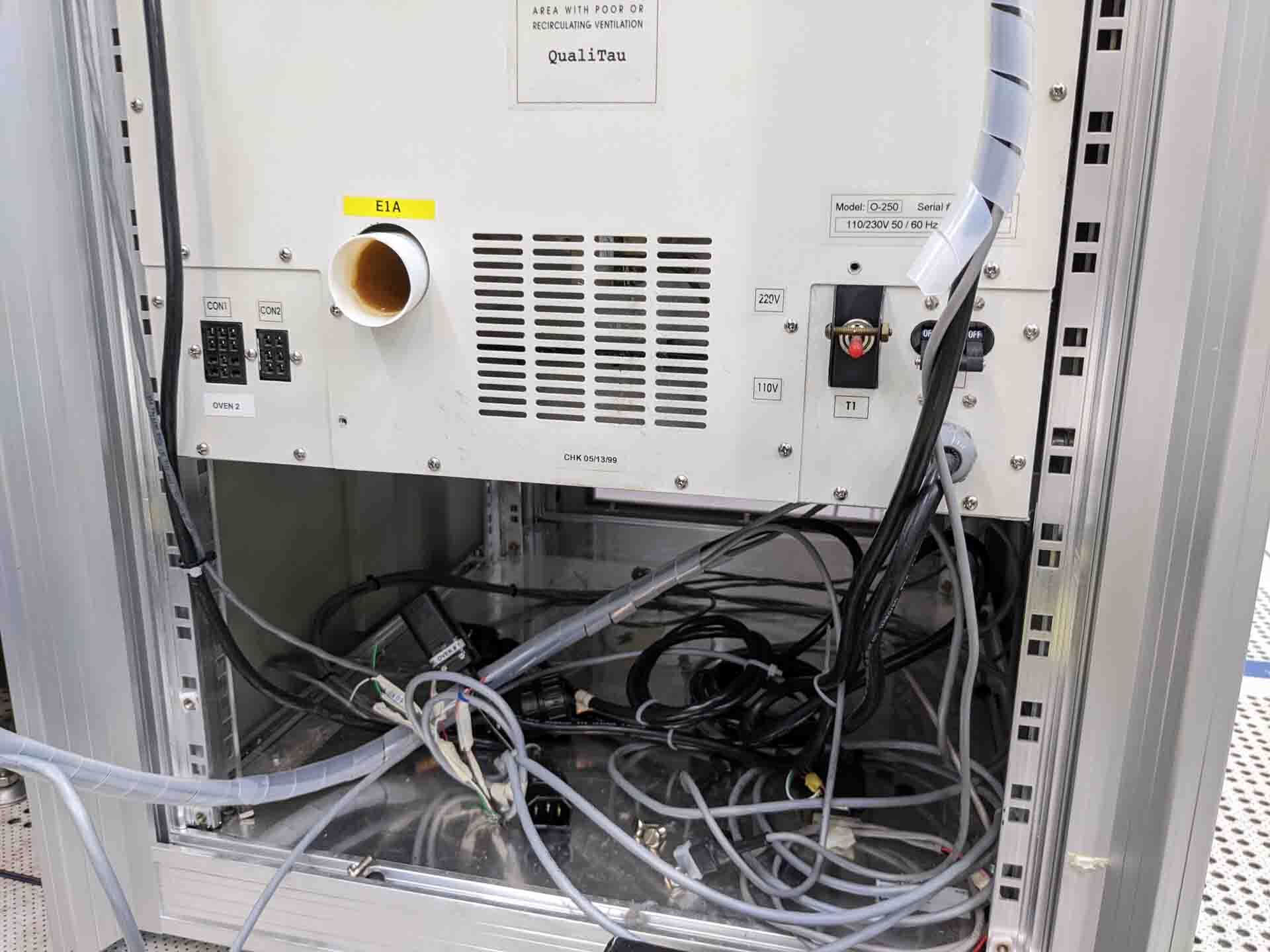

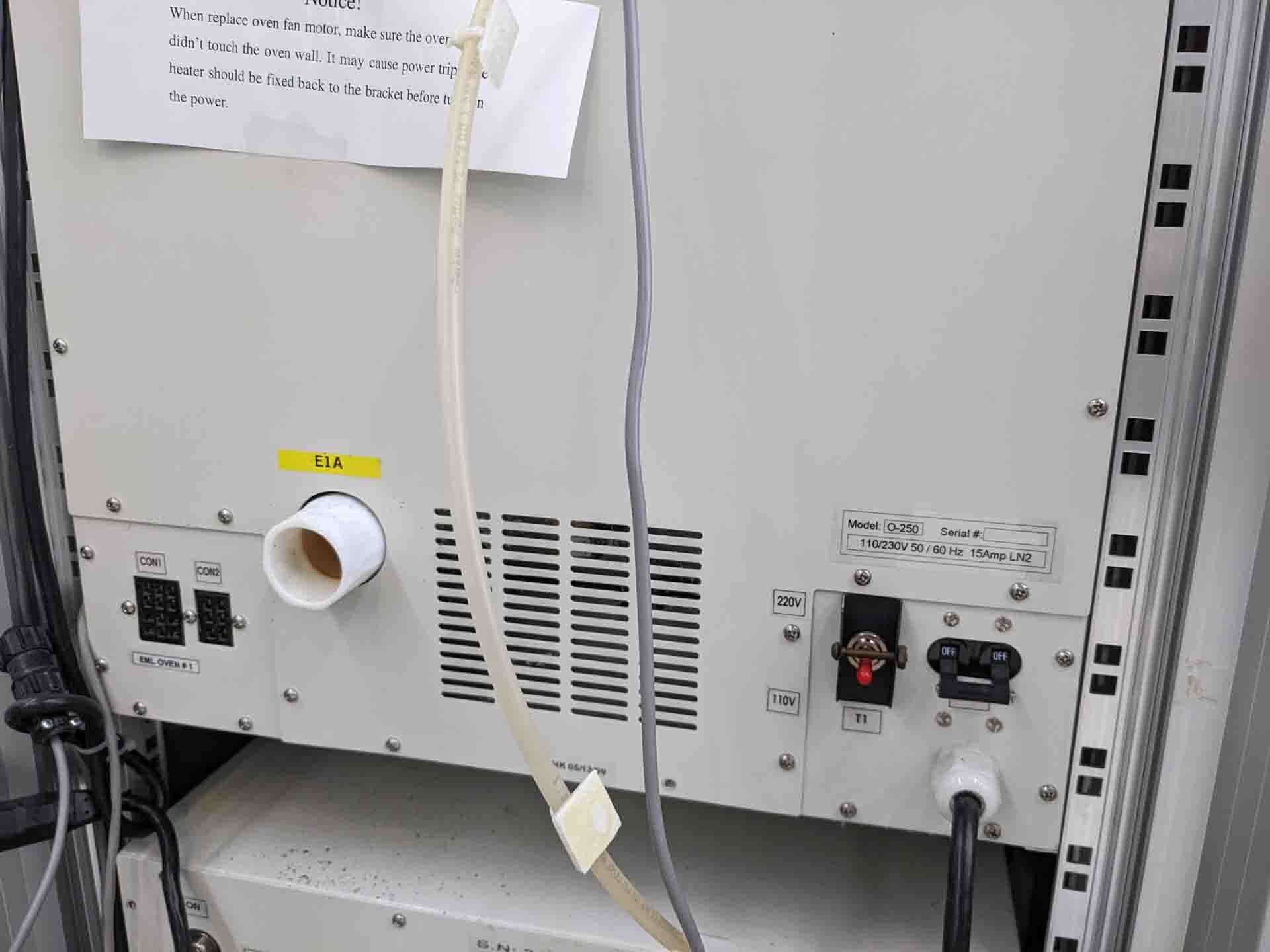

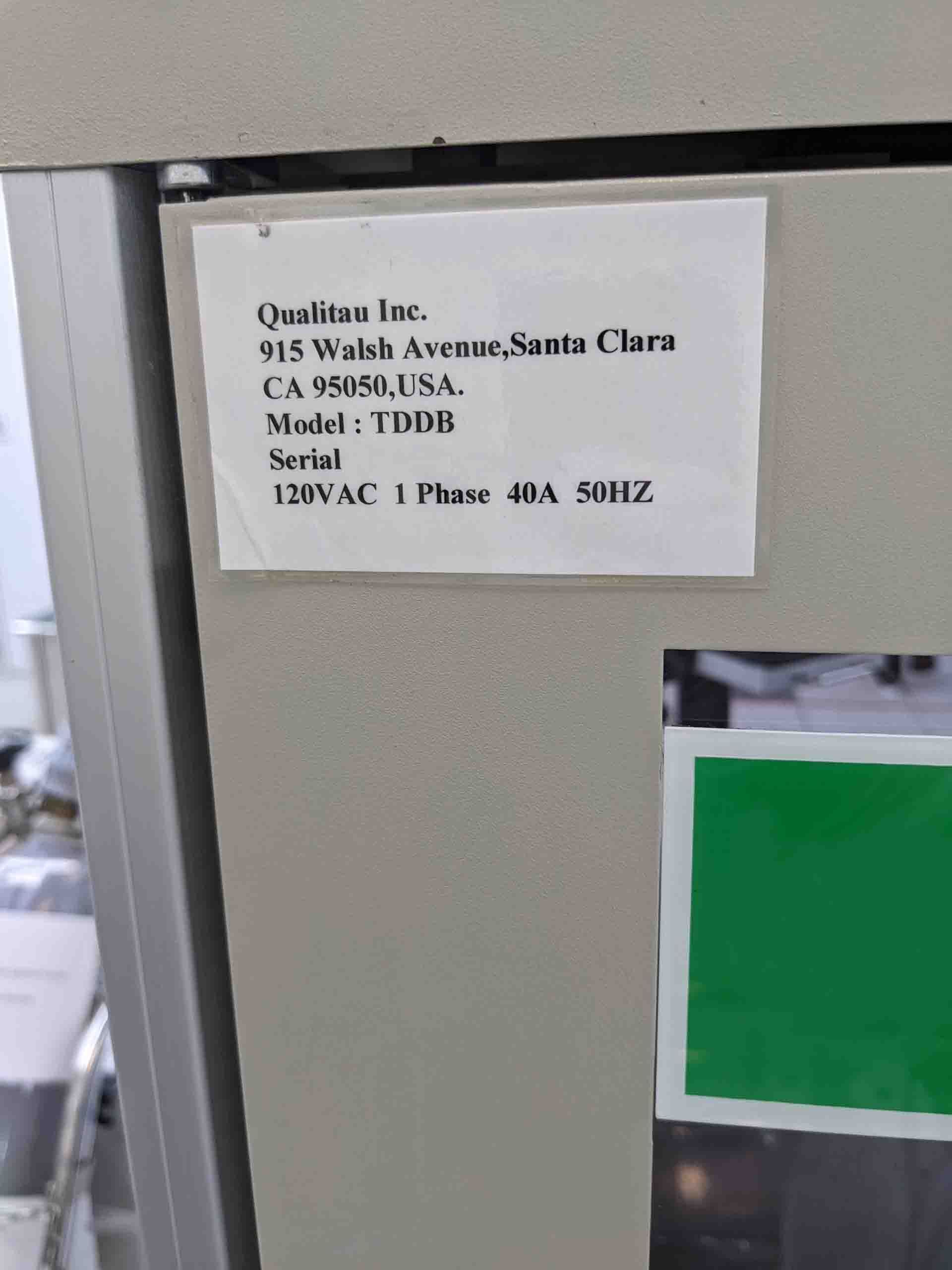

Used QUALITAU O-250 #293608606 for sale

URL successfully copied!

Tap to zoom

QUALITAU O-250 is an automated final test equipment which allows for comprehensive inspection and test of various products and components during the manufacturing process. The system is comprised of several subsystems, including an automated vision inspection and testing unit, a sophisticated application programming interface (API), a test data repository, and a reporting module. The automated vision inspection and testing unit is designed to identify defects, measure physical characteristics, and perform other tests, according to preset standards and requirements. A high-speed camera is used to capture and inspect images of components and assemblies, while an inspection machine can be used to perform a range of tests, such as spectral analysis, waveform analysis, and burn-in tests. The unit can also be used to interpret data and draw conclusions, as required for quality assurance purposes. The sophisticated API provides users with access to a range of support functions, including sophisticated command and control functions, data storage, data communication, and reporting. The API is capable of communicating with external systems, such as vision systems, so that data can be exchanged in a secure, efficient, and reliable manner. The test data repository is used to store data from tests, such as results and images, along with additional relevant data, such as reference codes and product specification information. The data repository is managed by a secure SQL database, so that the data is accurate and reliable. The reporting module is used to generate a range of reports, including individual test results, trends, reports and audit trails. Each report is designed to meet specific requirements, and all reports can be customized to include relevant company logos and other corporate identity elements. O-250 unit provides users with a comprehensive, secure, and reliable solution for testing and inspecting components and assemblies during the manufacturing process. The machine allows users to identify and isolate defective components and assemblies, while ensuring the quality of final products. This tool is ideal for any company looking to improve its quality control processes.

There are no reviews yet