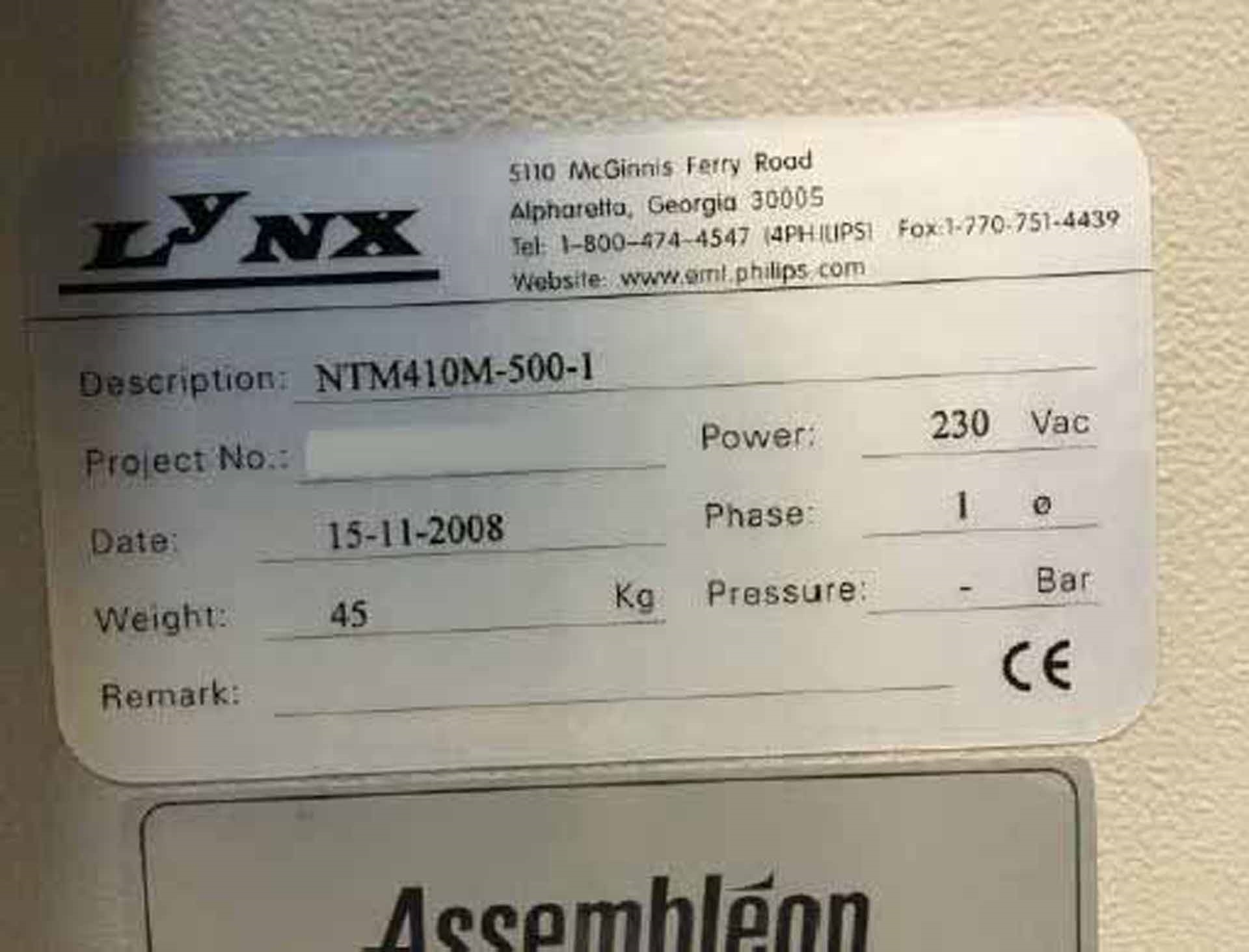

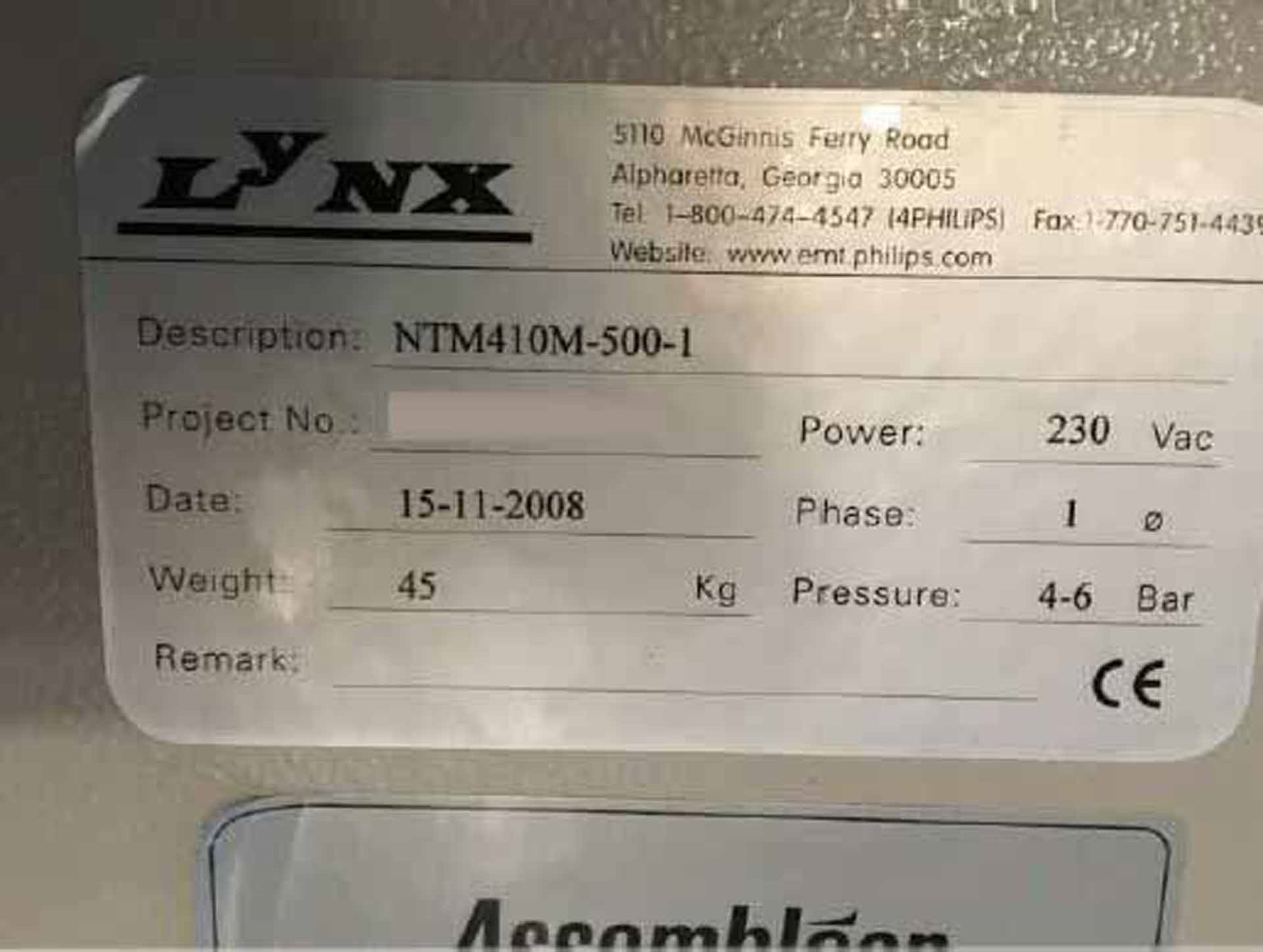

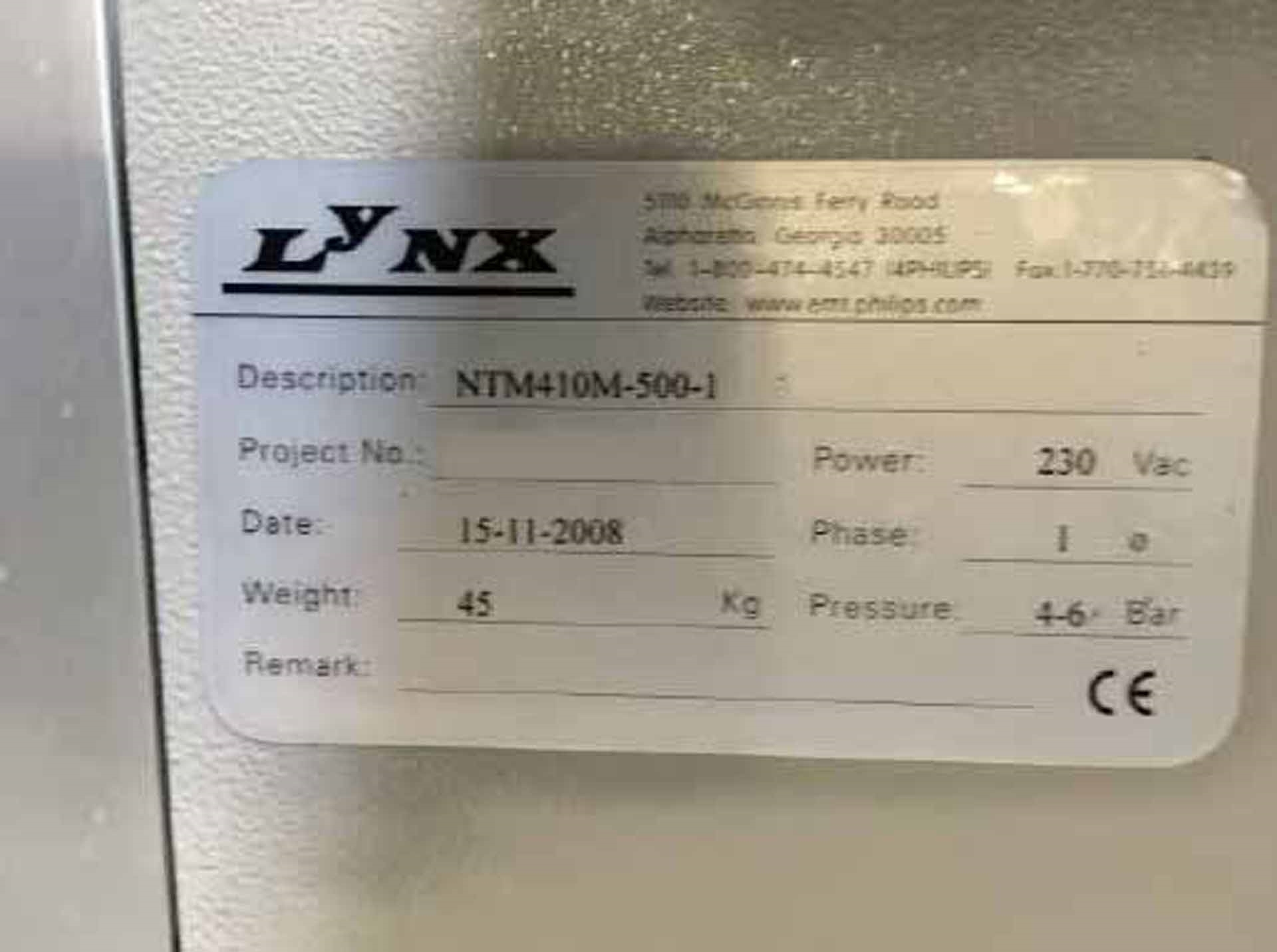

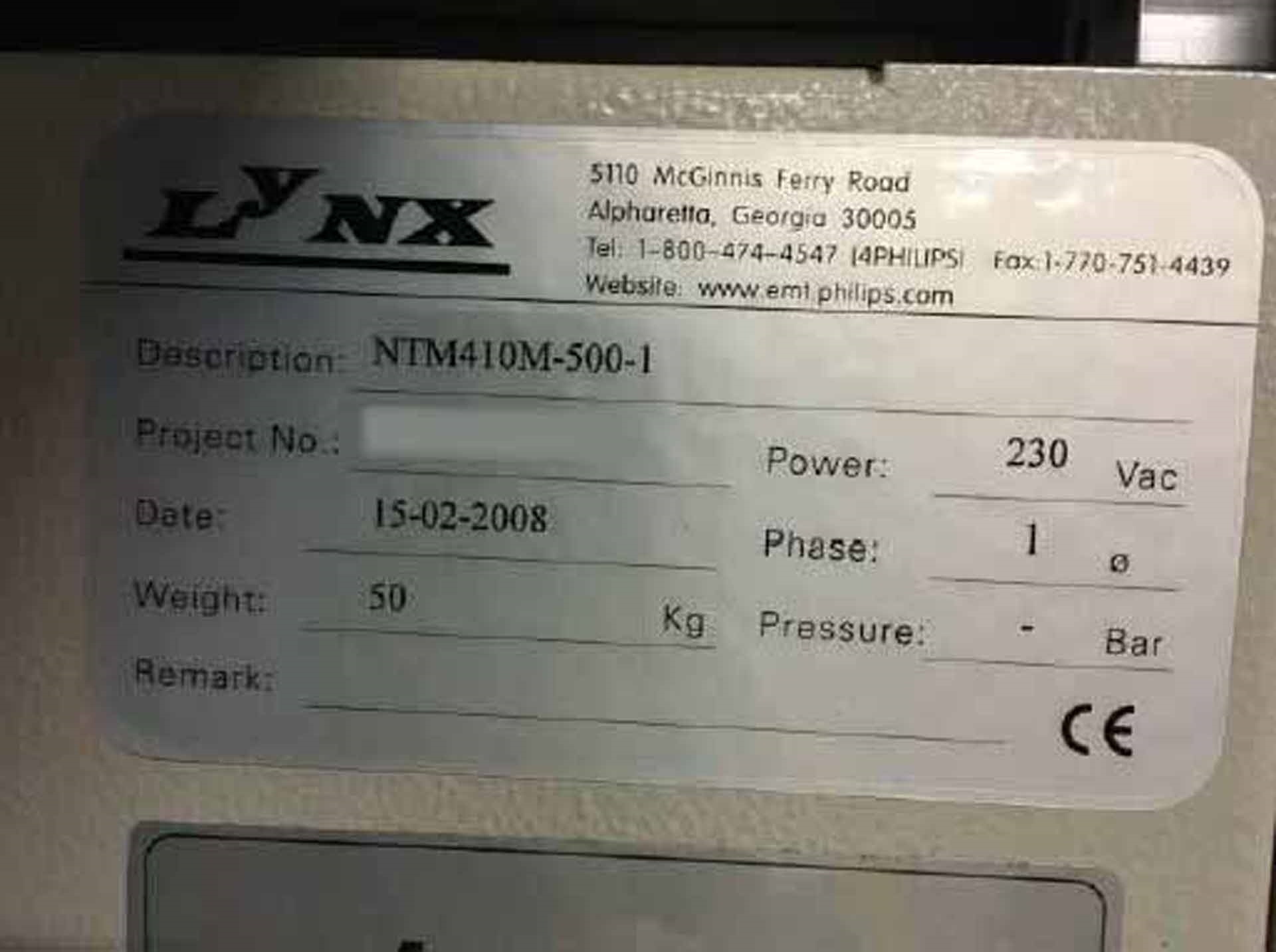

Used NUTEK NTM 410M-500-1 #9222595 for sale

URL successfully copied!

Tap to zoom

ID: 9222595

Vintage: 2008

Linking conveyors

One zone

Segment length: 500 mm

Conveyor width adjustment using hand crank

Inspect function at exit sensor

Controlled by PLC

Adjusted incoming and outgoing speed

PCB Length: 80mm - 457mm

PCB Width: 50mm - 250mm

CE Marked

2008 vintage.

NUTEK NTM 410M-500-1 is an advanced low-cost automated handler designed for high-performance inline testing of printed circuit boards (PCBs). It has been designed to enable faster and more reliable testing for a wide range of devices for the electronics industry. NTM 410M-500-1 is based on the NuTech STM 410M-500-1-A platform, which is a modular test handler chassis designed for testing applications such as Wafer Level Chip Scale Packaging (WLSCP). It is built on the NuTech T-Joint Structure, which combines many features that maximize the number of testing nodes. The base platform includes four removable sections at the top, bellow the sections are the four functional platforms - the Electronic Load Board (ELB), Power Conversion Module (PCM), Compressor Platform (CP) and the Command/Control Platform (CT). NUTEK NTM 410M-500-1 also includes eight Core Carrier Platens that can hold up to four Core Carrier Modules (CCMs). Each of the CCMs can accommodate up to four Core Carriers. All of the Core Carriers with active components are placed in the dedicated CCM For Testing. The low profile low-cost Core Carriers are capable of handling a variety of compliant and non-compliant components such as; DIPs, SOICs, and QFPs. This allows NTM 410M-500-1 to be used in automated testing applications where a wide range of compliant and non-compliant device types are present. NUTEK NTM 410M-500-1 is equipped with a highly efficient aerosol evacuator and Filter Plate Device (FPD) that can be used to evacuate airborne contaminants from the test site. The FPD is adjustable and can be configured to match the user's specific application. The FPD works in conjunction with the Aerosol Evacuator Filter Cartridge (AEFC) to remove airborne particle contamination from the test site. NTM 410M-500-1 also comes equipped with an automated conveyor equipment for complete unattended operation. The conveyor system includes the Automated Conveyor Unit (ACS) for handling, the Automated Conveyor Overhead Positioner (ACOP) for loading/unloading, and the Transport Inspection Device (TID) for real-time micro-contamination inspection and correction. ACS and TID will both have their own conveyor machine allowing the handler to unload up to four products simultaneously on four dedicated automated conveyors. NUTEK NTM 410M-500-1 is also equipped with a set of high-performance test heads that are designed to test a wide range of components. The test heads come with a variety of hardware and software options to meet the user's specific requirements. All of the components in NTM 410M-500-1 are organized to a three-step process which includes feed, test, and product transfer. This process is completed using a series of actuators, DC motors, and encoders. NUTEK NTM 410M-500-1 is designed with safety in mind. Robotics and automation are designed in accordance with the international safety standards ANSI/RIA RF 6/2006. This will ensure high performance operation and operator safety. NTM 410M-500-1 also offers a variety of communication protocols including ethernet, RS-232/422/485, USB, and TTL. Finally, NUTEK NTM 410M-500-1 is an extremely cost-effective and efficient automated handler that will enable faster and more reliable testing for a wide range of devices for the electronics industry. It is designed with the latest advancements in automation and safety protocols, making it a perfect choice for a wide range of automated testing applications.

There are no reviews yet