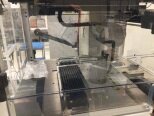

Used DATA I/O PS 288 #9215058 for sale

URL successfully copied!

Tap to zoom

ID: 9215058

Vintage: 2008

Programming system

With pick and place, marking, and media transfer sub-systems

Handler throughput: 1000 cph

FlashCORE Programming architecture

Footprint

High-mix programming

X-Y Robotics with high performance servo drive system

X, Y, Z, & Theta rotation

Placement force: < 10N

Vision alignment and self-calibration

Component processing range: SOIC 8 – QFP256, 600 mil DIP included

Auto-optimize program

Programming modules:

Package types: PLCC, TSOP, SOP, BGA, µBGA, QFP included

Device support:

Flash memory: NOR, NAND, MCP, SuperAND, Disk on chip

Microcontrollers

PC Network: Ethernet (LAN/WAN)

Monitor: 800 x 600 SVGA 12.1" TFT Touch screen display

Windows with touch screen

Compressed air usage:

Air pressure: 80psi (5.5 Bar)

Air flow: 3 CFM (85 liters/min)

Operating temperature: 55°F to 86°F (+13°C to +30°C)

Humidity: 35% to 90% RH Non-condensing

Noise: < 60 db

Operating system: Windows 98

Power requirements: 208 – 240 VAC, 50/60 Hz, 1 Phase, 10 A

2008 vintage.

DATA I/O PS 288 is the latest final test equipment designed by O Corporation, a leading global provider of high performance automated device programming solutions. It is the ideal choice for testing high volume, complex mixed signal, frequency- and voltage-sensitive semiconductor devices. O PS 288 system is comprised of a Programmer Console, including basic program functions and a pass/fail test interface, as well as a primary test head. This unit has a high throughput of up to 1,00,000 pins/hour, while providing the highest levels of accuracy and repeatability. It is capable of testing a wide variety of devices, from single-die devices with advanced architectures to high pin count ball grid arrays. This machine can also program external tester memory devices to support targeted test applications. The Programmer Console allows users to quickly configure the tool, as well as to create, debug and optimize programming files, without the need for external software. A variety of test parameters can be defined, including pin limits, operational limits, power, thermal and die metrology for each die. The data collected by the program can be saved and shared to ensure that test parameters and database information is shared across departments. The primary test head is the heart of the asset. It is an automated test platform, with a precision test bed and a comprehensive, integrated measurement model. This equipment is designed to be flexible and high-speed, allowing for conductive, radiometric, dielectric, optical and structural testing of semiconductor components. It also includes a Digital Logging System to store reference data for tests, as well as to track performance over time. In conclusion, DATA I PS 288 unit is a high performance, reliable final test machine designed to test complex, high pin count devices. This tool includes a comprehensive, integrated measurement asset and automated programming functions for complex and high-throughput programming applications. With its flexible design, PS 288 offers users the ability to easily and precisely configure and test a variety of devices, enabling them to improve their product performance and reduce part costs.

There are no reviews yet