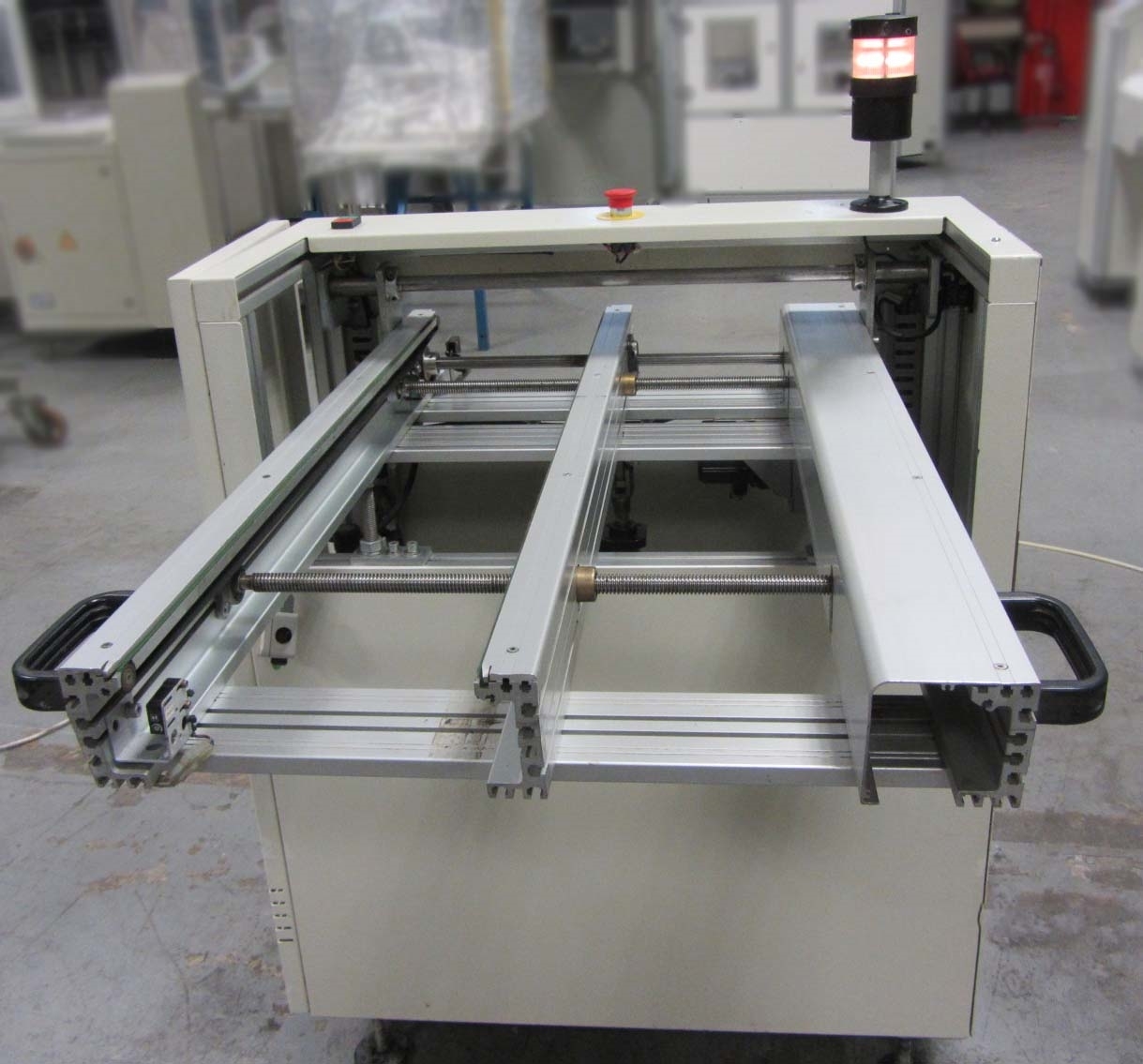

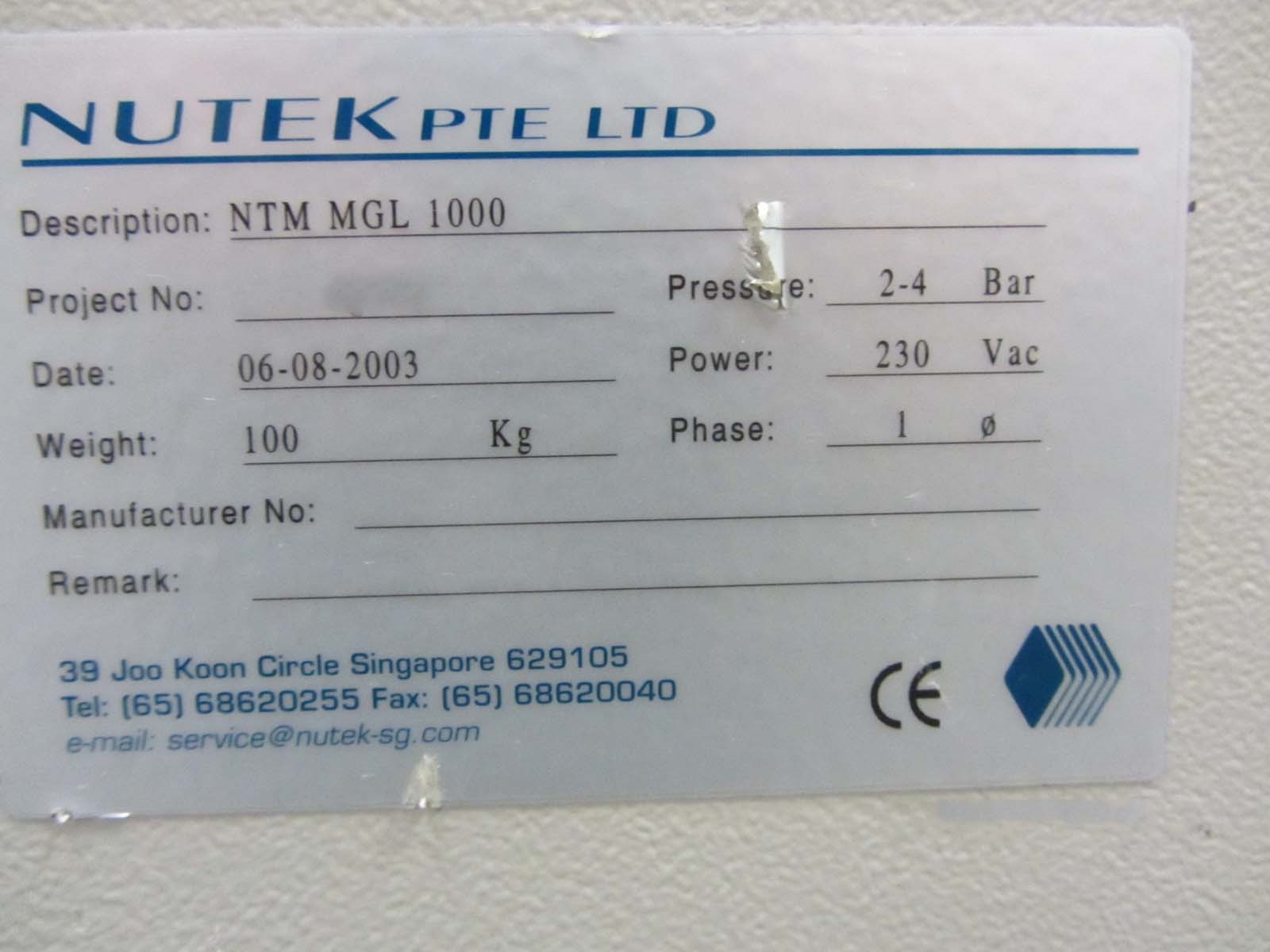

Used NUTEK NTM MGL-1000 #9268143 for sale

URL successfully copied!

Tap to zoom

NUTEK NTM MGL-1000 Handler is an automated component handling machine designed for use in high-volume manufacturing environments. This handler is capable of feeding and unloading components of different sizes at very high speeds while maintaining dimensional accuracy and repeatability at an economical cost. The MGL-1000 makes use of precision linear motions in order to take components from a magazine and place them accurately into a target area. Additionally, it utilizes vision systems to inspect the components for defects prior to placement. NTM MGL-1000 Handler has several key features that allow it to work quickly and efficiently in order to reduce cycle times for production. It utilises a dual feeder mechanism to feed components into the machine, where they are then surveyed and transferred to the target area for placement. Additionally, the handler features a series of vacuum feeds to increase the speed and accuracy of component position transfer. The MGL-1000 also has an intuitive GUI, making it easy to configure the machine to work with a variety of component sizes and designs. NUTEK NTM MGL-1000 Handler is manufactured with a sturdy aluminum frame and table, ensuring that it can reliably handle high volume component placement and transfers with minimal downtime. It is also equipped with built-in safety systems such as emergency stop buttons, ensuring the safety of machine operators around the components. The MGL-1000 has passed various types of testing, including vibration and endurance tests, and is rated for up to 8 hours of continuous operation. The MGL-1000 is designed to be easy to service and maintain, with service ports located at the front and rear of the machine. It also features easy access to the servo motors and vision modules. The modules can be configured via the GUI, and when combined with its easy access, the machine requires minimal downtime for maintenance. To summarize, NTM MGL-1000 Handler is a high-speed automated component handling machine, designed to provide reliable service in high-volume manufacturing environments. The machine features a two-feeder mechanism, vision inspection systems, and safety features to ensure accurate and repeatable component placement and transfer with minimal operator involvement. The combination of these features makes the MGL-1000 an ideal solution for component handling needs.

There are no reviews yet