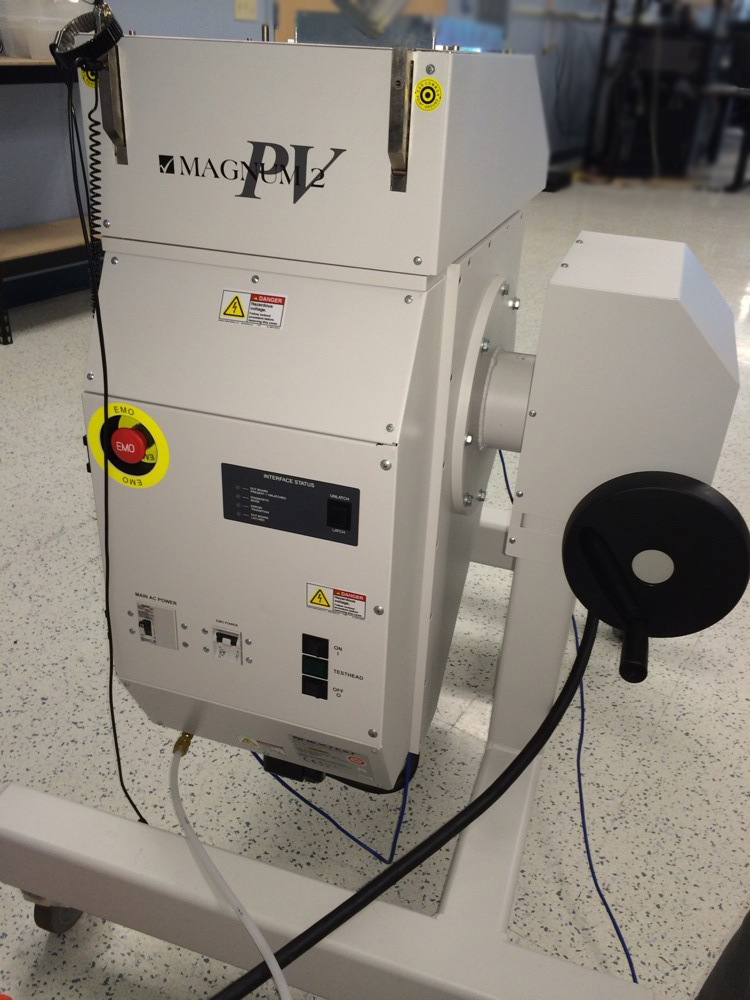

Used NEXTEST / TERADYNE Magnum II PV #9065004 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9065004

Vintage: 2012

Memory tester

Stackable Chassis

Single Chassis Manipulator

Display: Dual LCD 20"

OPTION, VRC32, HD2

Site Assembly includes:

(128) Digital Channels

(1) Test Site Controllers

(1) Algorithmic Pattern Generators

(16) DUT Power Supplies

(8) System PMU

(128) Per-Pin PTU

(16) High Voltage Pins

(1) 640-Channel, Tester Cable Interface

(1) Host Computer, One Chassis

Memory:

Error Capture Memory Option; ECR, 36GB / 1.152GB

Row/Column Memory Option; OPTION, RCM,36MB,HD2

Data Buffer Memory Option; DBM, 18GB / 1.152GB

Vector Memory Option; LVM, 64MV / 128MV

Interface:

DUT BD, MAG1TA, 128CH, MCX, CABLE BD

2012 vintage.

NEXTEST / TERADYNE Magnum II PV Equipment is a cost-effective, high throughput final test system for high volume production. It features an open platform and high level of flexibility, allowing for easy integration of new test technologies and customization based on the specific needs of the user. The unit features an automated robotic material handling machine with a four-stage loading tool, designed to ensure efficient loading and testing of components, and a high speed, vector enabled platform to quickly perform complex tests. It is capable of testing single-layer, mixed-layer, or multilayered printed circuit board assemblies. The asset uses a patented variable force probing technology, allowing for optimal contact testing at a wide range of force levels across all test points, resulting in more reliable final tests. The model also features a full range of analog and digital test resources, allowing for high-speed testing of all pin configurations and signal types. NEXTEST Magnum II PV Equipment is ideal for the high volume production of closed hardware components. The system is designed to quickly identify and diagnose any issues with the components, allow for rapid repair and comprehensive final testing before the components are used in production. The unit features various value-added features, including Load Board support, Thermal Measurement, offsetting to ensure repeatable accuracy, and advanced component analysis. TERADYNE Magnum II PV Machine also offers advanced process control capabilities to ensure accuracy and compatibility, with a built-in diagnostic toolset and integrated software tools to configure and monitor the entire testing environment. Lastly, in order to ensure traceability and accuracy, the tool offers an integrated full-featured data gathering capabilities including real-time test results logging. Overall, Magnum II PV Asset is a reliable, high throughput test platform for high volume production. It offers a rapid development cycle, an open platform, and flexibility for easy integration of new test technologies. The model is ideal for ensuring faultless components before they are used in production, and comes with robust process control and diagnostic tool capabilities.

There are no reviews yet