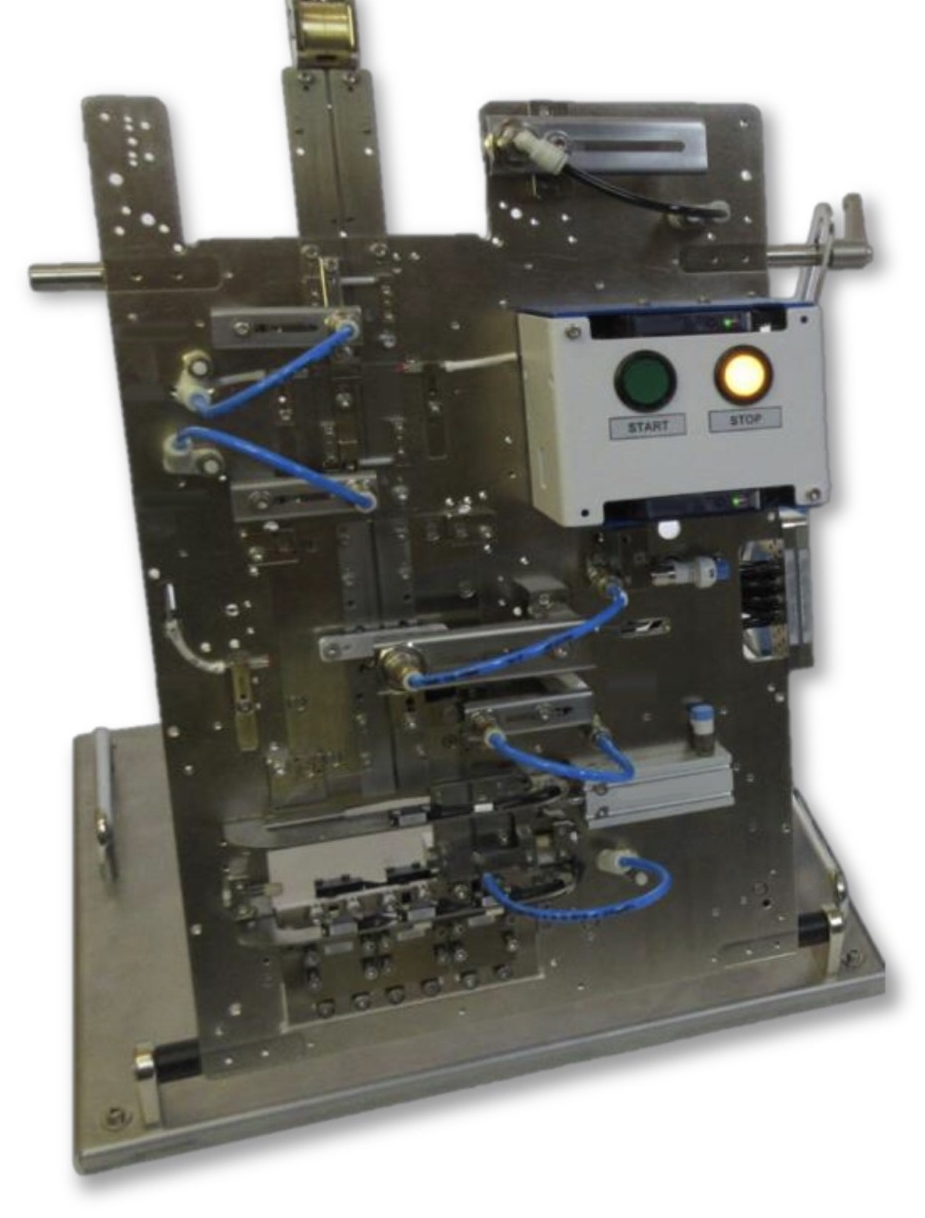

Used MICROHANDLING MH200 #9259592 for sale

URL successfully copied!

Tap to zoom

ID: 9259592

Handler

Temperature mode: Room temperature

Tri-temperature: -40°C upto +155°C

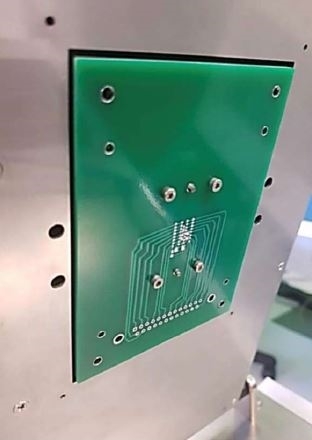

Interface: Parallel, RS232 standard

Conversion kit and Connectors

Input options:

Input tube

Bowl feeder

Tube auto loader

Output options:

(3) Outputs

Auto unloader

Tape and reel

Device types:

MLP, QFN, SO, TSSOP, QSOP, SSOP, SOT, SIP, ZIP, PLCC, LCC

DPAK

Package type: SOIC

Single site

(16) Leads

Power and pneumatics:

Electrical: 230 / 110 VAC

Air pressure: 6 bar

Air consumption: 6 l/s at 5 bar (5.3 SCFM at 72 to 145 psi).

MICROHANDLING MH200 handler is a multi-function wet bench tool used for handling and manipulation of small specimens. It is designed to be highly precise and accurate in its manipulations thanks to its micro-force control equipment, which allows for the maintenance of extremely tight tolerances. Its construction provides a wide range of mathematical optimization capabilities, allowing operators to determine the most ideal rotation or positional parameters for each specimen. MH200 handler is made from anodized aluminum and is highly durable, featuring a rigid frame and four (or more) motors for precise positioning and orientation. It is equipped to rotate a specimen in two axes, as well as a tilt axis. This gives the operator a high degree of flexibility in positioning the specimen. Furthermore, simultaneous movements in two axes can be managed, enabling complex motions. This is further enhanced by the use of a three-dimensional encoder, allowing precise and repeatable positions and rotations. MICROHANDLING MH200 handler includes an integrated controller that allows operators to adjust the velocity and torque of the system. This ensures that the movements are always optimally designed and that the forces applied to the specimen are always precise and appropriate. The built-in electronics also help to achieve long-term stability and low noise, making it suitable for applications requiring reliable and low-noise operation. The design also allows for an easy connection of different modules from MICROHANDLING range. This ensures that functionality is customisable and suited to different applications. Furthermore, MH200 handler supports a modularized user interface, allowing for easy and intuitive interaction with the unit. In order to maximize efficiency, MICROHANDLING MH200 handler is designed to reduce manipulator idle time. This allows for optimized motion and diminishes the time required to complete any given task. Similarly, optional load force control systems can be added, giving the operator more control over operation. This enables quicker and more precise specimen manipulation, leading to higher productivity. All in all, MH200 Handler is a feature-rich and reliable machine that is designed to provide precise and reliable motion control. Its several motors and sophisticated mathematical optimization capabilities enable a large variety of motions to be performed. It is equipped with a powerful auto-adjusting controller that keeps speeds and forces at optimum levels, and load control tool options that can be added toallow for rapid and accurate specimen manipulation. As a result, it is suitable for demanding precision-handling tasks.

There are no reviews yet