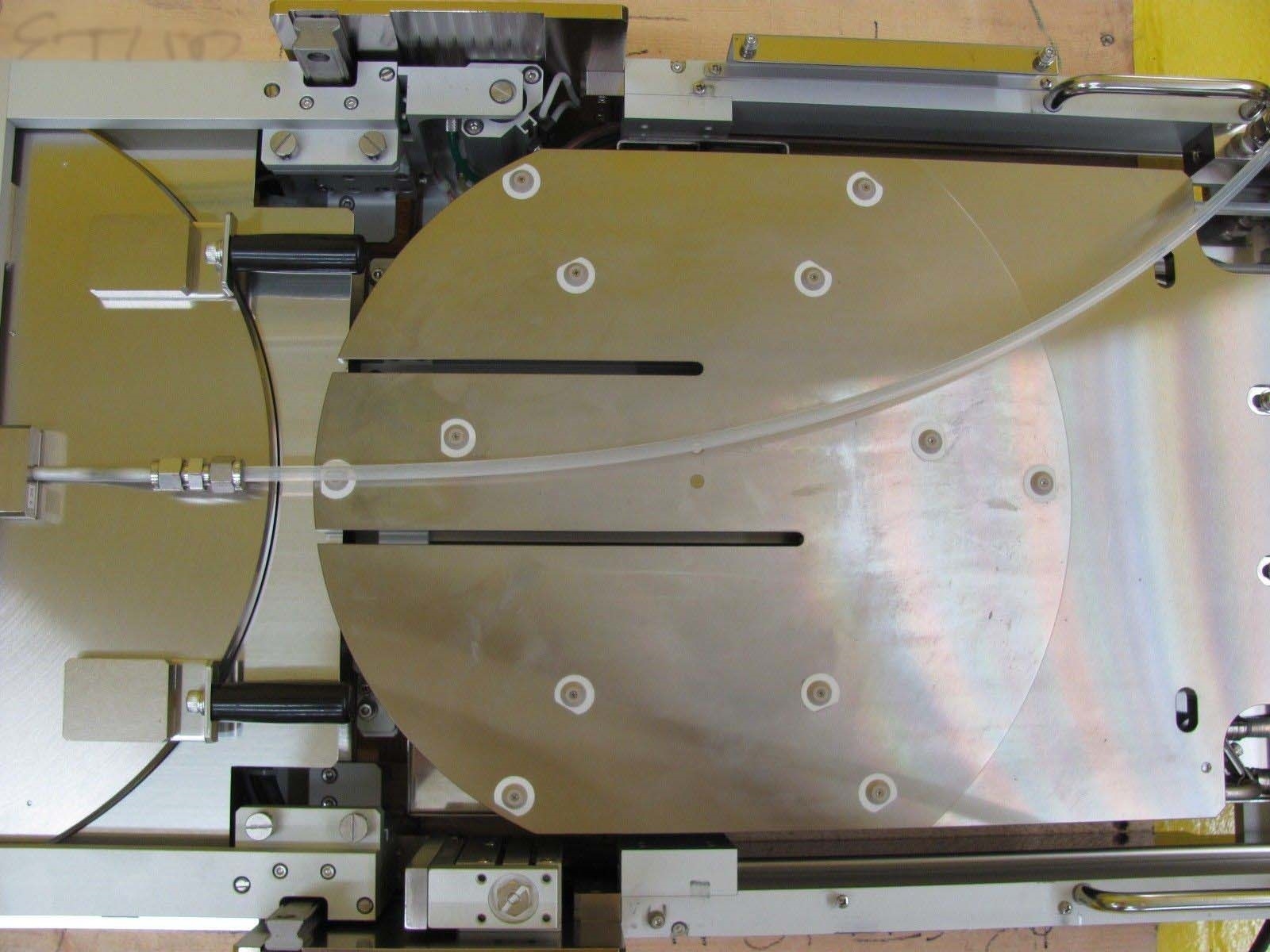

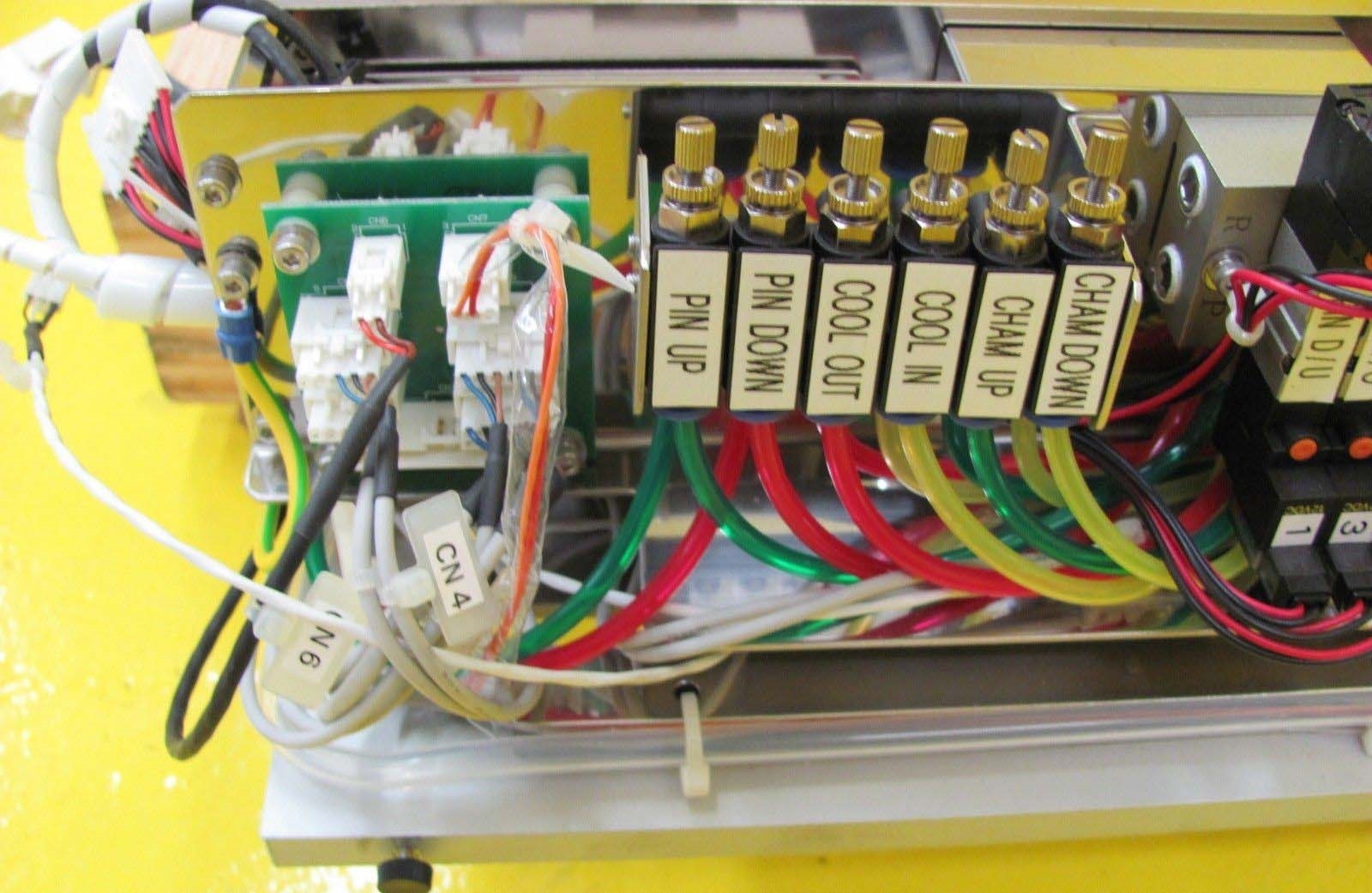

Chilling hot plate process station

Removed from TEL ACT12-200 system, 8"

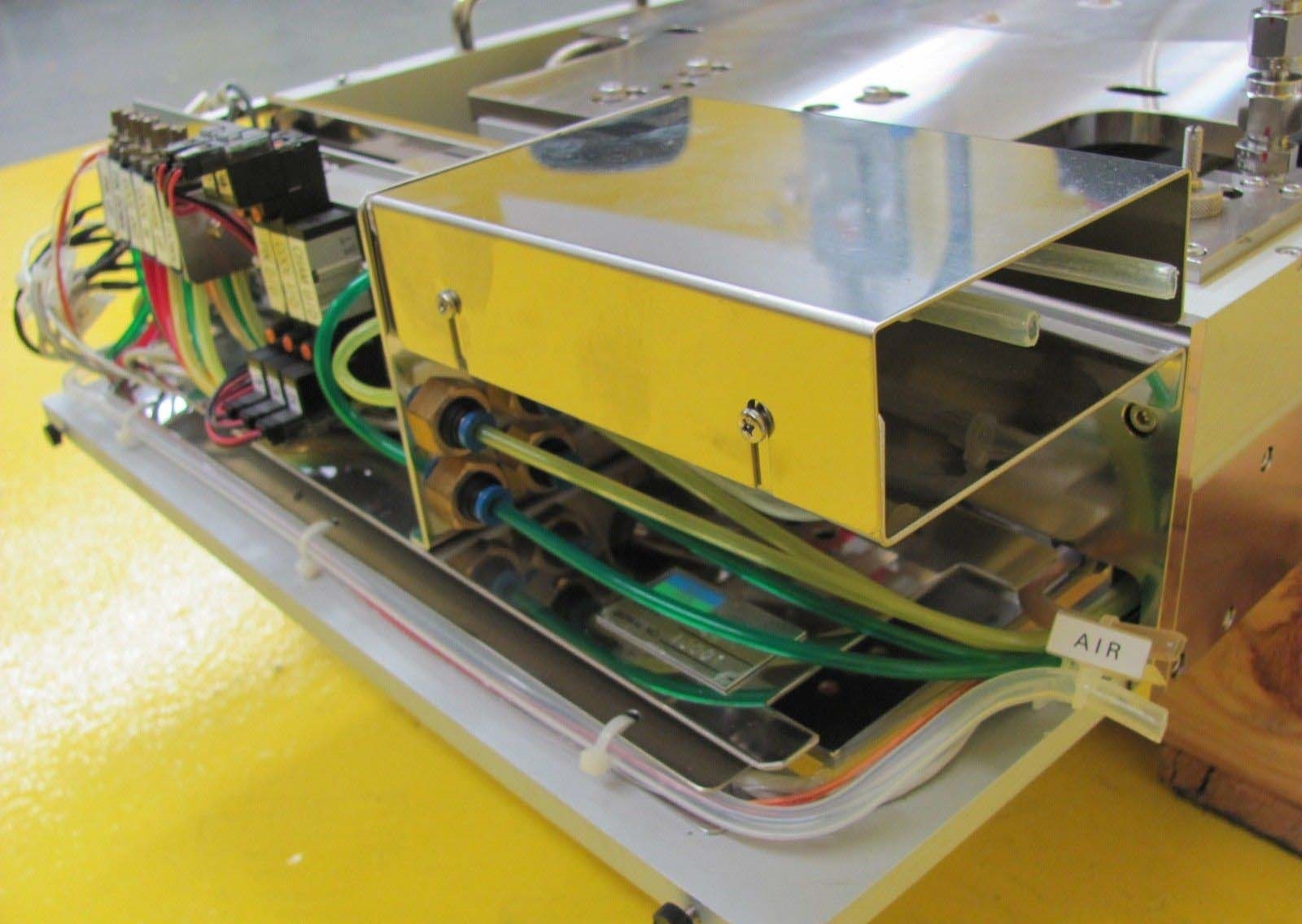

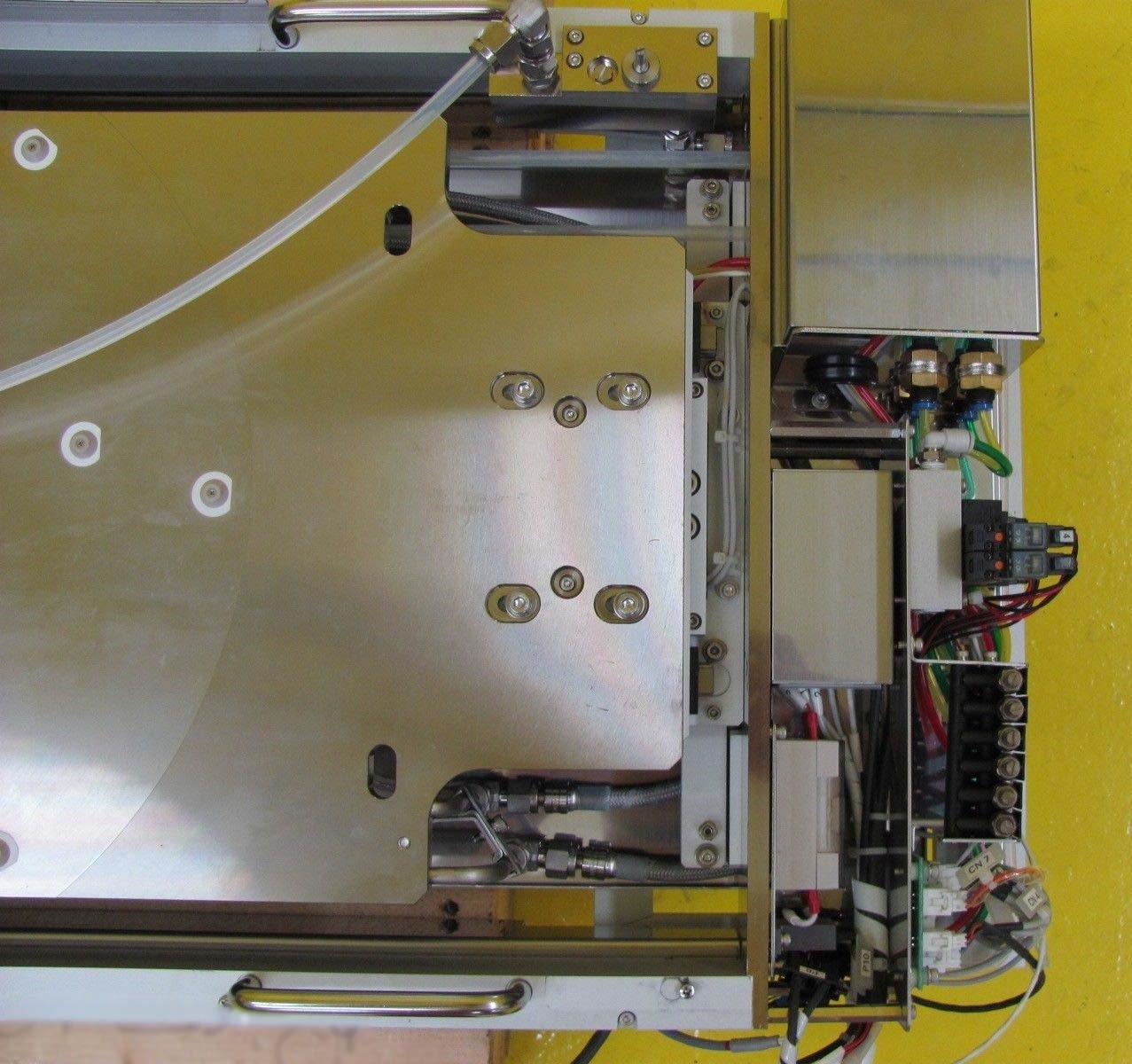

Assembly includes:

2985-41180-w6 CHP PEB SUB UNIT Assembly

2985-437216-w8 Base (ACT 12-CHP) Assembly col

2980-091282-12 Col plate AT12-SP-NDK

2985-410708-W2 CHP Plate support assembly

2985-411097-W1 CHP Chamber assembly

2980-091282-12 Col plate AT12-CP-NDk.

TEL / TOKYO ELECTRON 849 CHP is a machine that enables automated chemical vapor deposition (CVD). This machine is designed for superior process control and volatile exhaust control with its intelligent and highly efficient process control software. It features a temperature range of up to 800°C, as well as a 1200 W low-power magnetron power source for excellent process control. TEL 849 CHP also features a number of advanced safety technologies, such as the over-pressure sensor. This machine is a great choice for those working with high-precision parts, as it offers excellent process control that helps maintain the quality of the finished product. TOKYO ELECTRON 849 CHP is also equipped with a number of advanced features that make it ideal for large-scale production. Its modular design allows for easy exchange of components, and it is capable of handling high workloads with ease. Its advanced proprietary software makes it possible to monitor each process to ensure that it is running smoothly and running according to specification. It is capable of handling a variety of deposits, from simple layer films to advanced materials such as piezoelectrics and MEMS. 849 CHP also offers several advantages over traditional approaches to CVD. It is capable of faster processing times and improved deposition uniformity. The machine's chamber is also designed for improved exhaust control and low particle contamination. Its software also enables researchers to accurately predict the surface finish of the finished product. Overall, TEL / TOKYO ELECTRON 849 CHP is an excellent choice for both large-scale production and small-scale research. It is equipped with a number of advanced safety features and process control software, as well as a highly efficient power source. Its modular design allows for easy exchange of components, and its advanced software allows for accurate predictions of the surface finish of the finished product. This machine is sure to be an invaluable asset for any serious researcher or facility.

There are no reviews yet