Used AMAT / APPLIED MATERIALS xR80 Leap II #9329404 for sale

URL successfully copied!

Tap to zoom

ID: 9329404

Wafer Size: 8"

Vintage: 2002

High current implanter, 8"

Processor module

Beamline module

Source services module

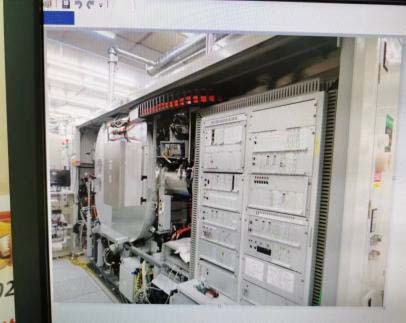

Processor rack

Mobile PC and desktop

Clean room PC

Signal tower

TEM Probe

ISO TX

Mains matching TX

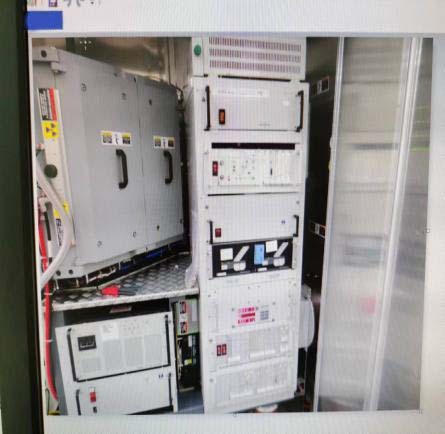

Beamline controllers PSU's and assy:

Pre accel / Mag controller

Beamline Inst

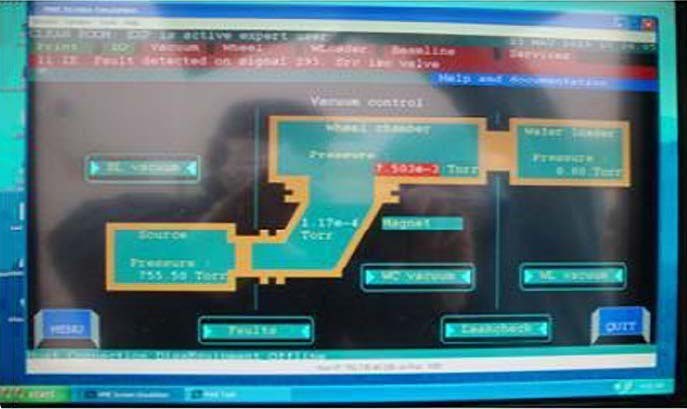

Vacuum controller

Turbo controllers

Focus PSU

Decel PSU

A Mag PSU

Pre A converter PSU

Source mag PSU

Suppression PSU

Beam path components source / Extraction / Flight tube / MRS and PFS assy:

Source head type: IHC

Extraction type: Dual bellows

Flight tube

MRS

Pre-defining

PFS Type: HD

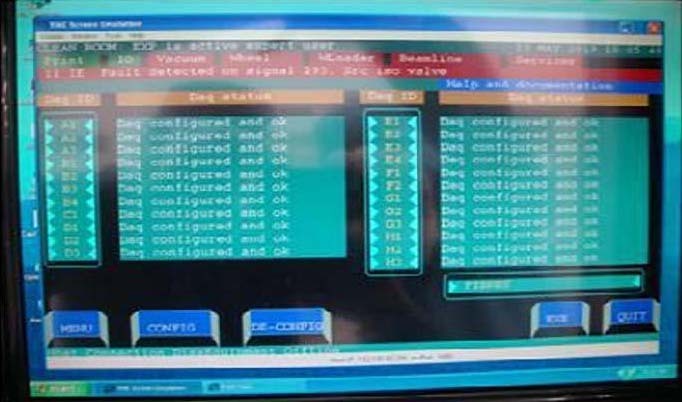

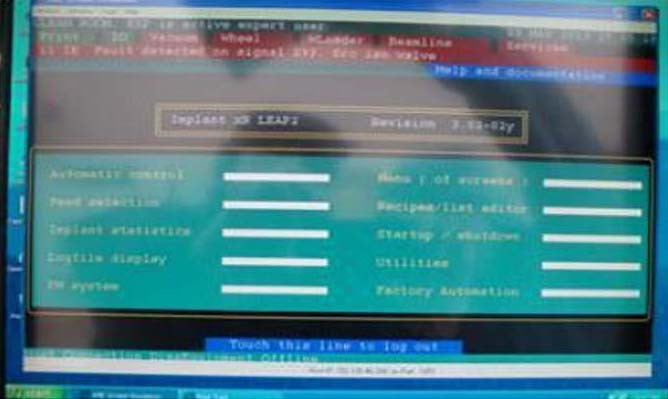

Control system: MOTOROLA 68040 Series

PC based operator interface

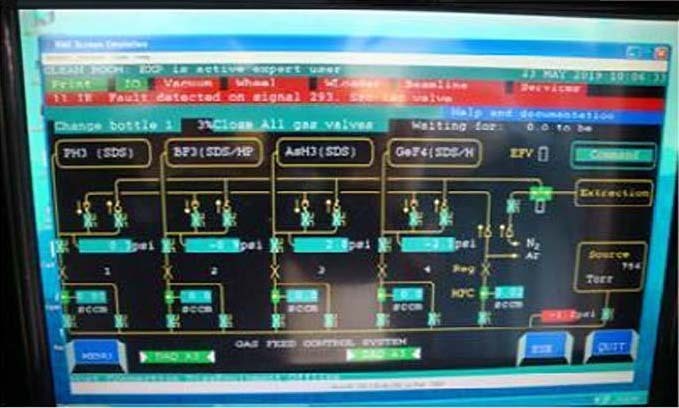

Gas cabinet:

SDS Module: AsH3 (SDS) / PH3 (SDS) / BF3 (SDS) / SDS

Purge Module

PSU's Controllers and assy:

Gas and temperature controller

Filament PSU

Arc PSU

Bias PSU

DPS

Pre A HV stack

G2 PSU, 8"

Source ISO TX

Vacuum system:

LEYBOLD 1000C Turbo pump

LEYBOLD 361C MRS Turbo pump

LEYBOLD Turbotronik NT20 Turbo pump controllers

EDWARDS QDP40 Beamline dry pump

CTI-CRYOGENICS OB -10 Side cryo pump

CTI-CRYOGENICS OB -10 Rear cryo pump

CTI-CRYOGENICS 9600 Side cryo compressor, 220 V

CTI-CRYOGENICS 9600 Rear cryo compressor, 220 V

Processor PSU's controller and assy:

Wheel and components

Spin motor

Gripper

Transfer arm

Clip actuator

Blade

A/B Sensor

Tilt assy, 0-7°

PFS DP Box

Beam stop

Beam profiler

Filament PSU (PFS)

Wafer loader:

Carousel

Indexer

W/L Door

Oriented

Cassettes / Trays: (3) Trays

Arm servo PSU

Arm servo controller

Control Rack:

DAQ PDU

Option chassis

Target system installer

W/L Controller

W/L Vacuum

Ground PDU

Target system vacuum

Spin / Scan controller

Direct drive interface

Plasma flood chassis

Amp scanner

Amp spinner

Spin / Scan PDU

Bleed resistor

VME:

CPU Main board

Loop controller

Tetrode source head

80 keV Stack with resistors on top

G2 Power supply side of gas cabinet

G2 Resistor next to source head

Source transformer

ISO Transformer W/L area

Larger beam / Stop

Decal chassis under B/line

HD PFS

Operating system: Windows NT

2002 vintage.

AMAT / APPLIED MATERIALS xR80 Leap II is a pre-fabricated ion implanter and monitor. This piece of equipment is specifically designed for the implantation and monitoring of very small substrate sizes, such as wafer chips used in semiconductor manufacturing. The Leap II is capable of high throughput implantation and real-time monitoring. The primary feature of the Leap II is its ability to operate with a variety of implant gases and dopant materials. Using the xR80 platform, the Leap II is capable of precise implants at temperatures as low as -100°C. It has an energy range of up to 800 keV which allows for greater control of the implantation process. Additionally, the Leap II has an extremely efficient mechanical cool-down equipment that allows for a faster warm-up and cool-down times. This allows for shorter cycle times and a more efficient process. The Leap II also features a high-resolution digital imaging system to perform inline substrate imaging to ensure the accuracy of the implantations. This unit uses a CCD camera to capture high-resolution digital images of the substrates, allowing for accurate process control. This monitoring machine provides real-time feedback for process optimization. The Leap II has an advanced wafer-monitoring tool which combines advanced mechanical, optical, and electrical components to provide accurate measurements of various parameters during implantation. This monitoring asset can detect potential errors and help prevent them from occurring. The Leap II's unique xR80 platform also has integrated control software that provides enhanced process tracking and control. This software allows for better process optimization and process traceability and can be customized for specific process or application needs. In addition to the high-performance waft analysis and process control systems, the Leap II also features a high-end robotic model for automated installations. This robotic equipment can be used to perform even the most complex installations, allowing for further process control and increased efficiency. Overall, AMAT xR80 Leap II is a powerful pre-fabricated ion implanter and monitor that provides efficient implantation and real-time substrate analysis. Its advanced control software allows for process traceability and the integrated robotic system provides automated installations. This unit is perfect for semiconductor chip manufacturers looking for efficient and precise implantations.

There are no reviews yet