Used ADVANTEST M 6741A #293648415 for sale

URL successfully copied!

Tap to zoom

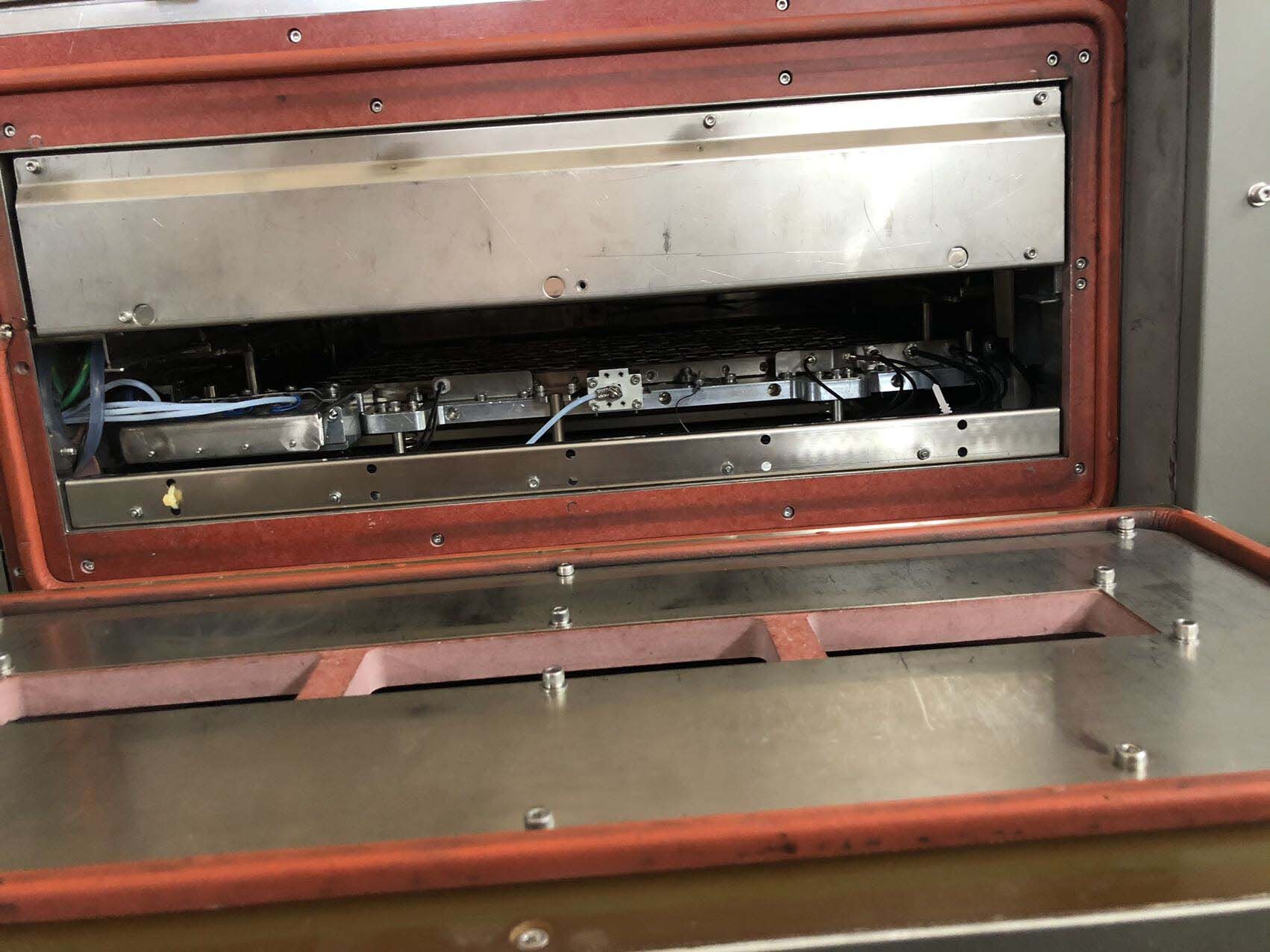

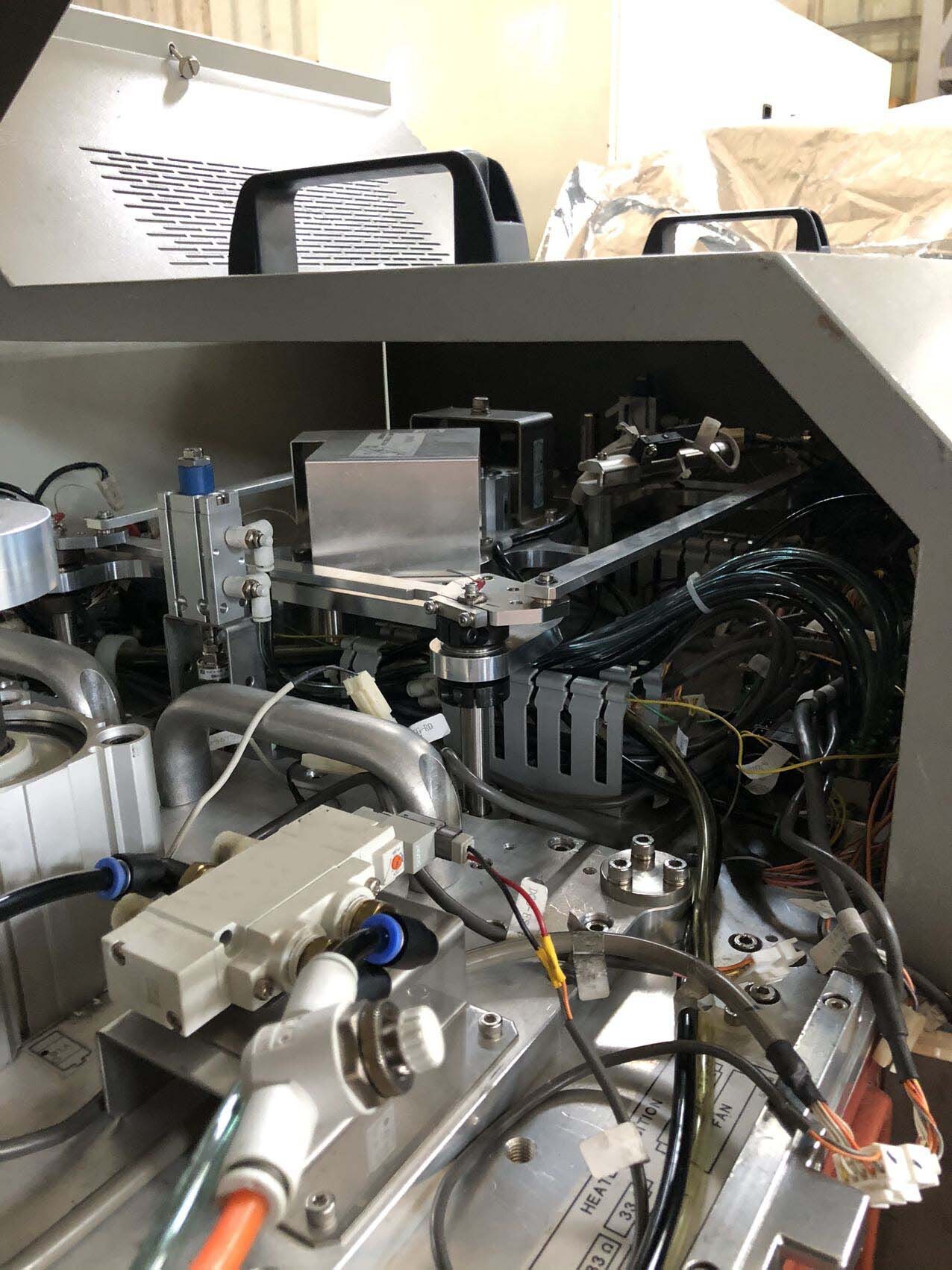

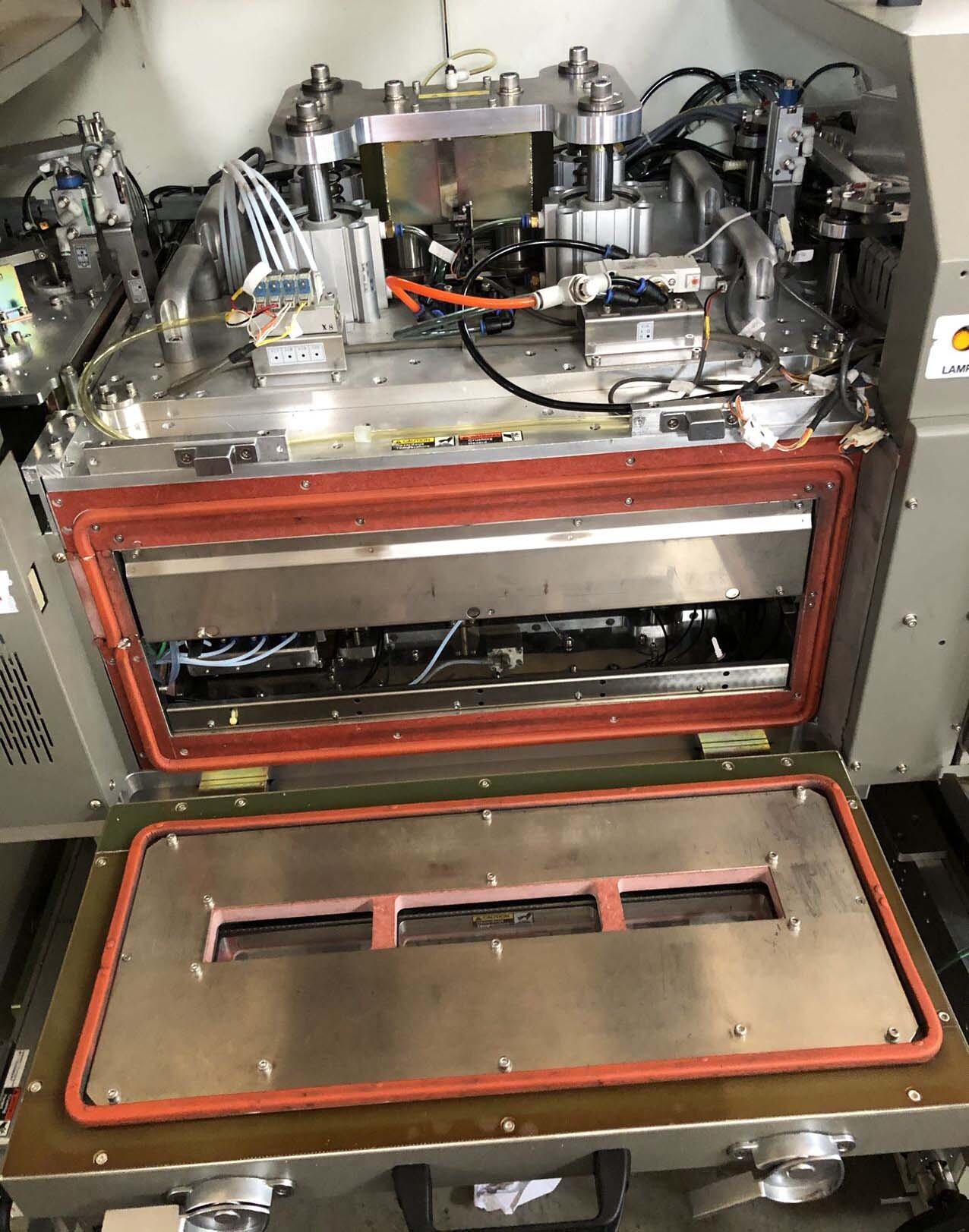

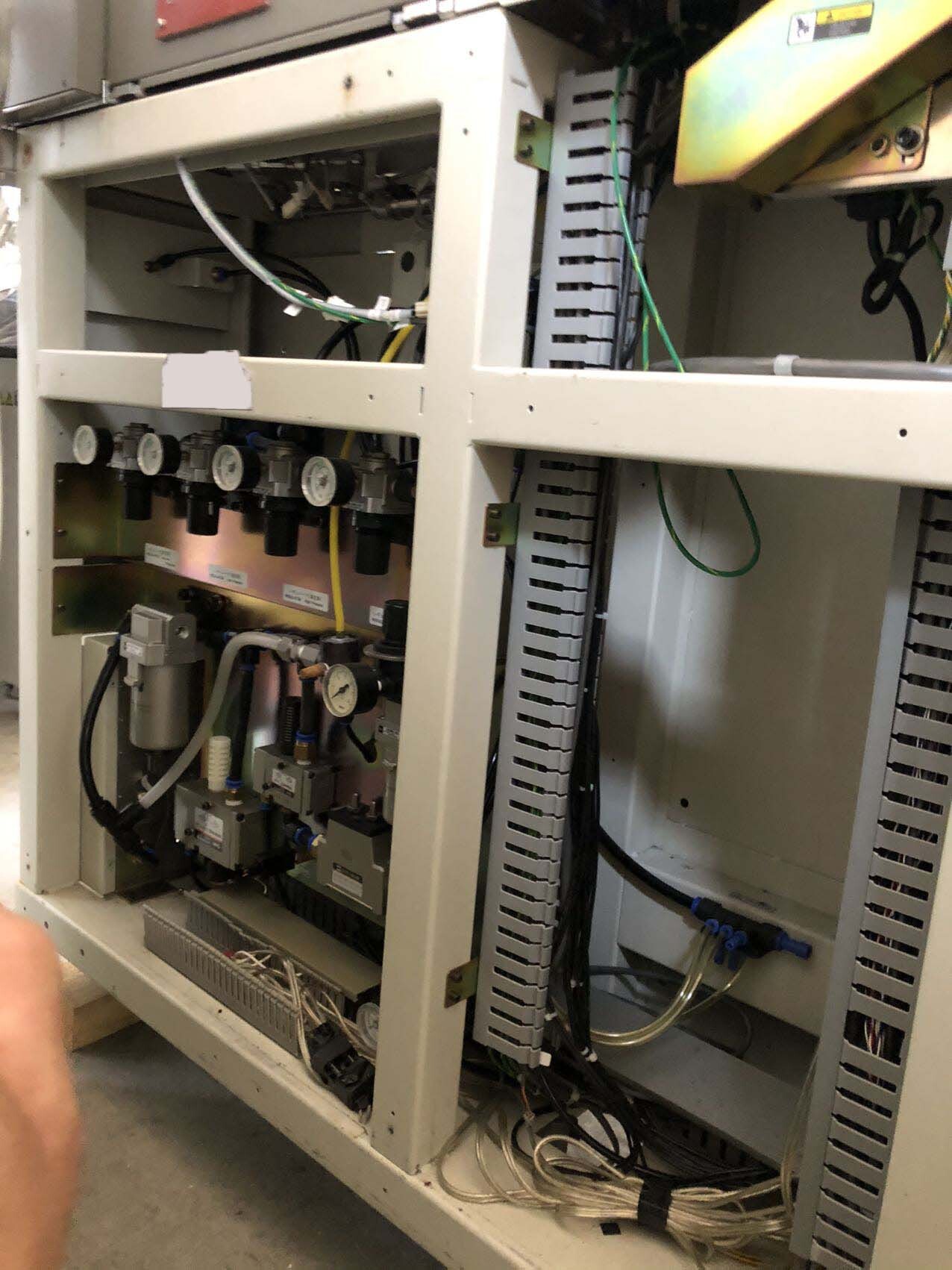

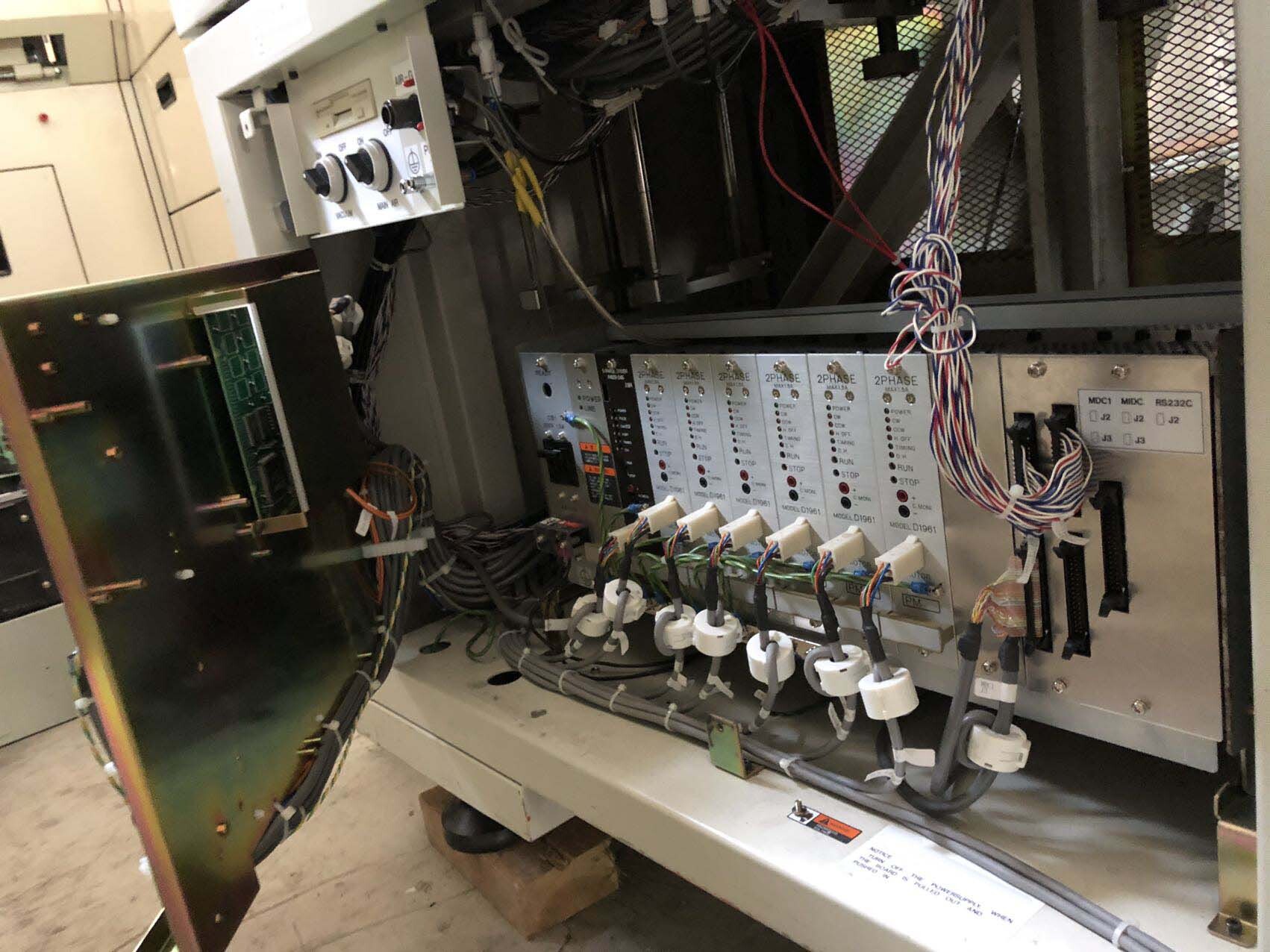

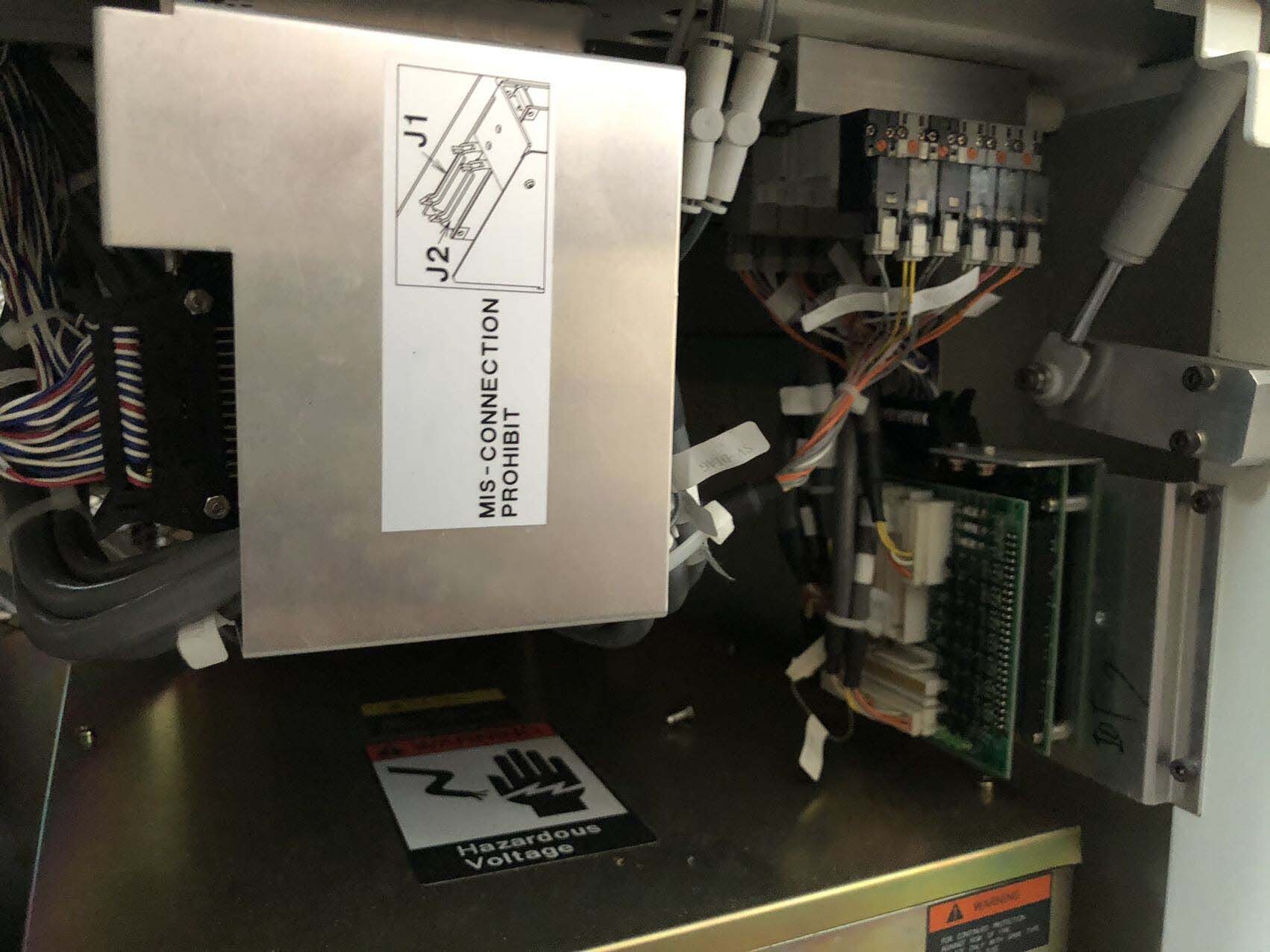

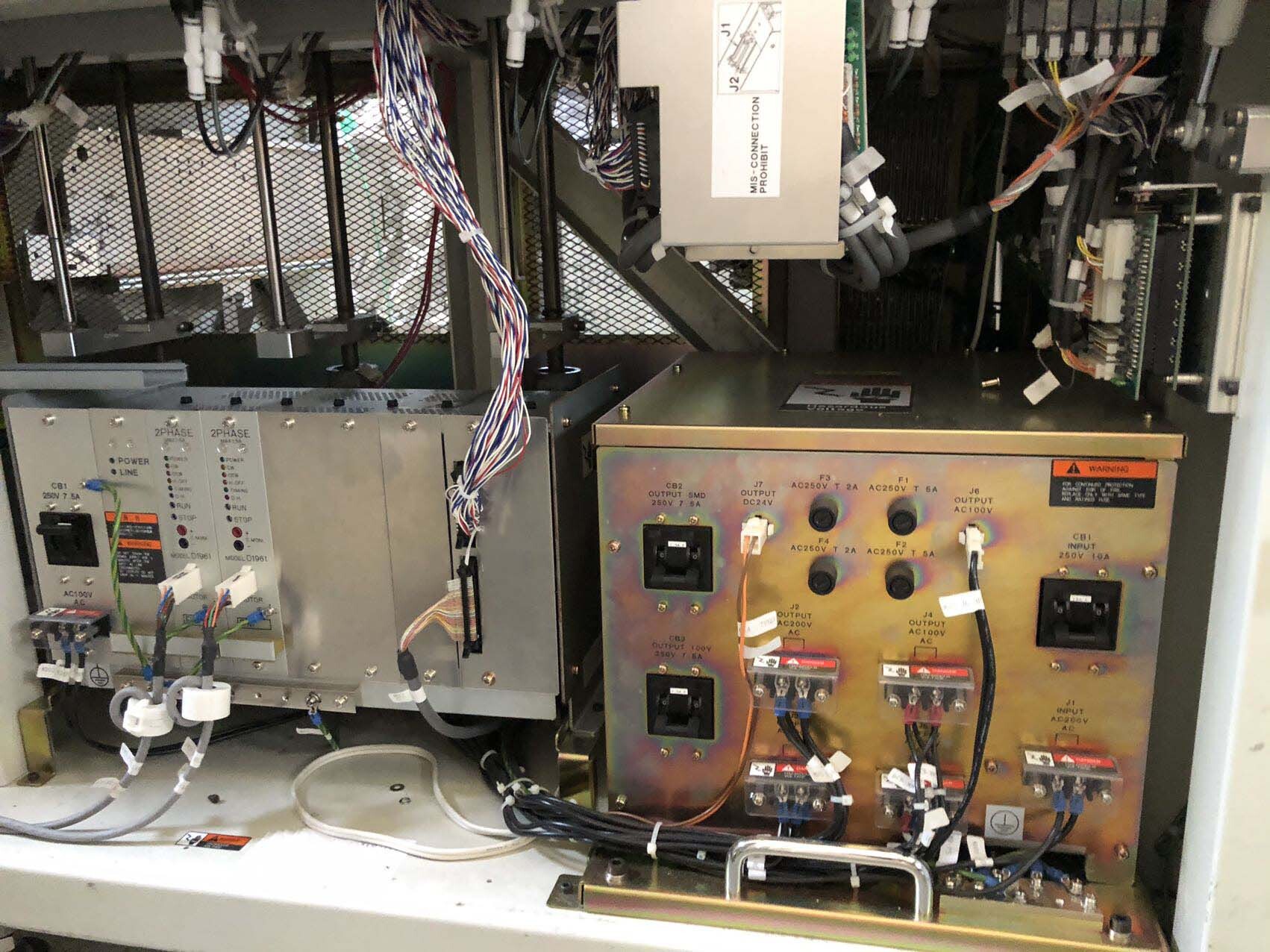

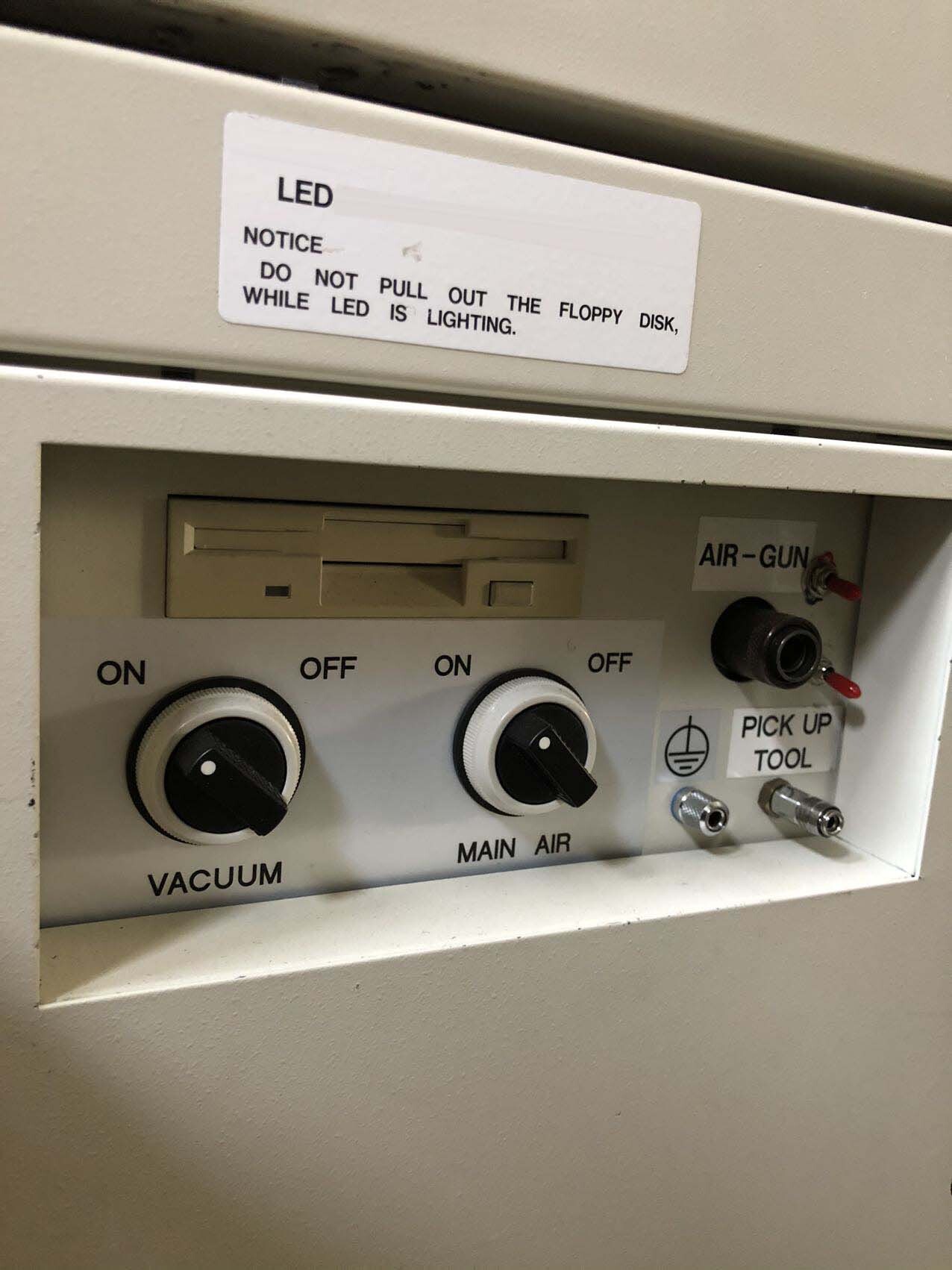

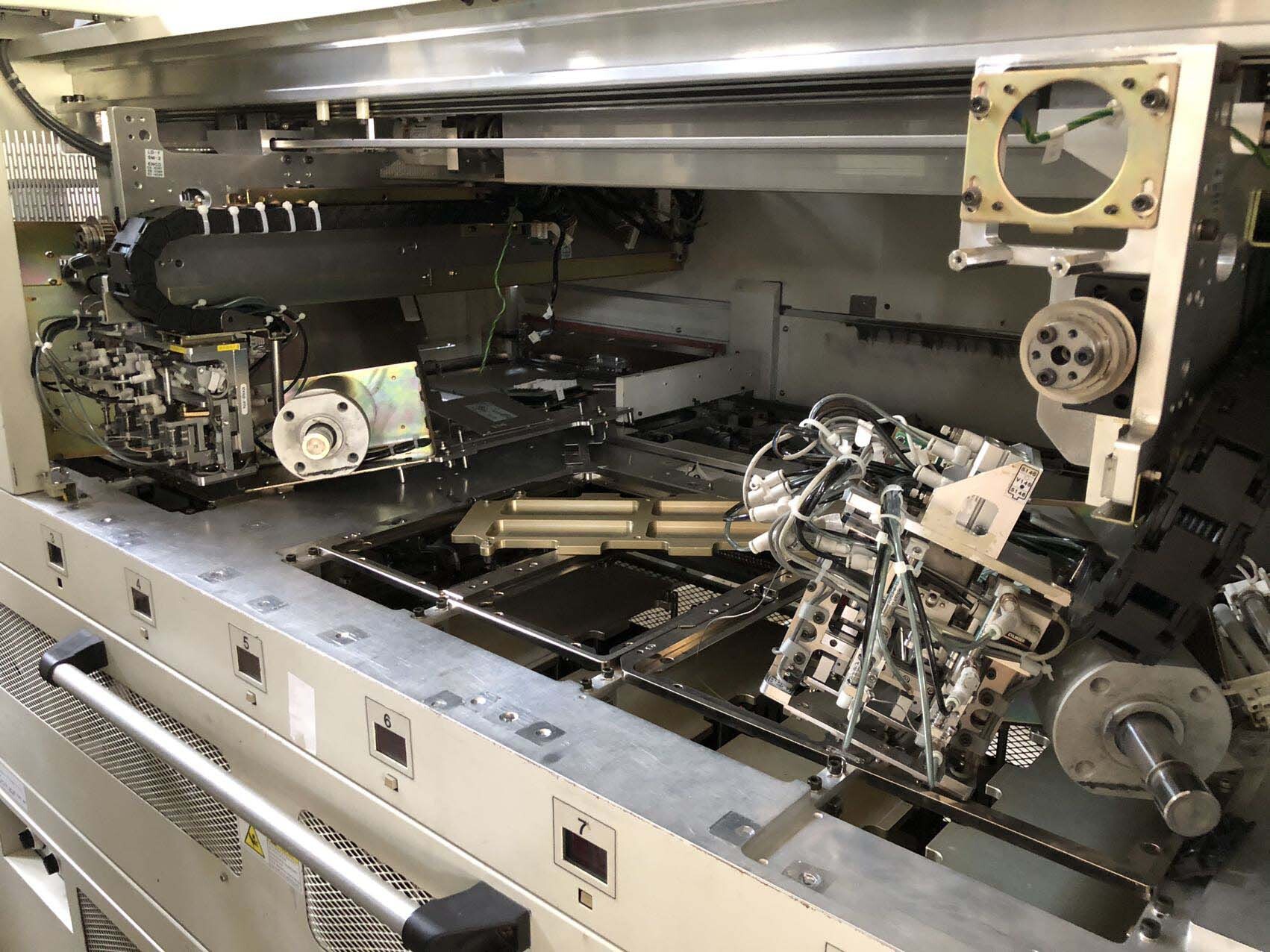

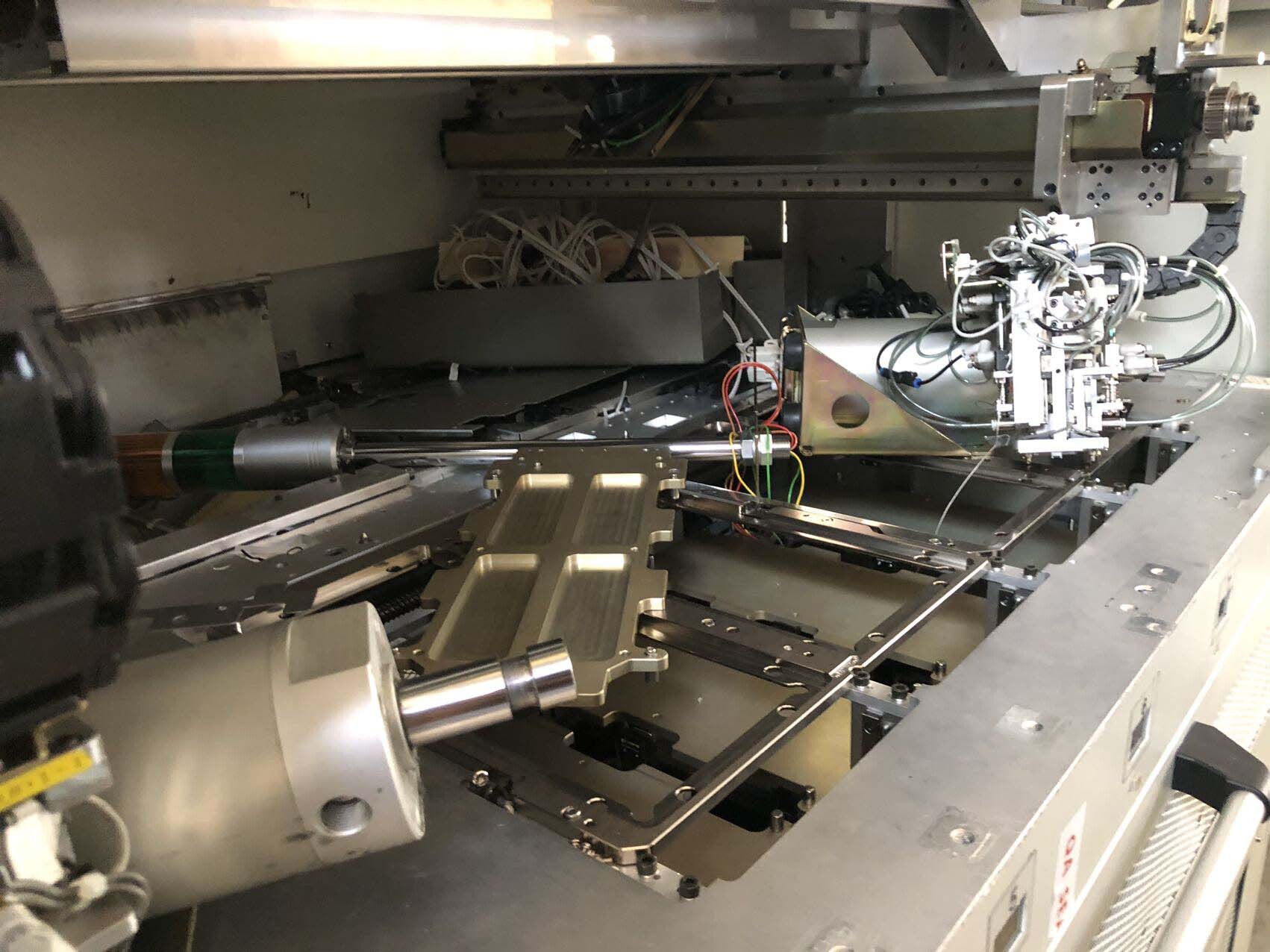

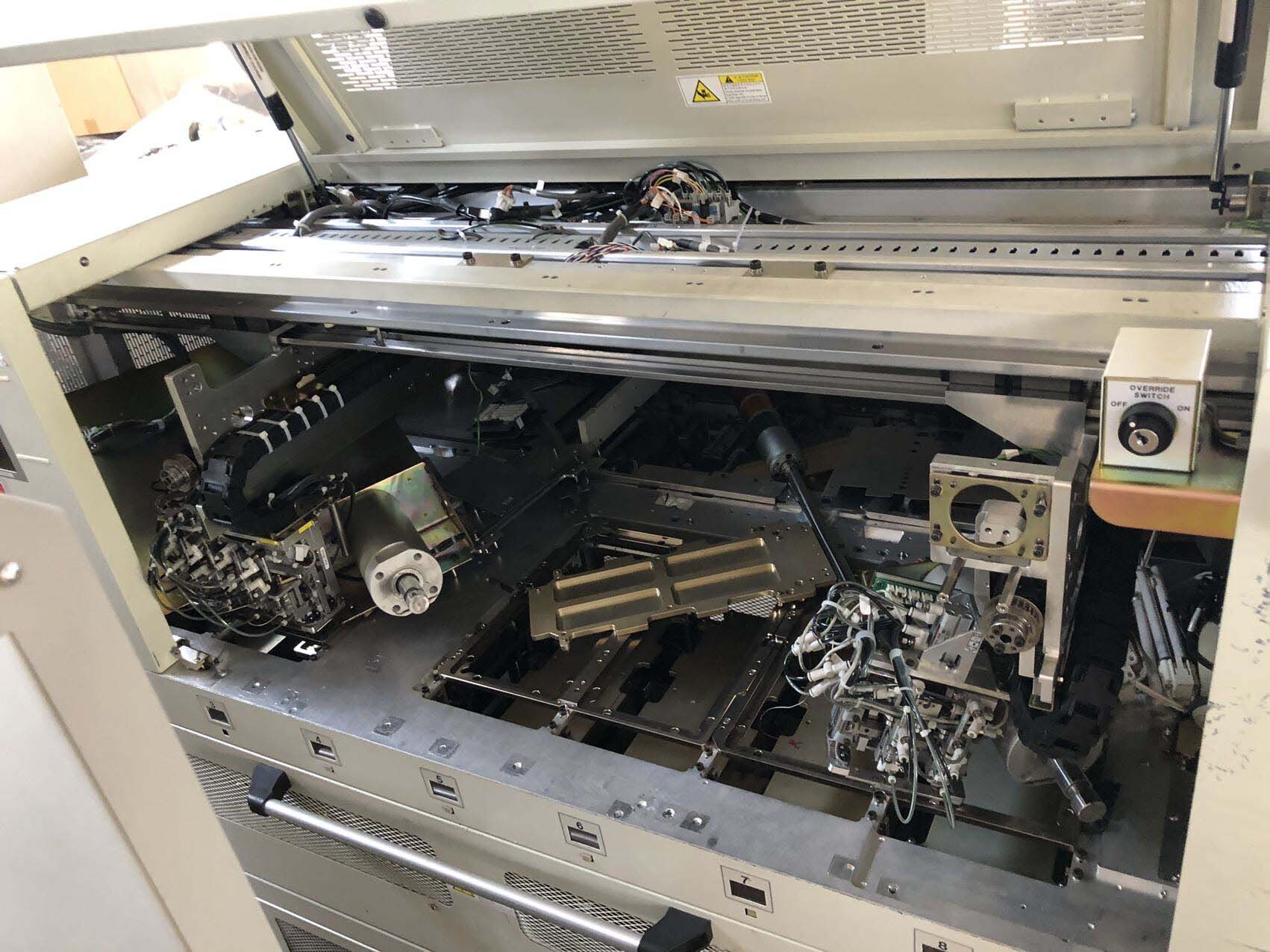

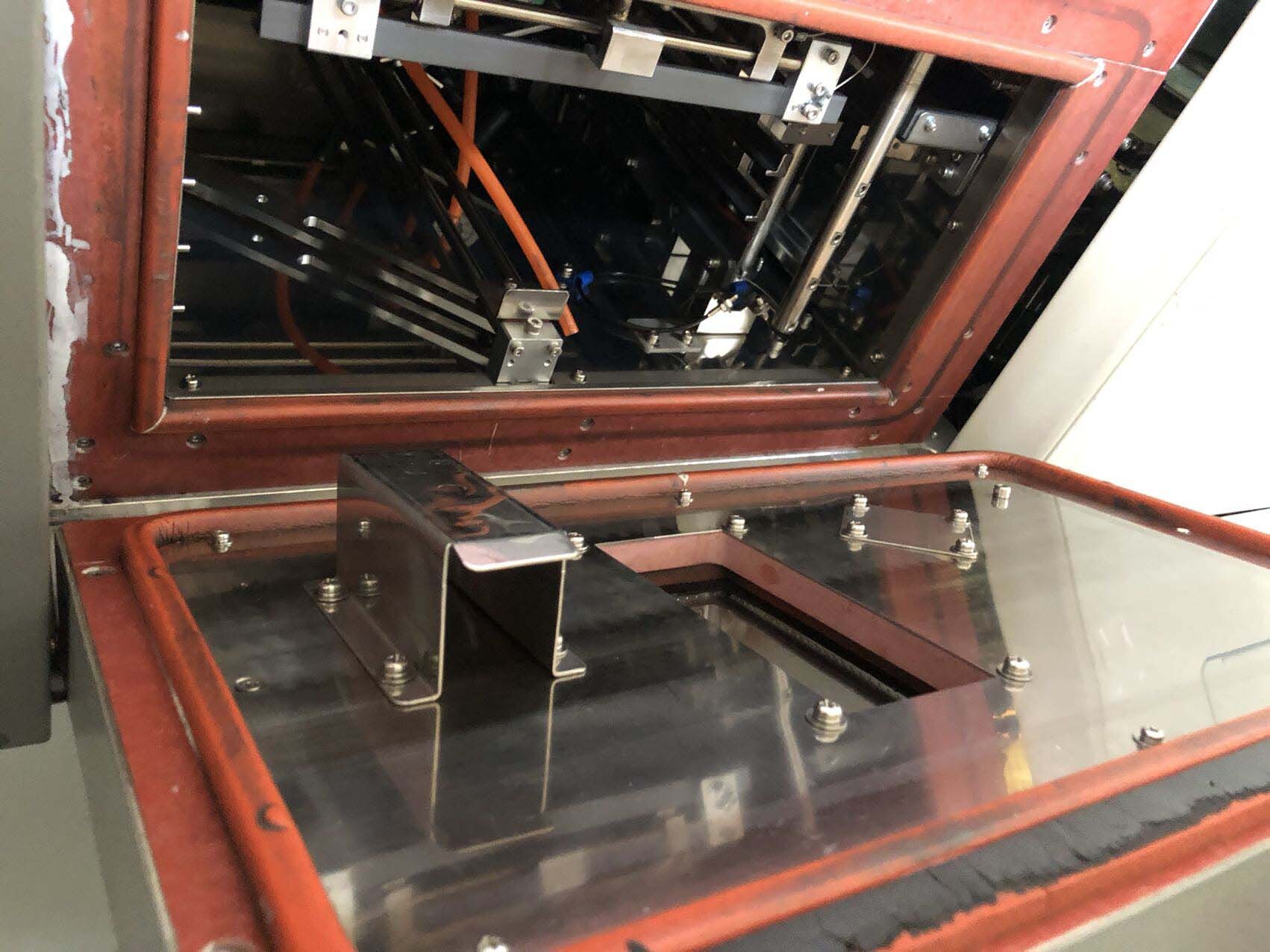

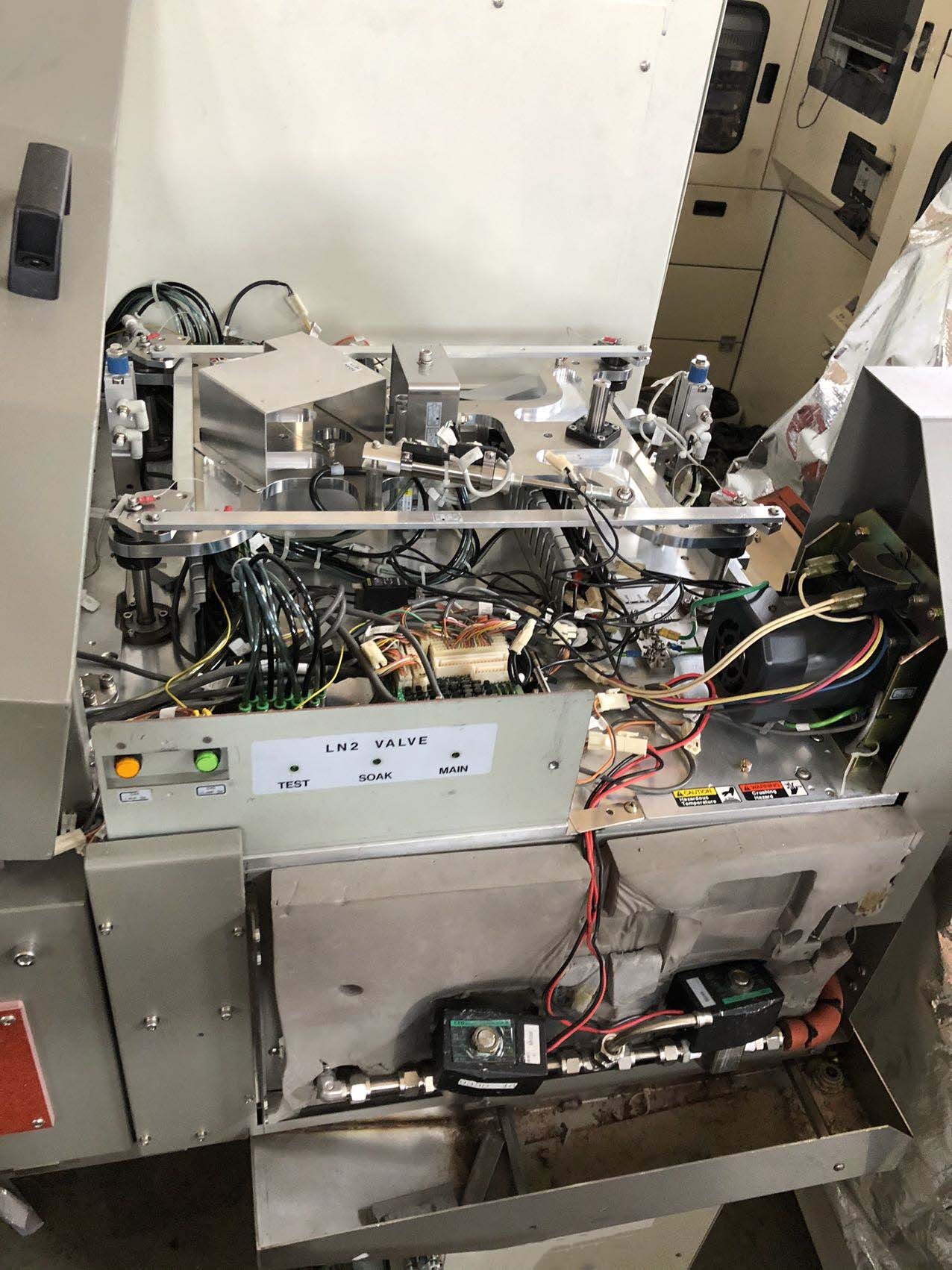

ADVANTEST M 6741A is a state-of-the-art fully automated handling solution offering high throughput and reliability with advanced vision and robotics capabilities. It is a multi-functional equipment comprising of different component parts; a loading area, a cassette station, a die loading arm, a transfer head, and an unloading area. This system is designed to ensure accurate and high-speed component insertion into frames of multiple sizes and configurations—critical for a variety of applications such as surface mount technology (SMT) processes. ADVANTEST M6741A is equipped with a die load arm that features a floating head base, allowing for smooth and stable component insertion and positioning. With the floating head technology, the arm can accurately align each component for consistent and thorough insertion into the frame. The advanced vision unit is able to precisely position components within a specified tolerance by utilizing image recognition and feedback to the drive machine, making it suitable for advanced applications. M 6741A also includes a highly reliable transfer head with fully automated vacuum tooling to transport and position components into the required frame positions with accuracy and speed. ADVANTEST M 6741A also has an integrated tool of sensors and machine vision, providing the ability to detect any faults or malfunctions during the component insertion process. This error detection asset is able to detect any issues during the component insertion process, allowing for swift resolution and adjustment of components. Additionally, the model can be automated using barcodes, allowing for quick and efficient component insertion for high-volume production. ADVANTEST M 6741 A can handle a wide range of component sizes and also provides high-speed placement of multiple parts in a single cycle. The equipment is also able to troubleshoot and correct any issues throughout the insertion process, thus minimizing any delays in the production cycle. Additionally, this handler is able to offer continuous production operations with minimal maintenance and human intervention, making it suitable for high-volume production operations. In conclusion, M 6741A is a high-performing automated handler that uses advanced robotics and vision technology to ensure accurate and repeatable component insertion for a variety of industrial applications. The system is designed to offer high throughput, reliable operations, and minimal maintenance, ensuring maximum efficiency and performance in any production environment.

There are no reviews yet