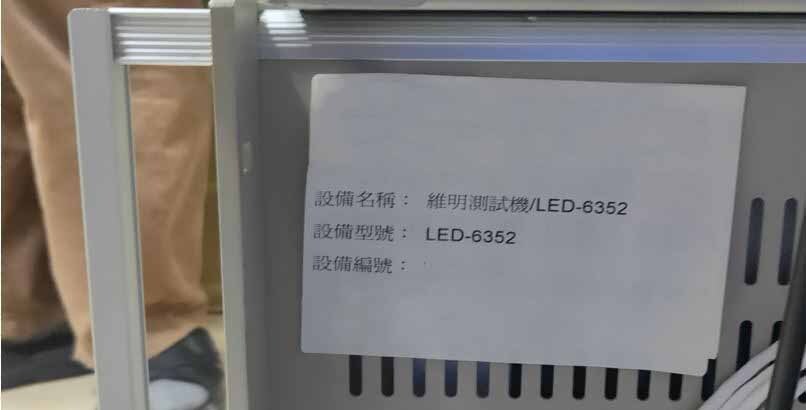

Used WEI MIN INDUSTRIAL LED-6352 #293604402 for sale

URL successfully copied!

Tap to zoom

WEI MIN INDUSTRIAL LED-6352 is a comprehensive final test equipment developed by WEI MIN INDUSTRIAL that is designed for inspections and analysis of linear LED strips for defects and other points of quality control. This system is comprised of three main components: a vision unit, a data recording and analysis machine and a automation control tool. The vision asset of LED-6352 model is designed to detect defects and variations in LED strips including problems such as missing LEDs, burned out LEDs, incorrect colors, and incorrect space between LEDs. This equipment works by using a special purpose high speed CMOS camera with a 7x zoom that captures the images of the LED strips at a rate of 6 million images per second. After the images are captured they are analyzed by a special software that can detect any discrepancies in the LED stock so that they can be addressed. The data recording and analysis system is able to track the LED strip process from start to finish, providing accurate and in-depth reports that can be used for quality control and evaluation. This unit collects data such as the total number of LED strips, the average current drawn by each LED strip, and the average luminous flux. This machine is also very helpful for reviewing the overall production process, as it gives an overview of which batches were successful and any other areas where improvement is needed. Finally, the automation control tool is responsible for controlling the robotic arms and other automated mechanisms used in the LED strip manufacturing process. This asset can be programmed to execute tasks such as extracting the LED strips from the substrate, mounting them to the wiring board, and then to the product outfeed. The automation control model can also be programmed to check and ensure that all components in the LED strip process meet our high standards of quality control. In conclusion, WEI MIN INDUSTRIAL LED-6352 equipment is a comprehensive final test system designed for high level inspections and analysis of LED strips and other components. This unit is comprised of three main components, a vision machine, a data analysis tool, and an automation control asset. All three components are able to detect defects, discrepancies and other points of quality control in the LED strip production process so that problems can be quickly and efficiently rectified.

There are no reviews yet