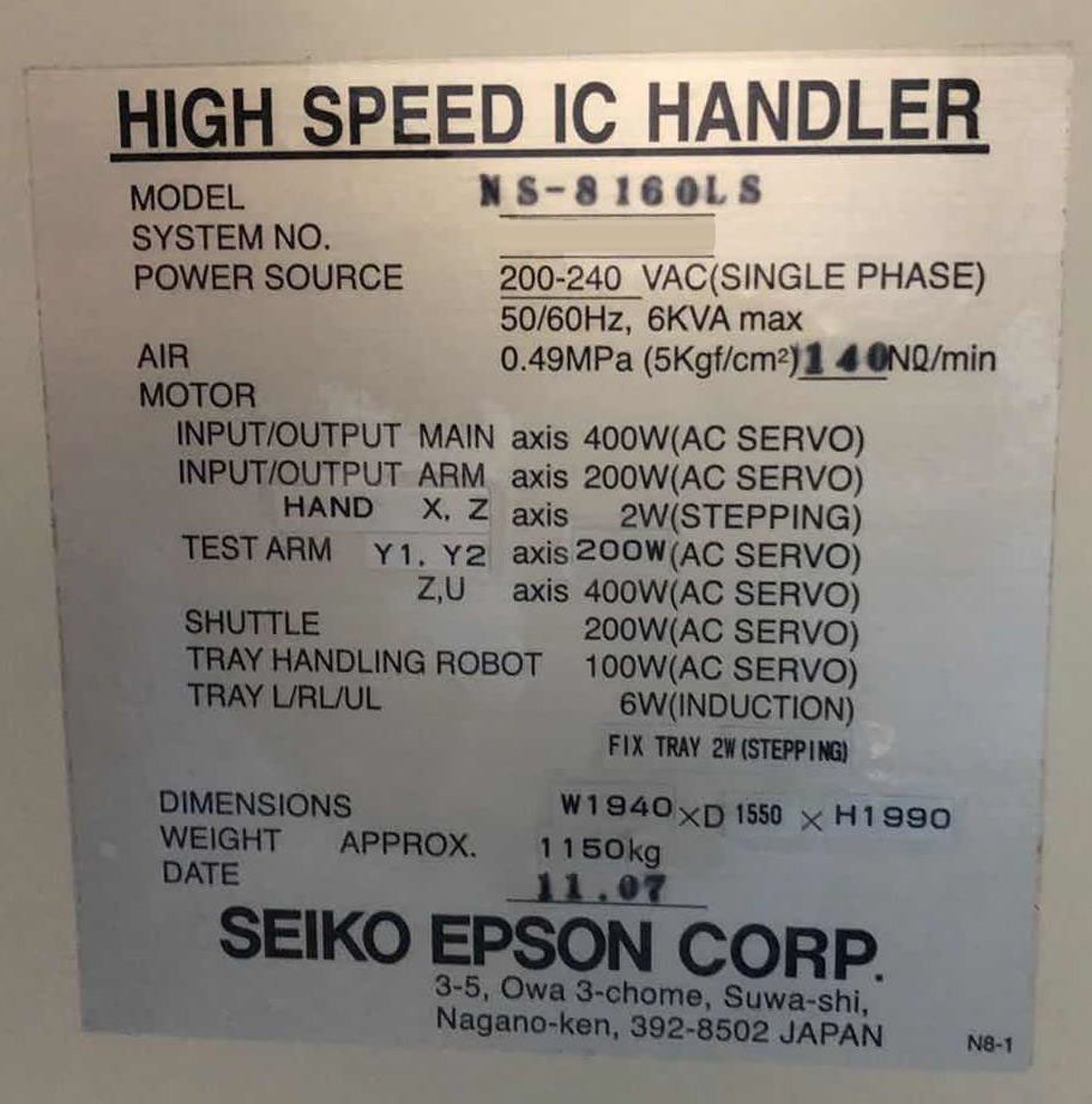

Used SEIKO / EPSON NS 8160LS #9282688 for sale

URL successfully copied!

Tap to zoom

ID: 9282688

Handler

Package type: QFP, BGA, PGA, UBGA, FBGA, LGA, TSOP, CSE, MLF, QFN, FCBGA, POP

Test site:

Layout capability (X x Y): x 16 (8 x 2)

Standard X pitch: 40 mm (Inline 8 site)

Standard Y pitch: 60 mm / 57 mm

Socket area: 340 mm x 130 mm

Contact force: 240 kgf

Pick and place I/O assembly:

(8) PNP Heads

Applicable tray:

TEDEC Tray

Auto loader

(3) Auto unloaders

(2) Fix manual unloaders

(2) Auto color trays

Temperature:

Controlled hot range: 50°C - 130°C ± 3°C

Heating method: Direct heater

Binning category: Bin 1 to 15

Tester interface supported protocol:

IEEE 488.1 GPIB

RS232

Parallel (<4 Site)

ESD:

Handler components grounding resistance:

<10 Static

<10 Dynamic

Ionizer blower / Test site: 1 kV - 100 V with decay time ≤10s

Performance:

Jam rate: 1/5000 units

Index time: 0.4 sec

Maximum units per hour (UPL): 13000

Utilities:

CDA Requirement: 0.49Mpa

Power requirement

Empty tray: Pivot function

2011 vintage.

SEIKO / EPSON NS 8160LS is an integrated, low-volume material handling system for a wide range of industries. It is designed for convenient installation in material handling facilities and provides high efficiency and reliable operation. SEIKO NS8160LS has a motor-driven, open loop, multi-axis control system with multiple controllers for driver and robot. It features a touch-sensitive touchscreen interface with easy-to-understand instructions. EPSON NS 8160 LS is designed to move, locate, and manipulate objects of varying sizes. Its flexible conveyor and decentralized robot and driver architecture provide high performance and flexibility to fit into many local production requirements. It is capable of handling parts up to 2.25 kilograms in weight, and can work in an environment up to 40 degrees Celsius. SEIKO NS 8160LS is equipped with advanced safety functions to ensure safe operations including safety door and non-contact Sensors to detect the presence of objects. It also supports traceability and process control by providing the ability to record, track, and control the production process. NS8160LS is designed for high reliability with a Zero Maintenance System (ZMS) that eliminates regular maintenance and downtime. NS 8160 LS is easy to install and use. It includes a host of features to improve service and performance. For example, it features realistic and intuitive simulation to ensure accurate operation. It also has user-friendly software with simple programming and visualization tools for quick setup and operation. Its compatibility with existing equipment and application systems offers further benefits. NS 8160LS is a powerful and reliable solution for automated material handling operations. Its advanced features and modular design make it an ideal choice for a wide variety of applications, while its reliable and efficient operation makes it a cost-effective solution for industrial operations.

There are no reviews yet