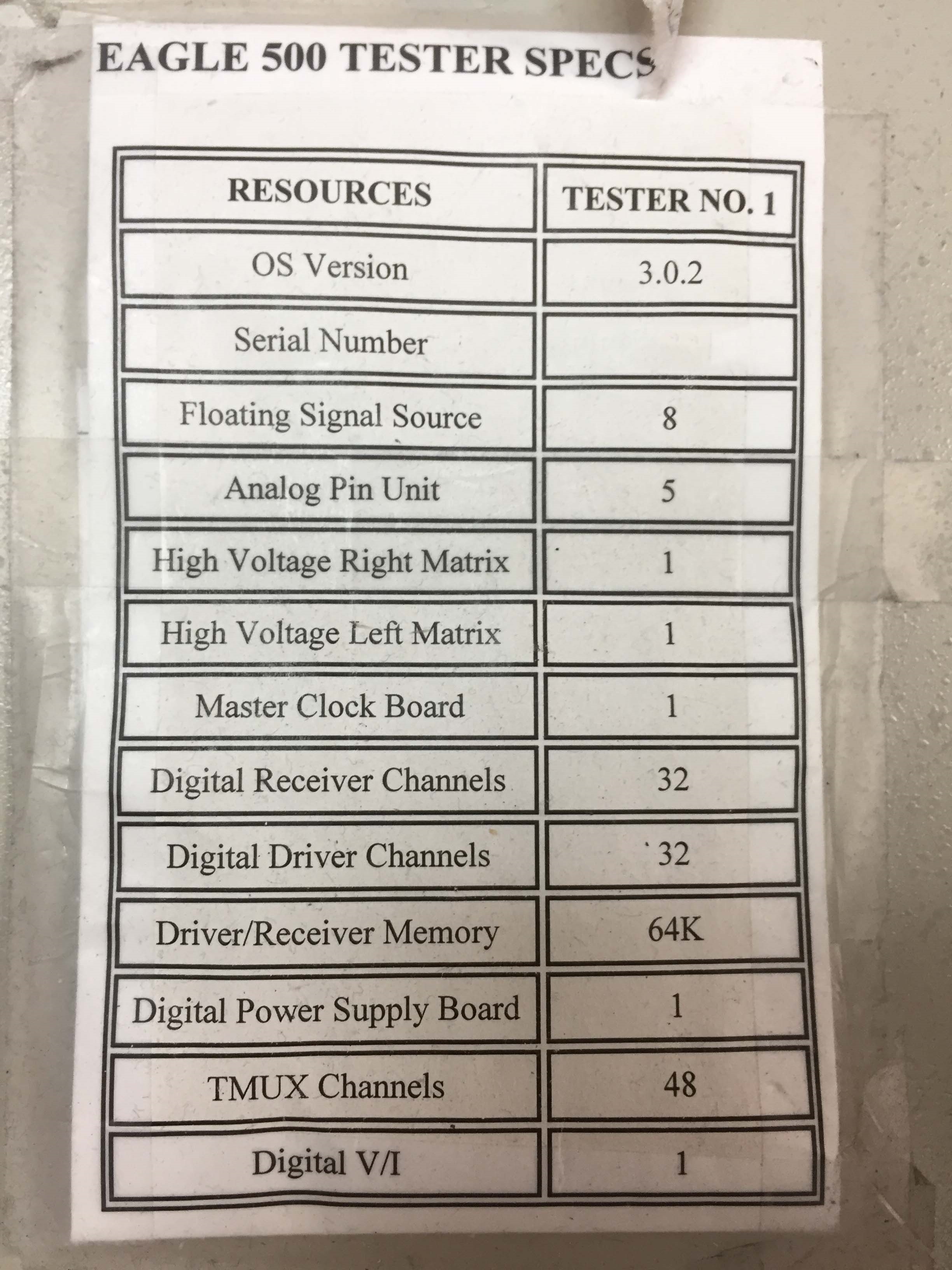

Used TERADYNE / EAGLE ETS 500D/SS #9194600 for sale

URL successfully copied!

Tap to zoom

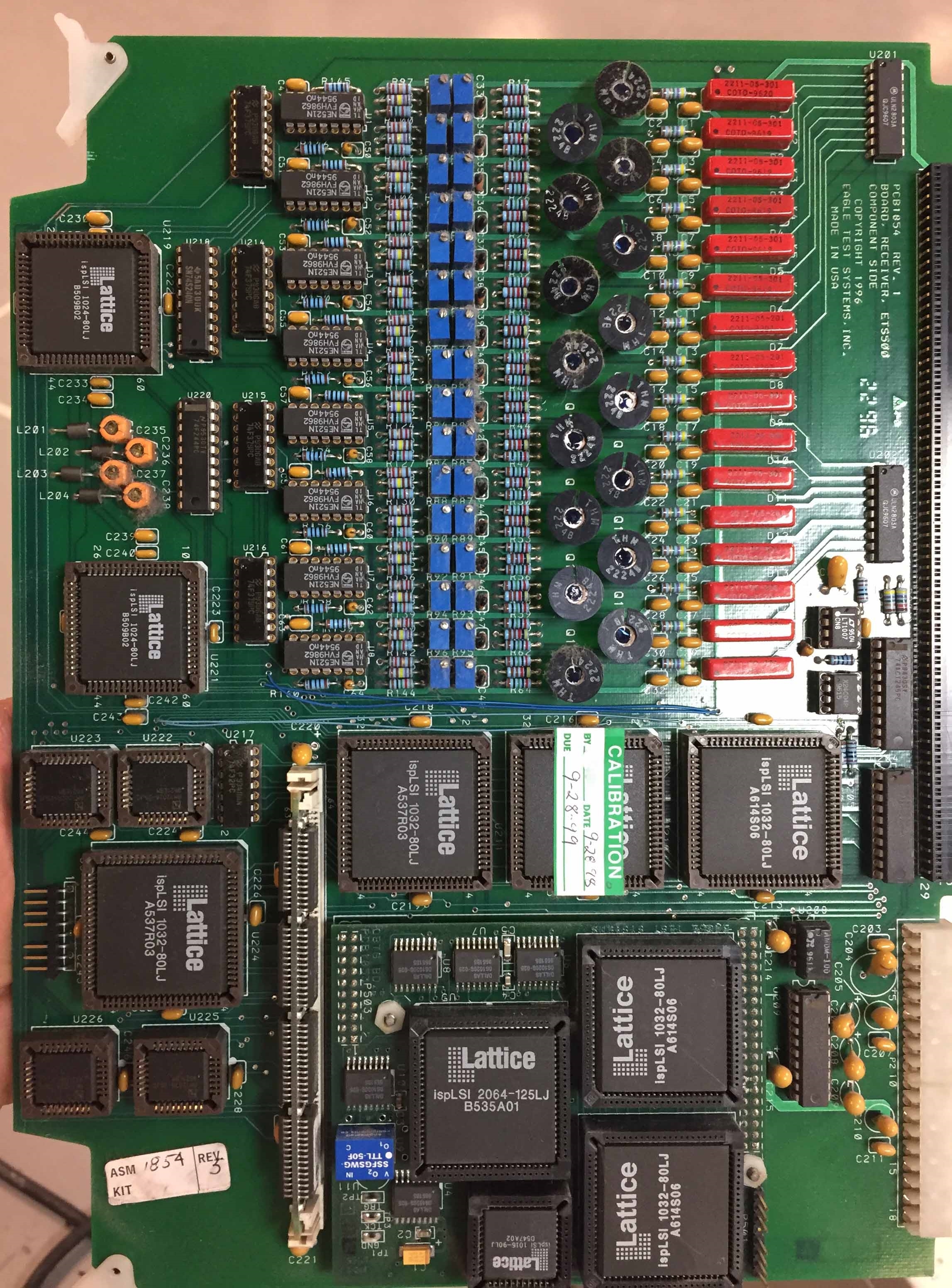

ID: 9194600

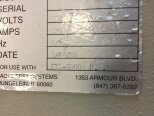

Tester

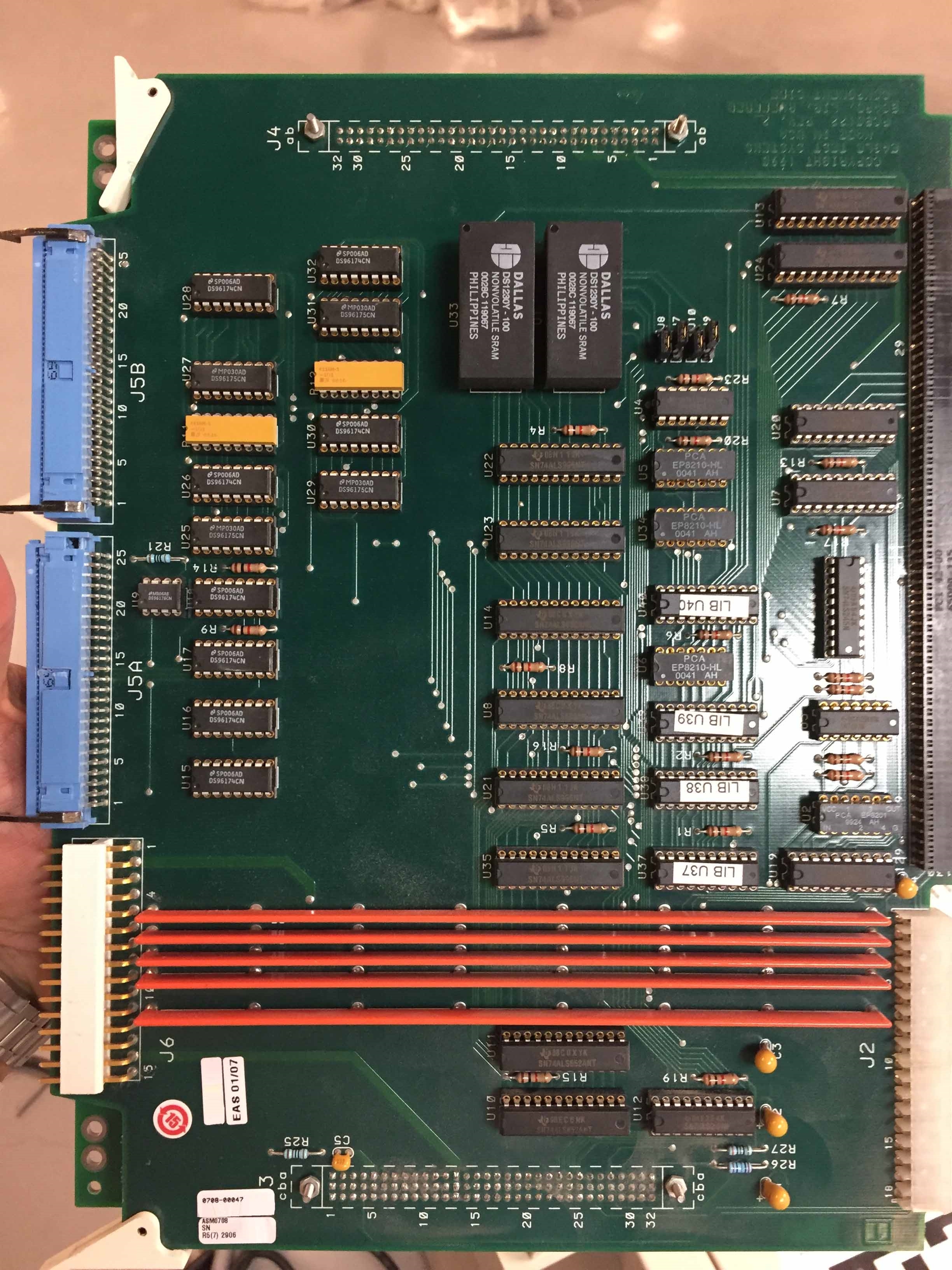

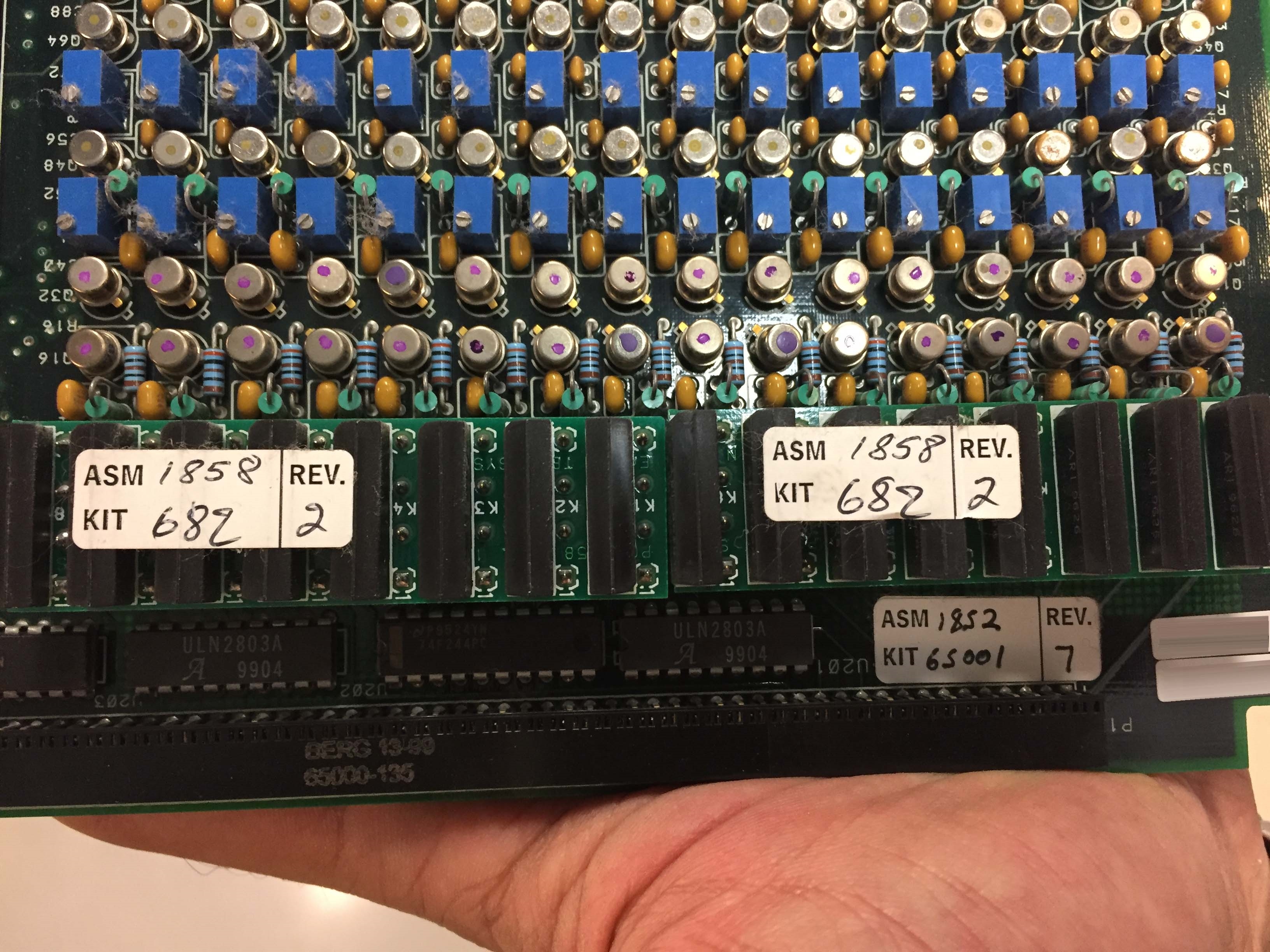

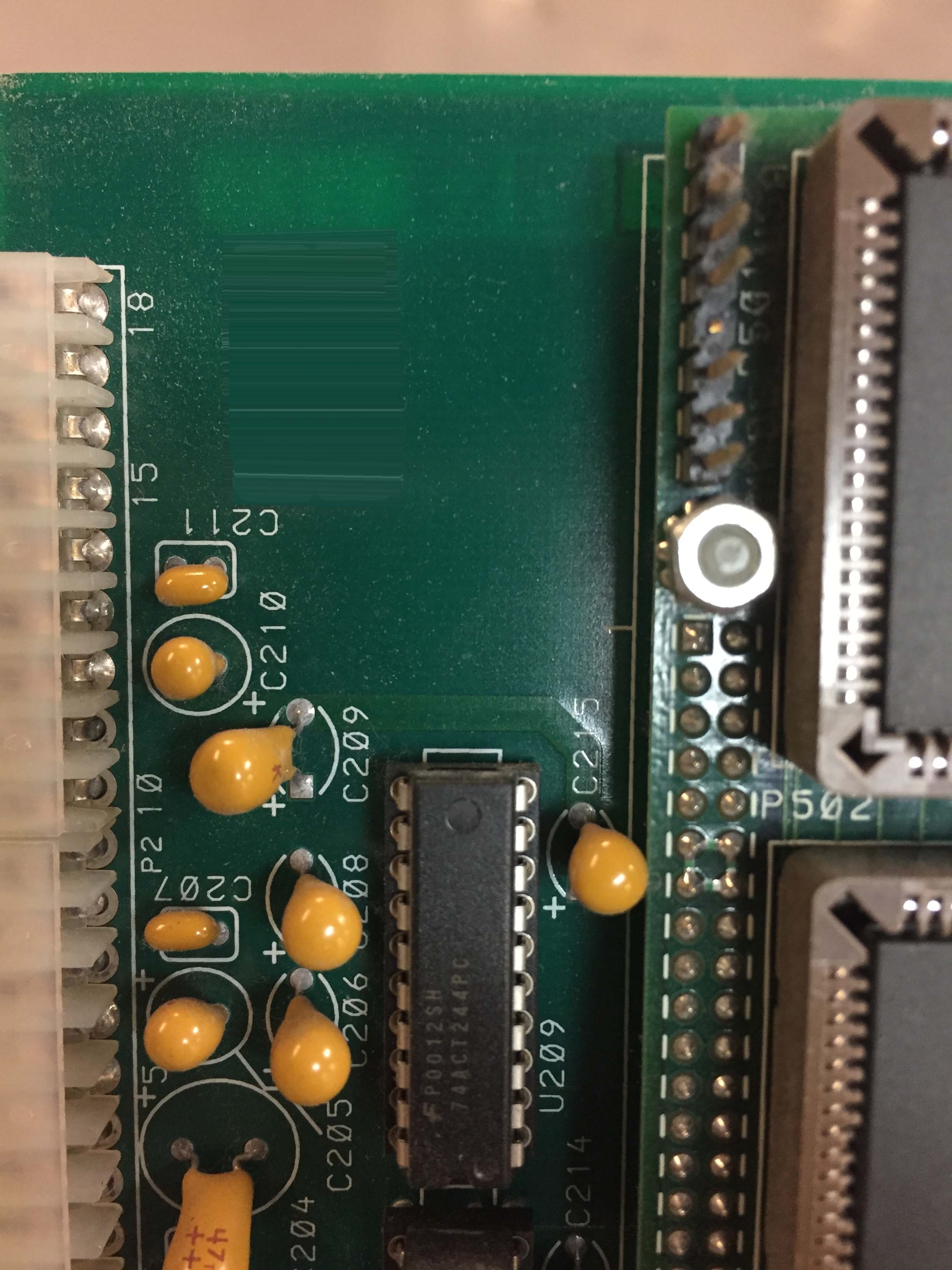

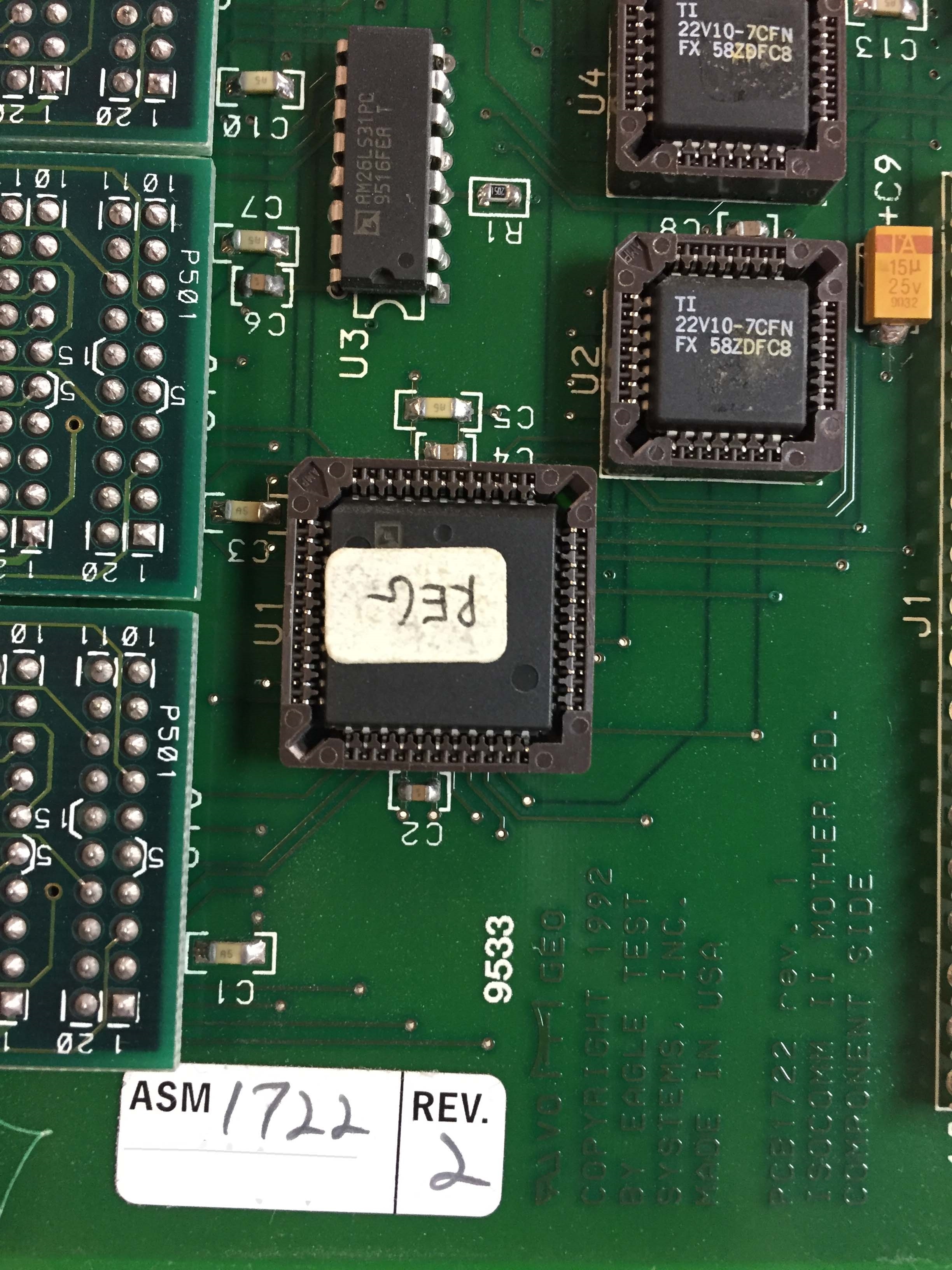

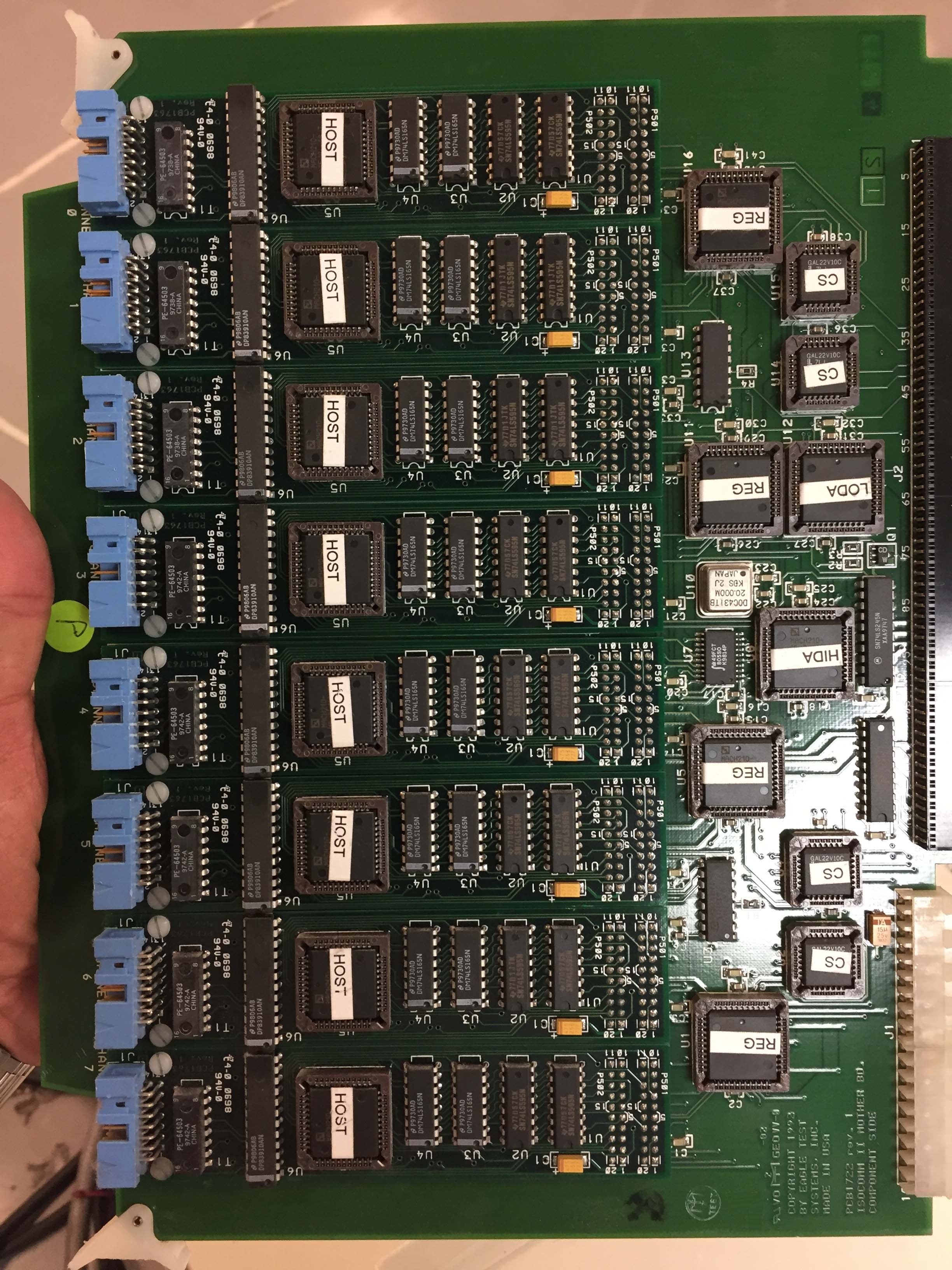

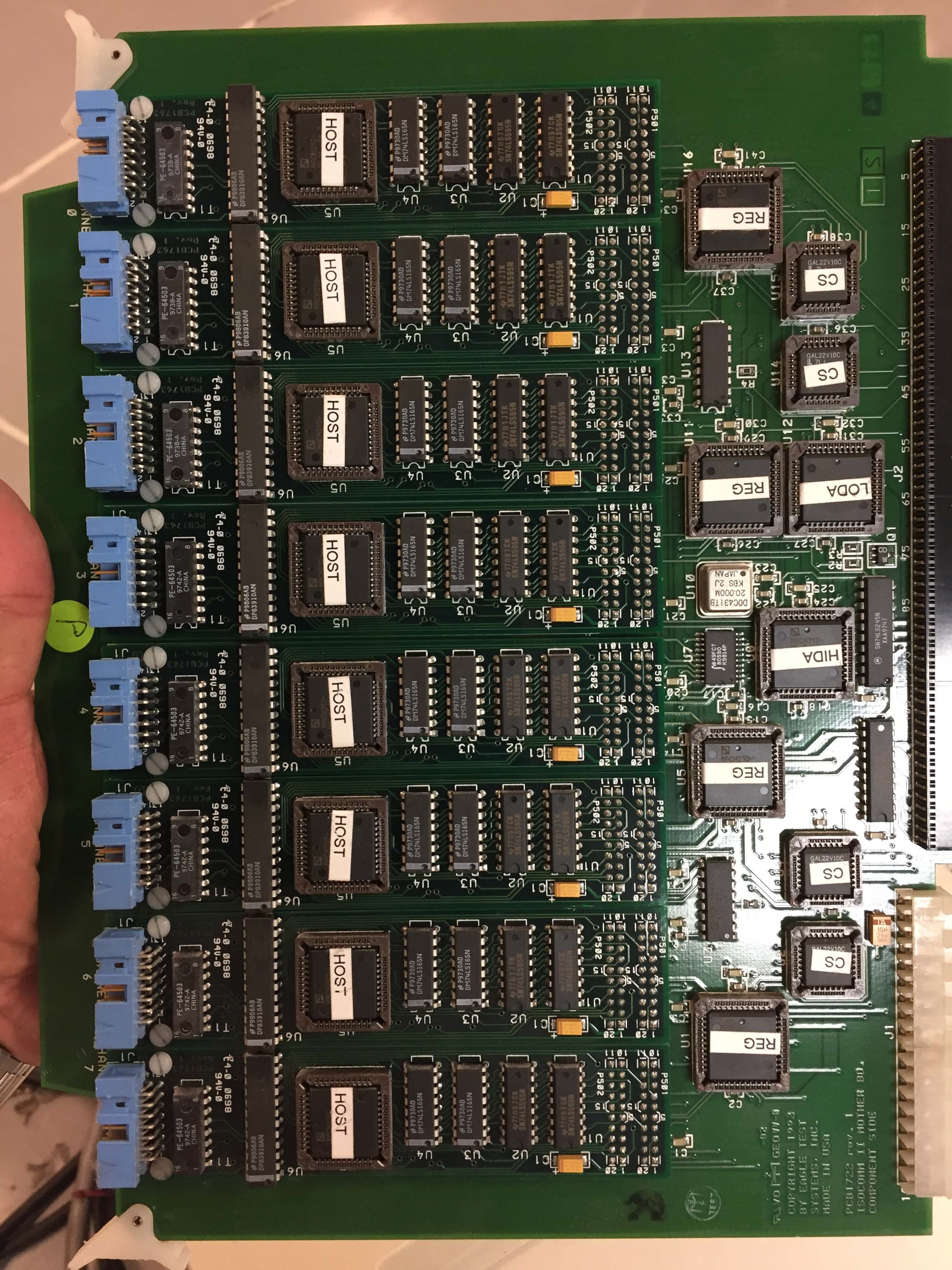

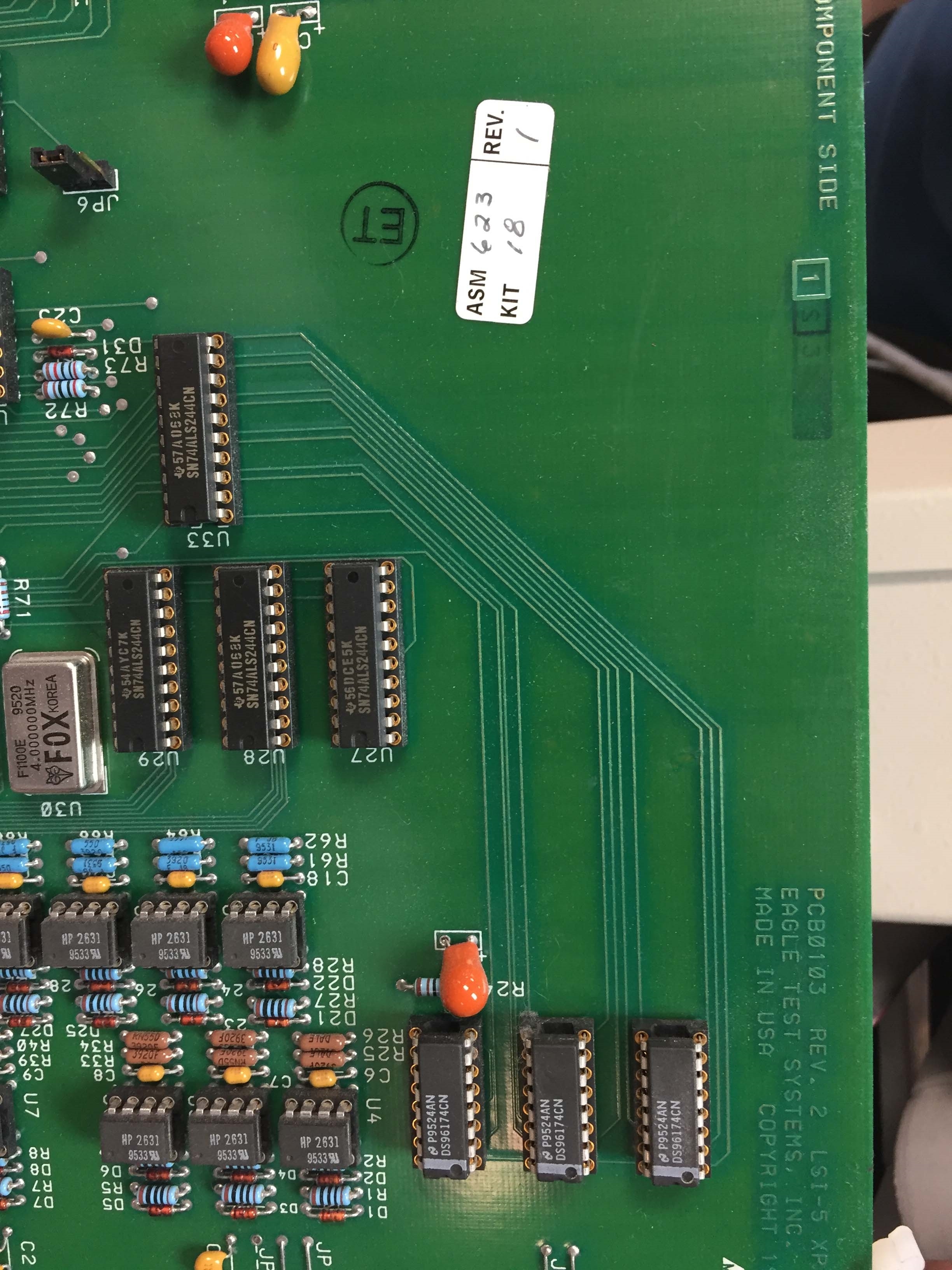

Slot 1: ASM 1725 / FSS2000 Board

Slot 3: ASM 1725 / FSS2000 Board

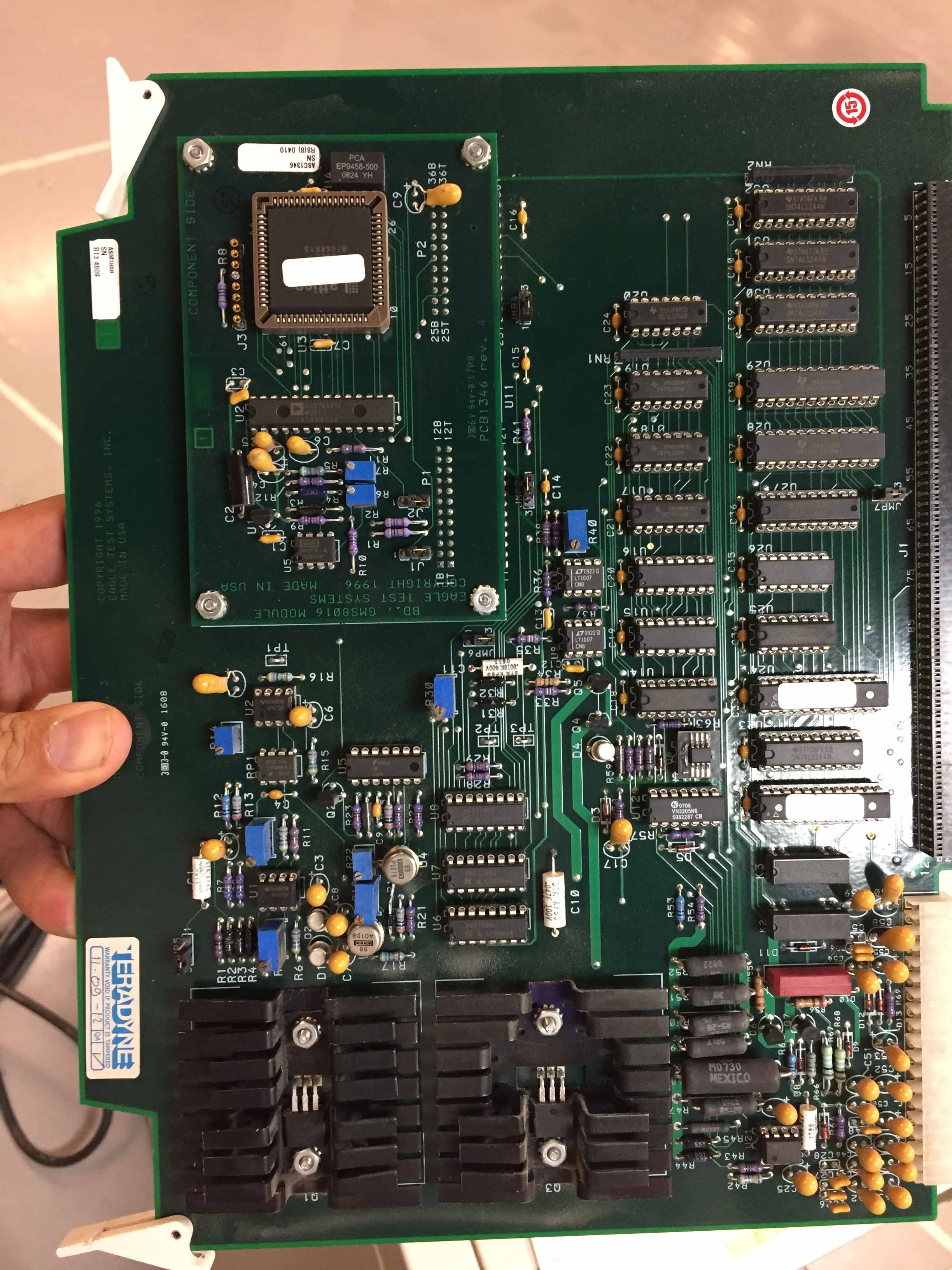

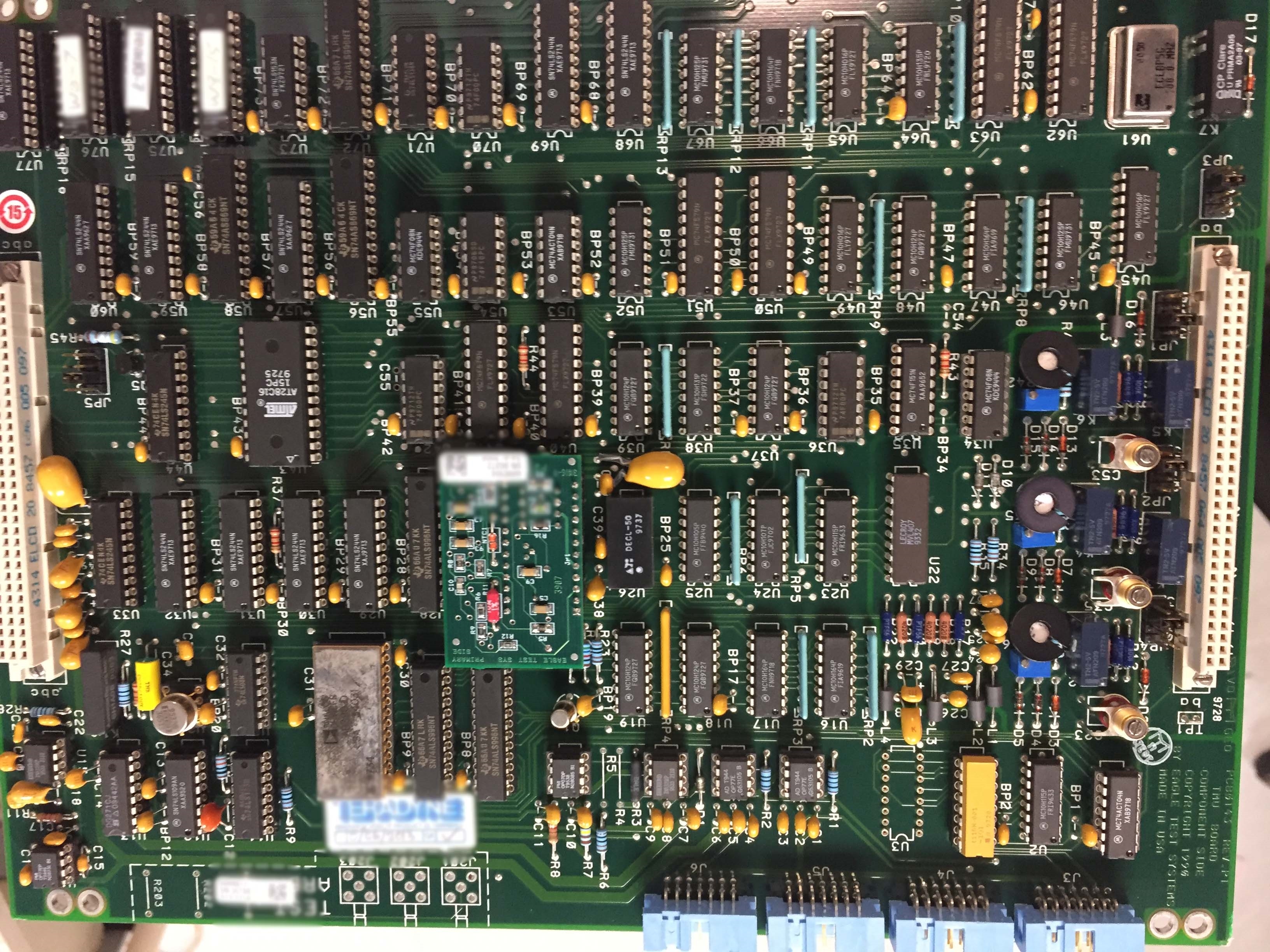

Slot 7: ASM 1686 / APU-8 Board

Slot 13: ASM 1686 / APU-8 Board

Slot 19: ASM 1686 / APU-8 Board

Slot 23: ASM 1725 / FSS2000 Board

Slot 25: ASM 2186 / APU-10 Board

Slot 29: ASM 1725 / FSS2000 Board

Slot 31: ASM 2186 / APU-10 Board

Diag and cal boards

(3) Spare boards:

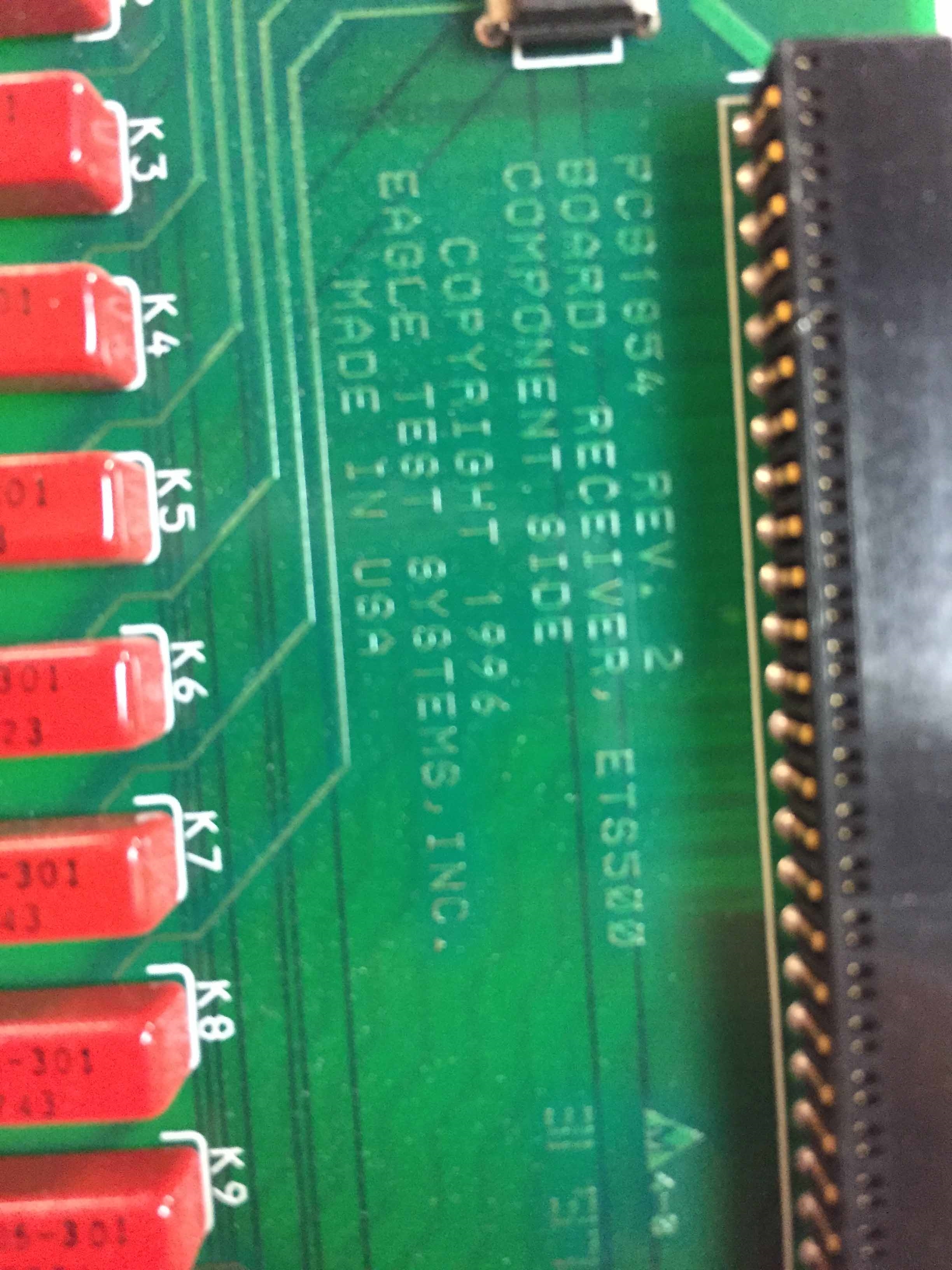

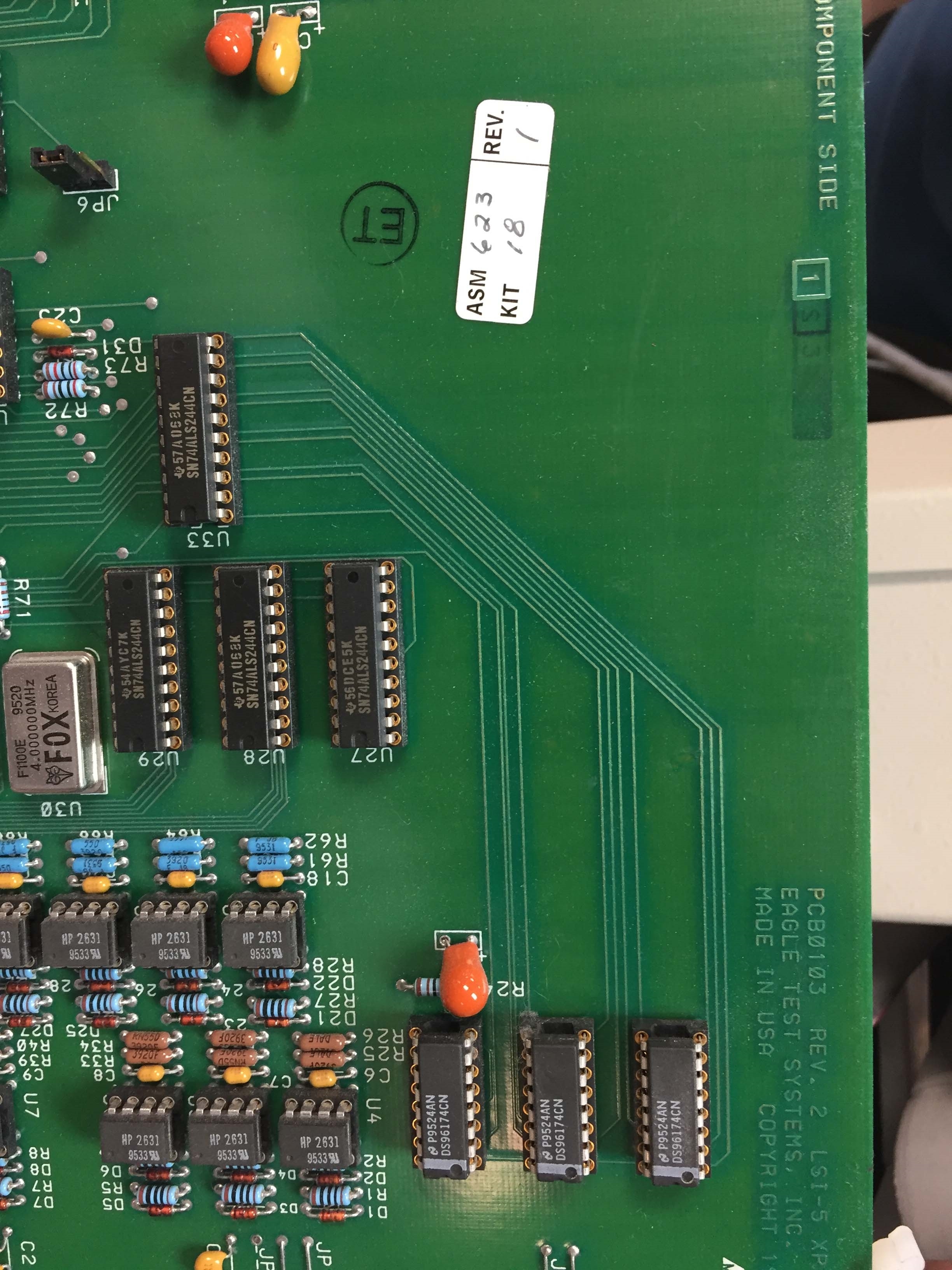

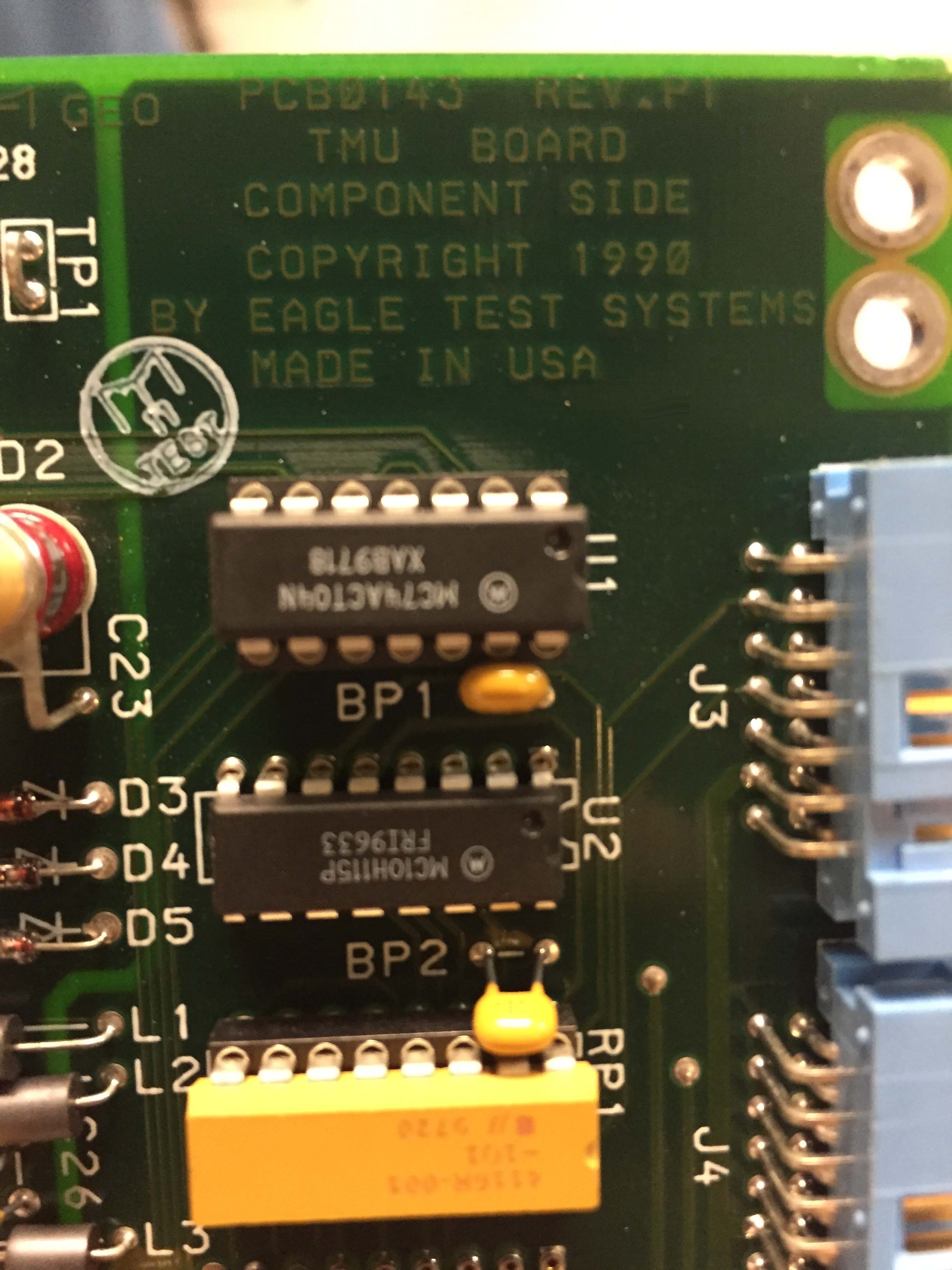

Spare board 1: ASM 0817 / TMU Board

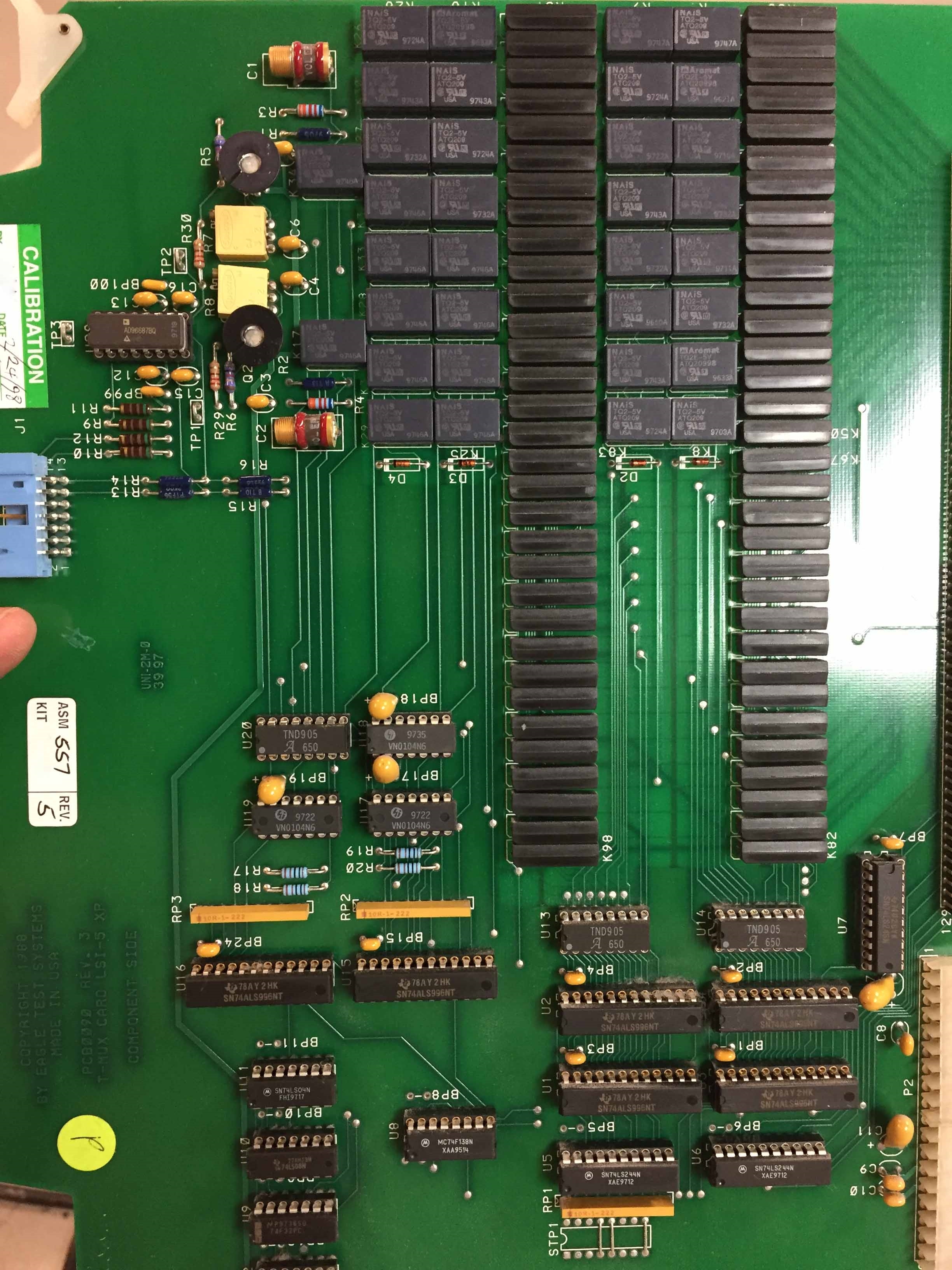

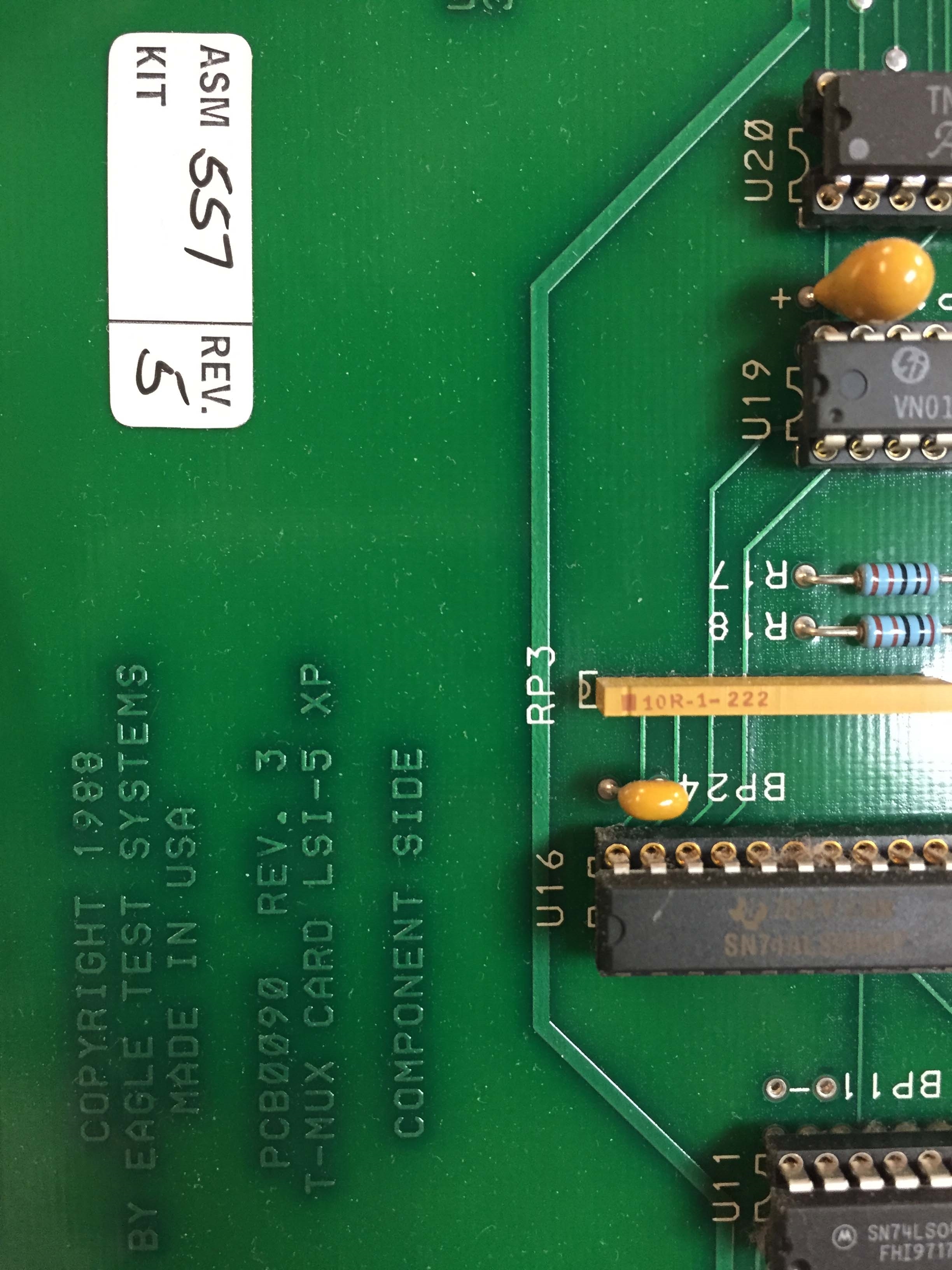

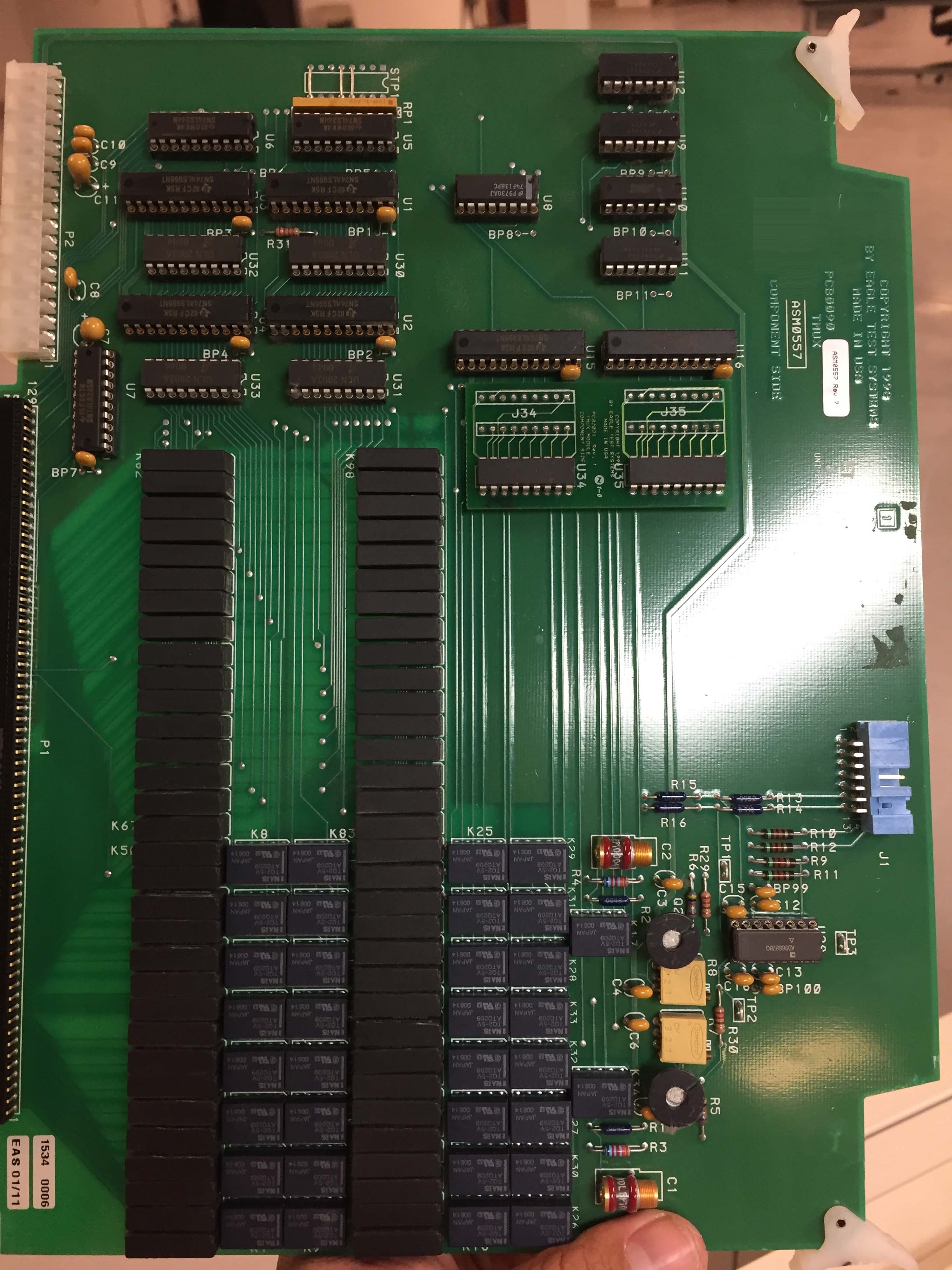

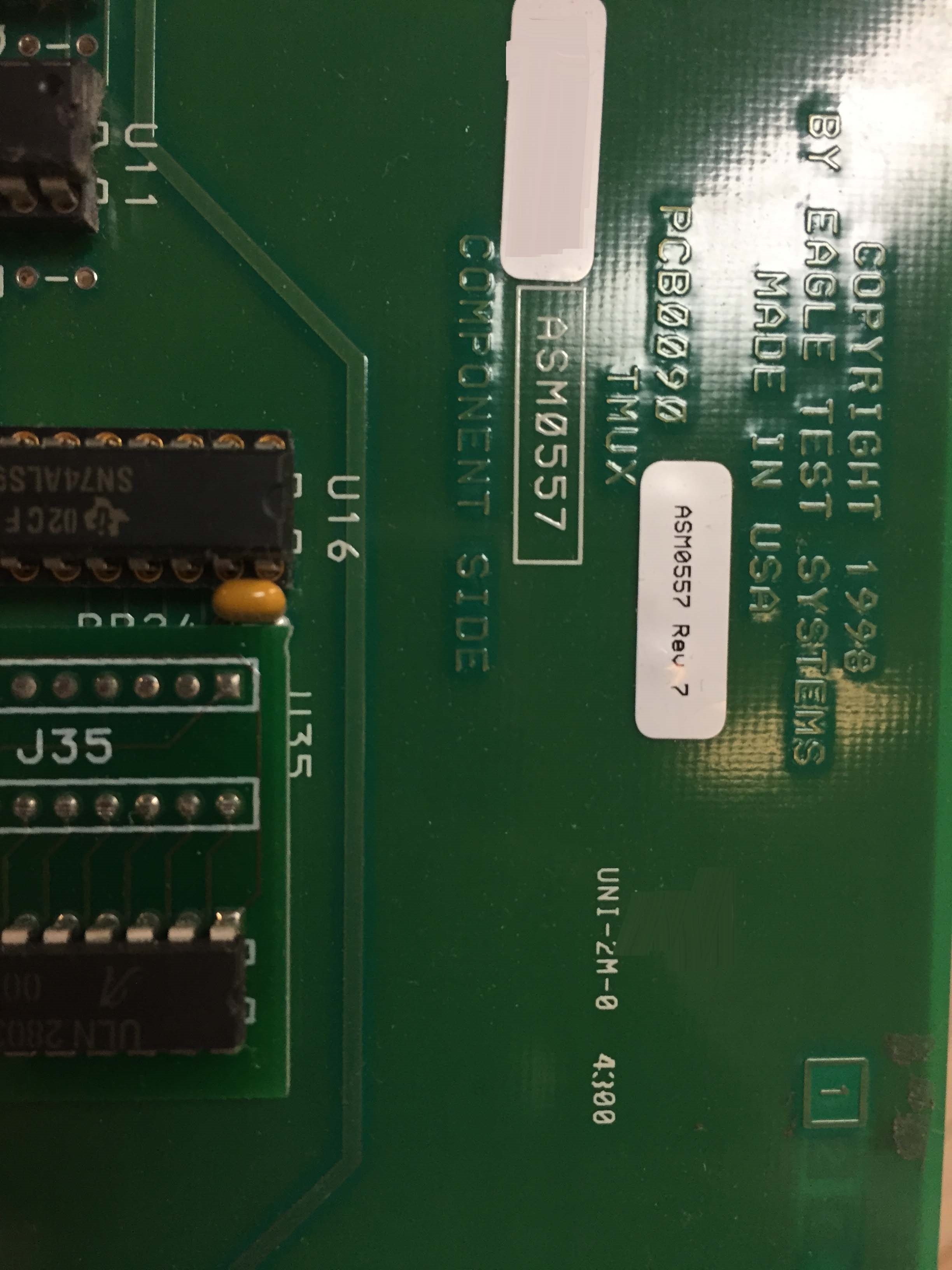

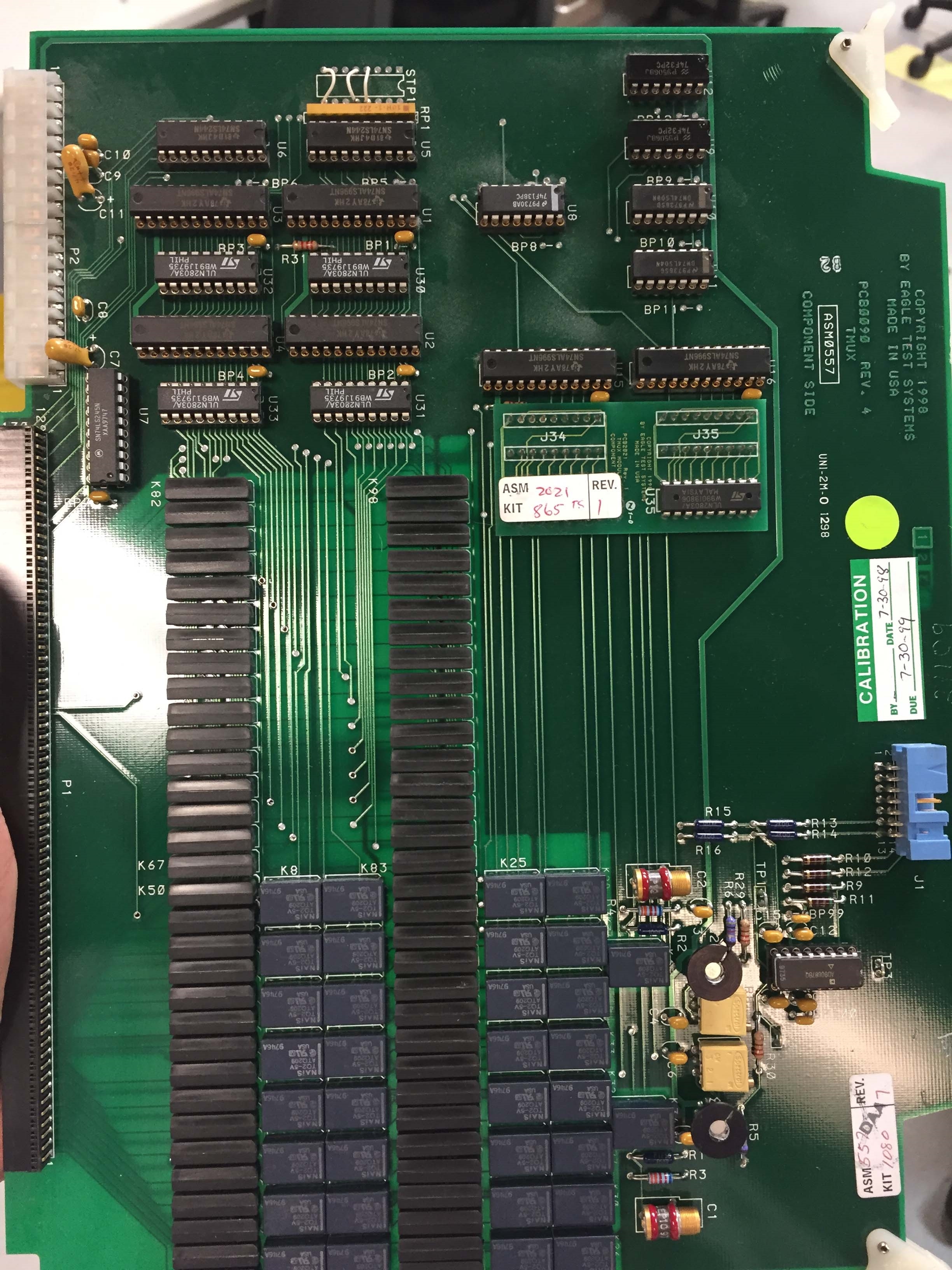

Spare board 2: ASM 0557 / TMUX Board

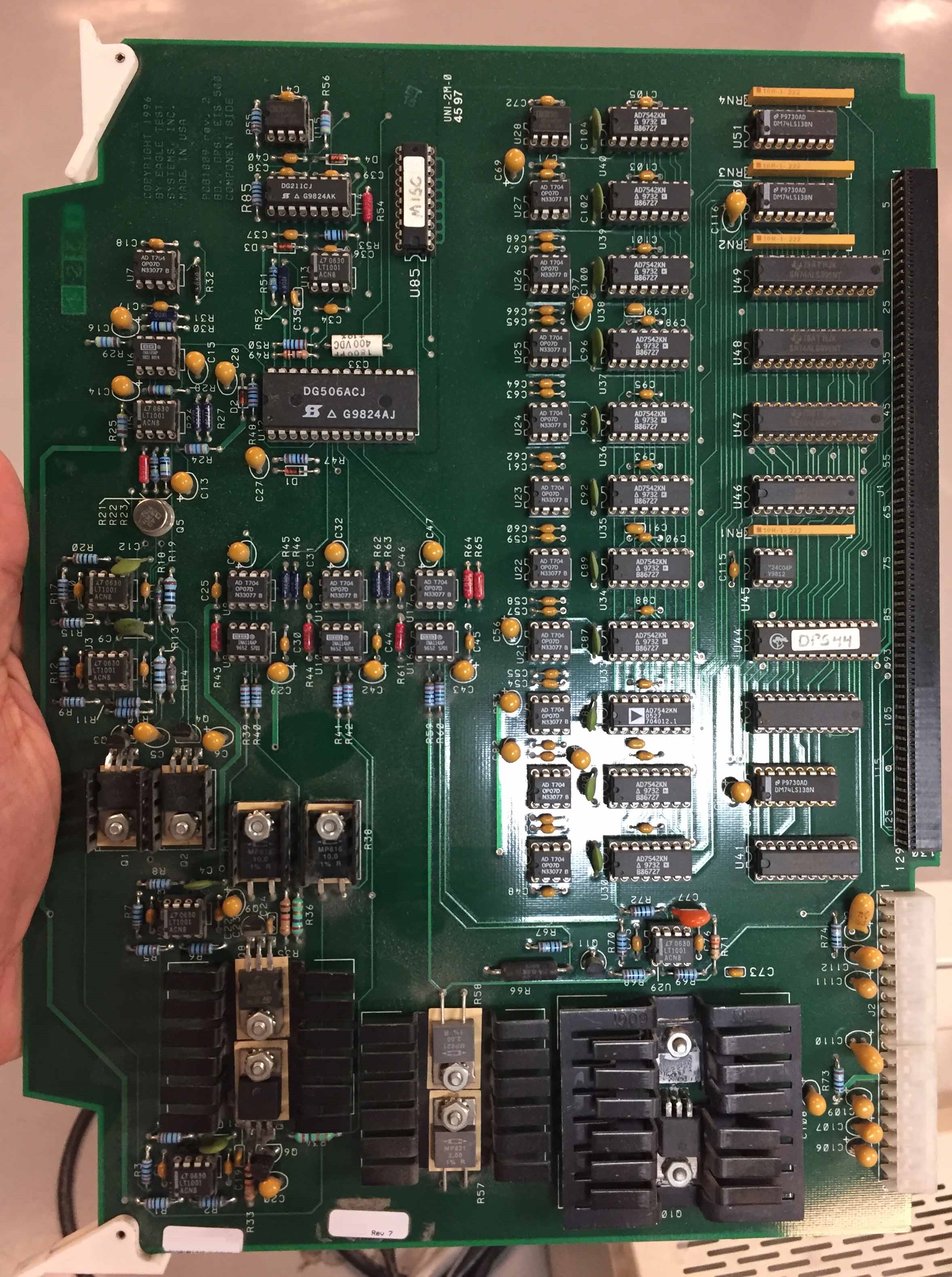

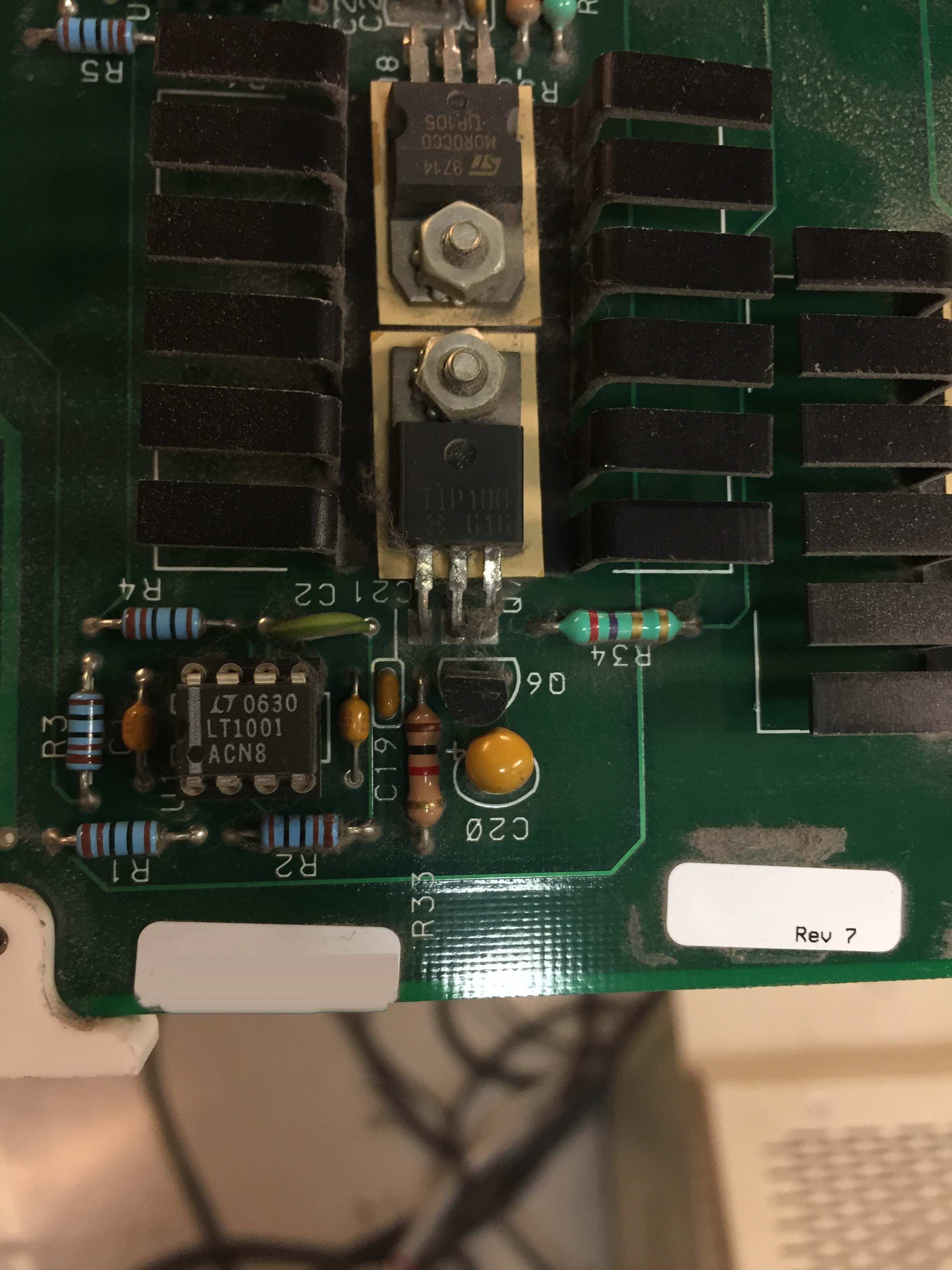

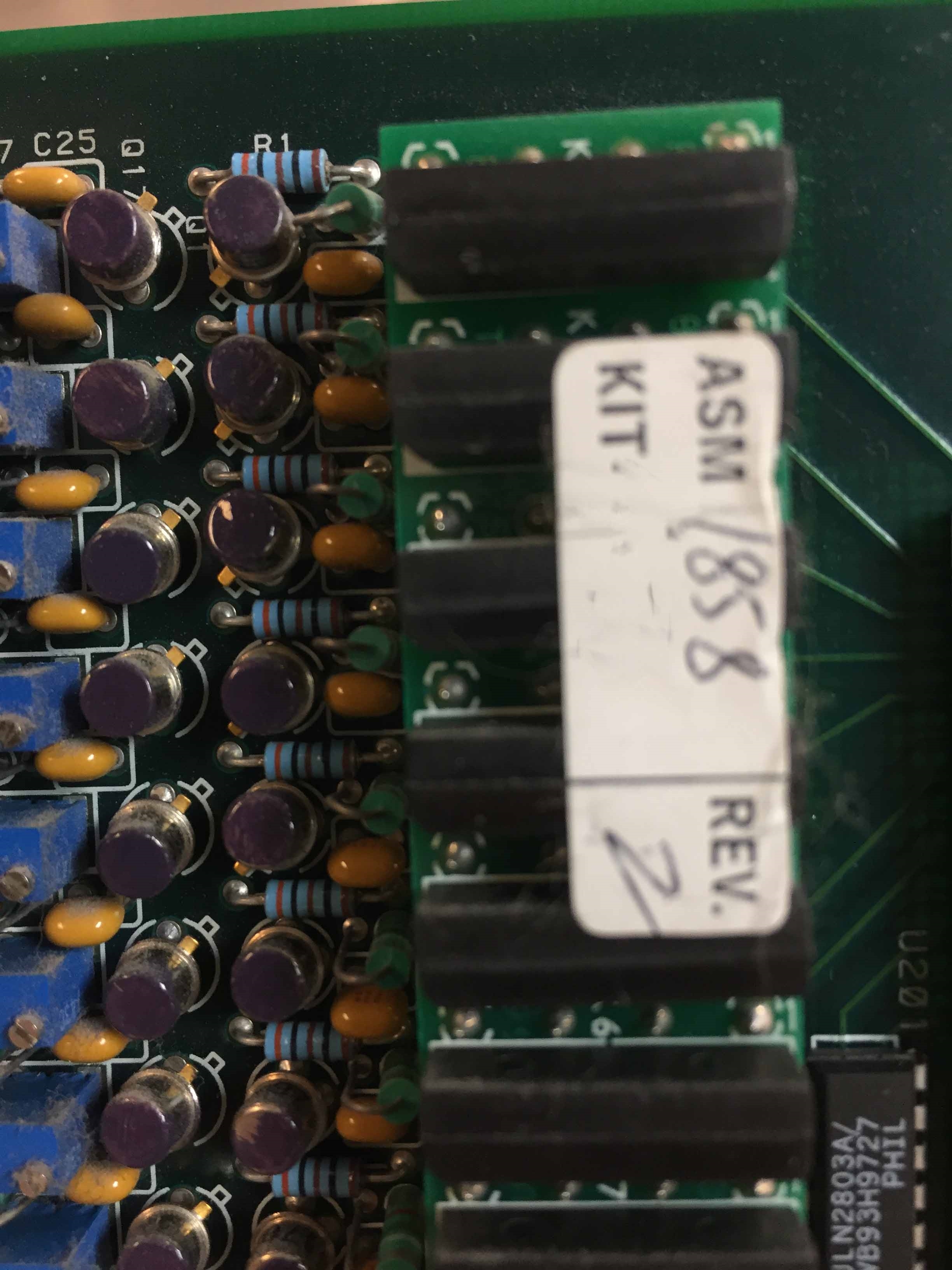

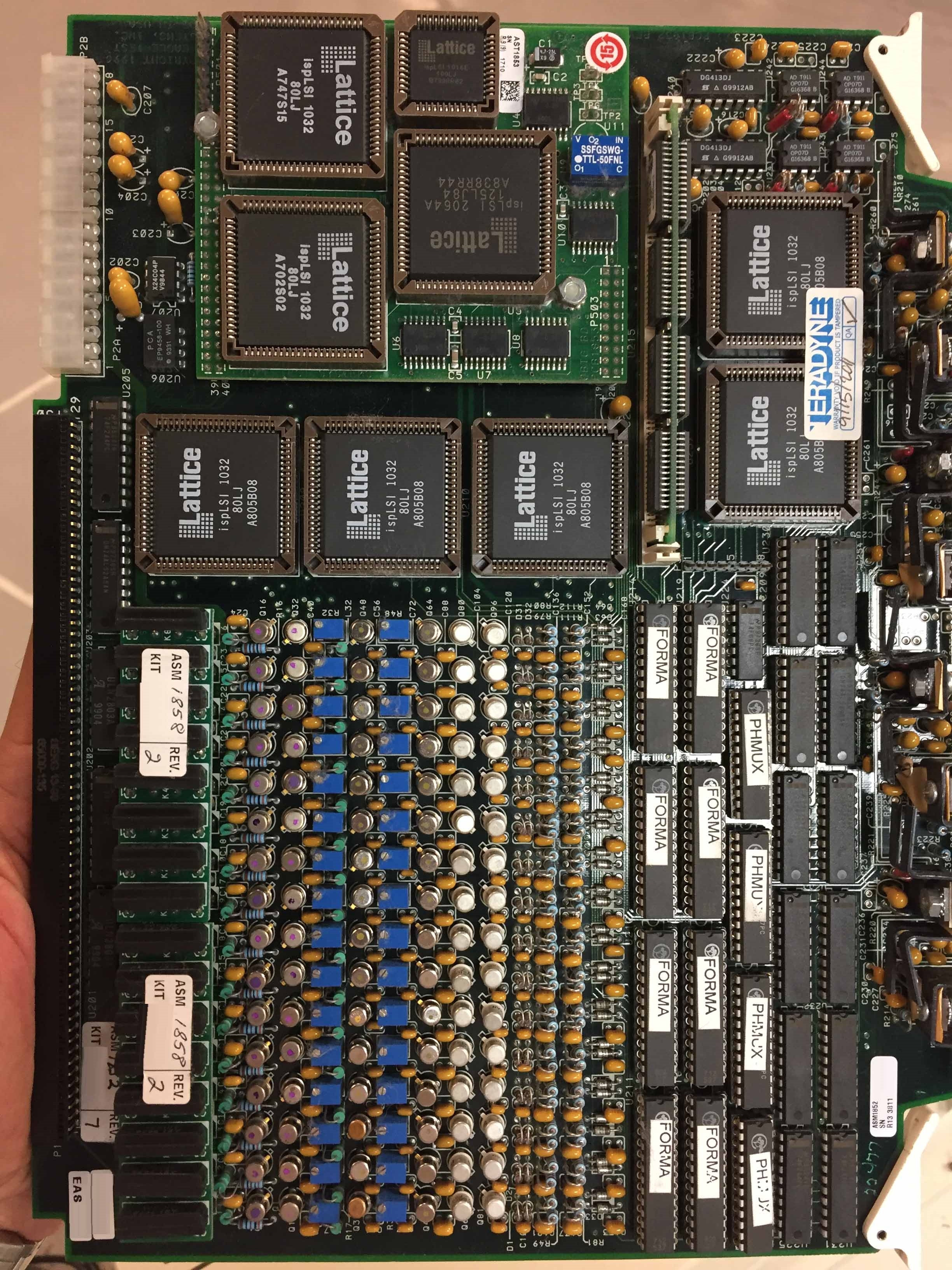

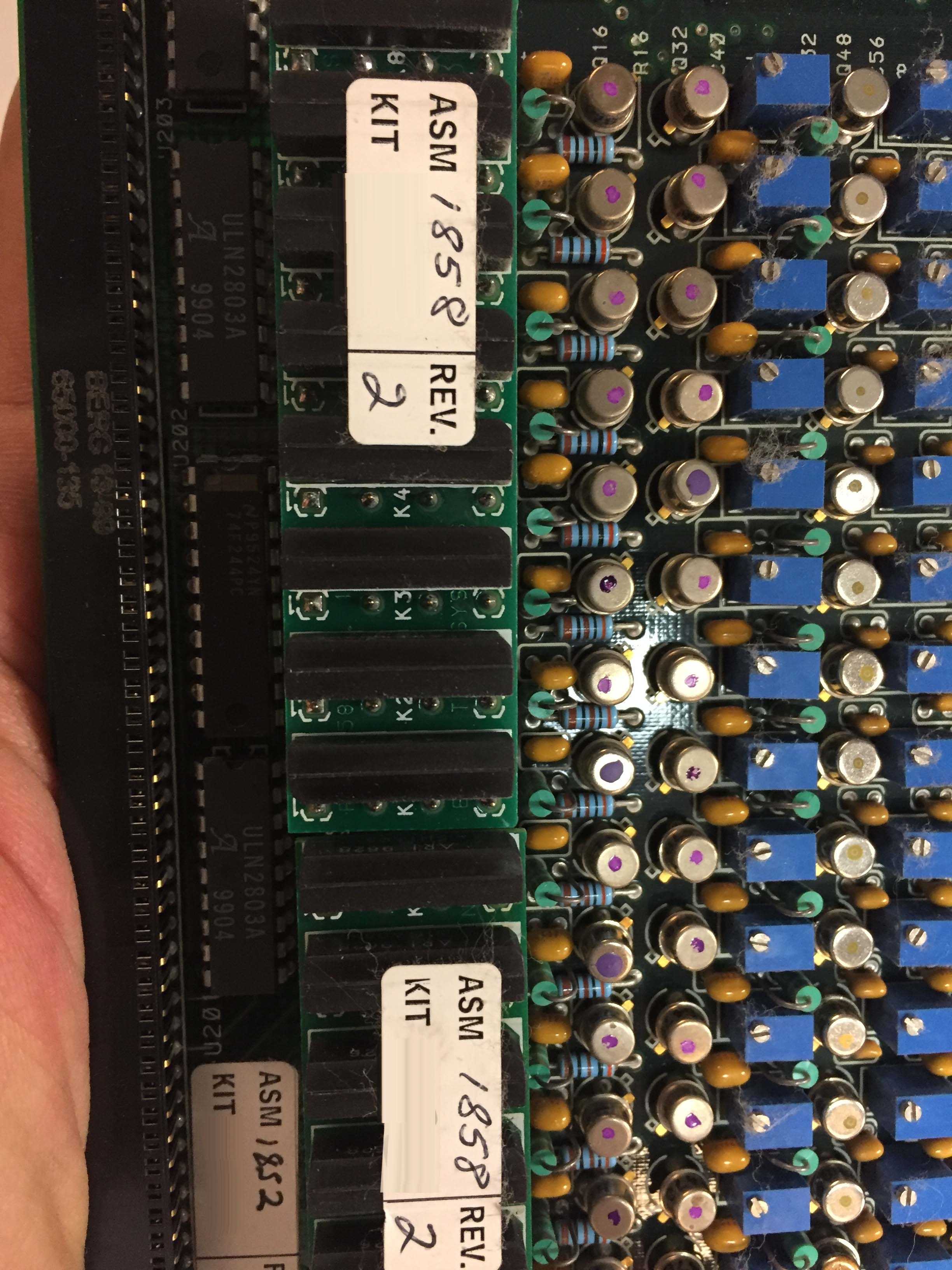

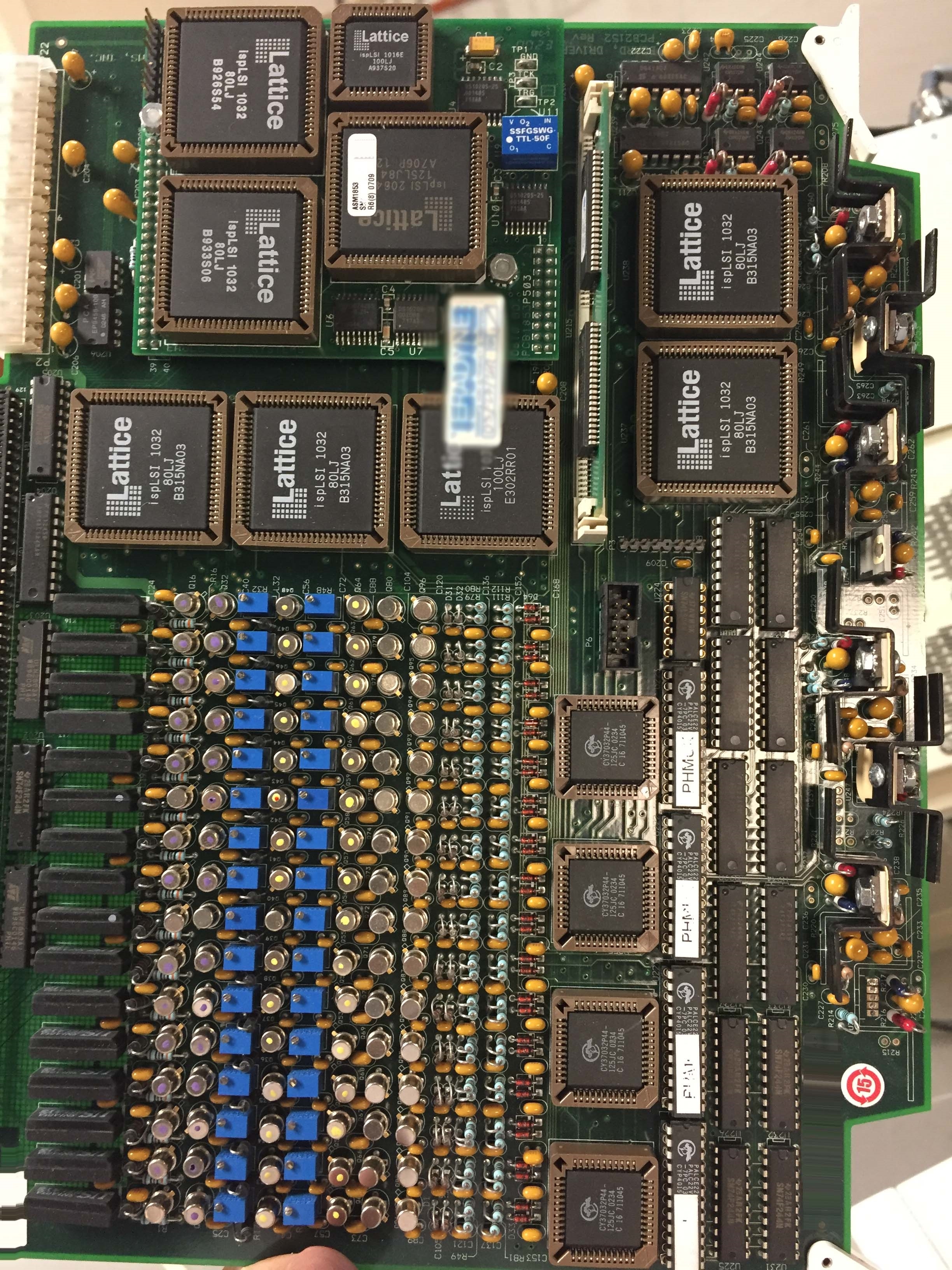

Spare board 3: ASM 1859 / Driver board.

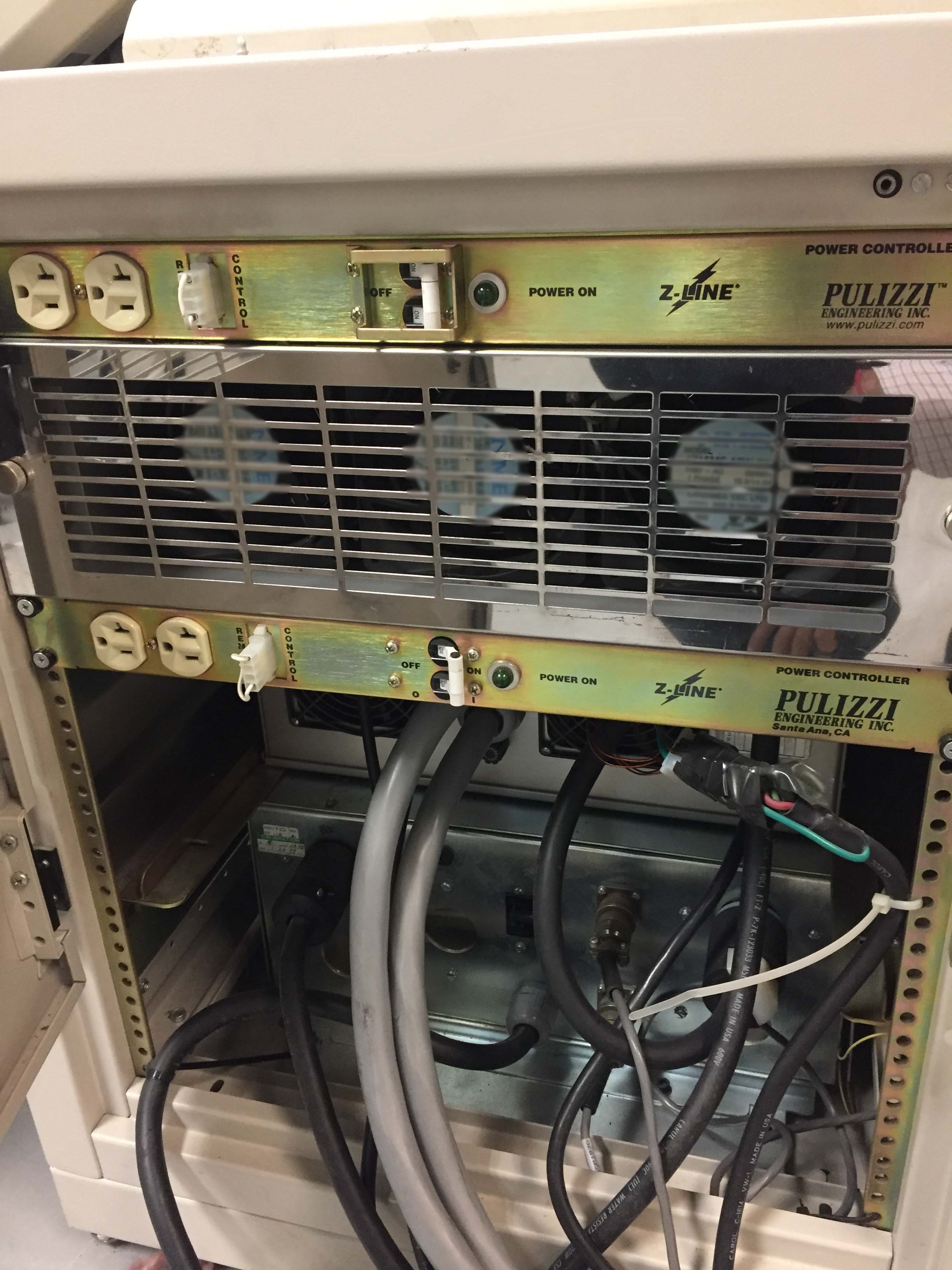

EAGLE ETS 500D/SS is a Final Test Equipment designed for use in the production of assembled printed circuit boards (PCBs). The system consists of a set of inter-related components including a high-speed Beam Height/Position Correction Unit, a multi-headed test handler, and a high-speed contact interface. The Beam Height/Position Correction Machine utilizes a set of sensors and digital image processing technology to accurately measure and adjust the height and position of the test probes relative to the components on the PCB. This ensures that the electrical connections between the probes and components are accurate and reliable during testing. The multi-headed test handler utilizes a vacuum to draw components onto the test bed, allowing them to be tested at multiple test sites simultaneously. This ensures that testing is carried out in a highly efficient manner. The multi-headed test handler is also equipped with a variety of automated features such as automatic component alignment. The high-speed contact interface is the interface between the Beam Height/Position Correction Tool and the multi-headed test handler. It is responsible for ensuring that the probes and components are properly aligned and positioned prior to testing. It also ensures that all the components are tested in an accurate and efficient manner. The ETS 500D/SS is designed to be compatible with a variety of test programs and test instruments. The asset is also capable of testing with a range of test probes and test boards. Additionally, the model has built-in software for error checking and diagnostic purposes to ensure accuracy and reliability. The equipment is designed to offer reliable and accurate performance in a variety of production environments. It is highly automated, offering a user-friendly interface and a wide range of testing features and capabilities. It is also capable of storing testing data, allowing for easy review and analysis. TERADYNE ETS 500D/SS is a high-quality, reliable final test system designed for the production of assembled PCBs. It offers accurate and efficient testing performance and is suitable for a variety of production requirements. In addition, it is capable of accommodating a variety of test programs and tests instruments. The ETS 500D/SS provides a reliable and cost-effective solution for PCB production requirements.

There are no reviews yet