Used MIRAE M640A #199533 for sale

URL successfully copied!

Tap to zoom

ID: 199533

Vintage: 2008

Test Handler

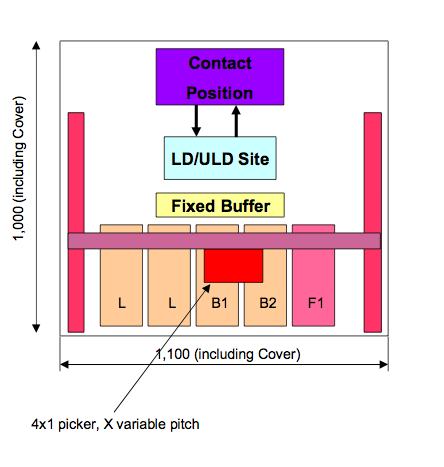

8 Parallelism

Docking Method: Horizontal

Target Packages: SD(mini & micro), MMC, TF, MS, Nintendo Card,..etc.

Device Carrying Method: Test Tray using P&P Head

Target Input/Output Media: JEDEC Tray

Tentative Throughput: 1,440 UPH (All Bin 1)

Index Time: Less than 10.0 seconds

Minimum Test Time: 0.0 seconds

Temperature: Ambient Only

Change-Over: Kitless (Flexibility Fixed)

Tester Interface: GPIB

Load/Unload Capacity:

- 5 Manual trays (2 Supply, 2 Pass, 1 Fail)

- On-the-fly Loading/Unloading

1. PRESS B/L UP: 0.5 seconds

2. PRE-CONTACT UP: 0.5 seconds

3. T-TRAY OUT: 0.5 seconds

4. HEAD PUSHER UP: 0.5 seconds

5. SORTING & LOADING (2 CYCLE): 16 seconds

6. HEAD PUSHER DOWN: 0.5 seconds

7. T-TRAY IN: 0.5 seconds

8. PRE-CONTACT DOWN: 0.5 seconds

9. PRESS B/L DOWN: 0.5 seconds

CYCLE TIME: 20.0 seconds (When Minimum Test Time is ZERO)

Current Expected UPH: 1,440 EA

As one T-TRAY is used, CYCLE TIME = INDEX TIME

2008 vintage.

MIRAE M640A handler is an advanced, user-friendly robotic material handling device designed to optimize automation in a wide range of applications. This handler uses advanced programmable logic controller (PLC) technology to provide precise control over various material-handling processes. It is equipped with a load capacity of up to 6 kgs and a working speed up to 5 meters per second, allowing it to quickly and efficiently transport goods and materials. The device is capable of customized behaviors and functions, from simple point-to-point material handling to complex multi-dimensional switch-based flow routing for load transfers. M640A's intuitive user-friendly software allows for a wide range of material handling operations, which can be easily programmed and adjusted even by novice users. The device's small, ultra-compact design makes it easy to use in tight spaces and its modular construction allows it to perform long-distance material handling tasks. The device's performance is enhanced by its smart dynamic motion technology; while moving, MIRAE M640A handler can detect changes in the environment and adjust its behavior accordingly. Its Smooth Control System (SCS) with vector speed control can adjust position, speed and torque with greater accuracy and control, allowing it to keep up with changing material handling environments. The device is also equipped with various safety features including a minimum of three redundant sensors to detect dangerous faults, a hardware watchdog and E-Stop detection. M640A handler is the ideal device for handling all kinds of goods and materials in any variety of material handling applications. Its advanced features and user friendly software ensures smooth operation, reliable performance and maximum safety at all times.

There are no reviews yet