Used SYMTEK 300/439 #9361482 for sale

URL successfully copied!

Tap to zoom

ID: 9361482

Tri-temp handler

Temperature range: 55°C to +150°C

Temperature accuracy: ±2°C

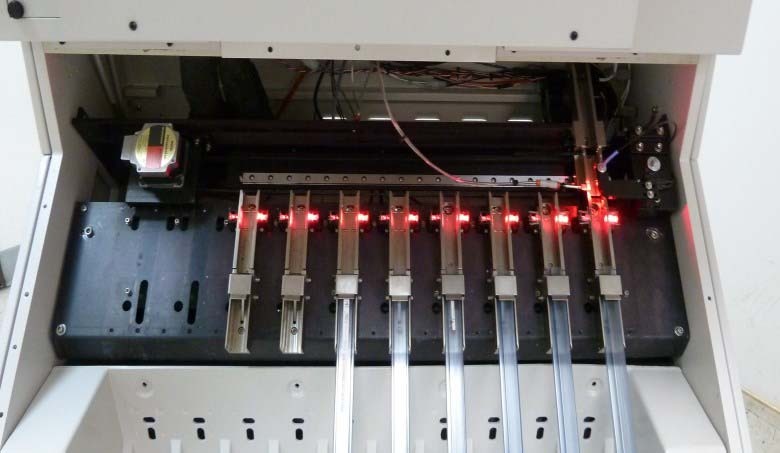

(16) Programmable output tracks capacity (SYMTEK 300)

Expanded soak chamber

With turntable input and Auto tube loader (SYMTEK 300)

Soak time range

Mean Time Before Jam (MTBJ): 1 in 3000 Parts

Air requirements:

85 PSI @ 2 CFM (80 SCFH for hot system)

LN2 Pressure: 25 PSI for cold

Communication interface and protocol:

Parallel

RS232C

GPIB

MOD-BUS

CDA-LN2 Air switcher with multiple hot air output

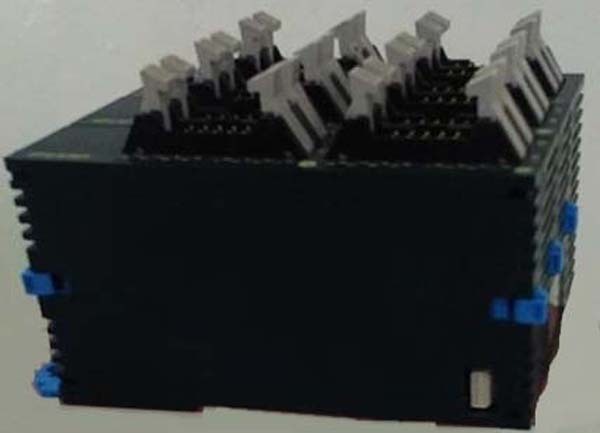

80 ns / Step integrated controller

Includes:

SESSCO UTHA Controller

Touchscreen HMI

Sort shuttle type algorithm

Sort parity and double drop detector

KEYENCE Fiber optic sensor

ORIENTAL Motors

SMC

Power supply: 115 VAC, 20 A, 50-60 Hz.

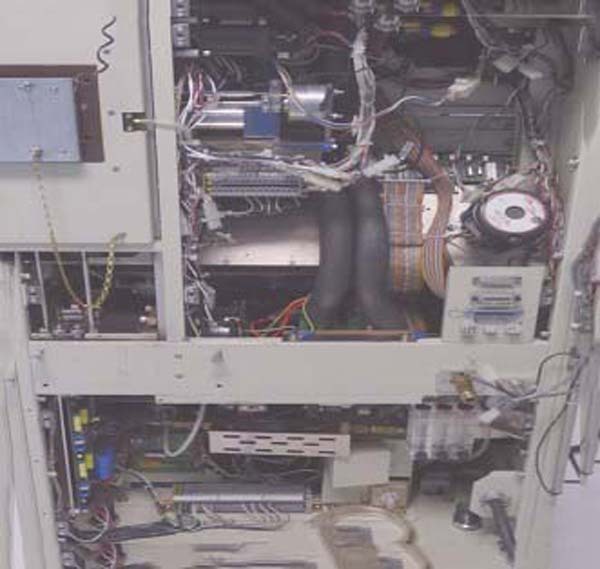

SYMTEK 300/439 handler is a high-performance pick and place equipment that is designed for the aerospace, medical, and automotive industries. It is capable of handling up to ten pieces at once, with up to 300 placement locations and is used to assemble or maintain complex assemblies. The system is made up of a main controller, two parts feeders, and four interchangeable heads. The main controller is the brain of the unit, as it programmatically directs the operation of the handler. It manages the entire sequence of operations for each part, and allows for up to sixteen axis of motion that enable the handler to accurately pick, place, rotate, and inspect all components. The parts feeders are located in the base of the machine, and act as a supply station for the parts. The bottom parts feeder is equipped with a vision-based recognition machine that allows it to identify and select parts of specific sizes and shapes. The top feeder is equipped with two-axis orientation to ensure that parts are correctly oriented before being placed on the transport. The four interchangeable heads are all designed to operate in combination with the parts feeders and controller. The first head is a pneumatic gripper, which is used to manipulate parts from the feeders on to the transport. The second head is an actuator that is used to sequentially place the parts on the transport. The third head is a vision tool that is used to monitor the parts being placed on the transport to ensure accuracy. The last head is a pneumatic actuator that is used to rotate the parts on the transport. The 300/439 handler is also equipped with a range of safety features that ensure the safety of its operators. These include a collision detection asset that stops the machine if it detects any obstruction or abnormal load, a warning model that alerts the operator to any potential problems, and an emergency stop button that shuts down the machine if there is any risk to personnel or the machine itself. In summary, SYMTEK 300/439 is a high-performance pick and place equipment that is suitable for use in the aerospace, medical, and automotive industries. It is equipped with a main controller, two parts feeders, and four interchangeable heads that allow it to accurately place parts on a transport. It is also equipped with numerous safety features to ensure the safety of the operators.

There are no reviews yet