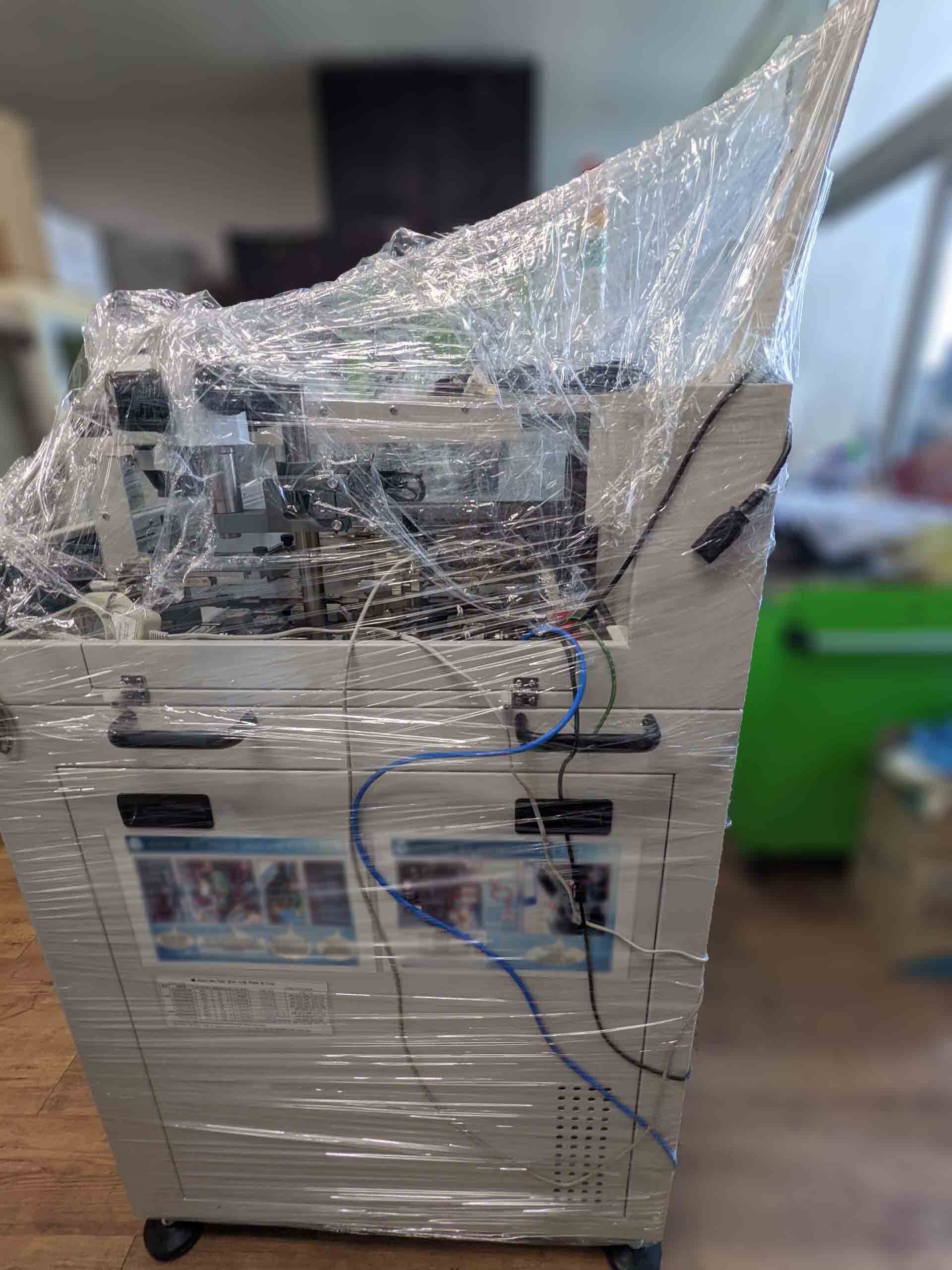

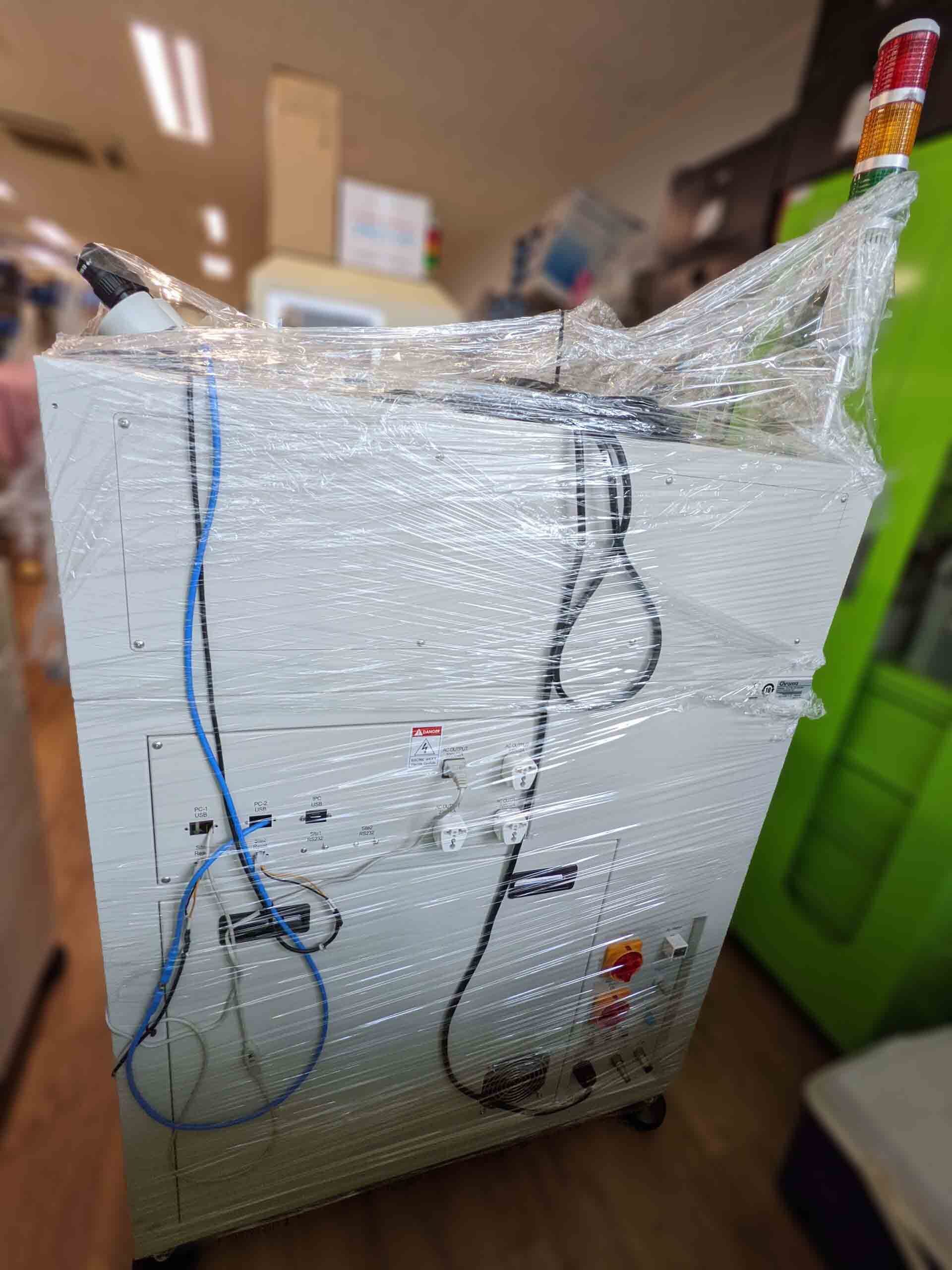

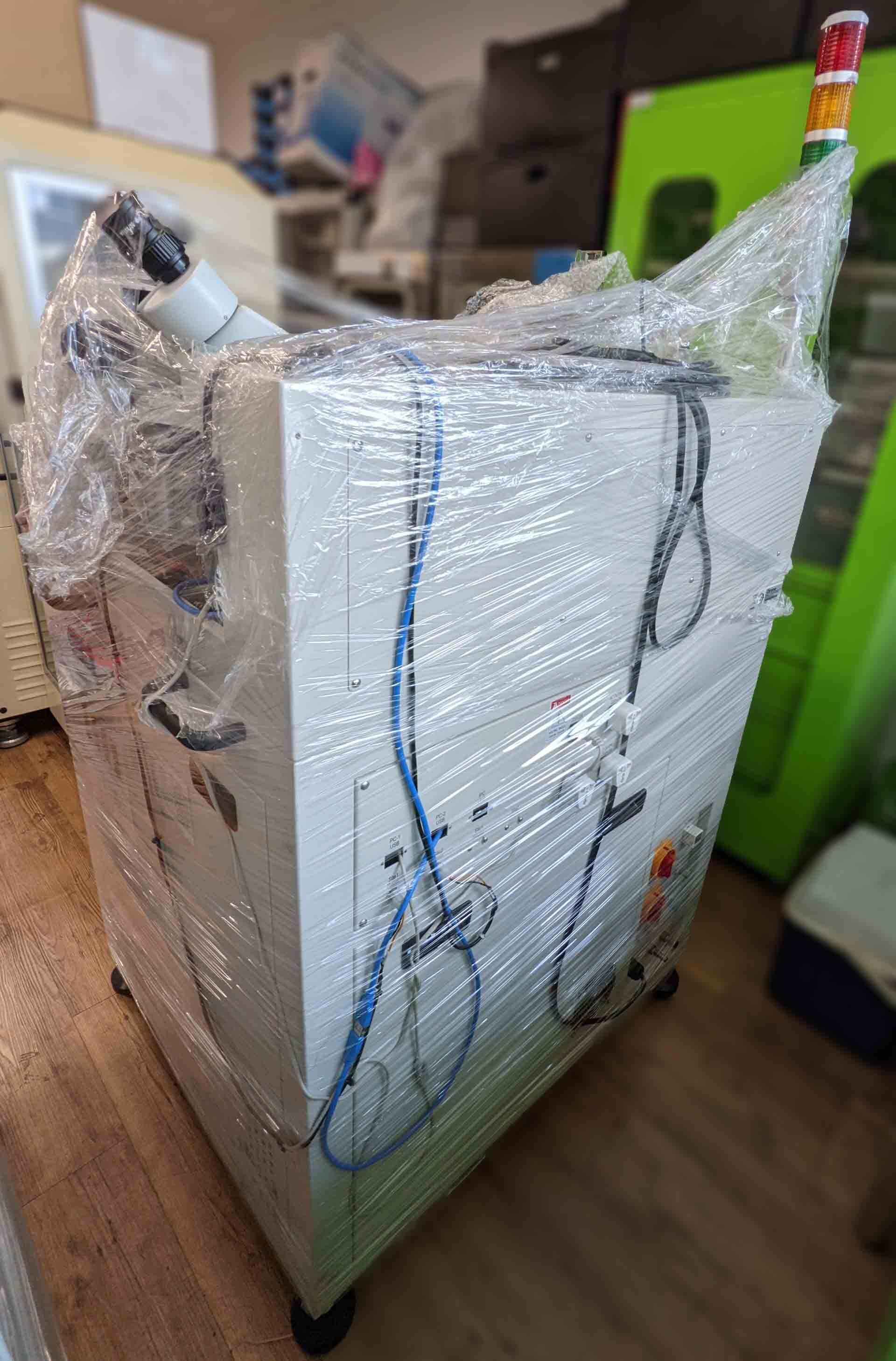

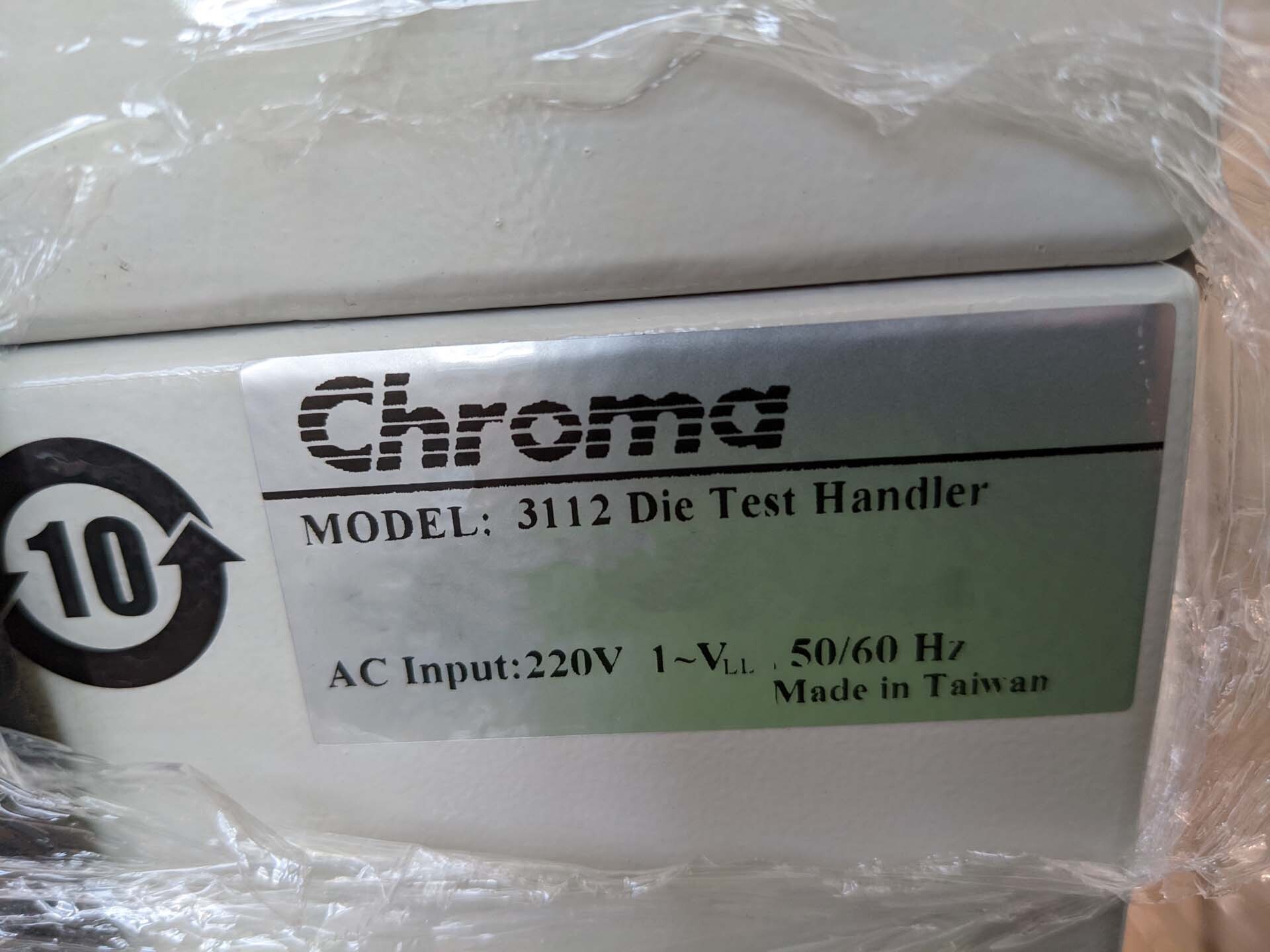

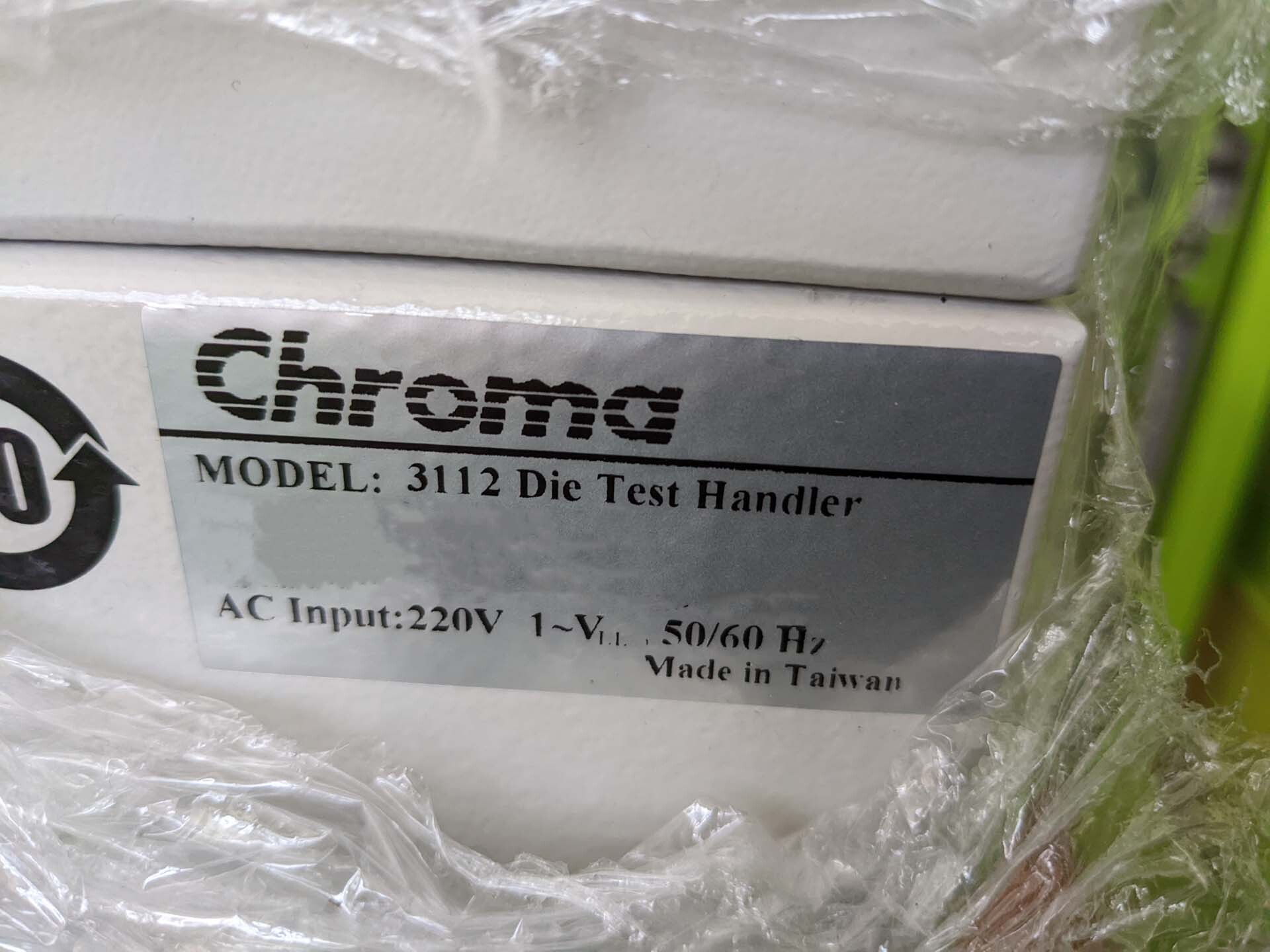

Used CHROMA 3112 #293604602 for sale

URL successfully copied!

Tap to zoom

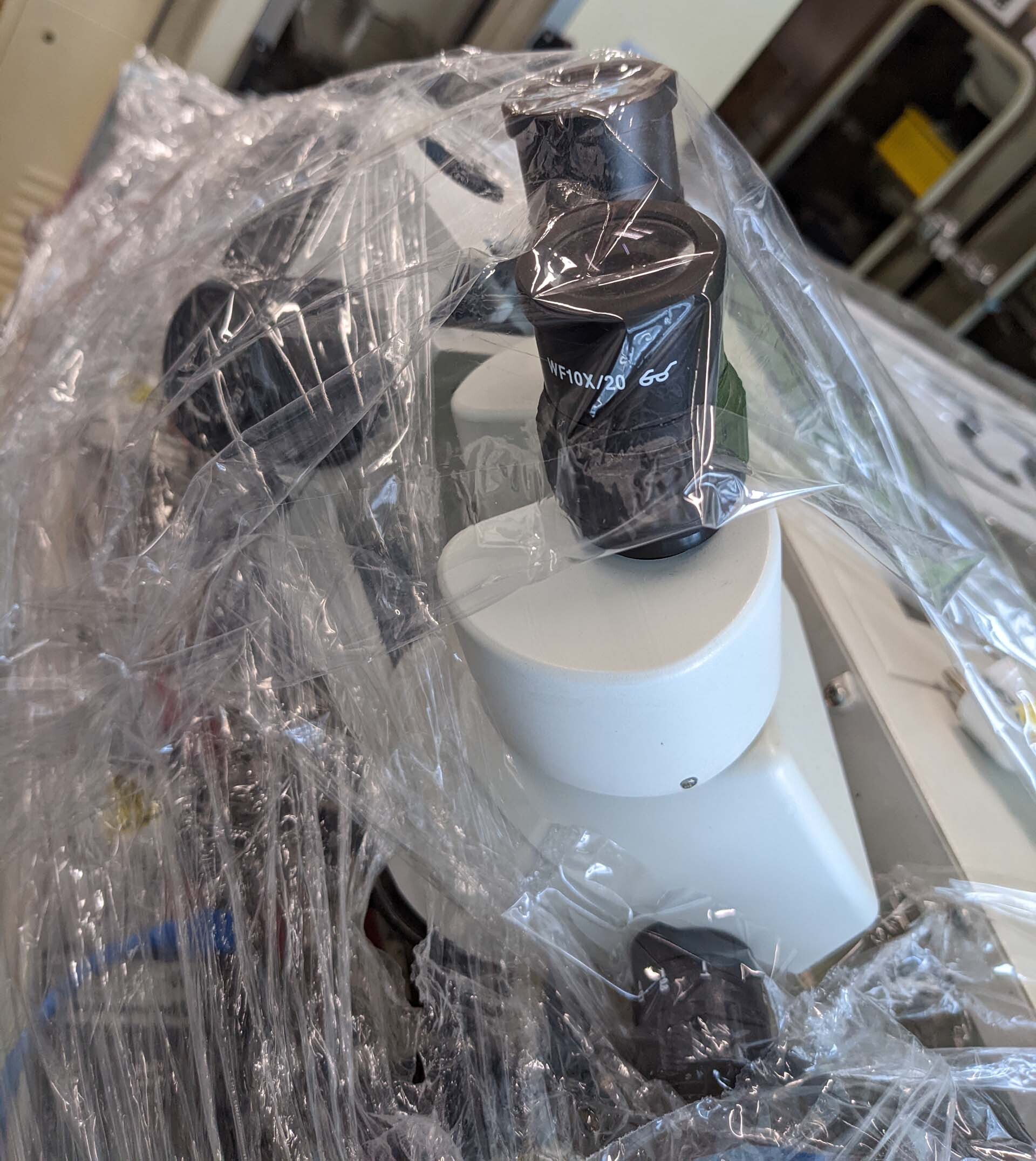

CHROMA 3112 automated handler is a highly versatile tool that simplifies many manufacturing processes. It is an ideal solution for any businesses seeking to reduce production timelines and labor costs. 3112 handler can be used for a variety of processes, including device grinding and dicing, wafer handling and imaging, and die preparation. At its core CHROMA 3112 is an automated equiment that utilizes a robotic arm. The arm utilizes an electrostatic plate to protect and store delicate components throughout the process. It is outfitted with various multidirectional drive configurations, as well as a vision-guidance equipment to ensure accurate movement and positions of devices. A vacuum motor enables proper vacuum pressure to cushion devices during transfer, further protecting delicate components. For device grinding and dicing, 3112 is able to handle wafers as thin as 0.3mm, using a special "wafer dicing blade" system for accurately cutting and localizing each chip. An image acquisition unit is included that can handle real-time inspection and capturing of features. Via an HR CCD camera, the unit can also perform tasks such as scan alignments and part pick registration. When it comes to die preparation, a selectable die pre-prep vacuum unit is included. This enables more accurate placement of die sets when compared to manual processes. Further contributing to the accuracy, is a laser-guided alignment machine that enables the handler to double-check wafer alignment and placement against design parameters. Overall, CHROMA 3112 automated handler empowers businesses to streamline manufacturing processes and reduce labor costs. With its various drive configurations, precision components, and vision guidance tool, businesses can ensure accuracy and efficiency throughout production.

There are no reviews yet