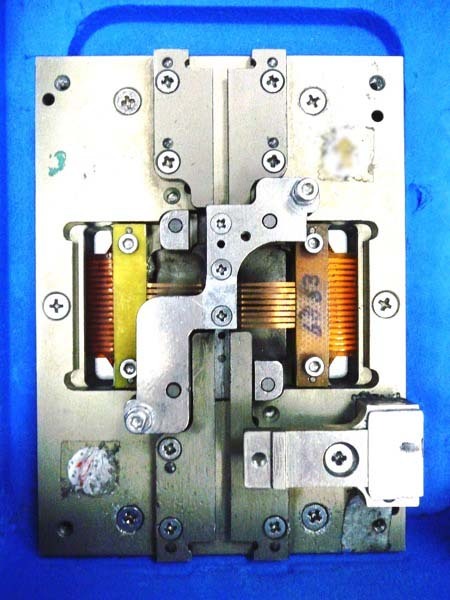

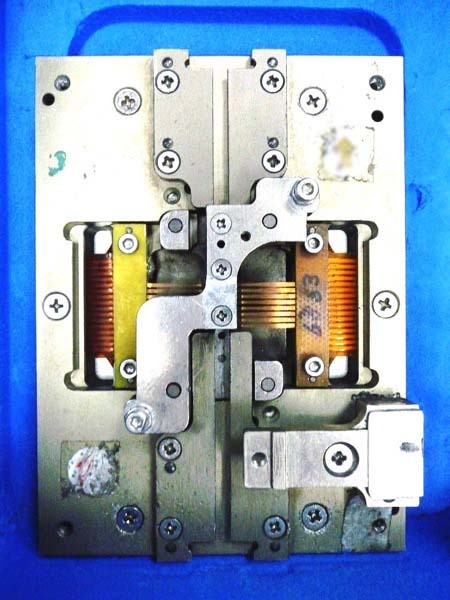

Used MICROHANDLING MH245 #153077 for sale

URL successfully copied!

Tap to zoom

ID: 153077

Test handlers

Configuration Available: SOIC150mil

Standard contact

Ambient and hot test

Input / Output is Tube to Tube

The Handler can be directly docked to the Tester.

MICROHANDLING MH245 Final Test Equipment is an industrial-grade micro-precision test platform that provides high level accuracy in a variety of industrial production and test applications. The controlled six-axis X-Y-Z stage is accurate to within nanometer range and enables fast and accurate part placement when performing a variety of tests. Its large range of motion, combined with its robust mechanics, provides a versatile platform for testing components originating from several industries. MH245 provides a wide range of precision test functions, from component placement and actuation, to micro-assembly and alignment. Its ergonomically designed user interface provides an intuitive, straightforward work environment for the user. The 6-axis process is powered by direct-drive brushless motors, along with matched rotary encoders, which provide accurate control and repeatability throughout the range of motion. Additionally, its highly configurable motion range allows for even more precise motion control depending on a particular test. MICROHANDLING MH245 also features a state-of-the-art vision component that can provide live visualization and real-time adjustment of component position. By using a high-accuracy vision component, MH245 is able to quickly and accurately recognize component features, making component identification and placement easier and more accurate. This feature allows users to quickly move components without the need for any physical contact, ensuring a safe and efficient test process. MICROHANDLING MH245 is also equipped with several additional features that provide further testing capabilities. In addition to the 6-axis motion and its configurable range, other features such as automated component handling, integrated display screens, and PC control are also included. All these features make MH245 a powerful, yet flexible testing system that can be used in a variety of industries and applications. In addition to its many features, MICROHANDLING MH245 also ships with a variety of calibration and data logging capabilities. This allows users to customize the test process according to their specific requirements and gain a deeper understanding of their test results. Furthermore, MH245's self-calibration capabilities provide a more accurate and reliable testing environment that ensures higher-quality results. Overall, MICROHANDLING MH245 Final Test Unit is an industrial-grade micro-precision test machine that provides high accuracy and repeatability when performing a variety of tests in industrial production and production testing. Its intuitive user interface, 6-axis motion, vision component, integrated display screens, automated component handling, and calibration capabilities make it a powerful and capable platform for testing and verifying components.

There are no reviews yet