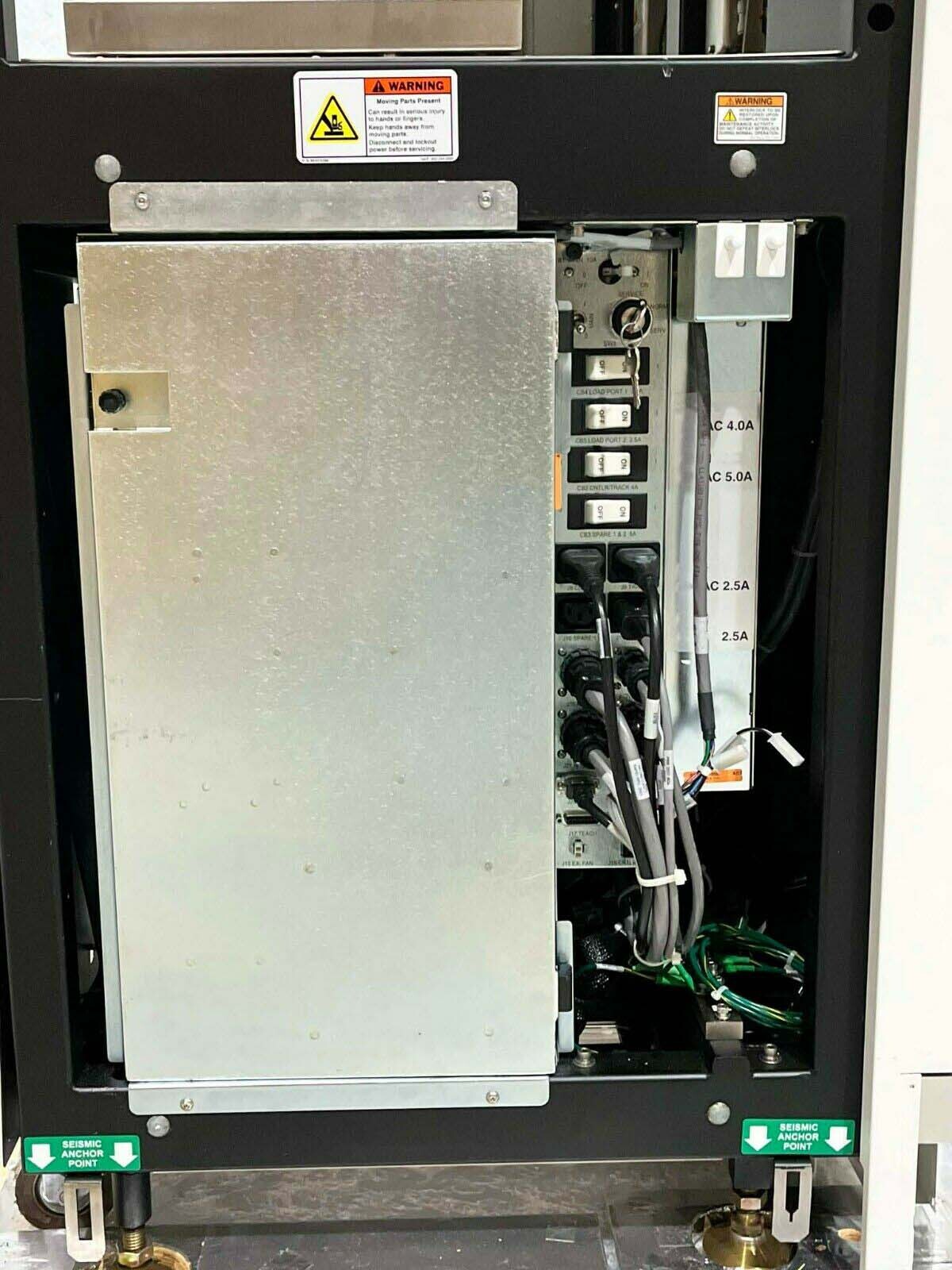

Used KLA / TENCOR 300 DFF #293594753 for sale

URL successfully copied!

Tap to zoom

ID: 293594753

Wafer Size: 12"

EFEM Interface for Archer, 12"

Make / Model / Part number / Description

BROOKS / PRI AUTOMATION / ABM-407B-1-S-CE-S293 / - / Robot

KLA / TENCOR / - / 0014446-000 / -

BROOKS / PRI AUTOMATION / ESC-218BT-S93 / - / Robot controller

KLA / TENCOR / - / - / Robot controller

BROOKS / PRI AUTOMATION / - / 6-0002-0408-SP / Pre aligner

BROOKS / PRI AUTOMATION / - / PRE-300BU-I-CE-S2 / Pre aligner

KLA / TENCOR / - / 0029191-000 / -

ASYST / 300FL / - / Load port

ASYST / S3 STD / - / Load port

ASYST / KT07 / - / Load port

ASYST / - / 9750-0038-01 / Load port.

KLA / TENCOR 300 DFF is a fully automated defect inspection hander. It is designed to streamline processes, improve throughput, and ensure quality in operational operations and defects analysis. An efficient and accurate method of defect detection and analysis, KLA 300 DFF is an increasingly popular tool for manufacturers and other production entities worldwide. The core of the equipment is composed of advanced signal processing and computing modules which in turn are powered by a proprietary real-time operating system. This platform enables the unit to accurately identify defects in products as they are received, often before they can be detected on assembly lines. The machine also provides actionable information by tracking, recording, and analyzing defects enabling users to make timely and informed decisions. High resolution frame grabbers and a wide field of view provide reliable defect mapping and data collection. Camera options range from 5.0MP to 16MP with resolutions up to 8K and a pixel size of 4.7um. The tool is designed to adjust calibration to the product and provide stable, accurate data collection even if the product size or shape change from batch to batch. The application runs on Windows 10 and supports a variety of database and database management systems. Fully automated through collaborative software, the asset includes enhanced operations for image manipulation, database control, search scripts, and programmable feature fields. It is also compatible with a range of material types from fabric to plastic. Operators can analyze several parameters in one inspection although multi-parameter handling is not always necessary. The model handles infinitely long parts and the surrounding image ensures for a seamless 100% inspection. For further accuracy, users can rely on the unique pixel detection input and intuitive control of the equipment. TENCOR 300 DFF is robust and reliable enough to be used in a variety of industries, including semiconductor manufacturing, automotive, and medical fields. It is proven to not only improve quality while reducing costs and downtime, but also to improve the customer's operational efficiency.

There are no reviews yet