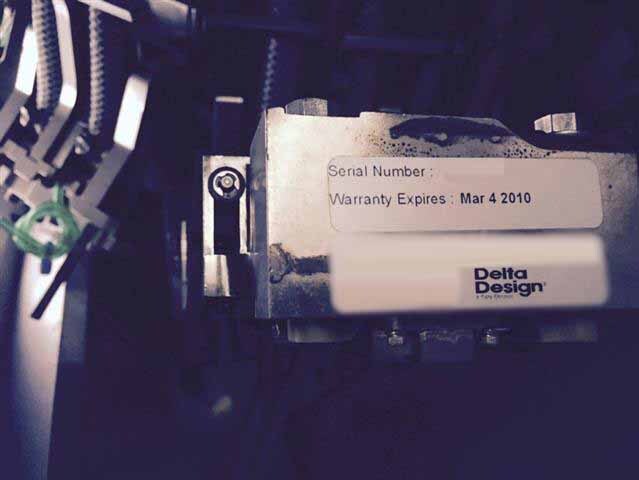

Used DELTA DESIGN Summit ATC #9116828 for sale

URL successfully copied!

Tap to zoom

ID: 9116828

Vintage: 2005

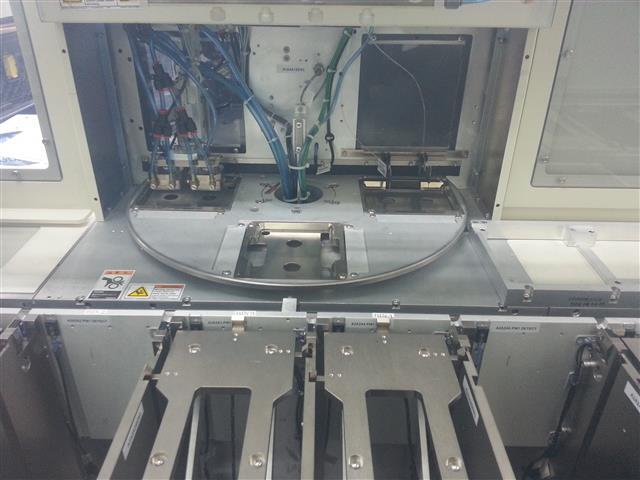

Handler

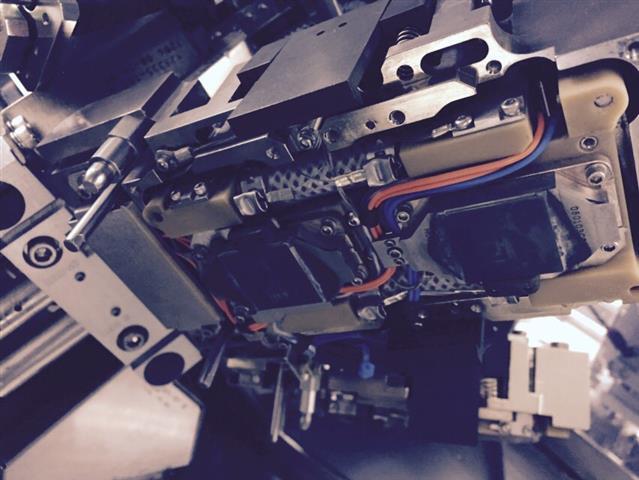

Test site module

Coobo input / Output module

Configured for JEDEC tray

AFFINITY Chiller

Docking plate for ultraflex

Includes:

Active thermal control / Full temperature operation: -30°C to +110°C

Correlation to ETC2000

Thermal characterization system

Test sites: Single / Dual

Universal device kit

Specifications:

Platform:

Media: JEDEC Trays

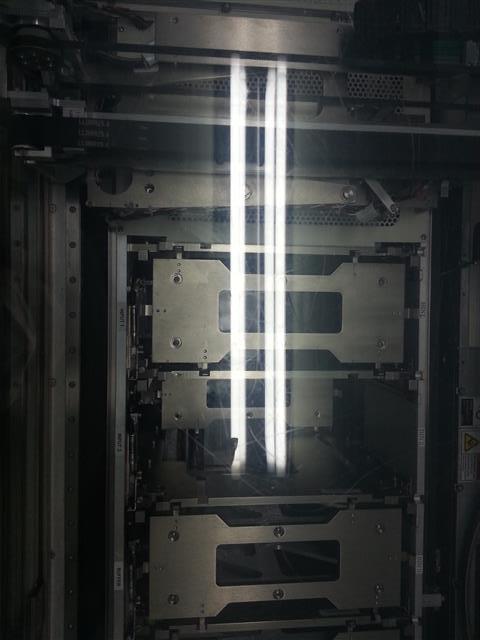

Input:

(2) Automated input positions

Automated empty tray buffer

Sort: (5) Automated tray positions

Test site: Vertical test head docking plane

Turret capacity:

(8) Chucks

Index time: 900ms (Device and configuration dependent)

Throughput: 1600 / 1840 UPH Max (Test time and device dependent)

Temperature range active: -10°C to +110°C

Variation from setpoint: ±2.0°C of Setpoint at start of test

Power dissipation:

Power density to 100W/cm²

Maximum: 200 W (Package dependent)

Thermal feedback method:

Heater temperature

Power dependent

DUT Temperature

User interface:

Windows-based

Color touchscreen

Communication interface: RS 232 / GPIB

Air single site: 80 psi

22 to 27 scfm (Clean, dry air)

Chiller:

Cooling: Water-cooled

Water: 25-50 psid

Minimum flow vs temperature:

From: 4 gpm at 59°F(15 lpm at 15°C)

Up to: 13 gpm at 77 °F (49 lpm at 25°C)

ESD: < 100V

Power requirements: 208 VAC, 50/60 Hz, 3 Phase, 40 Amp

2005 vintage.

DELTA DESIGN Summit ATC (Automatic Transfer Controller) is a programmable, easy-to-use, adjustable-weight controller designed for a variety of industrial applications. It is a single-screw, programmable, easy-to-use, adjustable-weight controller based on a solid-state relay technology. The controller includes built-in functions such as four-level on-board fault diagnostic equipment, adjustable control parameters, adjustable output speed resolution, and adjustable peak speeds. This allows for custom control of the automated transfer by each user. It also allows for greater accuracy and precision in the application's settings. Summit ATC has an integrated motion controller and allows for easy integration of third-party motion controllers. This allows for tighter coordination of production flow and automated tasks. The motion controller can be used to execute motion tasks such as movement of conveyor belts, mixers, indexers, and elevators. The ATC also has an interactive user interface, enabling the pre-configuration of the desired motion. This user interface is designed to facilitate production and process optimization. By utilizing the motion controller, users can modify parameters such as speed, acceleration, and deceleration in real-time with a few simple clicks. This allows for precise control of motor speed and torque, eliminating the need to predefine production speeds. The automatic process control also helps to ensure the highest quality of production. Furthermore, the controller can be activated to provide an automatic downtime recovery system, which can be rebooted during power outages and other disruptions. DELTA DESIGN Summit ATC is engineered for unit control in a variety of industrial environments. This includes HVAC applications, production lines, motor controls, energy management, and more. It is also compatible with various industrial communication protocols such as MODBUS, Ethernet, and ModBUS II. The controller has an increased safety rating, allowing for safe operation in control systems. Furthermore, the controller is also equipped with a neural network capability, making it ideal for complex applications. Overall, Summit ATC is an ideal programmable controller for a variety of industrial applications. It is designed for easy integration, provides accurate control, and runs with minimal downtime. The controller is a versatile tool that can provide users with a working machine for any application.

There are no reviews yet