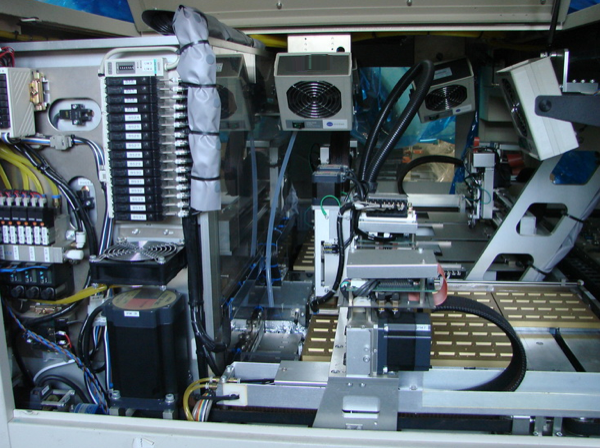

Used SYNAX SX 1701 #168378 for sale

URL successfully copied!

Tap to zoom

ID: 168378

Vintage: 2000

Pick & Place Handler

Specifications:

Applicable device:

Type: SMD: BGA, CSP, QFP, SQFP

Outside dimensions: 5mm x 5mm to 60mm x 60mm; t= 0.9 to 5 mm

Lead pitch: 0.4 mm maximum

Weight: 0.2 to 10g

Applicable tray:

Type: input tray / input empty tray

Dimensions (D x W): 200 to 330mm x 110 to 180mm

Type: output tray / output empty tray

Dimensions (D x W): 200 to 330mm x 110 to 180mm

Capacity:

Input tray: elevator with 300mm stroke

Input empty tray: elevator with 300mm stroke

Output tray: elevator with 300mm stroke

Output empty tray: elevator with 300mm stroke

CAT1: elevator with 300mm stroke

CAT2: elevator with 300mm stroke

CAT3: elevator with 300mm stroke

CAT4: 1 tray

CAT5: 1 tray

CAT6: 1 tray

Number of categories: 6 maximum

Contact area:

Method: direct / drop-off / open socket

Number of test sites: 2 or 4 ch

Socket pitch (2 ch): 80mm, X-axis

Socket pitch (4 ch): 40mm, X-axis in-line

Test head dimensions (W x D x H): 1,200 x 100 x 1,075 mm

Centering contact-position in this area

Temperature:

Operating modes: room temperature, high temperature

Range: 50°C to 125°C

Deviation (transfer area): +/- 5°C

Deviation (contact area): +/- 3°C

Heating capacity:

5 to 20mm: 80 pcs (4 x 5)

20 to 28mm: 64 pcs (4 x 4)

28 to 40mm: 64 pcs (3 x 3)

40 to 60mm: 64 pcs (2 x 2)

Heating method: sock buffer: hot plate heater

Contactor: built-in heating blow

Options:

Input 90° rotator

Output 90° rotator

Conversion kits available (for an additional cost):

128LD: TQFP conversion kit

456: BGA conversion kit

10X10X1.4T-2.0FP-64P conversion kit

27X27-328P: BGA conversion kit

Facilities:

Compressed air: dry air of 5.0kh/cm^2 or more

Vacuum air source:

Built-in diaphragm vacuum pump

Pumping volume: 100L/min

Ultimate pressure: 100Torr maximum

Electrical data:

Power supply: 200VAC, 50/60Hz

Maximum power consumption: 10kVA maximum

Controller circuit: 7.0kVA maximum

Heat circuit: 3.0kVA maximum

Earth leakage breaker: 30A/15mA trip

Power cable: 5m

2000 vintage.

SYNAX SX 1701 handler is an efficient and economical automated solution for transferring wafer data from multi-station probers to back-end probers for testing. It is a fully automated, high-speed handler capable of operating up to 8 stations at the same time. The handler is designed to handle a wide range of wafer sizes and varieties, with a maximum size of 200mm. SX 1701 includes a state-of-the-art wafer transfer control, allowing the handler to transfer wafers quickly and accurately between multiple probers and their associated equipment. The transfer mechanism is capable of transferring wafers around 4 times faster than manual operations, while maintaining a reliable and consistent transfer. SYNAX SX 1701 is equipped with multiple safety features that include emergency stop buttons, safety covers and safety interlocks. Also included is a comprehensive system diagnostics package that allows for remote monitoring of the system and its performance. The system is designed for easy maintenance, with all parts and components easily accessible. SX 1701 is also equipped with an Advanced Automation (AA) control unit and interfacing to PC and PC/LAN, allowing users to access and control the handler from remote locations. The AA controller offers various operating modes, from manual and semi-automatic to fully automated operation. SYNAX SX 1701 also features an all-in-one, integrated prober interface that connects SX 1701 to the prober and its associated equipment, providing a quick and convenient method of transferring wafers. Overall, SYNAX SX 1701 is an efficient, economical, and dependable automated handling of wafer data from multi-station probers to downstream equipment. Its advanced features and high speed operation make it an ideal solution for a wide variety of wafer transfer needs.

There are no reviews yet