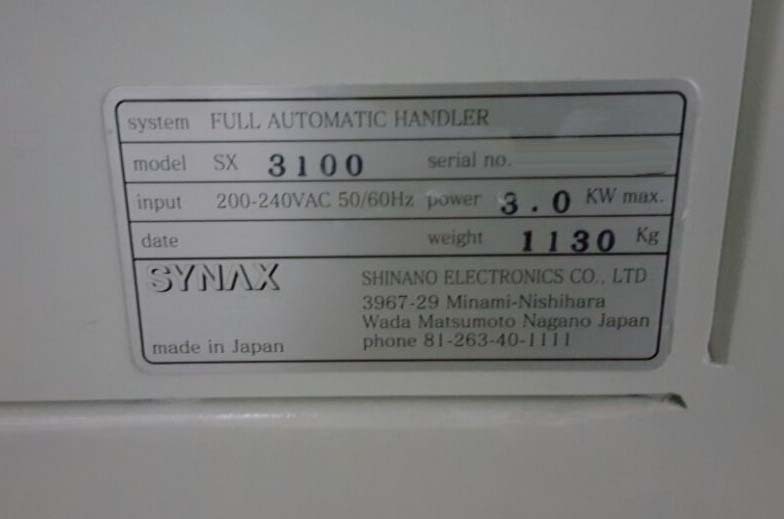

Used SYNAX SX 3100 #9146310 for sale

URL successfully copied!

Tap to zoom

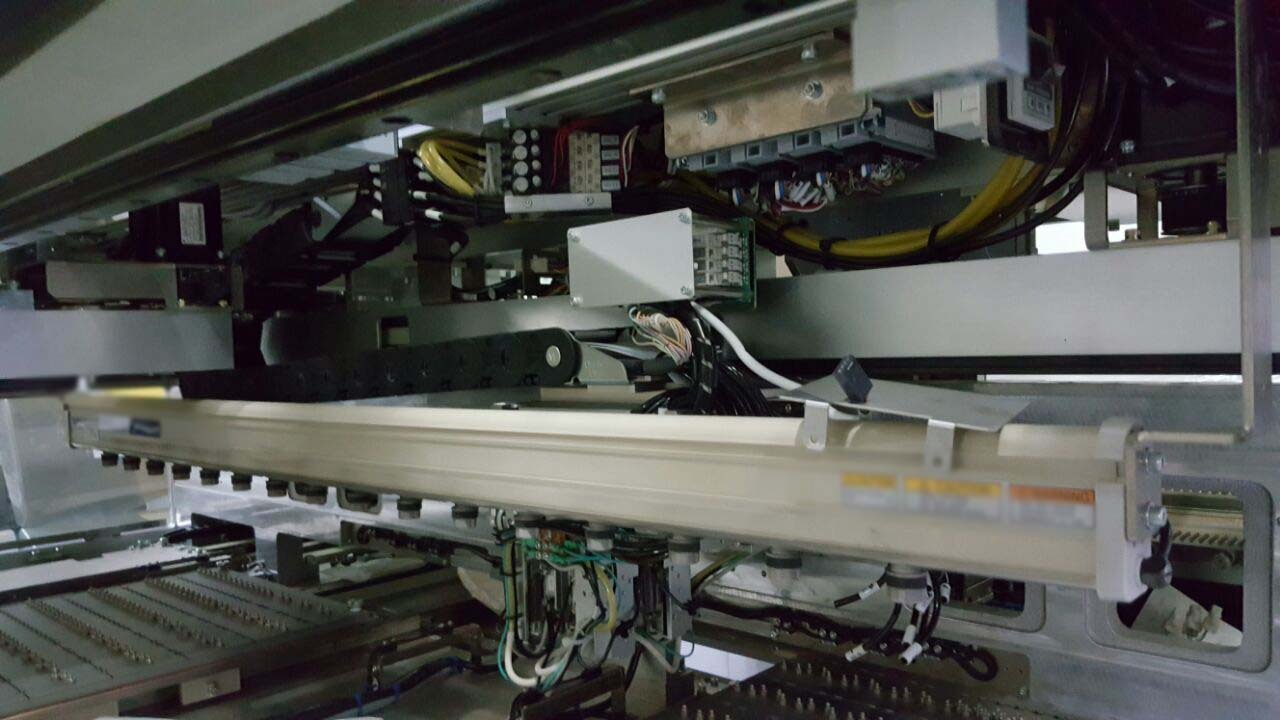

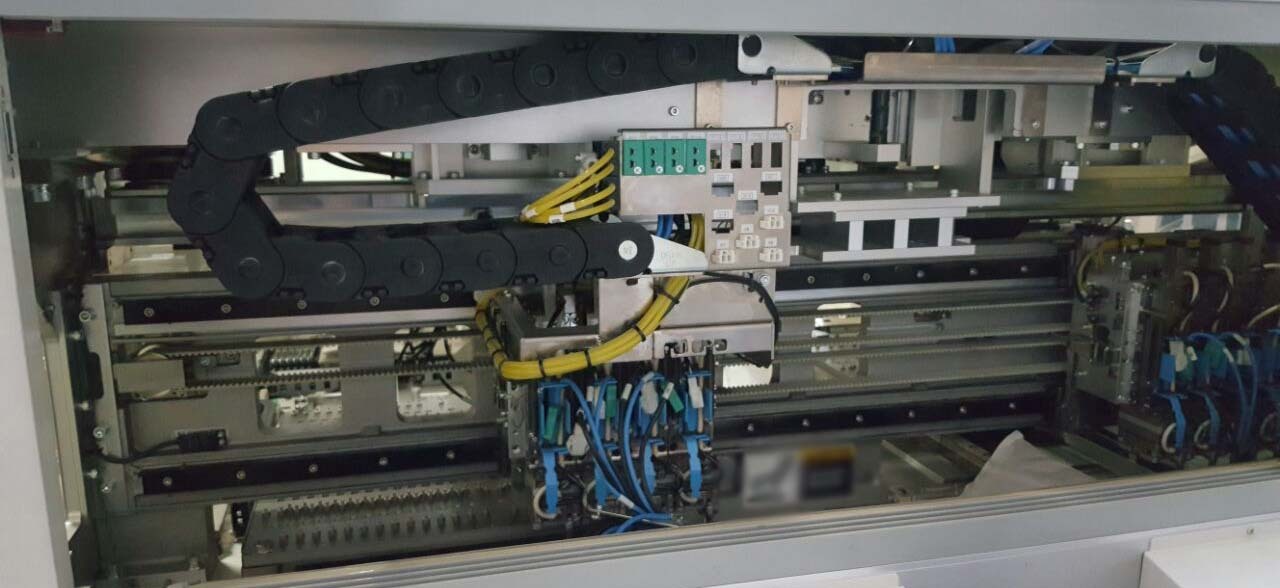

SYNAX SX 3100 is a powerful 3-axis handler designed for high-speed manufacturing and testing of multi-chip integrated circuit components. This high-performance equipment is designed for both wet and dry process operations, allowing the user to efficiently manage the complexity of modern semiconductor production. SYNAX SX3100 is capable of operating up to a blanket temperature of 37ºC and a wafer temperature of 250ºC, which allows it to handle a wide variety of multi-chip integrated circuit components. The rigid construction of the system allows for fast execution of operations for processing tasks such as wafer bonding, die-attach, laser processing, lead-frame qualifications, and die-isolation operations. SX 3100 also has a high-speed shuttle unit which allows for reliable manual movement as well as automated movements to and from specific points on a wafer surface. In addition, the handler utilizes an intelligent robot controller with onboard vision capabilities, allowing it to accurately locate and process the die on the wafer. The tool also has a self-diagnostic machine capable of managing any errors and triggering alarms. SX3100 has a user-friendly interface which allows users to configure the tool according to their needs and provides tools for easy data logging and analysis. The handler features an embedded tool management asset which allows for hassle-free connection of peripherals such as probes, probe cards and force-feedback systems. It also supports a wide range of process chemistry, including multi-flow, pulsed liquid formulations, and pressure-controlled liquids. SYNAX SX 3100 is well-suited for a variety of sample preparation applications such as thinning, back-side grinding, and cross-sectioning. With its capabilities of running both wet and dry process operations, the handler supports a wide range of high-speed applications such as die-sorting, die-oversizing, die-counting, wafer thinning, and image analysis. SYNAX SX3100 is a highly reliable and powerful handler for modern semiconductor production. It is capable of high-speed operation with a wide range of process chemistries, users are able to easily configure the model according to specific requirements and it possesses several advanced capabilities which ensure a smooth workflow and accurate results. This versatile handler is ideal for sample preparation and high-speed manufacturing of multi-chip integrated circuit components.

There are no reviews yet