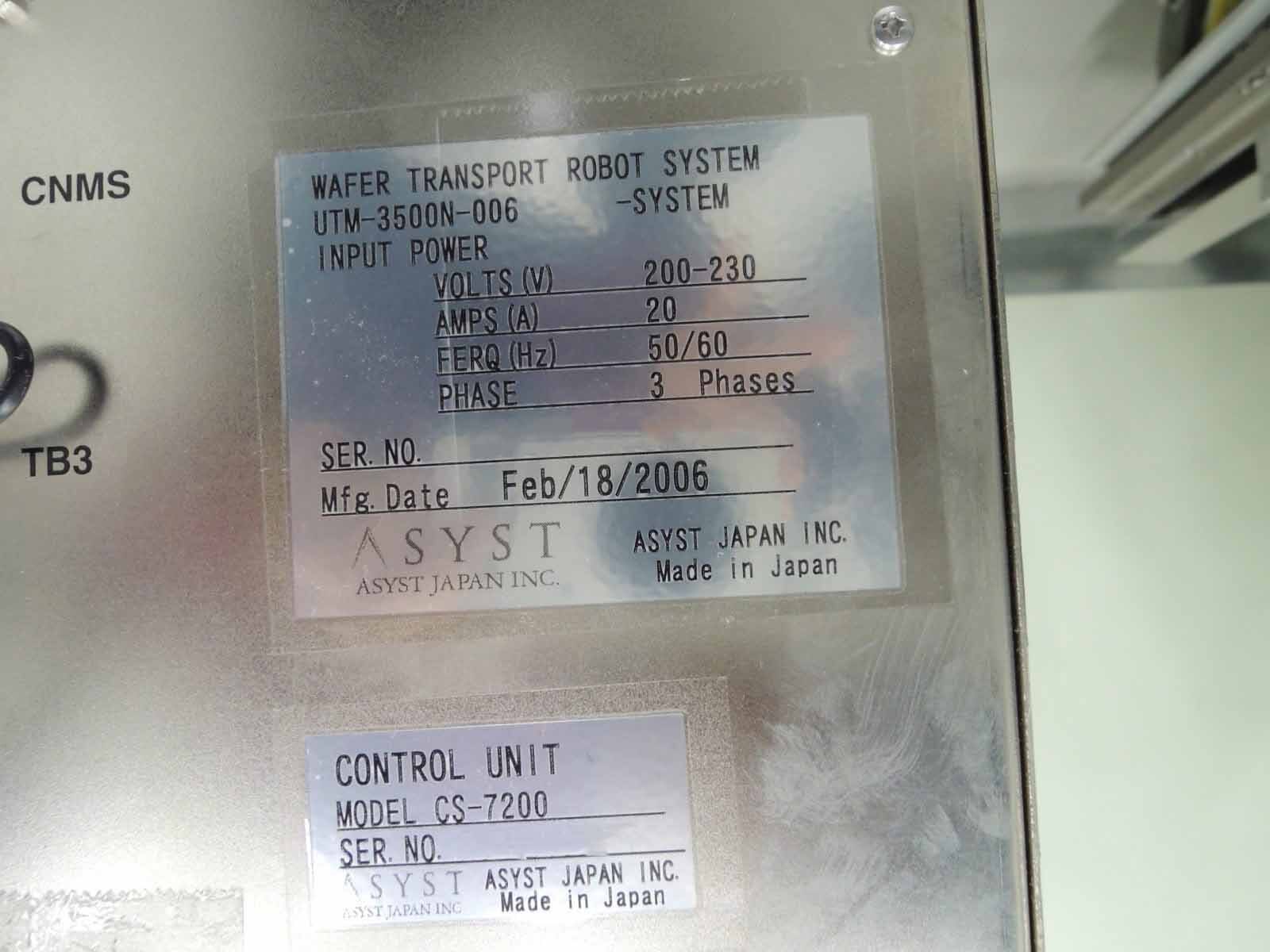

Used ASYST UTM-3500N-006 #293619314 for sale

URL successfully copied!

Tap to zoom

ASYST UTM-3500N-006 handler is an automated robotic device designed to sort, transfer, and organize products in production lines. It is equipped with a robotic arm with five axes for precise and repeatable movements, allowing it to quickly and accurately transport goods in various orientations. UTM-3500N-006 is built with a steel body and a weight capacity of up to 300 kg, allowing it to handle heavier objects than other handlers within its class. ASYST UTM-3500N-006 is powered by an efficient servo motor that is capable of producing high levels of torque and lifting power, making it ideal for handling heavy products and for flighting objects in tight spaces. The handler can be programmed with a simple command language to allow complex sorting operations. It also features a multisensors controller, which is capable of quickly detecting environment changes, temperature changes, and vibration. This ensures UTM-3500N-006 is better prepared to handle the complexities of production line automation. Other features of ASYST UTM-3500N-006 include a programmable pick and place equipment, along with adjustable spindles, allowing it to reduce waste material and increase production efficiency. An Automatic Identification System is also included, which allows equipment and product labeling. Furthermore, UTM-3500N-006 utilizes safety-approved mechanical hardware with a light-weight, non-toxi, and explosion-proof design, providing added safety and protection from the environment. In conclusion, ASYST UTM-3500N-006 is an automated handling robotic device designed for high efficiency and accuracy in production. It is equipped with a robotic arm with five axes, a powerful servo motor, and a multisensors controller to quickly detect environment changes. It also has programmable pick and place unit, an Automatic Identification Machine, and safety-approved mechanical hardware. UTM-3500N-006 is a reliable and efficient solution for sorting, transferring, and organizing products in production lines.

There are no reviews yet