Used NUTEK NTE 110ULXL-MW #9074090 for sale

URL successfully copied!

Tap to zoom

ID: 9074090

Vintage: 2011

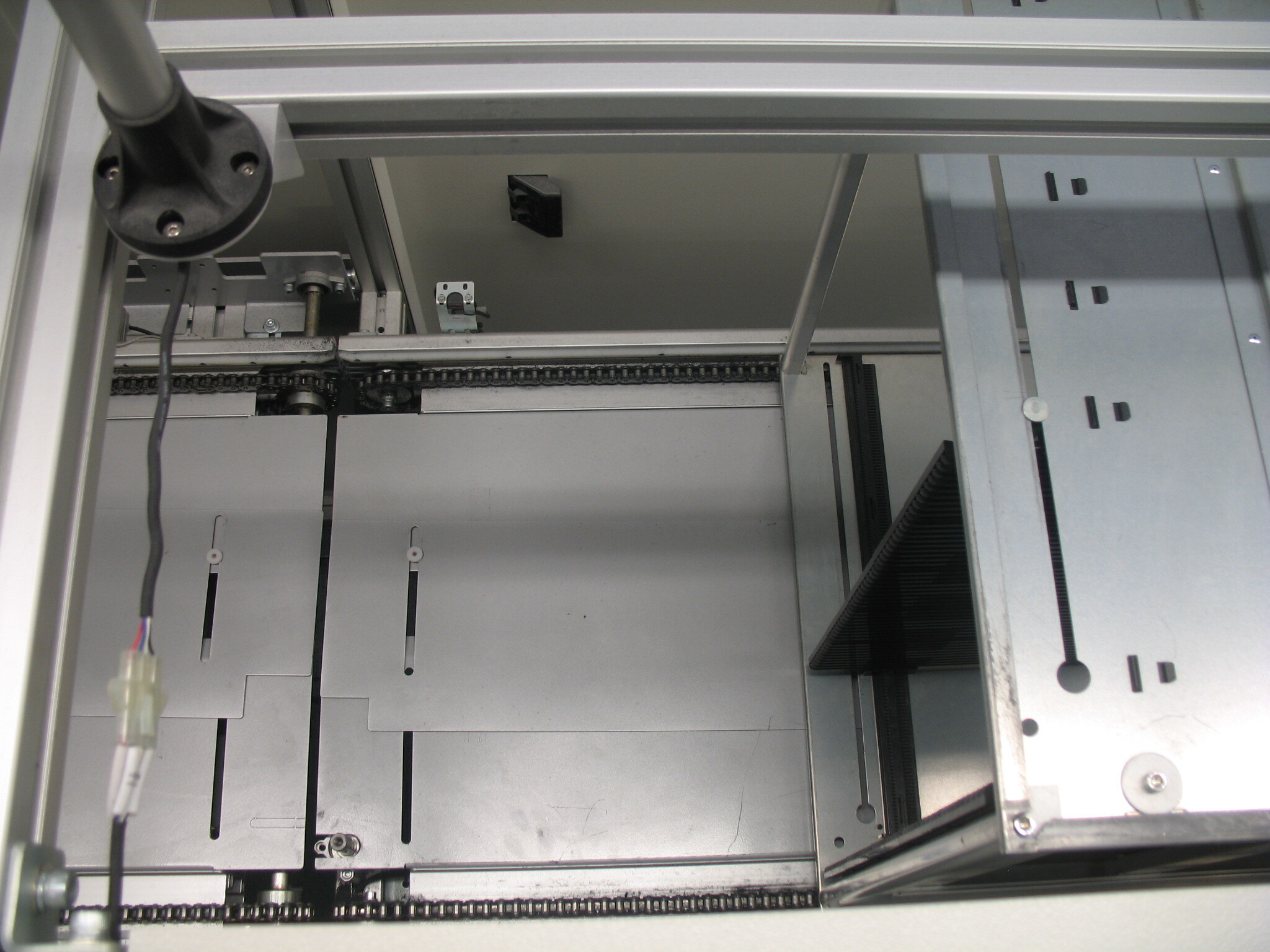

Multi-magazine unloader

Unloader: automatic magazine change over using a lifting platform,

Upper magazine conveyor: (2) empty

Lower magazine conveyor (3) full

2 or more different magazine rack dimensions

Max. Magazine width: 580mm

Max. Magazine length: 535mm

Magazine alignment: upper and lower pneumatic clamping

Selectable pitch settings: 10, 20, 30 and 40 mm

PCB width: 70 – 508 mm

PCB length: 80 – 508 mm

Regulated pressure on pneumatic cylinder

Exit and entrance sensors at front and rear conveyor rail

Sliding width adjustment

PLC controlled

Light tower: (3) colors

Includes documentations

2011 vintage.

NUTEK NTE 110ULXL-MW is a next-generation handler designed for high-speed production of advanced electronic assemblies. Its state-of-the-art features enable it to handle surface-mount components with greater precision and accuracy than ever before. By utilizing a variety of innovative technologies, NTE 110ULXL-MW is ideal for high-mix, low-volume operations. NUTEK NTE 110ULXL-MW is equipped with a classical four-head, storage cassette-to-board handler configuration. Its forced air component nozzle equipment provides accurately-directed air flow for precise part placement during placement cycles. The system also utilizes a dual-beam vision unit to ensure a high degree of accuracy, tolerance and precision. The dual-beam vision machine is further complemented by the optional Closed-Loop placement verification which provides real-time feedback and data to track placement performance. NTE 110ULXL-MW incorporates advanced automation and advanced monitoring features. It utilizes Automatic Disaster Recovery mode to enable the user to minimize the time needed to repair minor machine errors. The over-the-air monitoring tool allows remote monitoring of the asset from a centralized location. The model also provides comprehensive reporting and tracking capabilities. NUTEK NTE 110ULXL-MW features a flexible small component handling capability. The equipment offers the ability to handle various package types including 0402 (metric) components. The system also provides an optional automatic pick & place head for larger components, eliminating the need for manual handling. NTE 110ULXL-MW's dynamic component tray capacity provides improved feeder capacity and flexibility. The unit can accommodate up to 800mm feeders with both metric and imperial sizes. Moreover, the machine is compatible with a variety of standard feeder types including both continuous burning and multiple take design principles. NUTEK NTE 110ULXL-MW is an extremely reliable and efficient tool. Its advanced robotic control asset allows for an unprecedented level of flexibility and accuracy. In addition, the model is designed to maximize uptime and throughput with minimal maintenance. With its advanced features and precision controllers, NTE 110ULXL-MW is an excellent solution for high-volume production operations.

There are no reviews yet