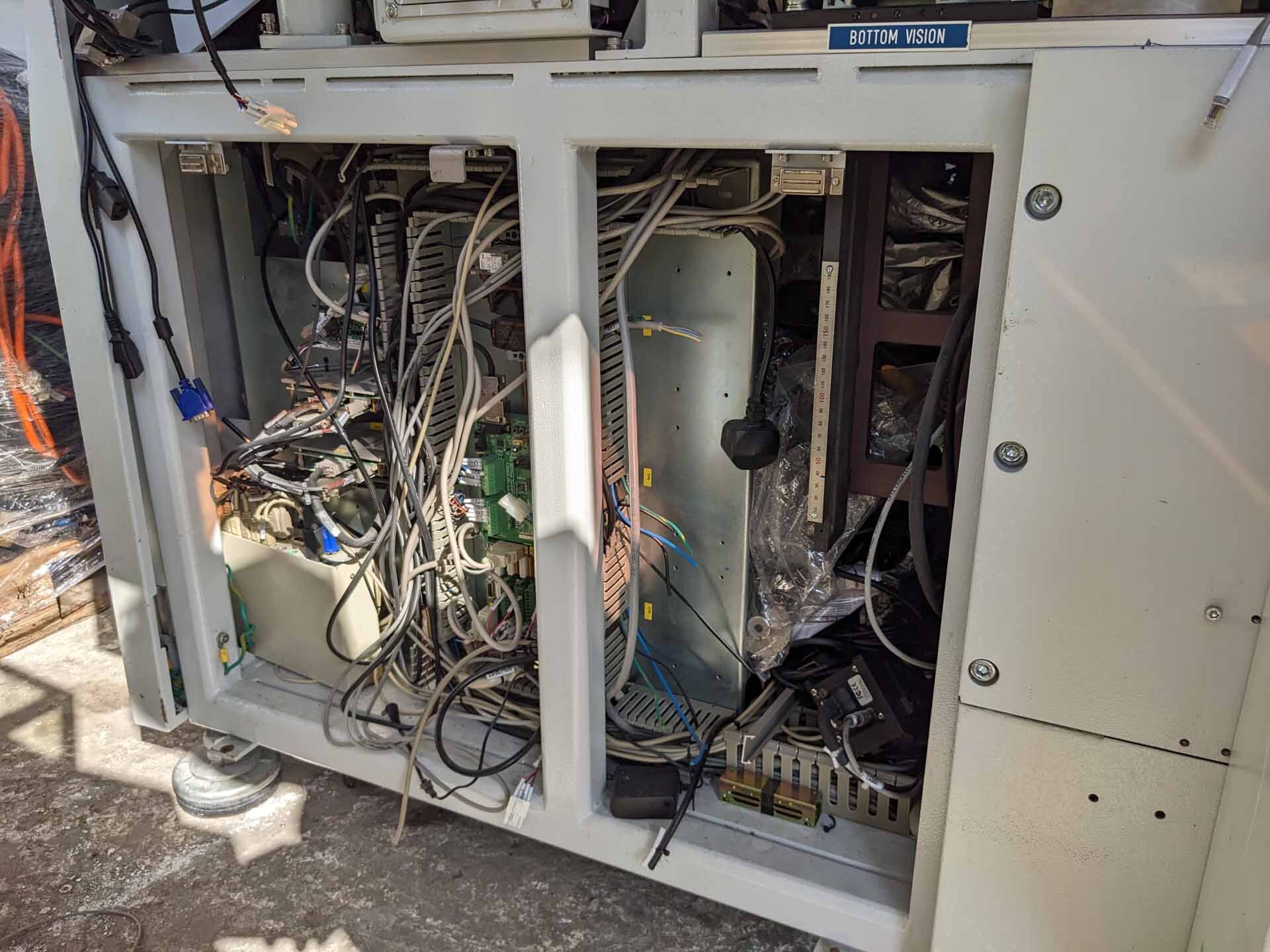

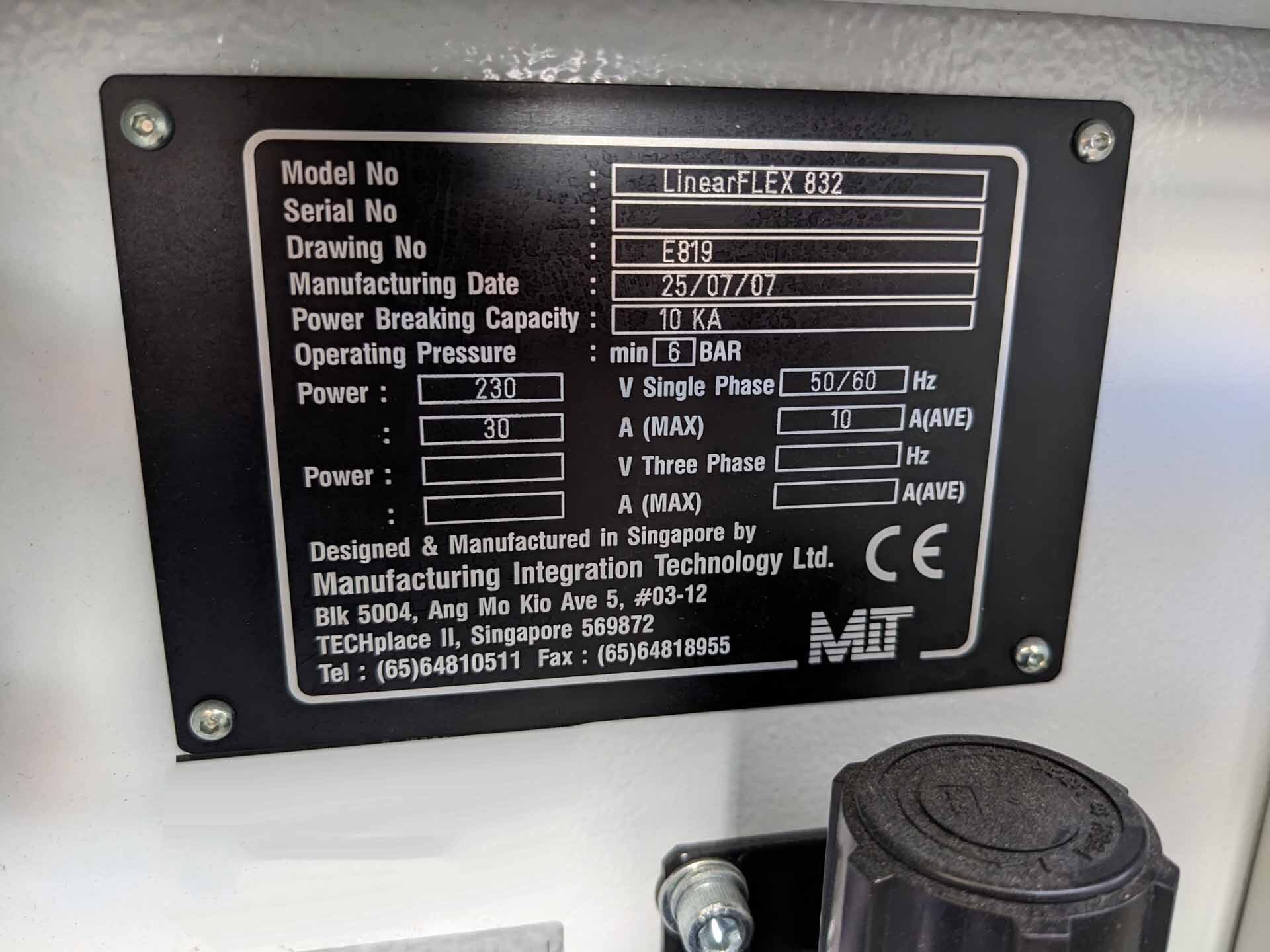

Used MANUFACTURING INTEGRATION TECHNOLOGY / MIT Linearflex 832 #293651841 for sale

URL successfully copied!

Tap to zoom

MANUFACTURING INTEGRATION TECHNOLOGY / MIT Linearflex 832 is a flexible, automated surface mount handler that is designed for efficient manufacturing of printed circuit boards (PCBs). The handler offers flexibility and performance with a simple, low-cost design that is ideal for high production environments. It features a high speed, integrated single-axis pick-and-place equipment with an intuitive touchscreen interface for easy operation. The handler includes a linear feeder tray system with a wide range of tape formats and ESD-safe motorized conveyor with a multi-sensor monitoring unit for accurate PCB placement. MIT Linearflex 832 is capable of simultaneous pick and place operations with an advanced vision machine for inspecting existing components and checking for correctness at high speeds. The handler contains two feeder ports that can be configured with feeders for leaded and lead-free parts, reducing setup times and improving flexibility. It also includes a top-mounted robotic arm provides easy access to components, while a wide variety of loader modules provide adaptability to changing production needs. The machine's vision tool utilizes dual color cameras to inspect components, reduce rework and ensure the highest quality of PCB assembly. A refrigerator-like 'cool chamber' prevents oxidation and maintains peak performance when handling a variety of different part types. MANUFACTURING INTEGRATION TECHNOLOGY Linearflex 832 can handle small, fast-moving parts and can process up to 10,000 components per hour. It features fast compression of parts and repair locations and provides sophisticated quality control, with no manual inspection time required. The machine is designed to meet the International JEDEC Temperature Cycling and Low Temperature storage standards, and is compliant to Directive 2011/65/EU (RoHS 2). It also meets current industry standards for traceability, with advanced barcoding to help manufacturers track and trace production output. Linearflex 832 is an advanced, flexible handler with a simple, low-cost design to enable efficient manufacturing. It is equipped with numerous features to provide accurate, high-speed PCB assembly with minimal manual inspection time. With its intuitive touchscreen interface and a variety of loader modules, the handler offers a powerful and reliable tool for meeting the demands of modern high-volume PCB production.

There are no reviews yet