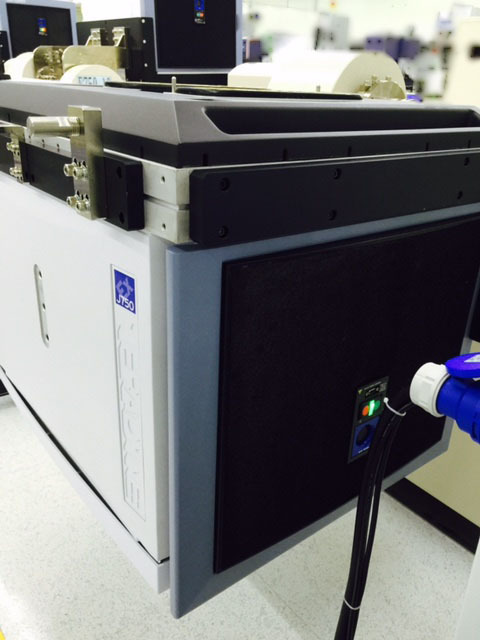

Used TERADYNE J750 EX #9112303 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9112303

Tester

512 Channels

(2) DPS

Vector memory: 16M

#slot[.subslot] Type idprom (type, revision)

-1 sli 239-624-00 1251-A

0 channel 239-700-04 1238-B

0 terminator 239-701-50 0838-A

1 channel 239-700-04 1419-B

1 terminator 239-701-50 0838-A

2 channel 239-700-04 1238-B

2 terminator 239-701-50 0838-A

3 channel 239-700-04 1238-B

3 terminator 239-701-50 0838-A

4 channel 239-700-04 1238-B

4 terminator 239-701-50 0838-A

5 channel 239-700-04 1049-B

5 terminator 239-701-50 0838-A

6 channel 239-700-04 1107-B

6 terminator 239-701-50 0838-A

7 channel 239-700-04 1142-B

7 terminator 239-701-50 0838-A

18 cub 239-020-09 1251-H

22 dps 239-016-06 0702-F

23 dps 239-016-03 0645-D

Not included: manipulator

Currently warehoused.

TERADYNE J750 EX is a powerful, high-performance final test equipment that enables quick and accurate test-data processing. Designed for high-volume production lines, this test system is capable of testing up to 75 million devices per hour, making it ideal for use in high-volume production operations such as semiconductor and automotive production lines. TERADYNE J750EX supports a variety of test programs and functions designed to handle a wide range of test scenarios. The unit is highly customizable, making it easy to tailor test programs to the precise requirements of the product being tested. Its on-board multi-site controllers, which are designed to precisely manage the scanning and probing tasks required for test execution, can be configured to serve up to 28 test heads. At the heart of the machine is its advanced algorithm control tool, which uses a variety of data to determine the most efficient way of testing each device. This asset offers an integrated design including in-circuit and functional test capability, plus built-in streaming data manipulation and analysis features. This model also features advanced fault diagnosis, with data streaming to store user-defined fault information. The equipment also includes a variety of hardware technologies such as microlithography, digital x-rays, and three-dimensional pattern recognition to ensure quick test completion. It utilizes a wide array of RF and signal-compression technologies to ensure rapid system operation. The unit also features a range of robotic and conveyor systems to ensure efficient handling and testing of products. Furthermore, J 750 EX is equipped with real-time data analysis capabilities to identify flaws and detect potential failures in the tested components. It includes a user-friendly graphical user interface and can be integrated with a variety of software applications such as Visual Basic, LabVIEW, and Java. This machine can be used with a wide range of robotic systems as well as a variety of third-party instruments. In summary, J750EX is a powerful and customizable test tool designed to handle high-volume production operations. It includes advanced hardware and software technologies, real-time data analysis capabilities, customizable test programs, and user-friendly graphical user interface. With its automation capabilities, it is capable of rapidly testing even the most complex components, thus ensuring the highest quality in the final product.

There are no reviews yet