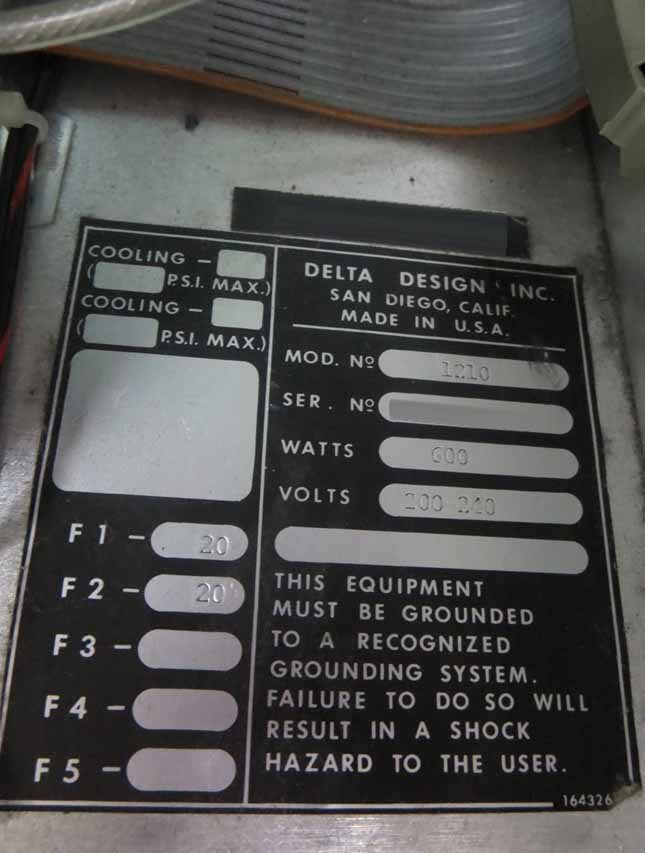

Used DELTA DESIGN 1210 #9162982 for sale

URL successfully copied!

Tap to zoom

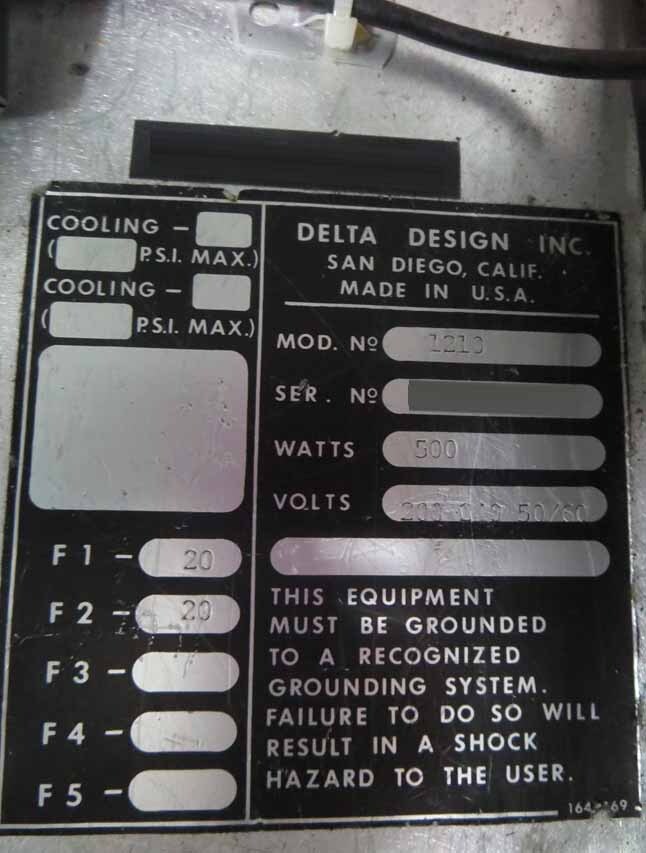

DELTA DESIGN 1210 handler is a highly sophisticated and versatile piece of automated manufacturing equipment. Designed to maximize production and efficiency, 1210 handler is capable of automatically handling multiple components of various shapes and sizes without operator intervention. DELTA DESIGN 1210 handler is made up of two main components - a main motion control equipment and a tray changer. The motion control system is responsible for providing a series of axis motions, while the tray changer is used to feed components into and out of the handler. The delta architecture of 1210 is specially designed to minimize cycle times, allowing for faster production, which leads to decreased cost. DELTA DESIGN 1210 handler is controlled by an intuitive human-machine interface (HMI), which is powered by a pair of Programmable Logic Controllers (PLC's). Additionally, 1210 handler is capable of integrating with almost any unit, allowing for the ultimate level of integration with other machinery and automation. DELTA DESIGN 1210 handler is designed with a number of powerful features that make it a versatile, efficient and reliable piece of equipment. The design is optimized for efficient component loading and unloading, utilizing the tray changing technology to quickly and easily feed components into the handler for processing. In addition, 1210 handler is equipped with temperature control, specifically designed to handle temperature-sensitive components, as well as conformance testing and vision-based inspection. In terms of accuracy and repeatability, DELTA DESIGN 1210 is capable of producing components with tolerances as tight as ± 0.0001", allowing for throughput with the highest degree of quality control and component conformity. The handler is also designed to be reliable, with a robust construction and high-torque servo motors that are designed to last. Overall, 1210 handler is an advanced, powerful and efficient piece of automated handling equipment. Its intuitive HMI, component loading and unloading technology, and its highly accurate motion machine makes it an extremely versatile and cost-effective piece of manufacturing equipment capable of providing the highest degree of quality control and component conformity.

There are no reviews yet