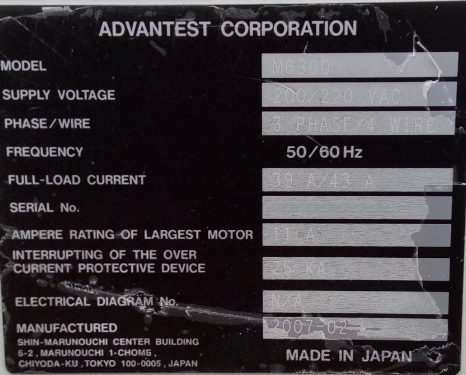

Used ADVANTEST M 6300 #293636445 for sale

URL successfully copied!

Tap to zoom

ADVANTEST M 6300 is a high performance handler specifically designed for the testing of a variety of devices, including radio frequency integrated circuit chips, optoelectronic sensors, and wireless semiconductor devices. The handler is equipped with a variety of features to optimize test throughput and maximize the reliability of tested devices. ADVANTEST M6300 utilizes vacuum-chuck technology to ensure reliable device mounting and contact during the test process. Device contacts are formed by a precisely controlled vacuum chuck, providing 360º coverage of the device edges. The handler is equipped with a conveyor belt that transports devices of different sizes between different test stations or load positions, while maintaining precise and repeatable orientation of each device during transport. M 6300 features a pick-up capability of up to 65mm by 65mm and separate test media handling and testing functions, allowing it to accommodate a variety of test media. In addition, the handler includes an advanced and customizable software suite, allowing users to create and customize different test programs for different test media and device configurations. Through the software, users can define test and measurement parameters and access real-time statistical data related to test throughput and quality. M6300 is outfitted with an optical recognition equipment that minimizes test mis-alignment and prevents mistakenly loading the wrong device into a test position. The system's vision-recognition accuracy is reliable even with nonstandard device shapes and sizes. The handler also includes an automated cleaning unit for optimized test accuracy and repeatability. The machine is specifically designed to reduce the amount of time and resources required to conduct thorough cleanups, as well as minimizing test media cross-contamination and misalignment. ADVANTEST M 6300 is designed with safety features to ensure reliable, efficient, and safe operation. The tool features a built-in safety interlock that prevents unexpected operation when certain conditions are not met, such as a missing device. In addition, the safety interlock requires continued operator input before the handler can start. The handler also includes visual and audible alarms to alert the operator in the event of an error. This ensures that the operator can quickly identify and address any problems before the test process begins.

There are no reviews yet