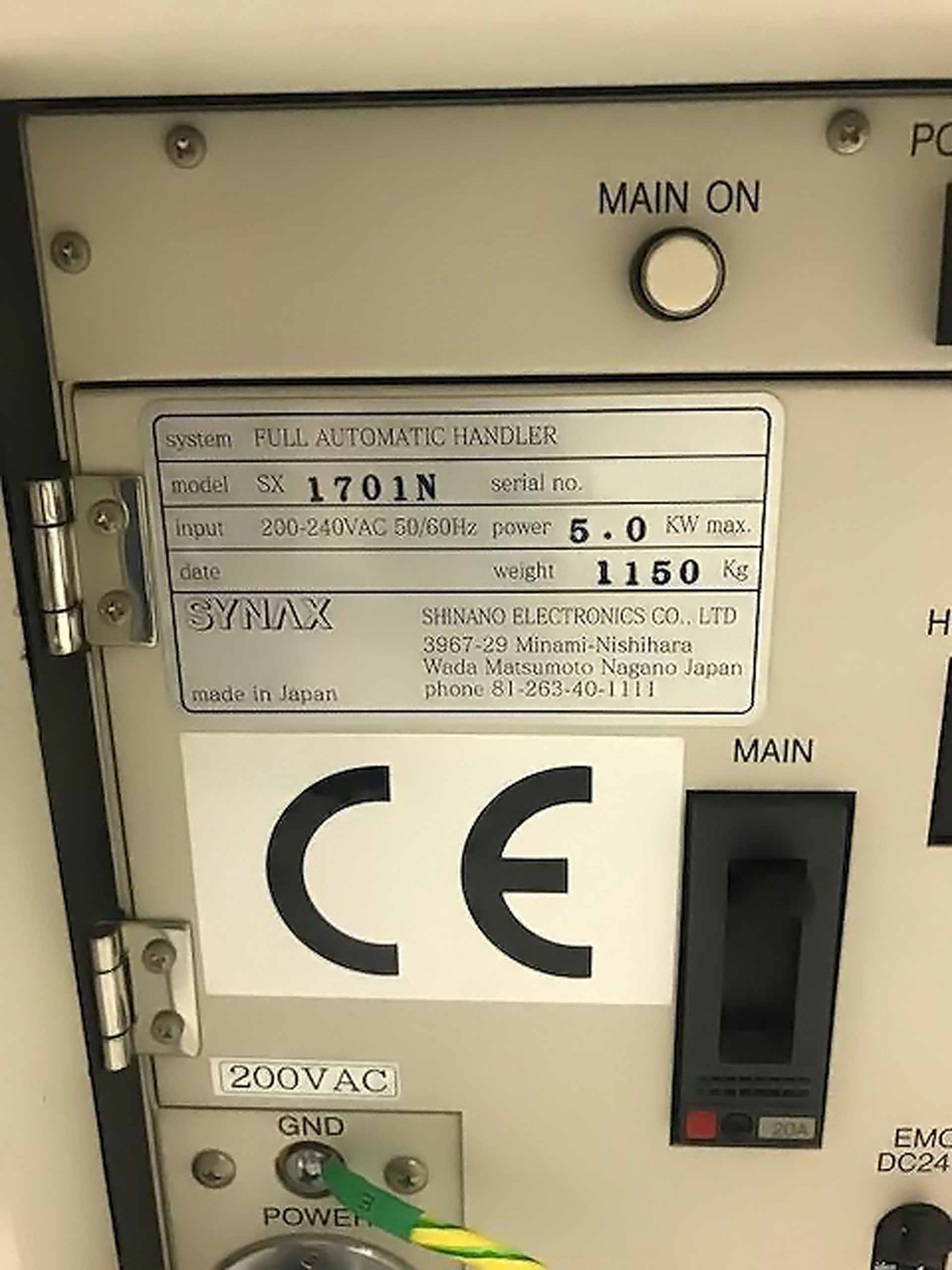

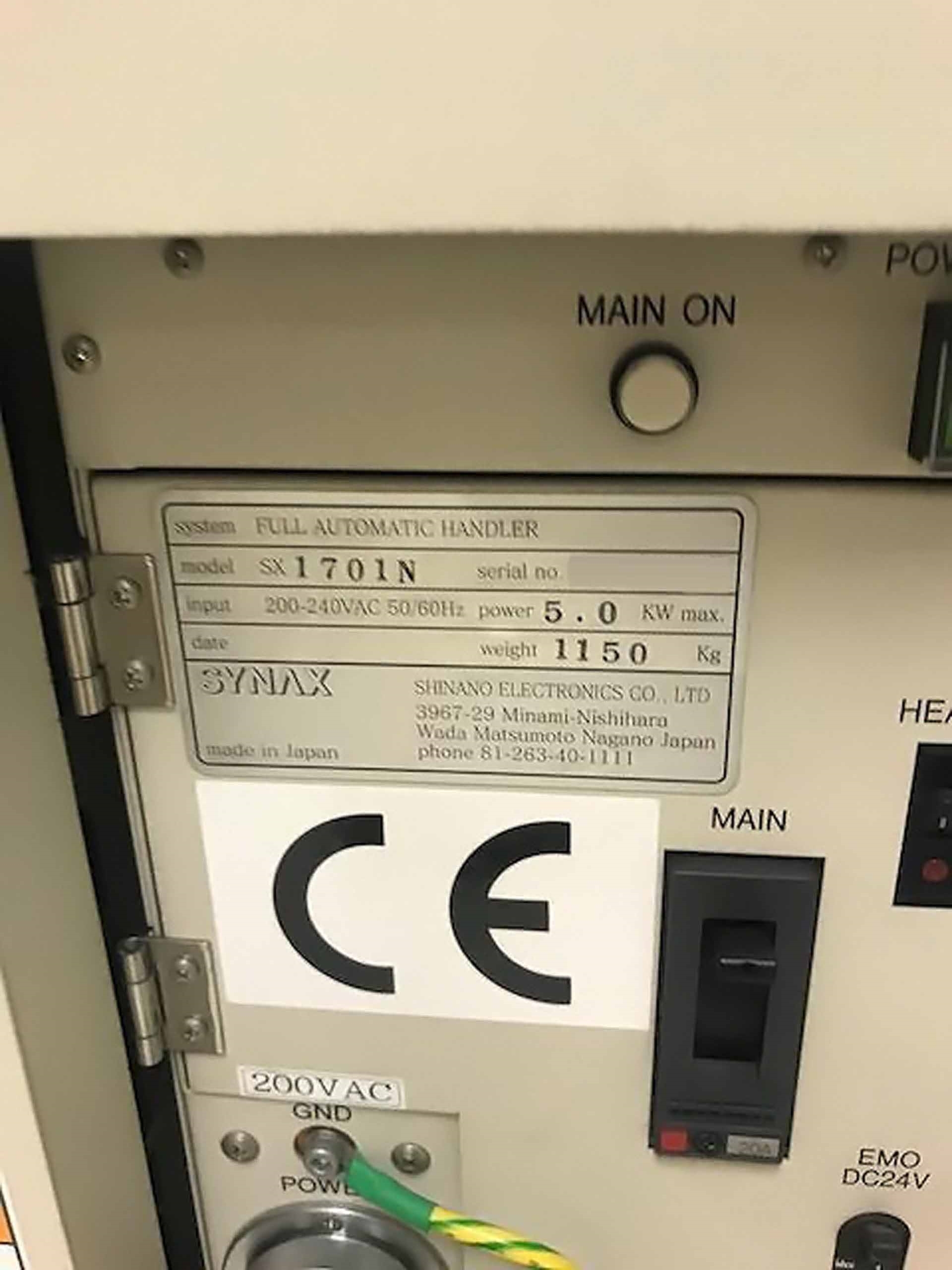

Used SYNAX SX 1701N #9218702 for sale

URL successfully copied!

Tap to zoom

SYNAX SX 1701N handler is a high-performance, fully automated 3D imaging solution for die-attached component inspection and analysis. It is ideal for applications that require complex evaluation of die-bonded components such as automotive and mobile, and displays excellent handling capabilities in the production environment while saving time and material costs. SX 1701N is designed with an integrated microscope and image capturing system, and is capable of up to 2x digital magnification with outstanding accuracy. The 3D imaging capabilities of SYNAX SX 1701N include tilted inspection, high-precision focusing, and dual-side optimization, all of which lead to detailed analysis and object identification. It also contains a wafer-probe station that can perform layer-by-layer operations, and it is equipped with a powerful and easy-to-use software package for changing inspection parameters. SX 1701N's optical navigation system offers precision positioning capability, enabling accurate location of die-attached components. The handler has an integrated liquid crystal display which provides a clear view of the inspection area and parameters. Its interactive touchscreen can be used to control and adjust inspection parameters in real time. Additionally, the handler has HD video capability, allowing users to capture, manipulate, and analyze images in high-definition. In addition, SYNAX SX 1701N is designed to interface with various industry standard software, as well as standard Inspection Data Export Format (IDEF) files, making it easy to integrate into existing systems. Its built-in system diagnostics, precision drive controls, and vibration-resistant materials allow for reliable operations in tough production environments. Finally, SX 1701N is user-friendly and has intuitive controls that make it easy to use and learn. Furthermore, its robust construction ensures not only reliable performance in a production environment, but also offers cost savings due to its low operating costs. This makes it highly efficient and an ideal solution for handling and evaluating die-attached components.

There are no reviews yet