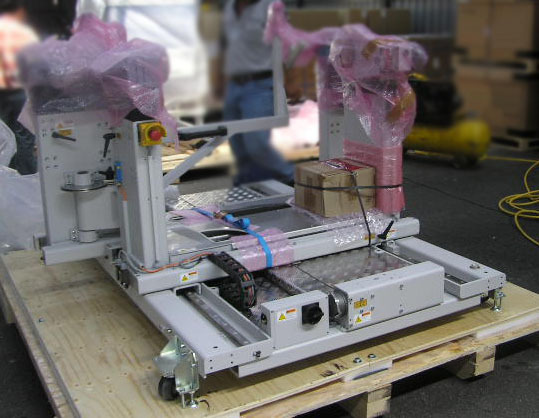

Used MICROHANDLING MP920 EVO #9064674 for sale

URL successfully copied!

Tap to zoom

ID: 9064674

Manipulators

Maximum test head weight 600kg (1320 lbs)

Max. interface weight 136 kg / 300 lb

Max. position of vertical movement: 1200 mm (47.24 ")

Min. position of vertical movement: 950 mm (37.4 ")

Compliance in z-direction:: +30 mm (1.18 ")

Twist compliance: +1.5°

Theta compliance around z-axis: +1°

Horizontal movement in y-direction: +30 mm (1.18 ")

Horizontal movement in x-direction: 980 mm (38.58 ")

Tumble movement: ± 95° from DUT vertical; Total: 190°

Tumble compliance: +1°

Vertical movement: +30 mm (1.18 “)

Twist compliance is ±1,5°

Horizontal movement in x-direction: 980 mm (38.58 “)

Twist movement is -5°, and +85° from DUT vertical; Total 90°

Tumble compliance: ± 1°

Theta movement: 100°

Admissible environmental temperature +15°C to +30°C

Admissible humidity 15 % to 60 % (at 30°C)

Sound level < 70 dB (A)

Test Configurations:

Test systems: Verigy V93000 512pin / 1024pin Verigy V4100, V5500 Teradyne J750 512pin / 1024pin Teradyne MicroFLEX, IntegraFLEX, UltraFLEX

Test handler: Delta, Mirae, Multitest, Rasco

2006 vintage.

MICROHANDLING MP920 EVO is a final test equipment for testing and validating micro-parts. This testing system combines several hardware components - such as cameras, height sensors, segmented gripping tools, and indexing units - with powerful software tools and algorithms to complete the entire test cycle in one unit. The machine includes a patented Smart Eye technology, which employs a high-resolution camera connected to a stable gantry to precisely control the movements of the gripper tool. The camera accurately detects the positioning of a micro-part, ensuring precise alignment and better performance. In addition, the calibrated camera also ensures accuracy when multiple parts are tested in the same session. MP920 EVO also includes several advanced algorithms for characterizing micro-parts. These include shape analysis and feature extraction algorithms to classify parts, and gesture recognition algorithms to analyze motion. This allows the tool to accurately scan and index micro-parts, and classify them according to their size and shape. The asset also includes an intuitive graphical user interface, which allows users to easily program tests and validate data. The intuitive interface is simple to use and allows users to quickly get started with the model and customize the parameters to fit their applications. Users can also export and store test results for future reference. For safety and accuracy, MICROHANDLING MP920 EVO is designed with a segmented gripping tool and a multi-level collision avoidance equipment. The collision avoidance system is designed to ensure that the unit doesn't collide with its environment or the micro-parts being tested. The machine also includes a containment tool, which prevents any particles, debris or hazardous materials from entering the workspace. Overall, MP920 EVO is a reliable and precise final test asset for micro-parts. This model combines the power of hardware - such as cameras, height sensors, segmented gripping tools, and indexing units - with advanced algorithms and a user-friendly interface, making it easy to use and highly efficient. With MICROHANDLING MP920 EVO, users can confidently conduct accurate tests and validate their data quickly and safely.

There are no reviews yet