Used NISSIN Exceed 2000 #9223171 for sale

URL successfully copied!

Tap to zoom

ID: 9223171

Wafer Size: 3"-4"

Vintage: 1997

Medium current ion implanter, 3"-4"

PN: E95-3005

Energy range: 10-200 kV

(4) Cassette stages

(2) Loadlocks: Left and right

(2) Orienters: Auto-flat / Notch find

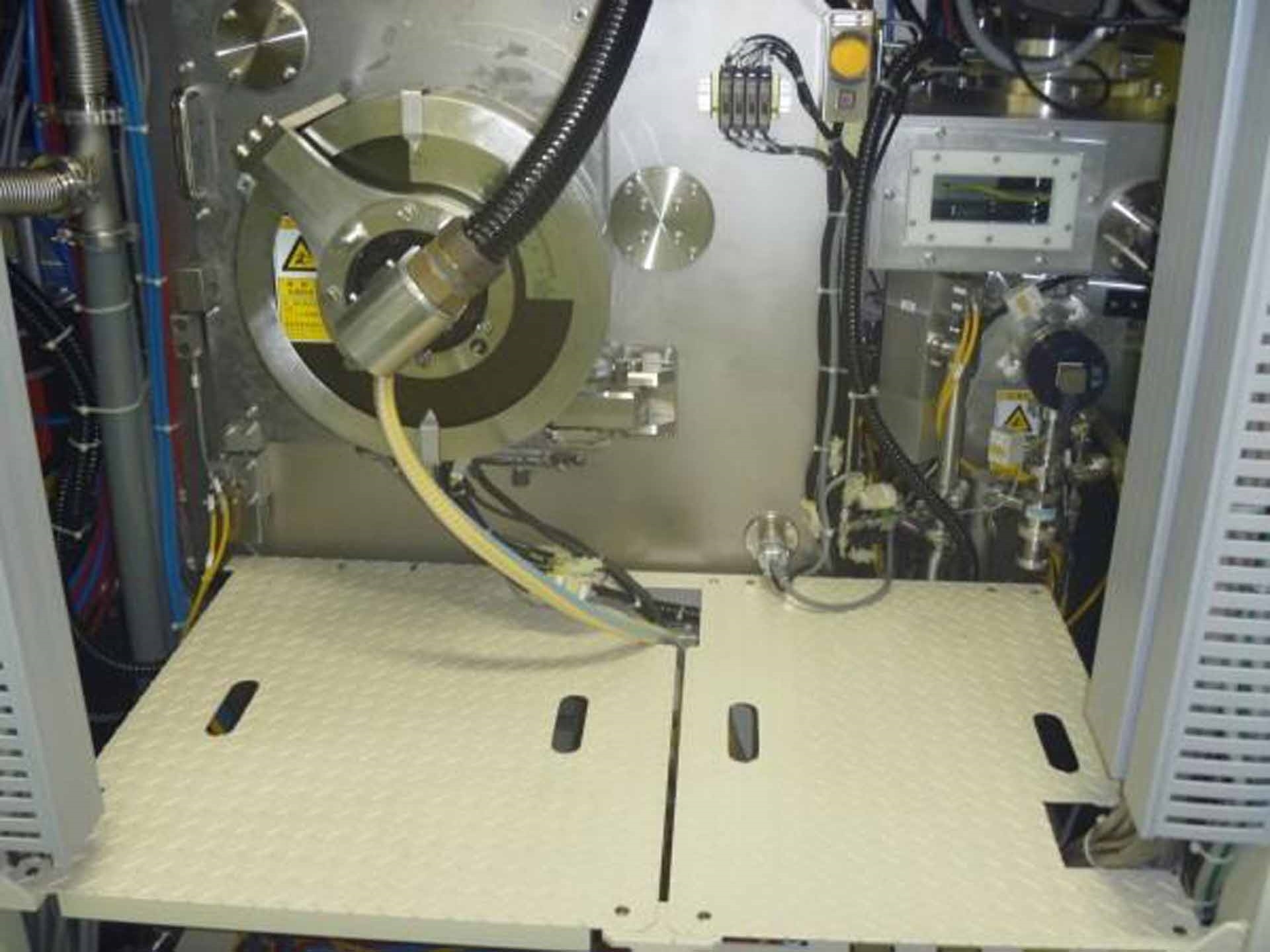

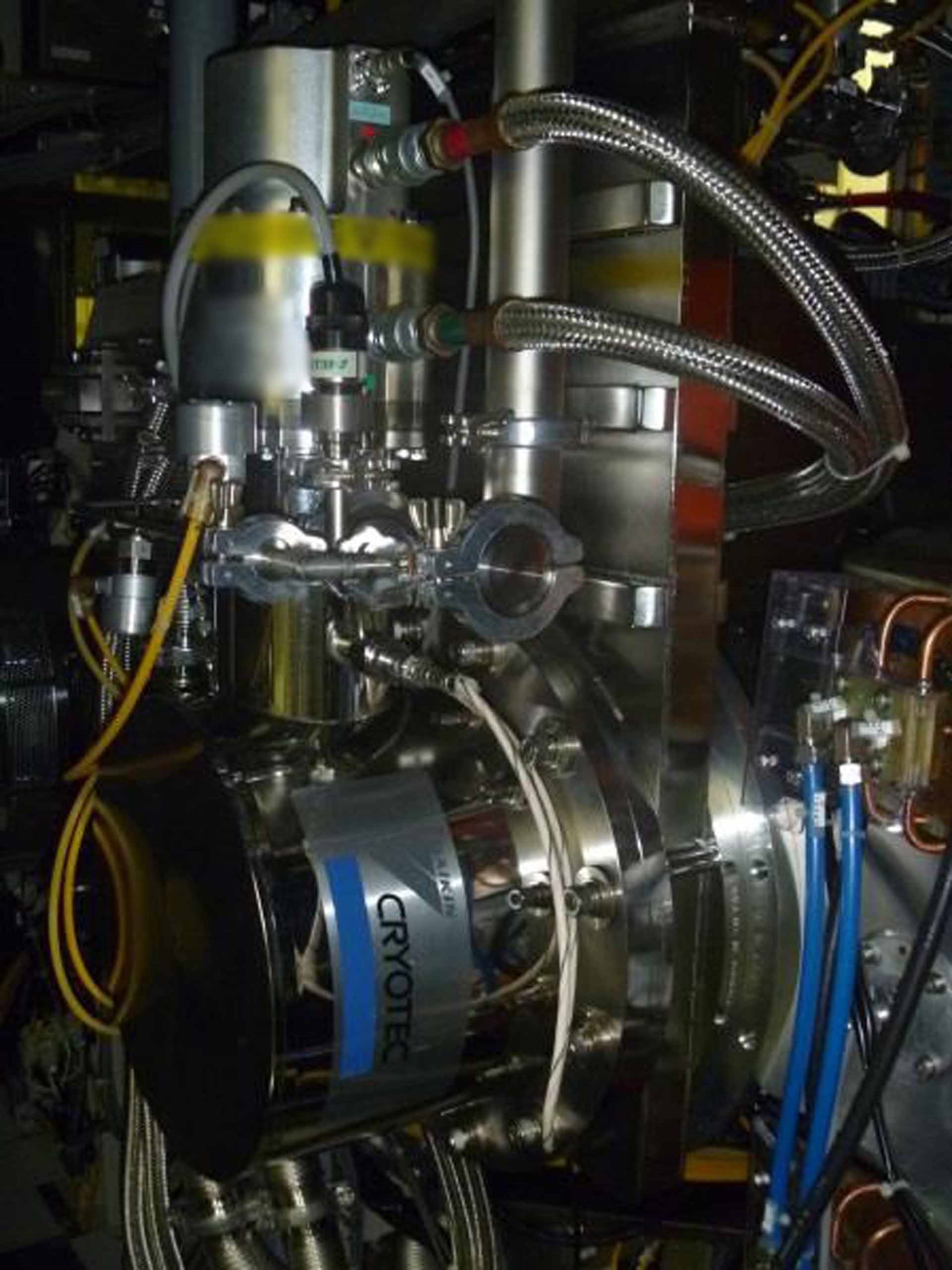

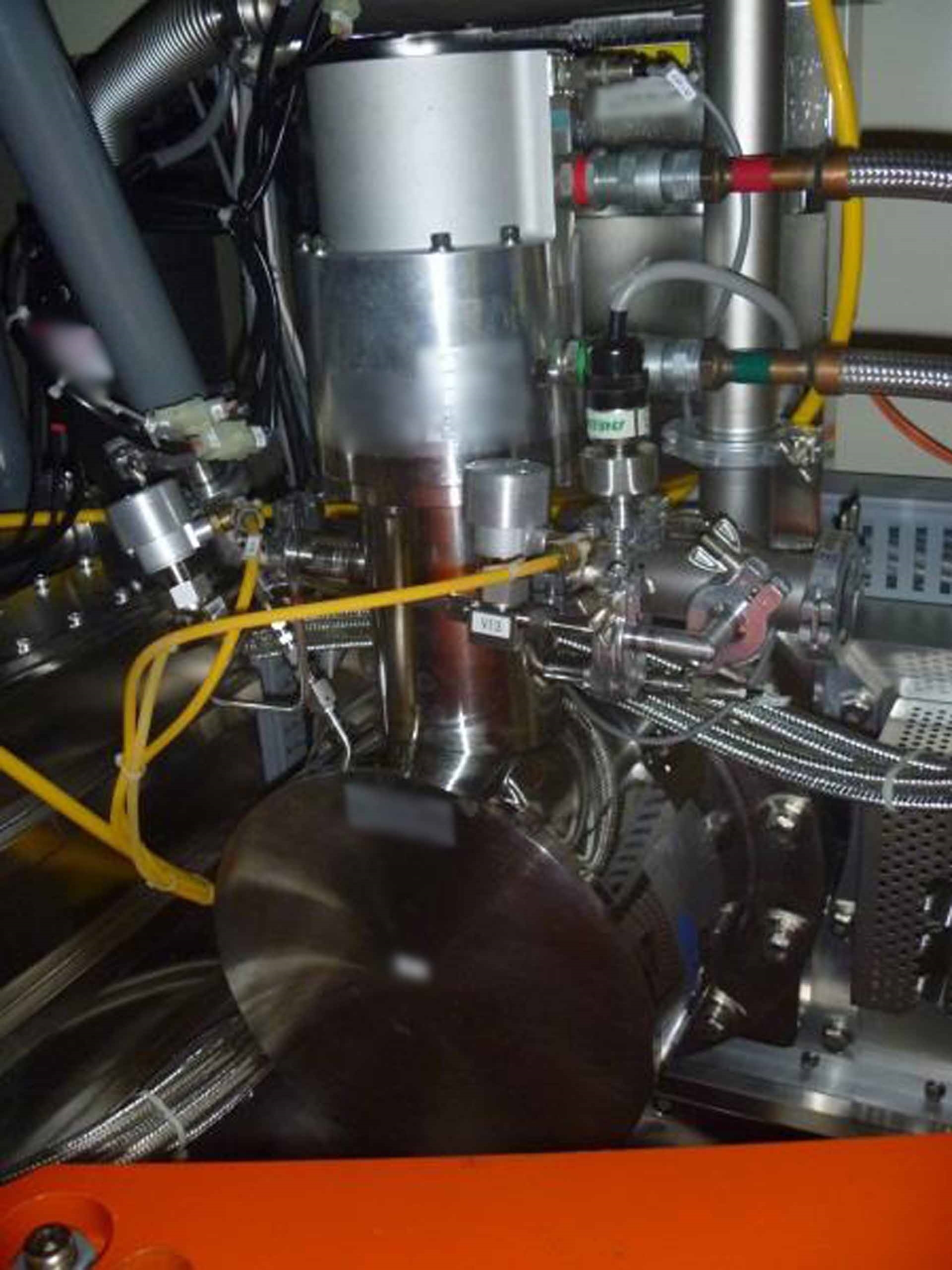

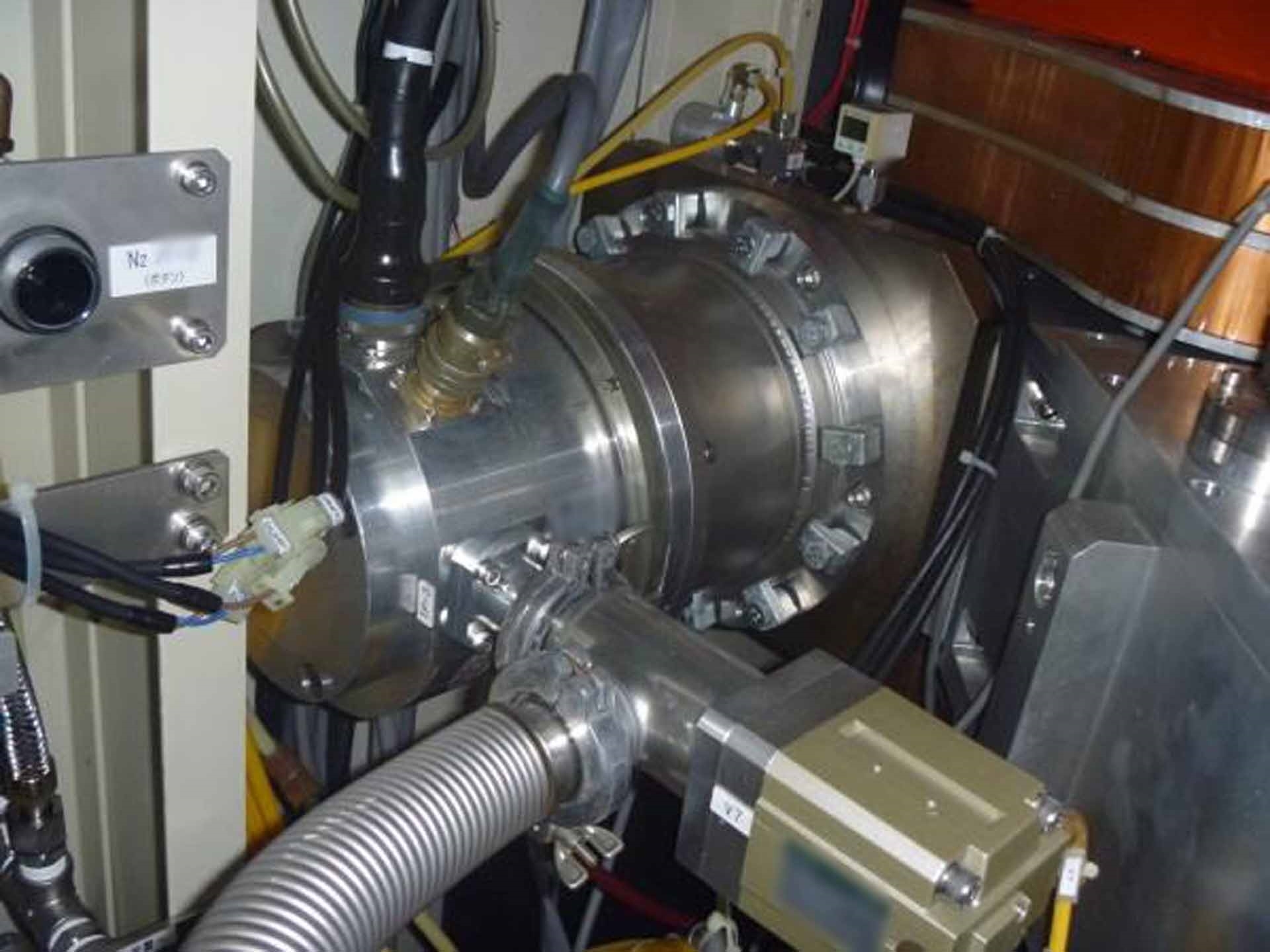

Ion source chamber

Beamline chamber

End station chamber

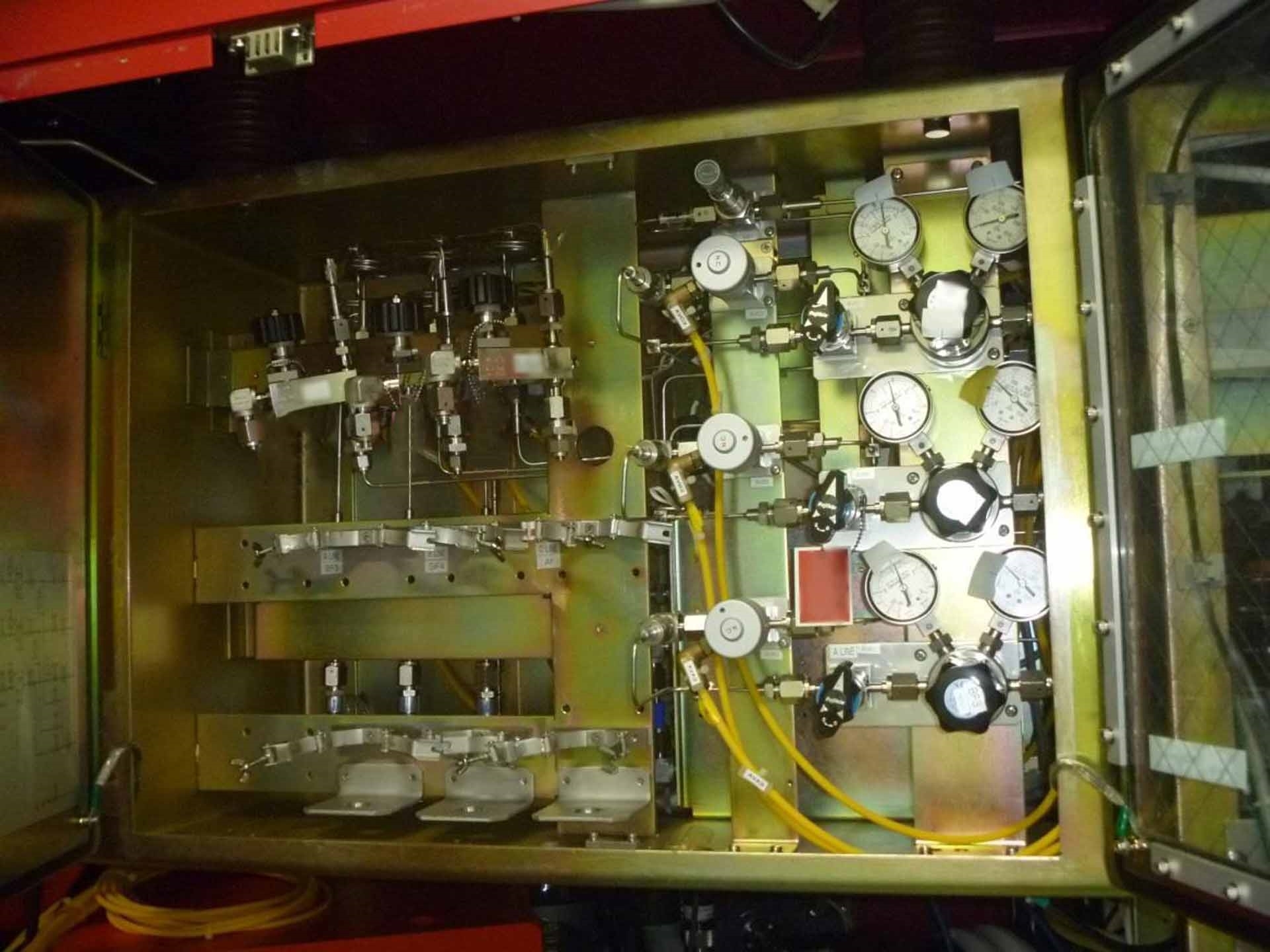

Pumps:

Dry pumps:

Make / Model / Class

ALCATEL / Drytel 34C / Load / Lock (DP-4), 450 L/sec

ALCATEL / Drytel 31 / Target chamber (DP-3), 450 L/sec

KASHIYAMA / SD 90V III / F.E.M (DP-2), 1500 L/sec

KASHIYAMA / SD 90V III / S.A.M / lon source (DP-1), 1500 L/sec

Turbo pumps:

Make / Model / Class

SHIMADZU / TMP51G / Load / lock (TP 4 and 5), 55 L/sec

SHIMADZU / TMP1002 / F.E.M (TP-3), 800 L/sec

SHIMADZU / TMP1002 / S.A.M (TP-1 and 2), 800 L/sec

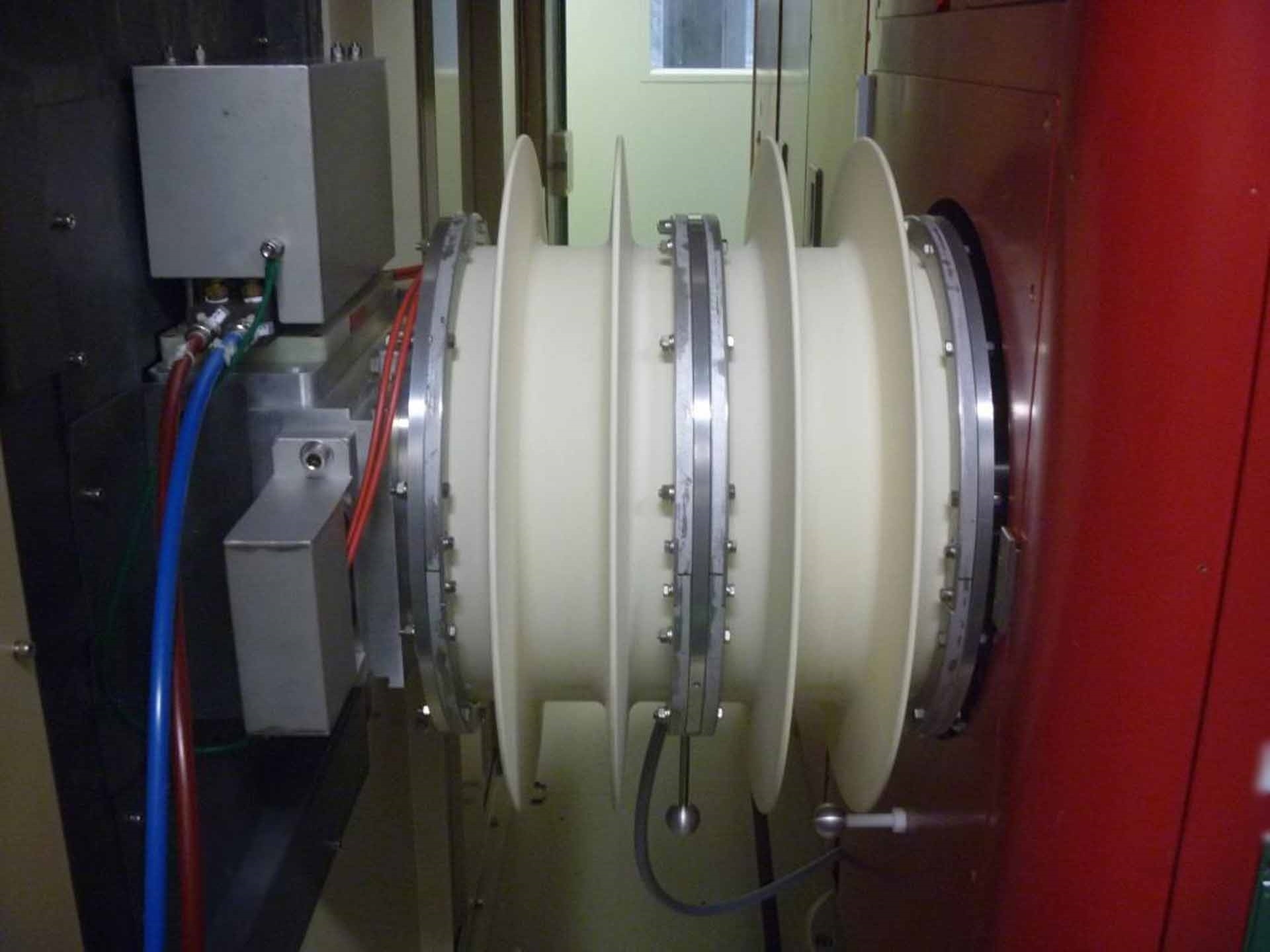

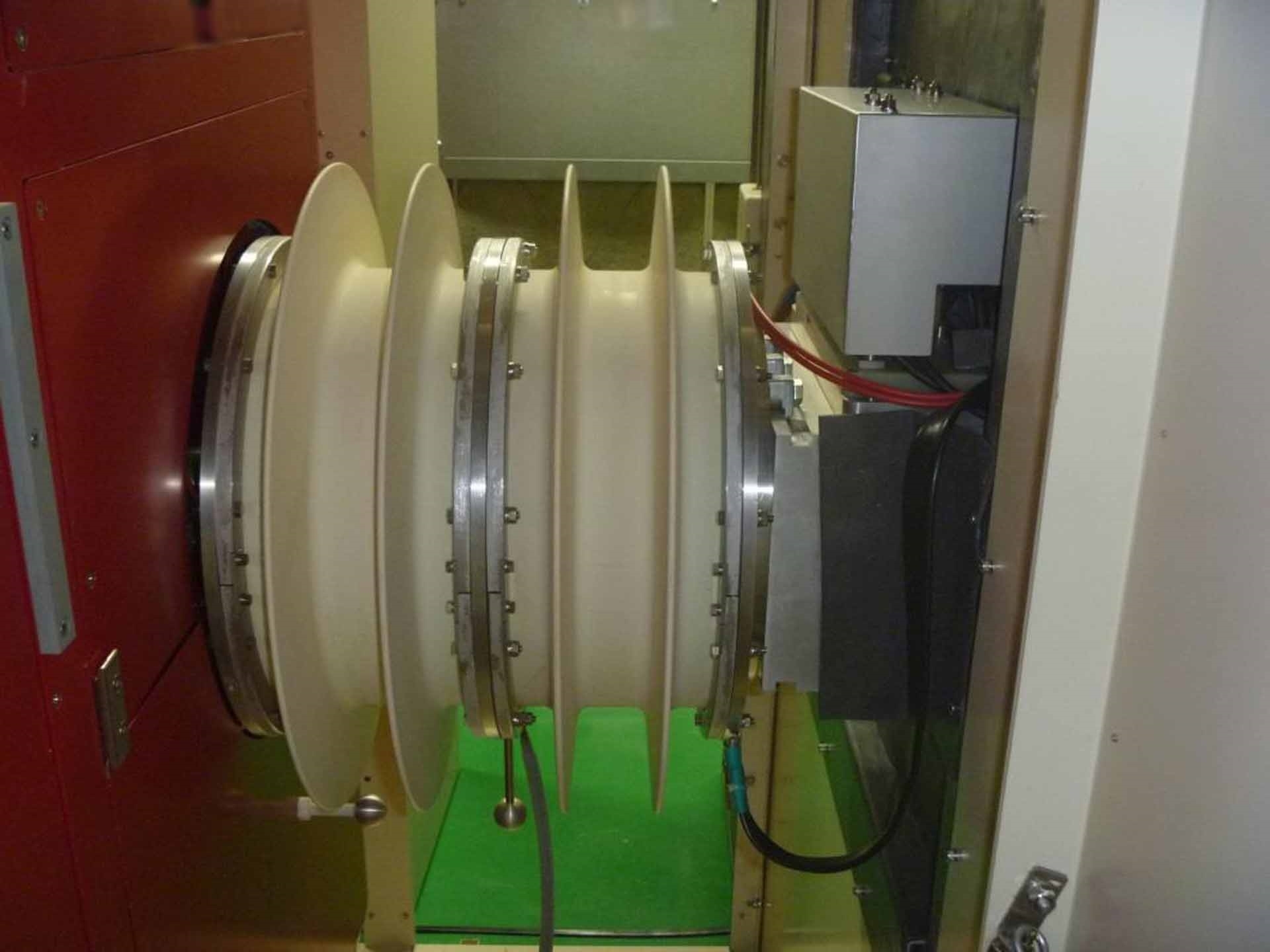

Cryo pumps:

Make / Model / Class

CRYOTEC-12L / V208SC612GN / Target chamber (CP-2), 4000 L/sec

CRYOTEC-12L / V208SC612GN / Collimator (CP-1), 4000 L/sec

DAIKIN U110CW Compressor

Process gas:

SiF4 (0.35L): 200 keV, Si+200 µA - 20 µA, SI++ 20 µA - 5 µA, 5E12

Ar (0.35L): 200 keV, 1000 µA, 5E12

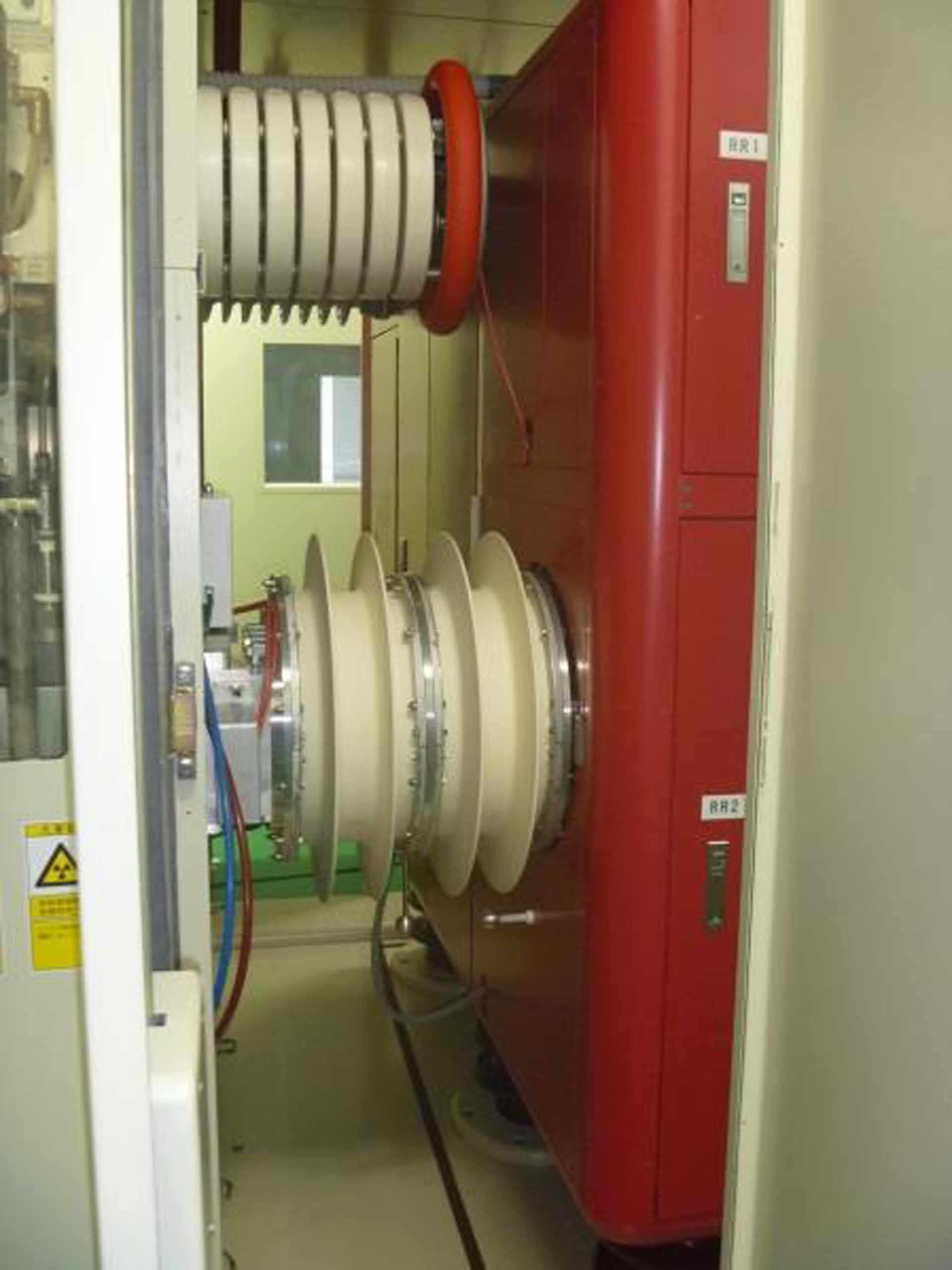

High voltage range:

Extraction power supply: 0 keV - 70 keV

Acceleration power supply: 0 keV - 180 keV

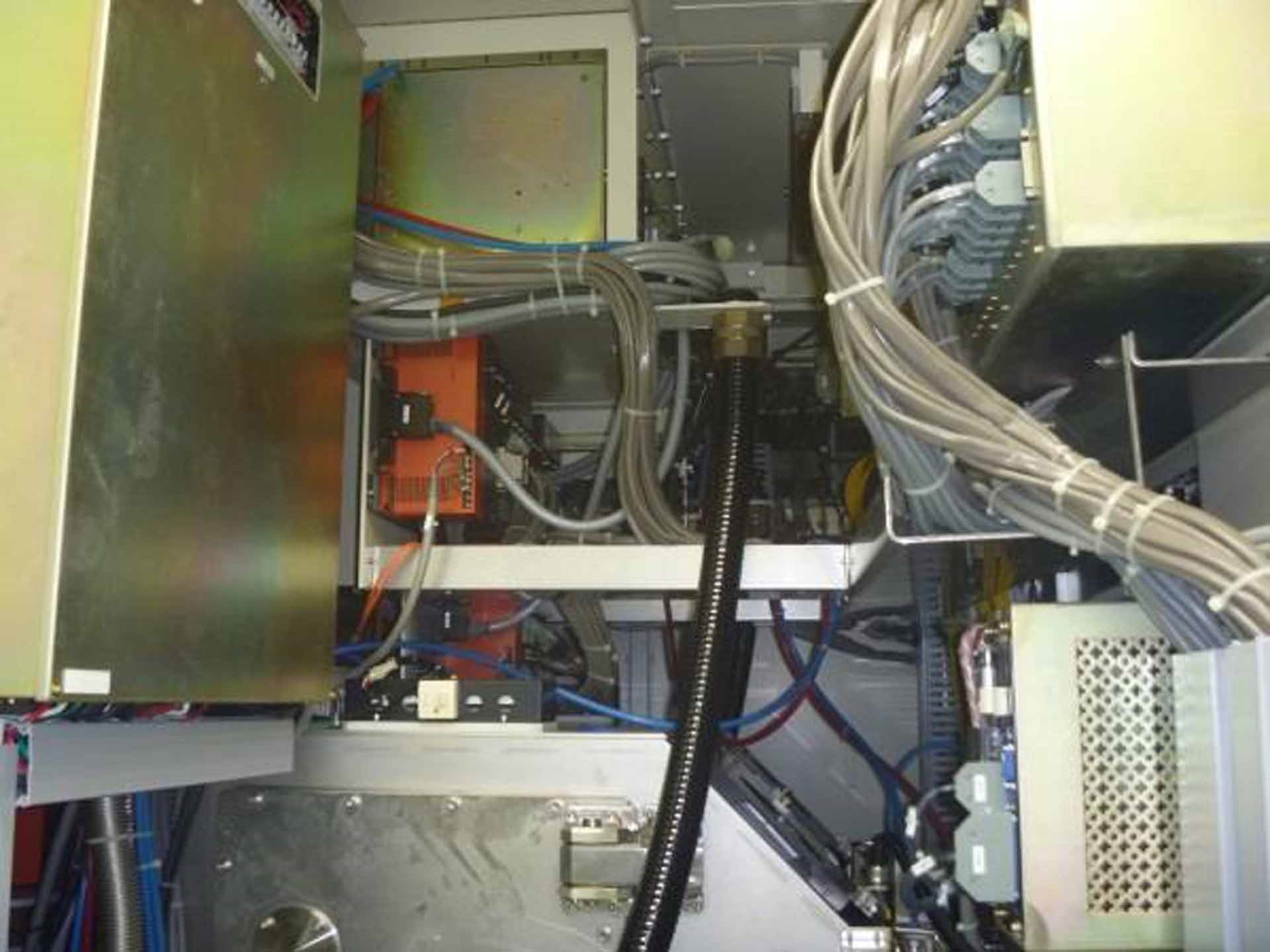

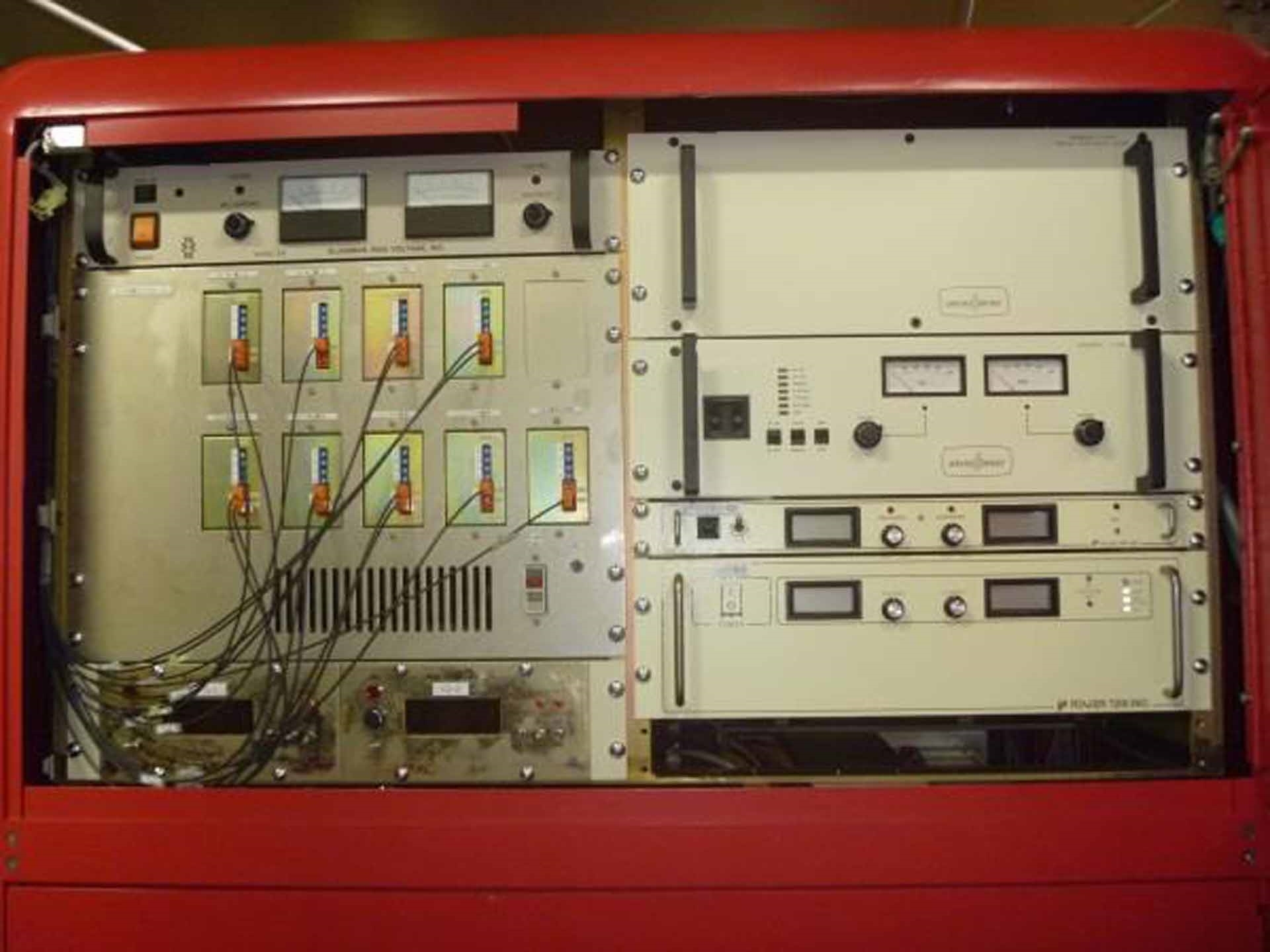

Power supplies (Assembly):

Arc

Filament

SAM

ACC

DEC

Focus

TRIM-Q

FEM

Column

DC / AMP

Faraday suppression

ISO TX 160 kV

HV Stack 160 kV

Controllers (Assembly): BSM, FEM, P/C, SAM, W/C, WFC, V/C, I/C, O/F, TQ, T/C, I/G, T/P

Utilities:

Air: 100-150 PSI

N2: 40-150 PSI

Cooling water: 60-150 PSI

Temperature: 4°C - 21°C

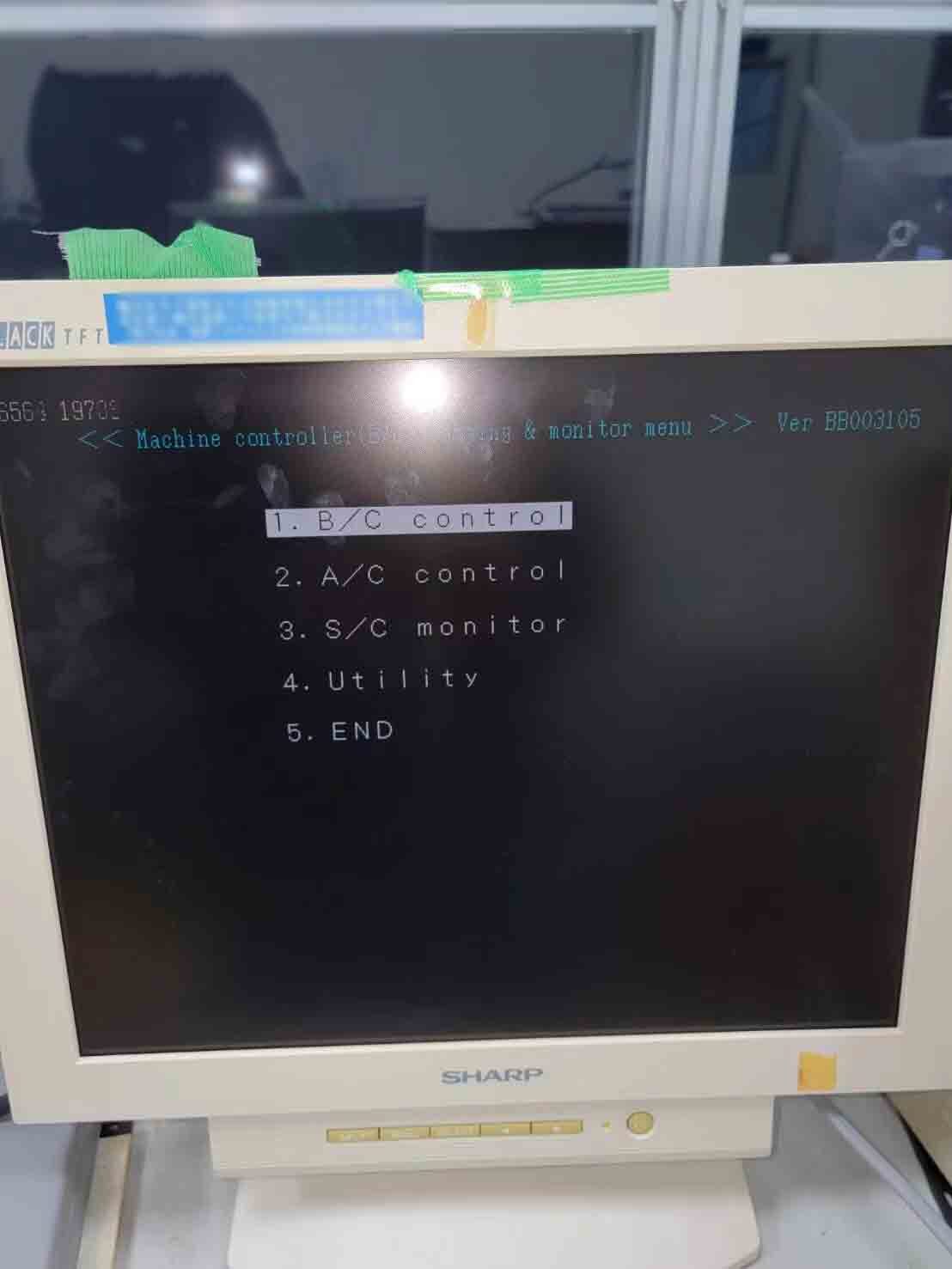

Operating system: Windows XP

Power supply: 208 VAC, 3-Phase, 65 kVA

1997 vintage.

NISSIN Exceed 2000 is an advanced ion implanter and monitor designed for high-performance semiconductor fabrication. This equipment uses state-of-the-art electronics, sensors, and control systems to precisely implant ions into a range of materials, resulting in consistent, uniform, and repeatable product quality. The system offers a wide range of implantation parameters which can be easily adjusted to meet specific design and process requirements. The primary function of the unit is to perform ion implantation. By using a wide variety of implantation parameters, such as ion species, implantation depth, implantation angle, beam energy, and many other parameters, the user is able to customize the implants to match the desired application. The machine also allows multiple customizable programs to be stored to save time and minimize setup time. The monitor is an integrated component of the tool that monitors the process status and current parameters during the implantation process. This monitor is a critical component for ensuring that the correct implantation parameters are maintained throughout the entire process. The monitor also provides real-time feedback on the dose and tolerance errors for improved control. The asset is highly reliable and repeatable, making it ideal for production of high-volume and broad-range process requirements. Its robust and automated design ensures even the most challenging applications can be met with consistent quality and repeatability. Exceed 2000 provides users with a reliable and repeatable automated implantation model with multiple customizable parameters. It is designed to meet the most demanding requirements in semiconductor fabrication and is an ideal choice for industrial production. The equipment's integrated monitor helps to ensure that the implantation parameters are maintained consistently throughout the process for improved product quality.

There are no reviews yet