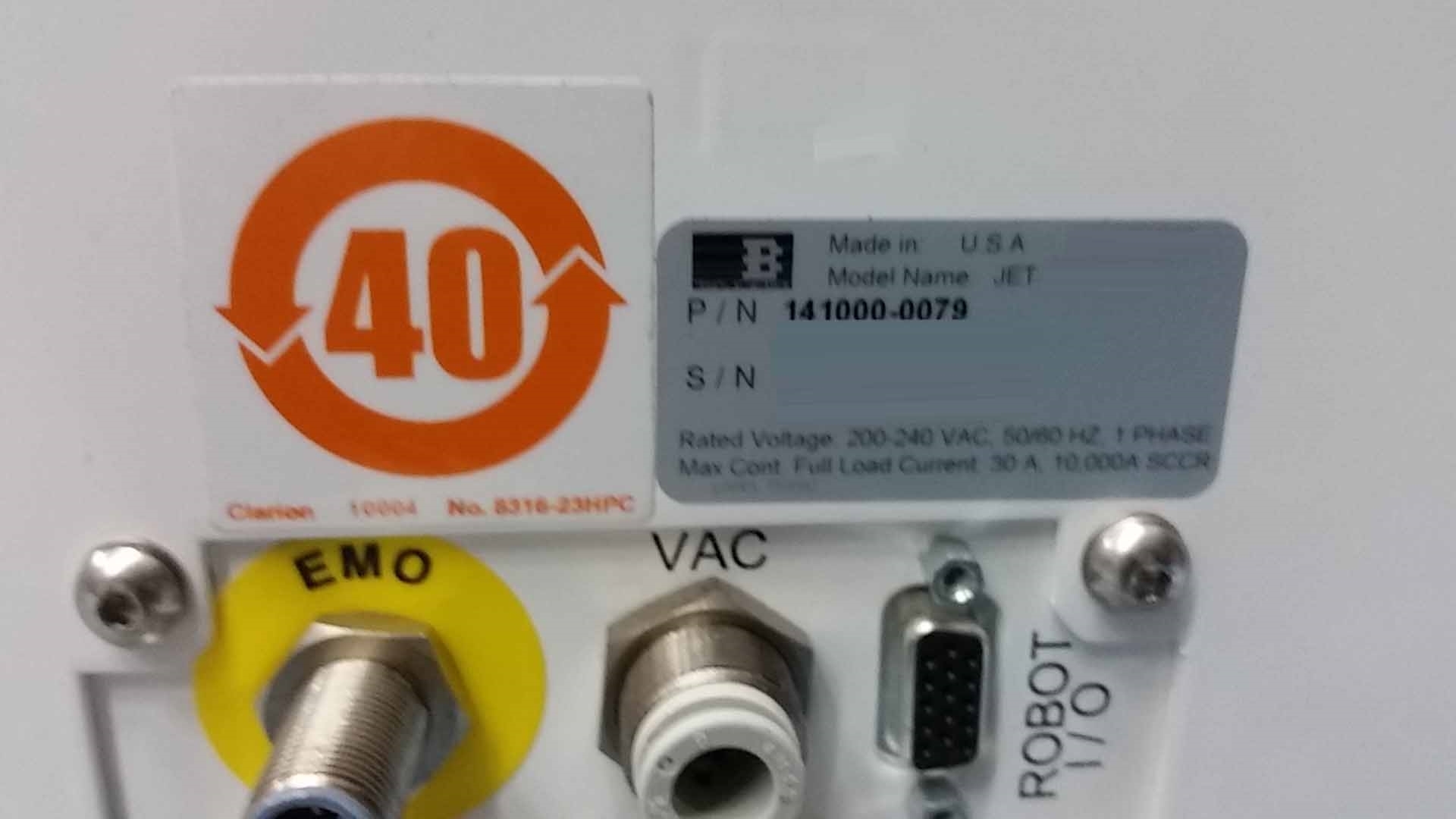

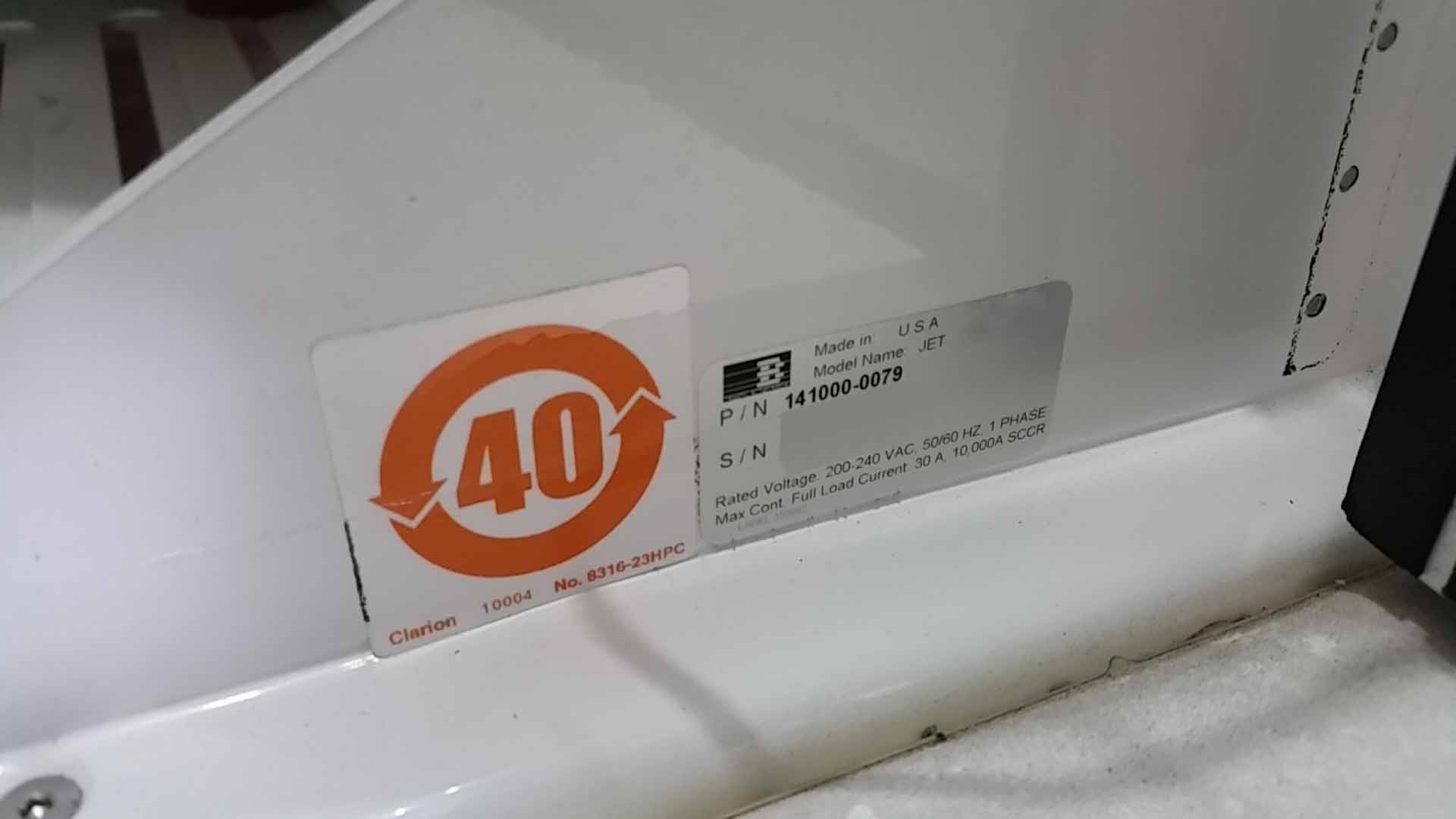

Used BROOKS AUTOMATION / ASM JET #9193427 for sale

URL successfully copied!

Tap to zoom

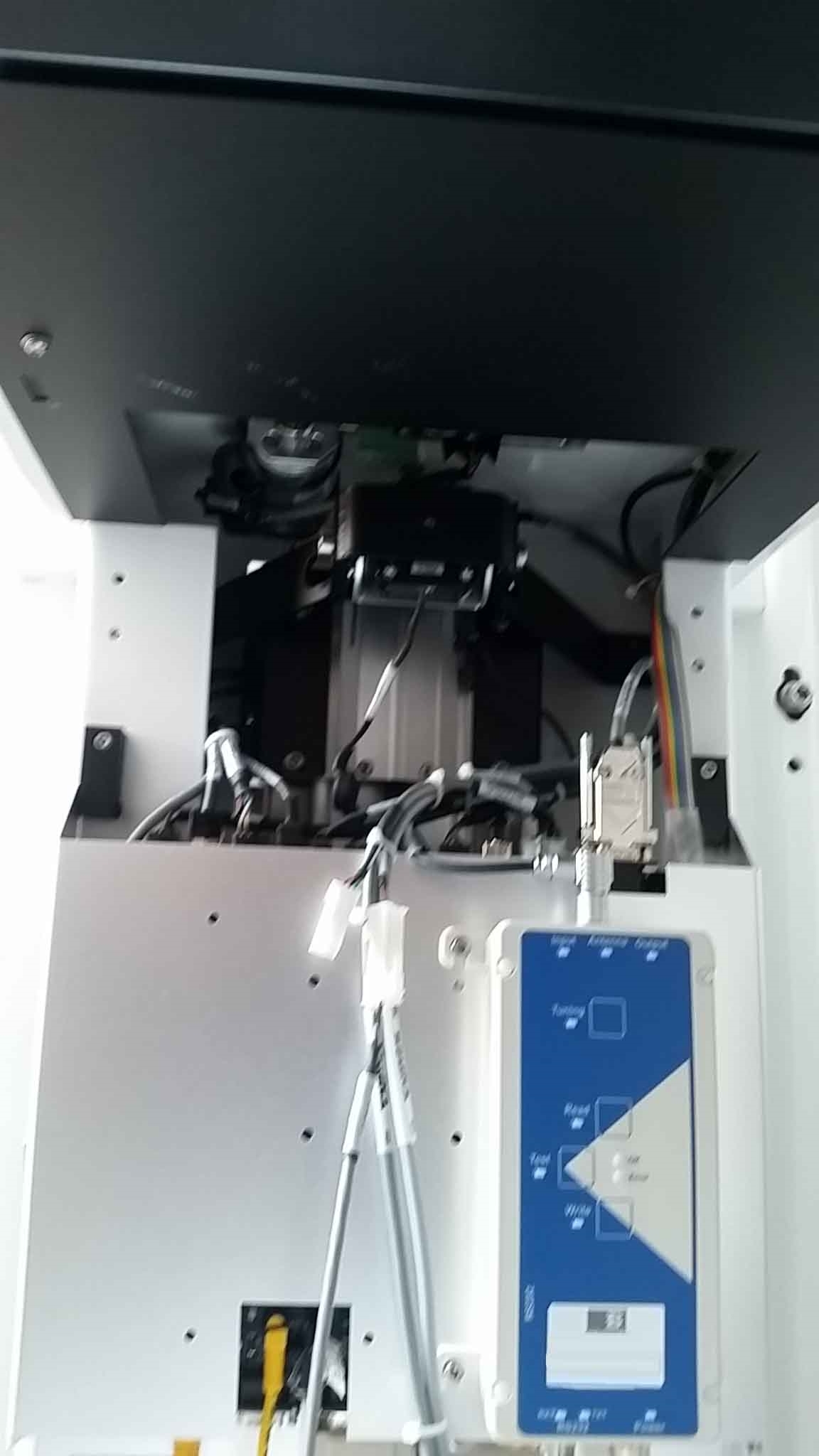

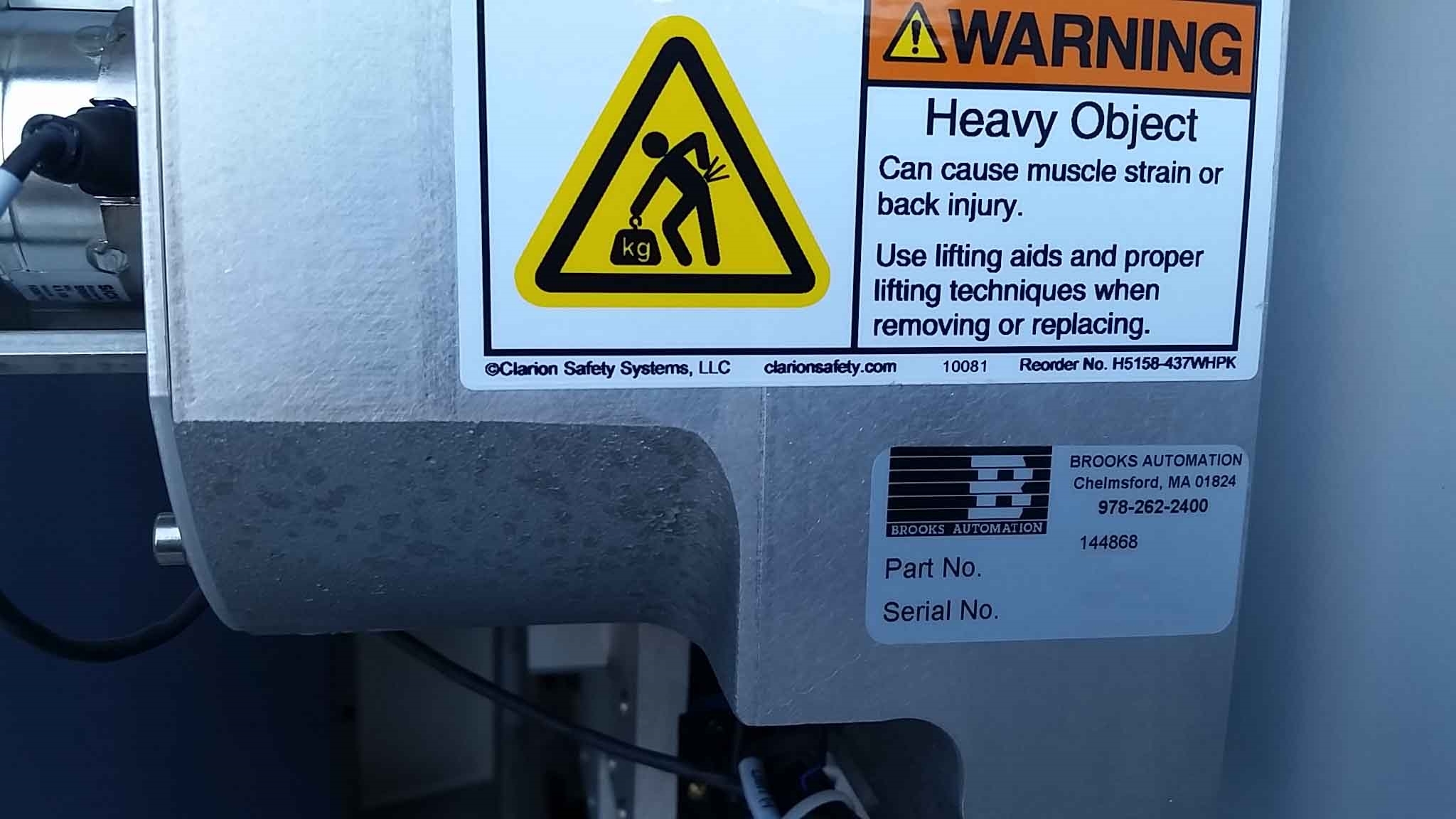

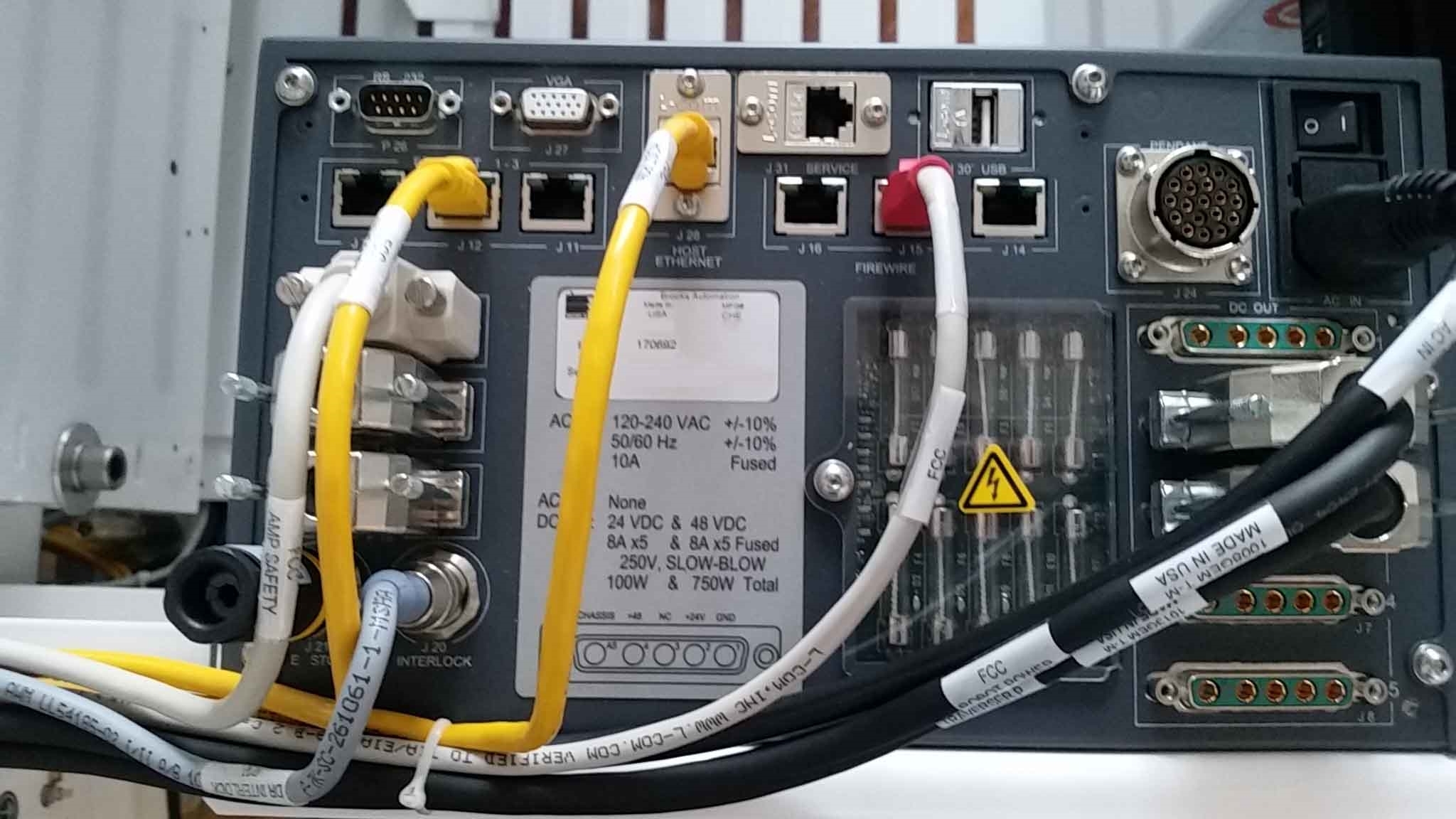

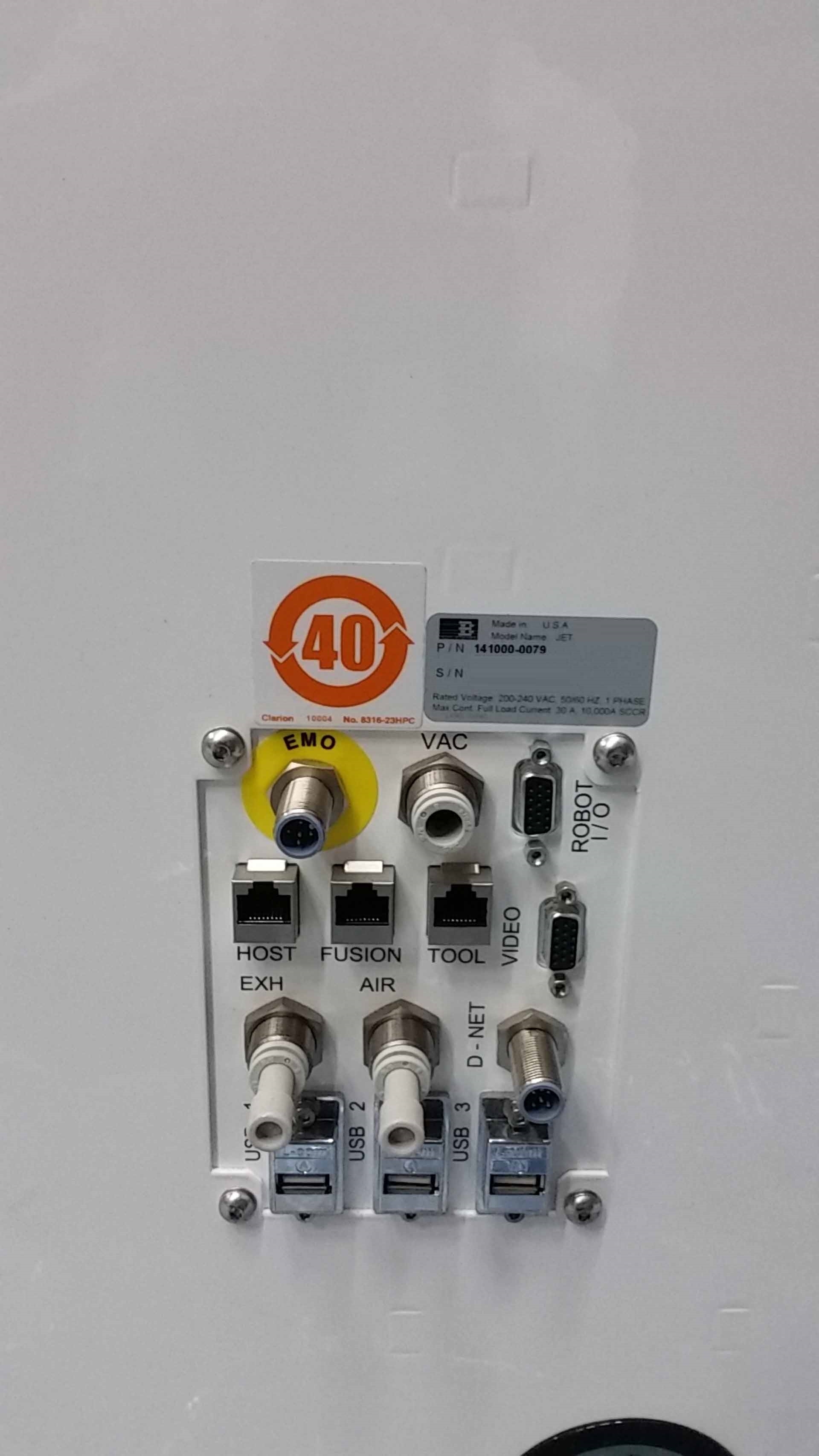

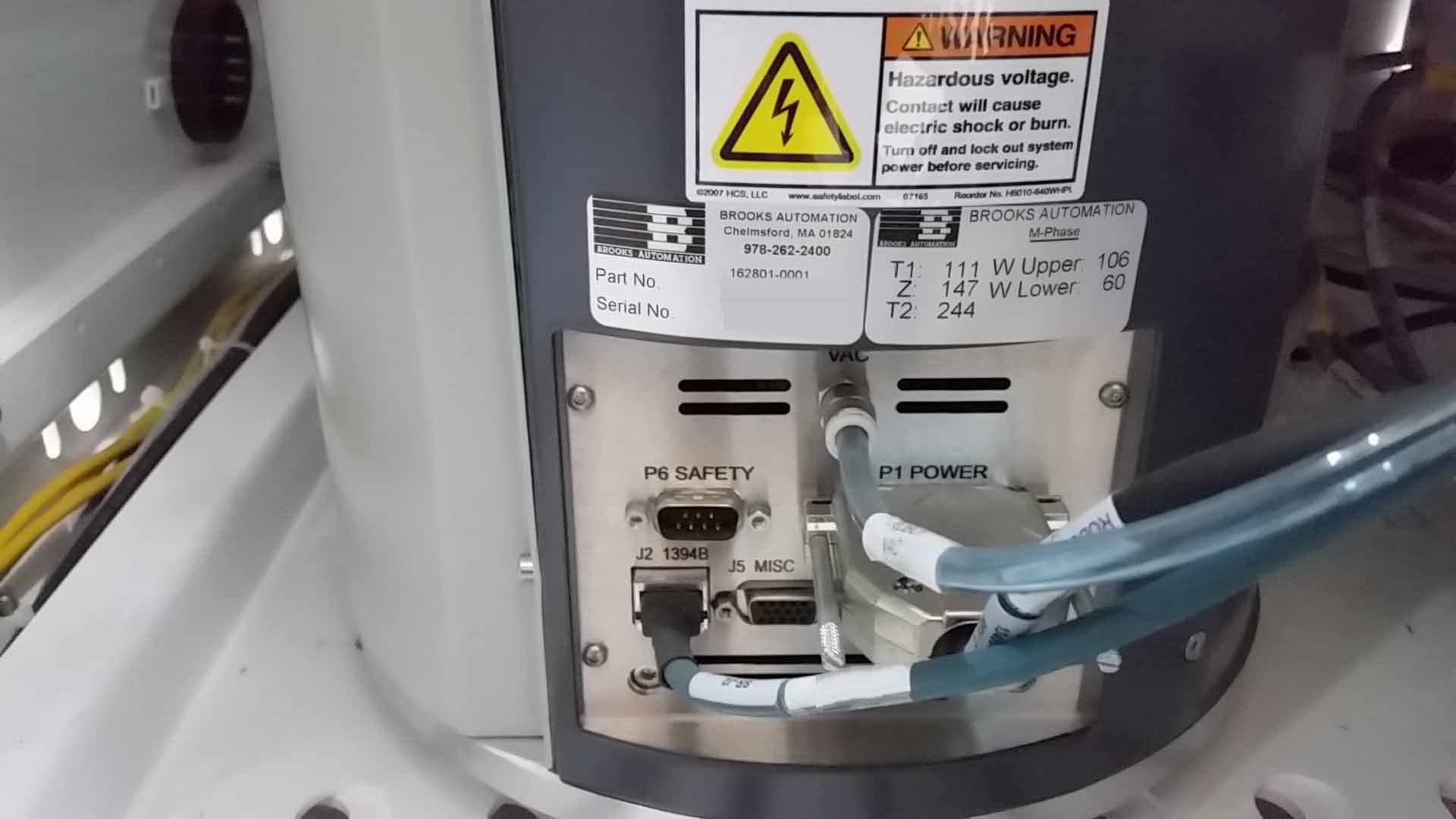

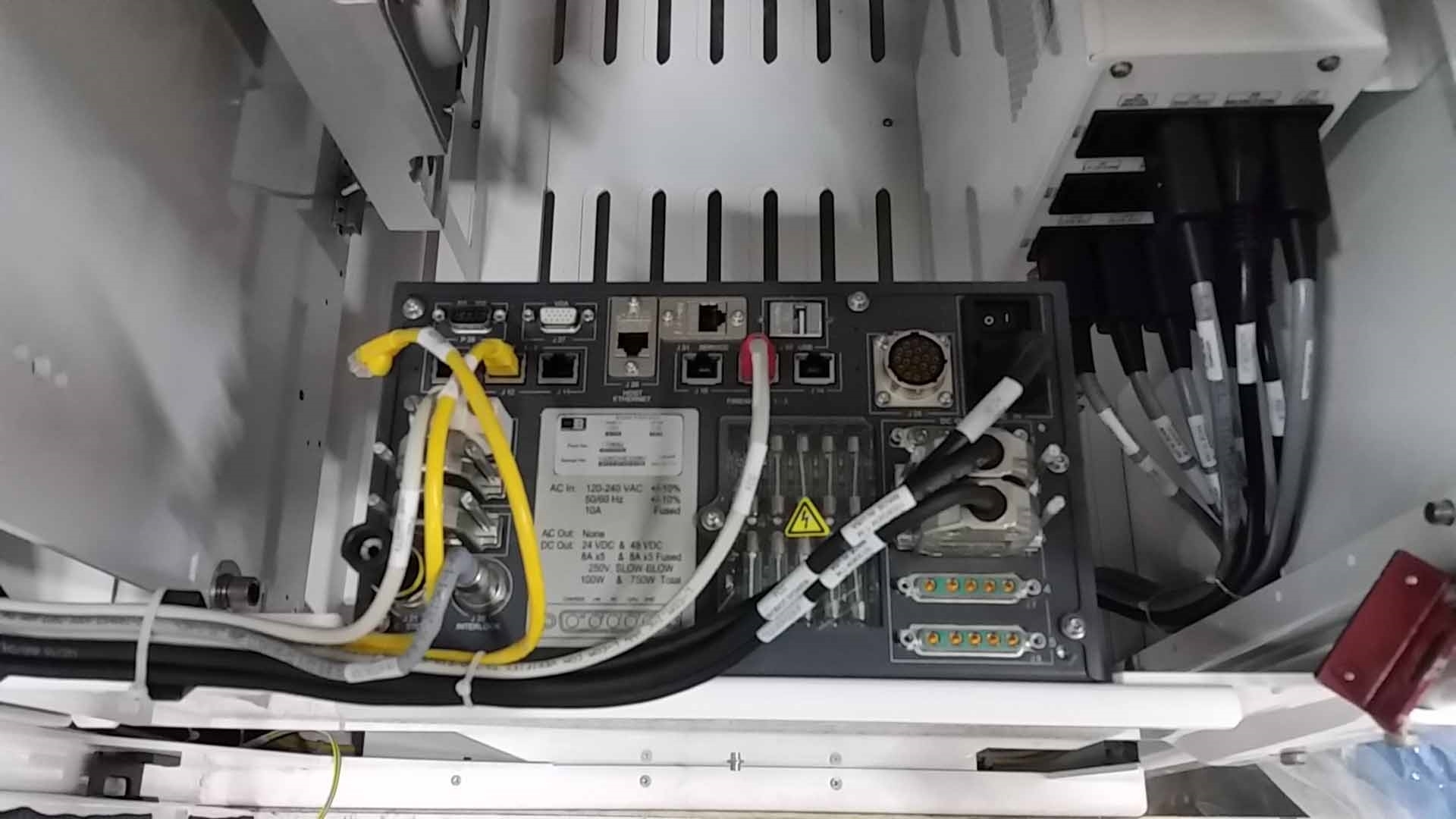

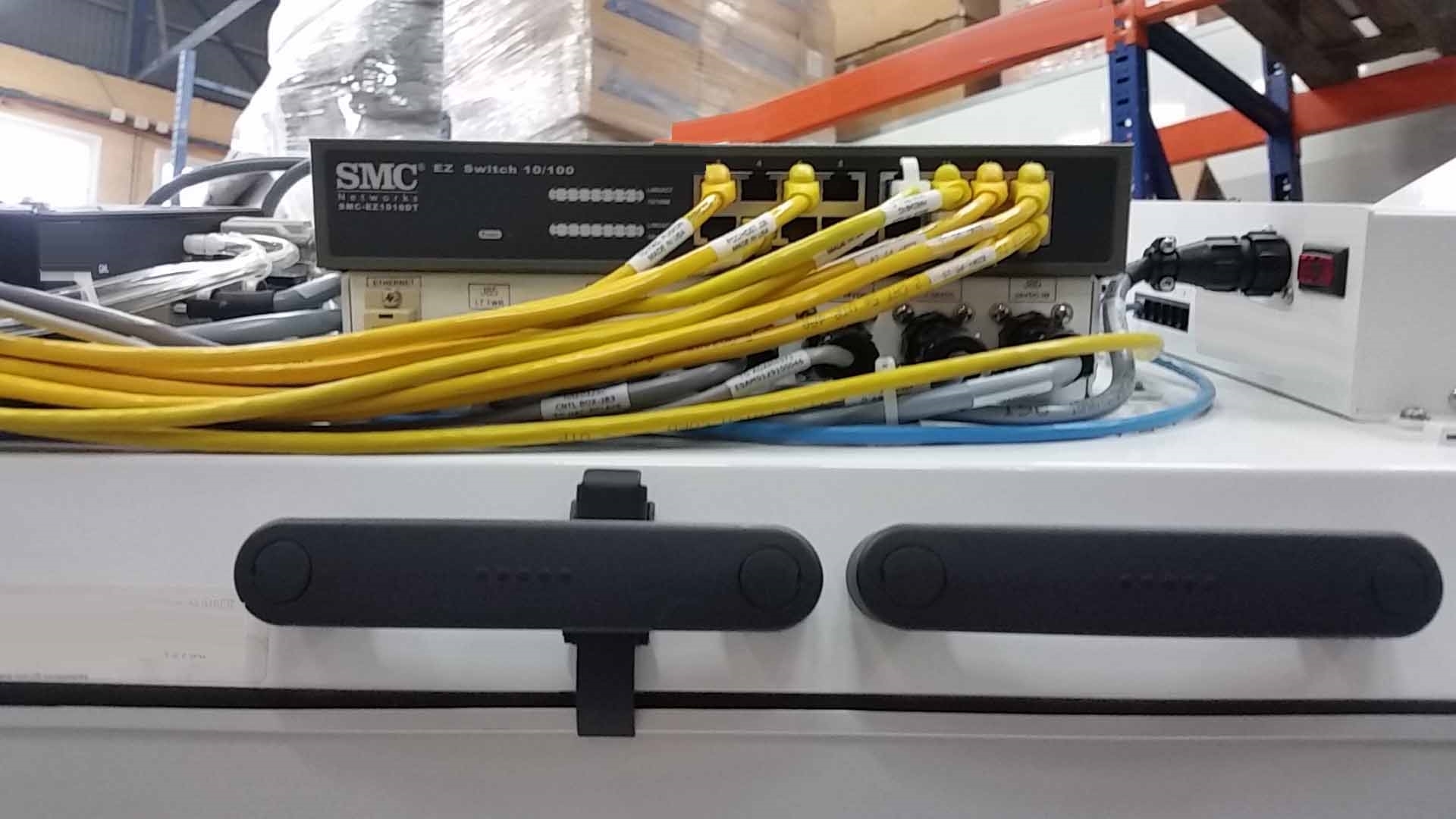

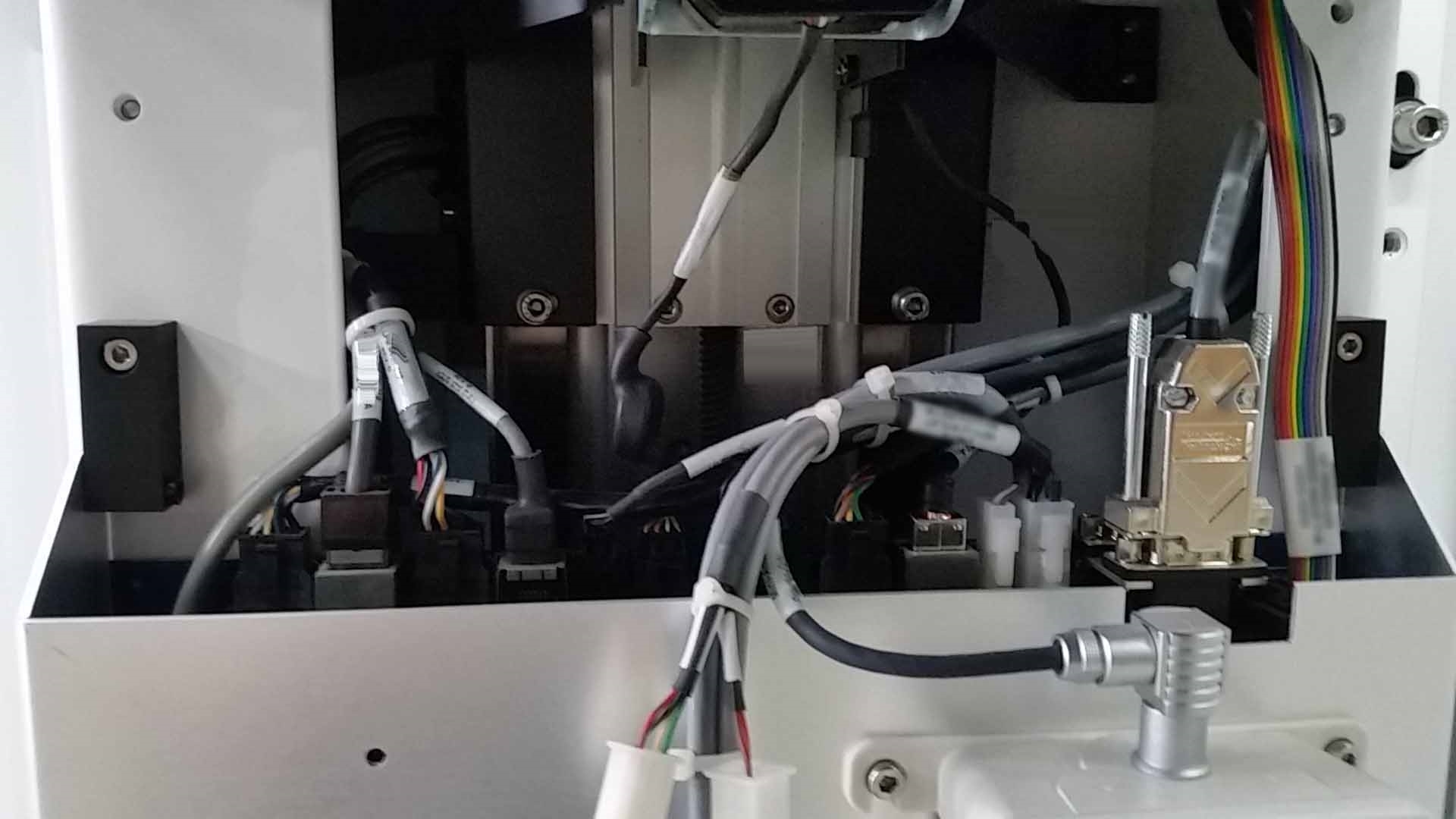

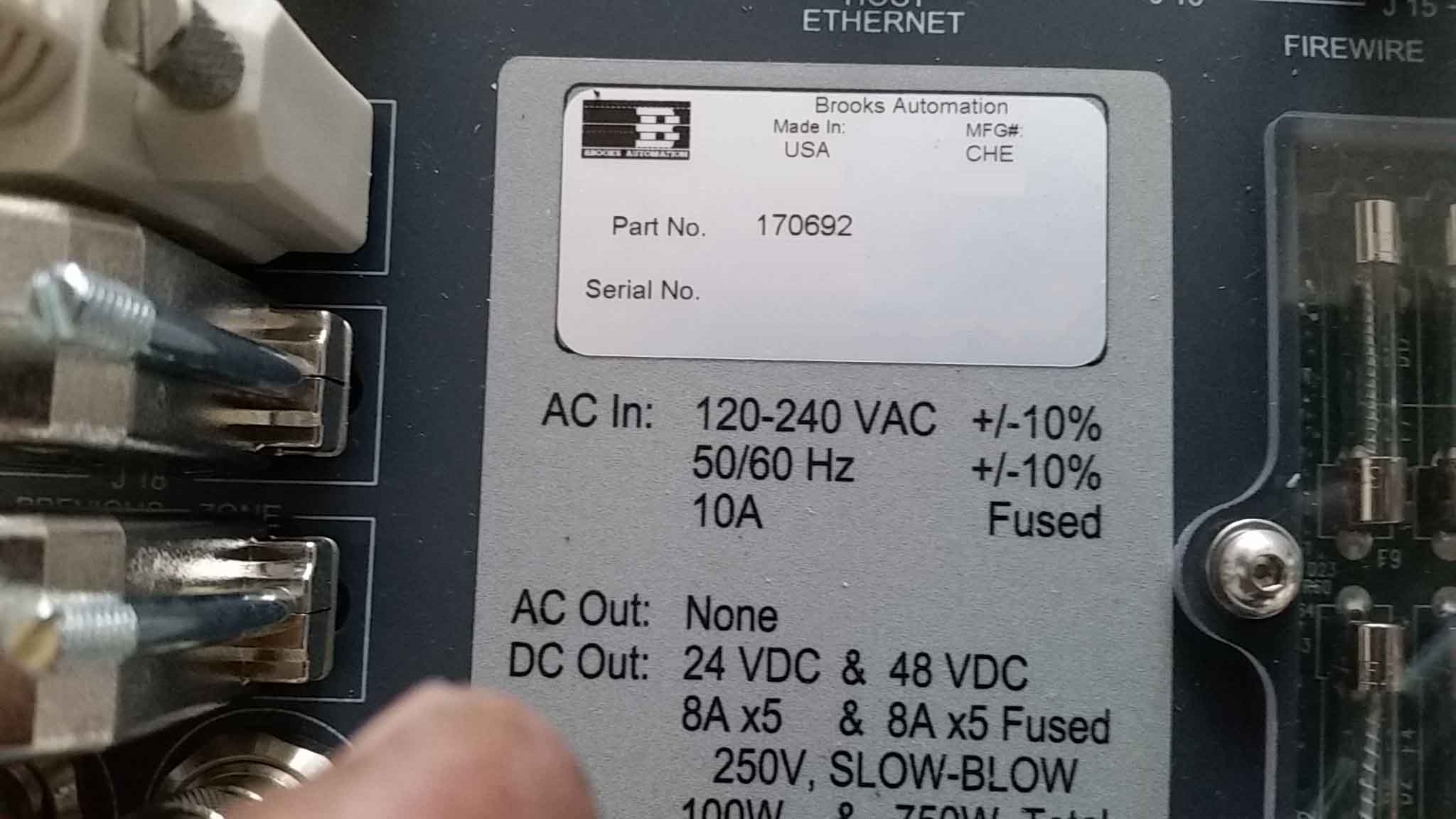

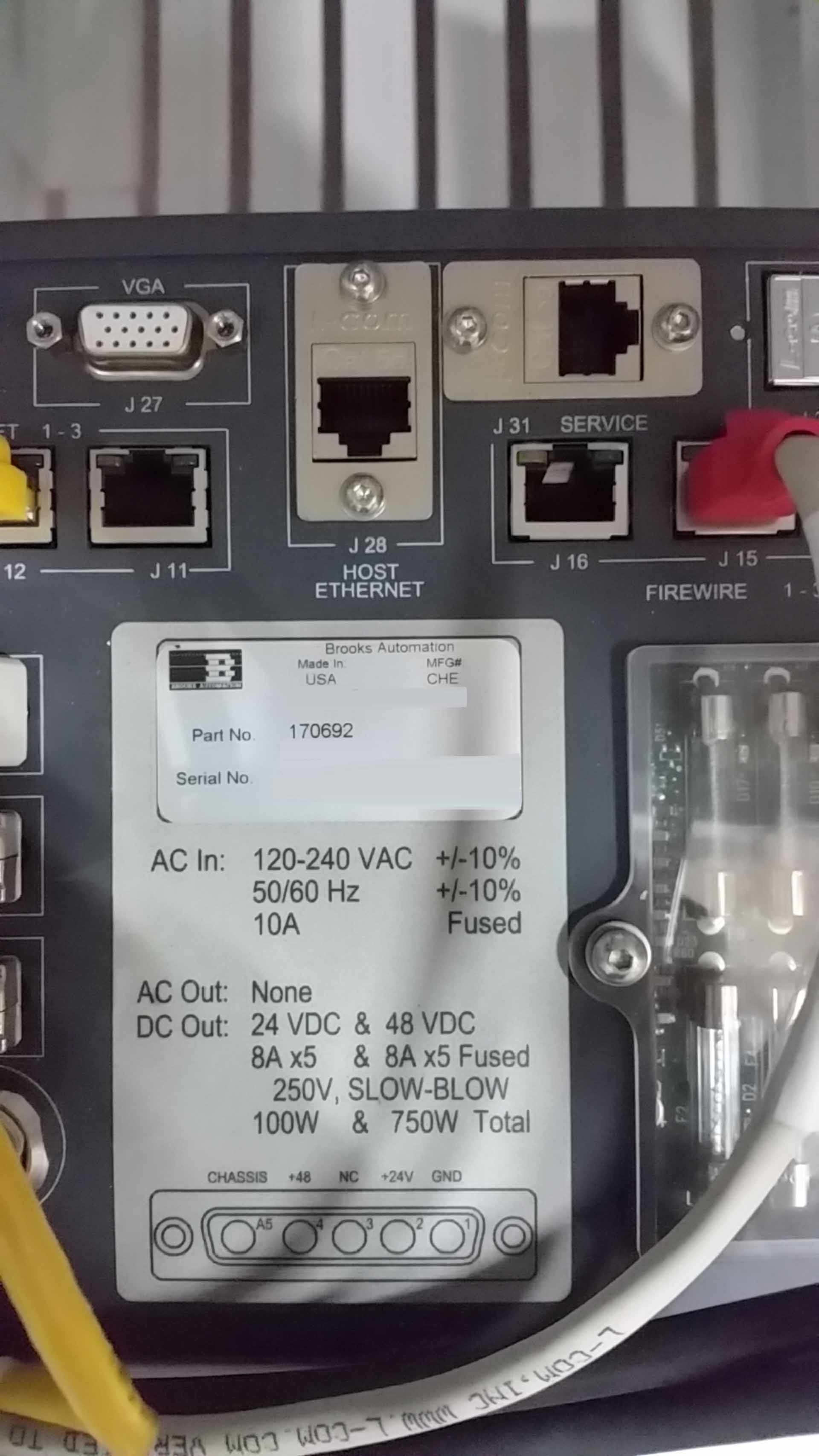

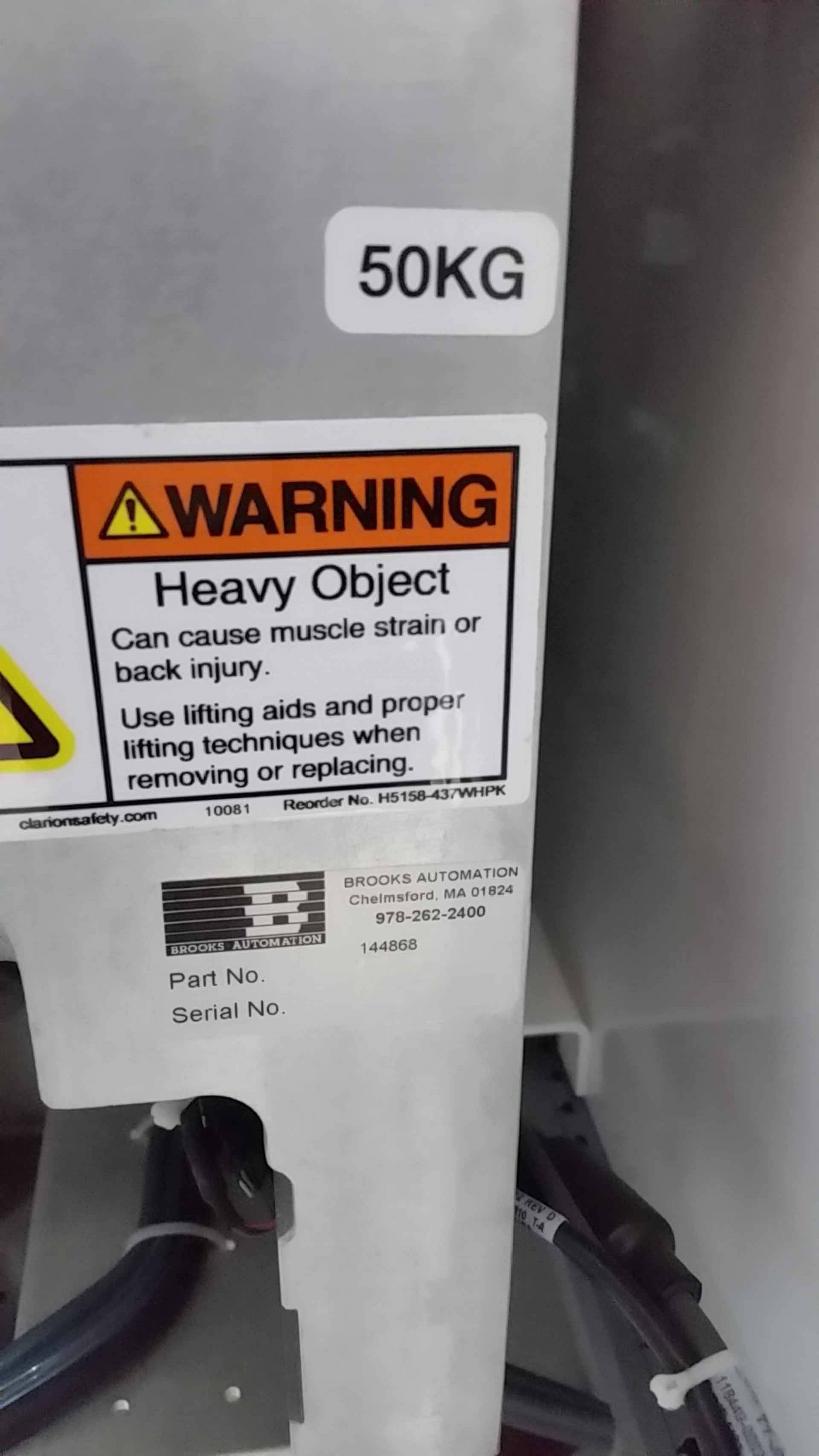

BROOKS AUTOMATION / ASM JET is an automated material handler designed to provide reliable and efficient processing of substrates. It is a flexible, cost-effective, and easy-to-use handler equipment, which is suitable for a wide range of materials. The system offers increased processing speed, improved uptime, and maximised material throughput. The unit comprises a robot loader/unloader, a rotary indexer, and a controller. The robot loader/unloader provides fast and accurate substrate transfer between the handler's in-station and out-station. It is equipped with precision sensors, which accurately detect differences in position and orientation of the substrate, and move it to the desired position. The rotary indexer is used to rotate the substrate and to ensure that it is in the right orientation for processing. It is made up of high-precision motors and precision-machined components that have been designed to provide smooth and repeatable motion, ensuring that the substrate is transferred accurately to the next stage of the process. The controller is used to monitor and control the operations of the entire handler machine. It is equipped with a Advanced Process Control Tool for improved accuracy, faster cycle times and decreased downtime. The asset can also be integrated with other systems such as MES, LIMS and Other company floor systems for efficient process control. ASM JET provides a flexible and reliable solution for handling a variety of substrates. It can handle up to 100 substrates per hour and is designed for 24/7 operations. It also has an easy to use graphical user interface and supports fault detection, logging and traceability. In conclusion, BROOKS AUTOMATION JET is an efficient and reliable automated material handler model. It offers advanced process control and easy integration to other systems such as MES, LIMS and Other company floor systems. It is a cost effective equipment, and provides increased processing speed, improved uptime and maximised material throughput.

There are no reviews yet