Used TERADYNE MicroFlex #9285493 for sale

URL successfully copied!

Tap to zoom

ID: 9285493

Vintage: 2006

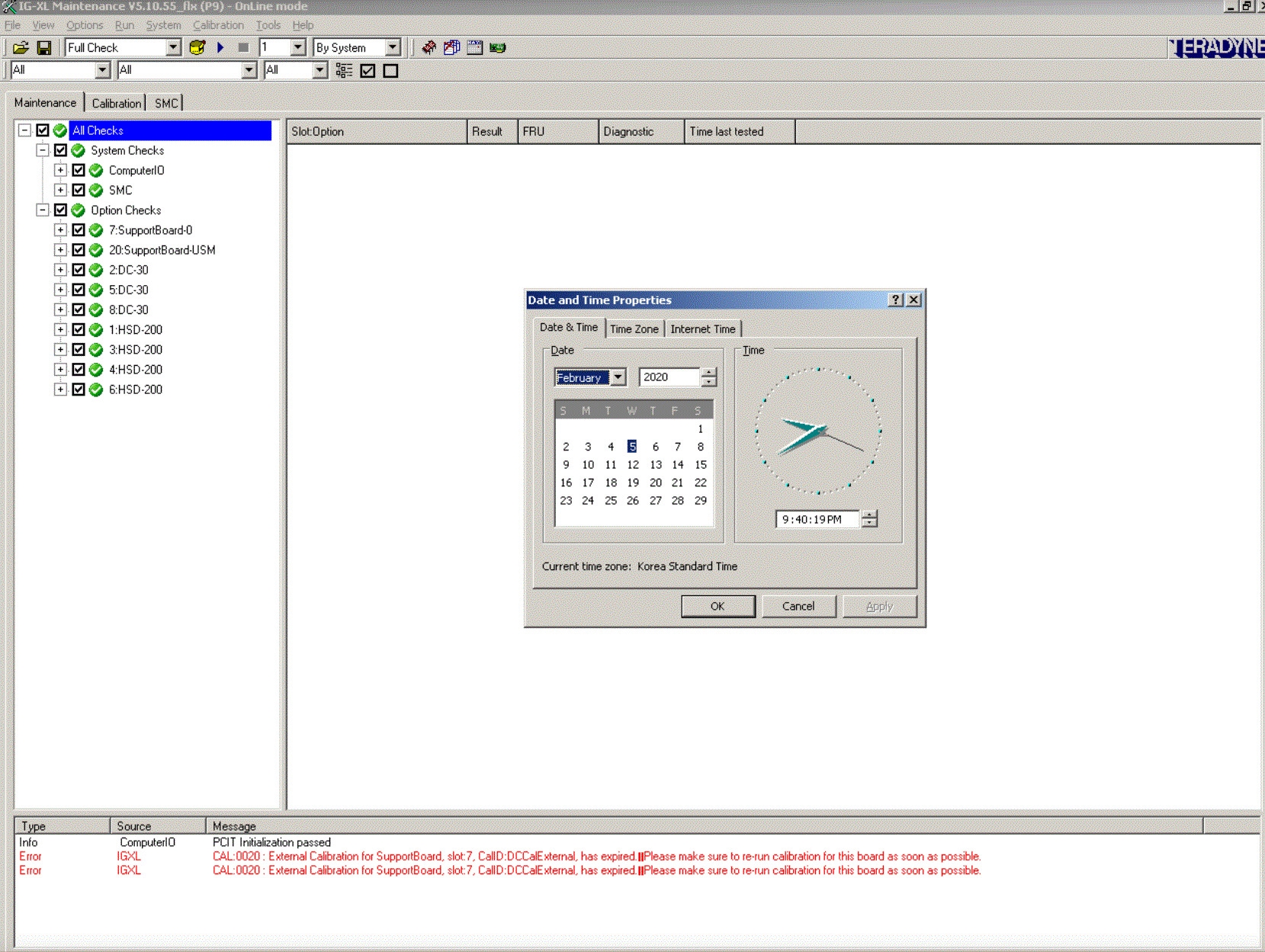

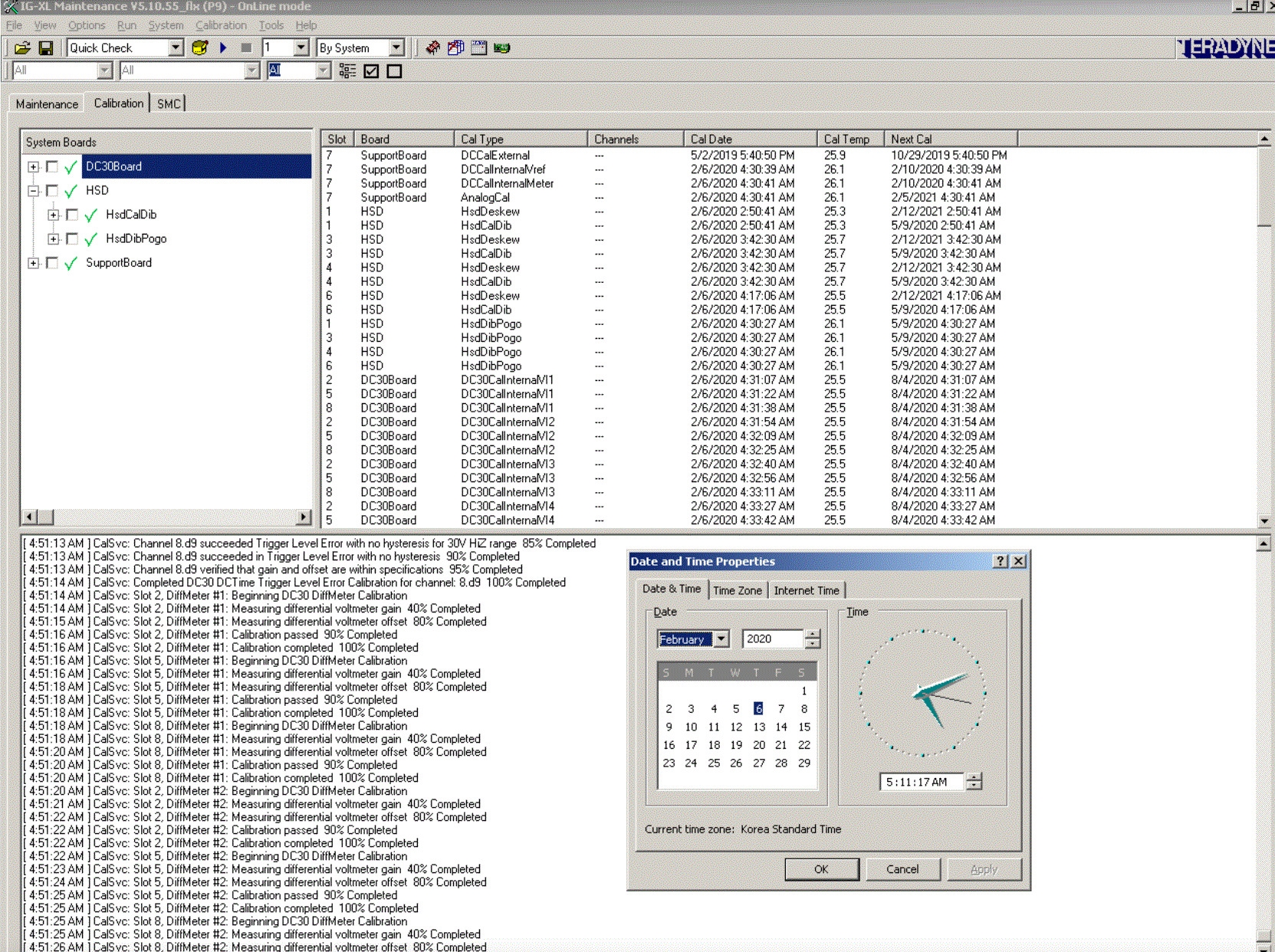

Tester

(2-4) HSD200

(2) DC75

XW8400

RF Cabinet

MICROHANDLING Manipulator

2006 vintage.

TERADYNE MicroFlex is a brand of final test equipment designed for the manufacturing and assembly of circuit boards and other electronic devices. The system is made up of several components, ranging from software to hardware, that work as a comprehensive test platform to conduct electrical, mechanical, and thermal tests on printed circuit boards and verify the performance of each component. The unit is equipped with a Connector Test Processor that identifies and tests connector pins, ensuring they are free of shorts and opens. It also detects faulty parts and identifies components that need to be replaced. The processor is connected to the control panel, which provides control over test parameters and the execution of tests. The panel is also able to provide an audit trail of the results of each test. In order to properly test boards, the machine is equipped with a functional test module. The module performs tests to ensure that circuits are functioning as expected. It is able to detect failures in components, analyze data, and send out diagnostic information to be used for further analysis. Additionally, the functional test module is a component of the tool that can be upgraded to run faster tests with better accuracy. The asset is also outfitted with an automated vision model that inspects boards to ensure they meet the required design specif ications. The vision equipment uses an algorithm to analyze images of the circuit boards and detect any defects that may result in failure. The system is also equipped with a probe test unit that is designed to detect faults and ensure that circuits are functioning as expected by verifying the electrical continuity of the contacts. Finally, an Ethernet testing module is employed to verify that the board is communicating properly with the outside world. To conclude, MicroFlex is a complete and comprehensive final test machine for verifying the performance of circuit boards. It is able to detect and analyze faults in components, visually inspect boards for design defects, and verify that the communication interface between boards and external networks is functioning correctly. As a result, manufacturers and assemblers can be assured that their products are functioning to their highest quality and reliability.

There are no reviews yet