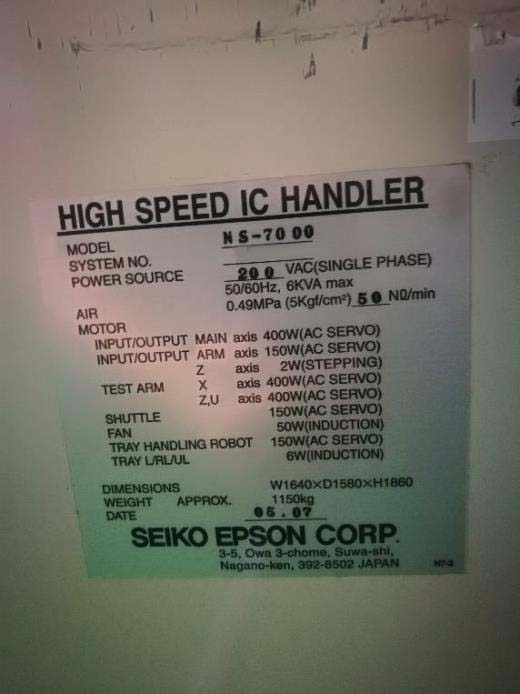

Used SEIKO / EPSON NS 7000 #9253481 for sale

URL successfully copied!

Tap to zoom

ID: 9253481

Vintage: 2005

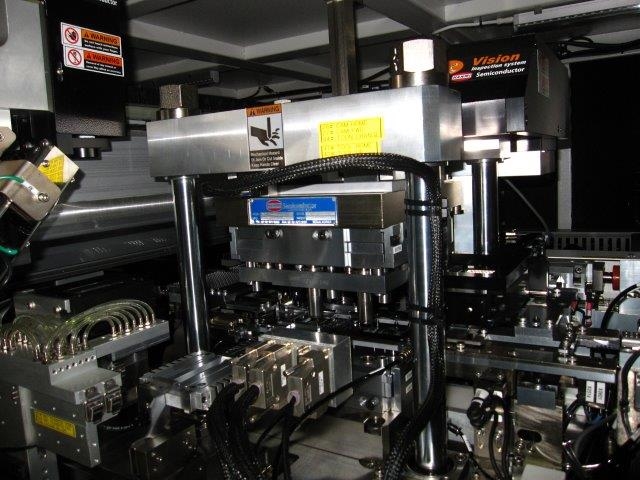

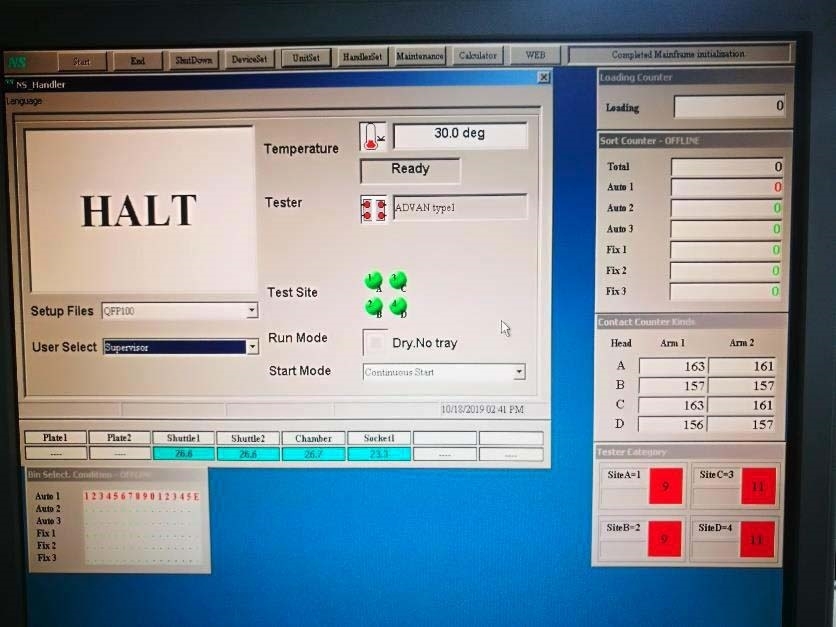

Pick and place handler

Device types: QFP, TSOP, CSP, WLCSP, BGA, QFN, PLCC, LGA, PGA

Minimum: 2 x 2 mm

Maximum: 50 x 50 mm

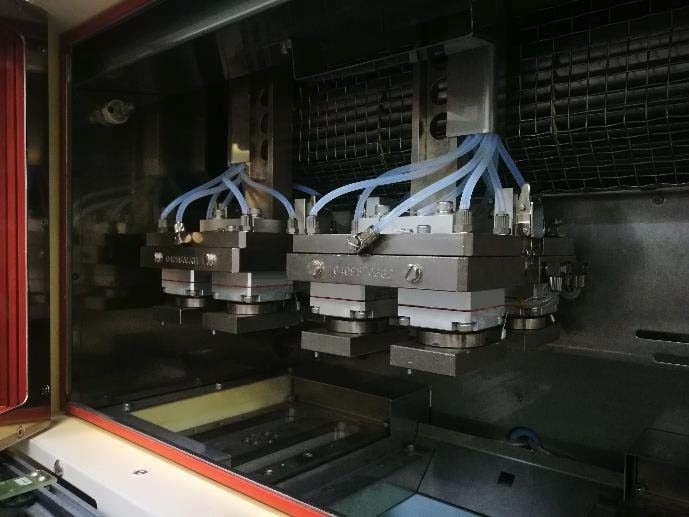

Input / Output arm hand type: Open / Close

Quad sites

Temperature: Ambient / Hot test

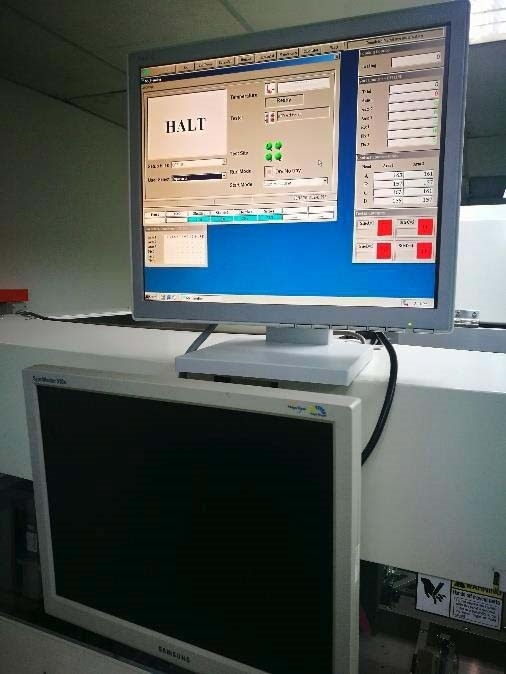

CPU: INTEL Pentium III 850 MHz

RAM: 128 MB

Unified drive box

(3) Ionizer fan blowers:

KASUGA KD-730B Loader/Unloader

KASUGA ND-503T-EP2 Chamber

2005 vintage.

SEIKO / EPSON NS 7000 handler is a high speed, low cost, production-level machine that processes printed circuits and assemblies. Utilizing a unique combination of high precision and speed, SEIKO NS 7000 is capable of processing single- or double-sided circuit boards as well as leadless and leaded components, as well as SMT, BGA and CSP packages. EPSON NS 7000 production-level handler is able to process up to 80 PCBs per hour, while easily accommodating a wide range of panel sizes, from 1" x 1" up to 249 mm x 252 mm. For increased flexibility and scalability, NS 7000 can be connected with the parts storage systems, allowing for convenient storage and deployment of parts prior to mounting. SEIKO / EPSON NS 7000 features an intuitive graphical user interface, allowing for quick and easy programming and setup of the machine. It is also equipped with its own vision equipment, further simplifying programming and allowing for improved quality control due to automatic part recognition. SEIKO NS 7000 also has a manual placement station with integrated vacuum pick-up, making it ideal for manual placement of difficult to place parts. EPSON NS 7000's high speed capabilities are further amplified by its use of system components such as the 2-axis high speed C-Axis and high-torque, 6-axis mX-Axis combined with fast, rigid and low-friction mX-Motion transports. This is further enhanced by the use of intelligent controls and advanced software, such as the FeedDuo Input modules and SEIKO Intelligent Unit Software. The feeder machine within NS 7000 consists of two Process Units, which allow for high flexibility and versatile manufacturing. The C-Axis handles the loading and unloading of PCBs onto the production line, while the mX-Axis functions as a loading and assembly unit. Due to its high levels of accuracy and speed, SEIKO / EPSON NS 7000 is an optimal tool for high volume production at low cost. Its ergonomic design ensures ease of use while its reliability and production levels makes it the perfect solution for an array of PCB processing needs. Furthermore, its automatic vision asset and feeder model provide an ideal combination for cost-effective production.

There are no reviews yet