Used MECHANICAL DEVICES Flex TC #9251014 for sale

URL successfully copied!

Tap to zoom

ID: 9251014

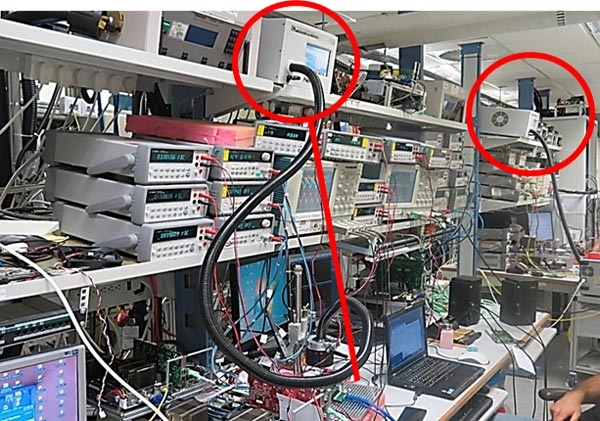

Benchtop temperature forcing systems

Maximum temperature: +155ºC

Minimum temperature: -55ºC

Temperature accuracy: < 0.5ºC

Typical transition rate: 25ºC to -40ºC in, 3 minutes

Remote interface ports: Ethernet TCP / IP

MTBF: 40,000 Hours

Power requirements: 208/220/230/240 VAC ±10% 50/60 Hz, Single phase, 10 A Max.

MECHANICAL DEVICES Flex TC is a scalable, comprehensive, integrated test equipment which provides the capability to analyze high-speed embedding products through the entire production line. It is designed to decrease cost of ownership, increase test coverage, and enhance test performance in a reliable, reproducible and highly efficient manner. The system offers a unique set of test equipment, diagnostic tools, mechanical fixtures, test procedures, and the most advanced software available resulting in improved test accuracy and repeatable data. The unit enables the user to configure the testing to their exact specifications, improving overall test coverage and throughput. MECHANICAL DEVICES FLEXTC machine provides a wide range of test capabilities under an integrated tool interface. Its module-based design allows customization to fit specific product testing requirements, with available customization options such as turning a single station into a multiple station, moving the fixtures, and using different types of faults attributes. The test asset is highly flexible, with the ability to configure more than 10,000 test items, which can be grouped into categories and expansions. These test items range from embedded tests, to basic board testing, to complete production line testing. The test model provides for flexibility in configuring test items to match product requirements, while also minimizing overhead associated with making changes and minimizes downtime. The customer can also easily switch between testing modes for flexible in-line testing and line-sweep board testing. The equipment allows for the execution of a variety of tests in different test steps, with some tests running concurrently in different test steps for maximum efficiency. Additional features include an effective self-diagnostics that can detect faults or errors for quick repairs and Automatic Poor Quality Analysis (APQA) that can identify and characterize incorrect test results. Flex TC is designed to assure product quality by facilitating thoroughly testing. The system also uses its advanced software and integrated diagnostic tools as an important component in its test operations, ensuring accuracy and providing customers with a significant advantage in their direct production processes. The unit is designed to continually monitor and evaluate tests and faults, and provide real-time feedback. The machine is a reliable and cost-effective platform to facilitate the efficient and effective testing of product reliability in the production line. Its comprehensive test solution optimizes testing for improved accuracy, higher throughput, and decreased cost of ownership.

There are no reviews yet